采用连续离心分离技术回收细铁尾矿中铁

陈禄政1,熊大和2,任南琪1,赵 鑫1

(1. 哈尔滨工业大学 城市水资源与水环境国家重点实验室,黑龙江 哈尔滨,150090;

2. 赣州金环磁选设备有限公司,江西 赣州,341000)

摘 要:

摘 要:采用SLon实验型连续式离心机(简称SLon实验型离心机),以高梯度磁选细粒赤铁矿尾矿得到的磁性产物(52.42% Fe)为试样,在给料体积速率为(24.5±0.4) L/min、给料固体浓度为20%和水束流冲击压力为0.45 MPa的条件下,研究转鼓转速和水束流往复速度对连续离心分离指标的影响。研究结果表明:转鼓转速和水束流往复速度分别通过改变颗粒受离心力和流膜流动特性影响分离结果;当转鼓转速为450 r/min和水束流往复速度为 36 mm/s时,铁精矿的铁品位和铁回收率分别为62.32% Fe和65.02%,说明应用SLon离心机分离提纯高梯度磁选细粒赤铁矿尾矿得到的磁性产物,再富集效果明显。

关键词:

连续离心分离;薄流膜分离;高梯度磁分离;细粒铁尾矿;铁回收;

中图分类号:X751 文献标识码:A 文章编号:1672-7207(2008)06-1257-05

Recovery of iron from fine iron tailings by continuous centrifugal concentration

CHEN Lu-zheng1, XIONG Da-he2, REN Nan-qi1, ZHAO Xin1

(1. State Key Laboratory of Urban Water Resource and Environment, Harbin Institute of Technology,

Harbin 150090, China;

2. SLon Magnetic Separator Company Ltd., Ganzhou 341000, China)

Abstract: An SLon pilot continuous centrifugal concentrator (SLon pilot centrifugal concentrator) was used to study the effects of drum rotation speed and reciprocating velocity of water sprays on the separation performance of the concentrator under the optimum conditions of feed volume flow rate (24.5±0.4) L/min, feed solids content 20% and impacting pressure of water sprays 0.45 MPa, with the high gradient magnetic separation concentrate assaying 52.42% Fe from fine hematite tailings as test material. The experimental results indicate that the drum rotation speed determines the centrifugal forces on particles and the reciprocating velocity of water sprays has a significant influence on the flowing characteristics of flowing film, thereby generating significant effects on the separation performance. By using the pilot concentrator to the magnetic concentrate at drum rotation speed of 450 r/min and reciprocating velocity of water sprays of 36 mm/s, a concentrate assaying 62.32% Fe with 65.02% recovery is achieved. It is therefore concluded that the SLon centrifugal concentration is efficient in reconcentrating the high gradient magnetic separation concentrate from the fine hematite tailings.

Key words: continuous centrifugal concentration; flowing film concentration; high gradient magnetic separation; fine iron tailings; iron recovery

随着原矿资源的日益枯竭,尾矿二次利用受到普遍关注[1]。铁尾矿是最主要的工业固体废弃物之一,由于我国铁矿石贫、细、杂和磁-浮工艺选铁水平高的特点[2],造成铁尾矿铁含量低,粒度微细,组成复杂,再次采用广泛应用的磁选或浮选处理效果欠佳[3]。目前,我国年排放铁尾矿超过1亿t,平均铁品位约11%,铁金属损失严重,并对周围生态环境造成严重污染[4],因此,研究铁尾矿中细粒铁的高效回收十分重要。

离心分离法与其他分离法相比具有分离过程简单、高效、成本低、分离物料下限粒度低、对环境友好等优点,近年来,随着环境污染和可持续发展问题日益突出,该分选技术再次引起人们重视[5-7],开始研究用于从各种固体废弃物中回收金[8]、铜[9]等稀贵金属。研究结果表明[3],采用我国传统间断式离心机分离提纯高梯度磁选细粒赤铁矿尾矿得到的磁性产物,可以得到铁品位合格和铁回收率较高的铁精矿。然而,该间断式离心机分离过程不连续导致设备故障率很高,无法有效应用于工业生产。

目前,用于固-固两相物系分离的离心机可分为反冲水式和单壁式2大类,前者基于流态化技术如Knelson离心机,后者基于斜面薄流膜分离如Falcon离心机,这2种离心机均适用于处理微金属含量物料,如用于从物料中回收微量金[10]和细煤除杂提纯[11-12],而不适用于高铁物料铁尾矿的分离处理。为解决间断式离心机应用时故障率高的难题,我国于20世纪90年代在间断式离心机基础上先后研制了逆流和射流连续式离心机[13];与间断式离心机相比,逆流和射流连续式离心机提高了单机处理能力,但富集比不高,水耗明显增大,至今没有得到工业应用。为此,本文作者研制SLon连续式离心机(简称SLon离心机)[14]。该机采用往复移动水束流冲击卸落离心沉降大密度富集层实现连续分离过程。以高梯度磁选海南钢铁公司在排细粒赤铁矿尾矿得到的磁性产物为试样,采用SLon实验型离心机,考察转鼓转速和水束流往复速度对分离效果的影响。

1 实验设备与方法

1.1 SLon实验型离心机

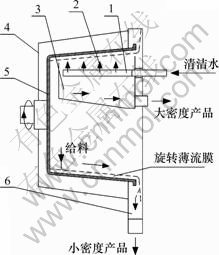

SLon实验型离心机(图1)主要包括1个圆锥形转鼓和1个独特的往复机构,其分离物料基于斜面薄流膜分离基本原理,即颗粒分离发生在1个厚度为几毫米的斜面流动薄流膜内[15-16]。转鼓转速和水束流往复速度是影响该机分离效果的2个重要因素。

1—往复机构;2—水束流;3—大密度产品收集装置;4—防护机罩;5—转鼓;6—小密度产品排放通道

图1 SLon实验型离心机原理

Fig.1 Principle of SLon pilot centrifugal concentrator

工作时,物料给至转鼓内壁表面上形成旋转薄流膜,不同密度颗粒在离心沉降和流膜紊动扩散作用下实现分离。密度大的颗粒受离心力大,离心沉降在转鼓内壁表面上形成富集层,随转鼓作旋转运动;密度小的颗粒受离心力小,以螺旋状快速流出转鼓成为小密度产品。往复机构在转鼓内腔上部作来回往复运动,其喷嘴喷射能量高度聚集的水束流逆向冲击转鼓内壁表面上富集层。在水束流冲击作用下,富集层局部产生流化,颗粒间聚结力急剧降低,掉入大密度产品收集装置得到大密度产品。

1.2 实验原料和预处理

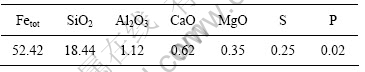

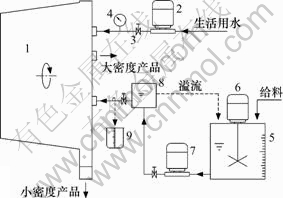

细粒赤铁矿尾矿,取自海南钢铁公司在排铁尾矿流中,采用SLon-500实验型高梯度磁选机[17](磁感应强度为0.9 T)对其进行预富集处理得到磁性产物。磁性产物化学和粒级组成分析结果分别如表1和表2所示。

表1 磁性产物化学分析

Table 1 Assay of magnetic product w/%

表2 磁性产物粒级组成分析

Table 2 Size-by-size analysis of magnetic product

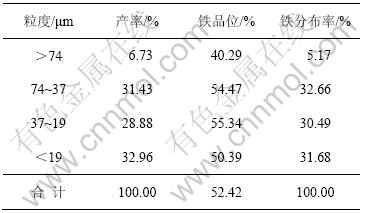

1.3 实验装置与方法

SLon连续离心分离实验装置如图2所示。生活用水经增压泵进入SLon实验型离心机往复机构形成水束流,水输送管路上串联的阀和水压力表分别用于控制和指示水束流的工作压力。一定固体浓度物料在容积为0.32 m3的搅拌桶内混合均匀后,由渣浆泵扬至给料恒压箱;配合调节渣浆泵和给料恒压箱底部的2个阀,使恒压箱内保持稳定的溢流返回搅拌桶,可以准确控制离心机的给料体积速率。物料进入离心机前的输送管路上并联一软管,将软管位置放低,物料全部流入流量测量容器,可快速检测出离心机的给料体积速率。

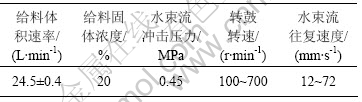

本研究中,SLon实验型离心机的给料体积速率、给料固体浓度和水束流冲击压力如表3所示。

1—SLon实验型离心机;2—增压泵;3—阀;4—水压力表;5—搅拌桶;6—搅拌电机;7—渣浆泵;8—给料恒压箱;9—流量测量容器

图2 SLon连续离心分离实验装置

Fig.2 Experimental setup of SLon continuous centrifugal concentration

表3 SLon实验型离心机实验条件

Table 3 Experimental conditions of SLon pilot centrifugal concentrator

2 结果与讨论

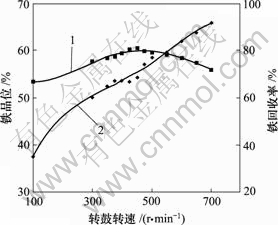

2.1 转鼓转速对分离结果的影响

转鼓转速决定离心力场和颗粒所受的离心力,是推动颗粒离心沉降的基本作用力,故对分离结果具有重要影响。图3所示为水束流往复速度为24 mm/s时,转鼓转速对分离结果的影响。结合表2数据和图3结果分析,当转鼓转速低于300 r/min时,大密度产品铁品位和铁回收率很低。这是因为此时颗粒受离心力小,离心机主要富集铁品位很低的连生体粗铁矿粒;当转鼓转速超过300 r/min时,随转鼓转速提高,离心机开始富集解离度和铁品位很高的细铁矿粒,导致大密度产品铁品位和铁回收率增大;当转鼓转速为425~500 r/min时,大密度产品铁品位达到稳定的最高值,铁回收率快速增大,说明此时离心机大量富集铁品位很高的细铁矿粒;当转鼓转速超过500 r/min时,大密度产品铁回收率继续增大但增速明显减缓,而铁品位明显下降,这是由于此时颗粒受离心力太大,离心机大量富集连生体细铁矿粒和脉石。主要考虑大密度产品铁品位指标,转鼓转速宜选择450 r/min(离心加速度48g,g为重力加速度,1g=9.8 m/s2),此时得到大密度产品铁品位达到60.55% Fe,铁回收率为68.46%。

离心机有效处理细粒物料需要的离心强度,与离心机种类和物料性质有关。如Knelson离心机用于从物料中富集细粒金离心强度多选择60g[10, 18],而Falcon离心机提纯细粒煤时最大离心强度高达300g[15]。本实验结果表明,SLon实验型离心机用于处理该种细粒赤铁矿物,离心强度约为50g时分离效果最佳。

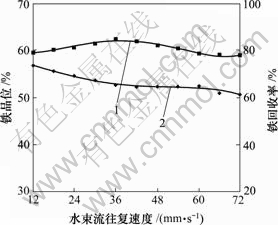

2.2 水束流往复速度对分离结果的影响

当固定转鼓转速为适宜值450 r/min时,水束流往复速度对SLon连续分离结果的影响如图4所示。由图4可见,水束流往复速度适宜有助于提高大密度产品的铁品位,而不对铁回收率造成明显影响;随水束流往复速度增大,大密度产品的铁品位先上升后降低,当水束流往复速度为30~42 mm/s时达到最大值且变化很小;铁回收率随水束流往复速度增大而下降,但当水束流往复速度为36~60 m/s时基本不变。实验结果表明,水束流往复速度为36 m/s时,大密度产品的铁品位达到最高为62.32% Fe,此时铁回收率65.02%。

1—铁品位;2—铁回收率

图3 转鼓转速对分离结果的影响

Fig.3 Effect of drum rotation speed on performance

1—铁品位;2—铁回收率

图4 水束流往复速度对分离结果的影响

Fig.4 Effect of reciprocating velocity of water sprays on performance

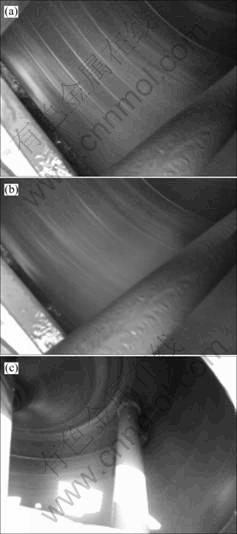

与射流切割物体时射流束横移速率影响切割速率相似[19],SLon连续式离心机采用往复移动水束流冲击卸落富集层实现连续分离时,水束流往复速度影响富集层移除率,并导致转鼓内壁表面上富集层厚度分布和薄流膜轴向流态发生变化,而流膜流动特性的变化影响分离结果[20-21]。结合图4和图5可知,当水束流往复速度太小时(图5(a)),离心沉降颗粒在转鼓内壁表面非水束流冲击区大量积累,富集层厚度沿转鼓轴向分布不均,流膜轴向流动缓慢,大量连生体铁矿粒和脉石由于获得过长的离心沉降时间沉积在转鼓内壁表面上,导致大密度产品铁品位降低和铁回收率上升;水束流以适宜值30 mm/s往复运动时(图5(b)),水束流及时冲击卸落离心沉降大密度颗粒,富集层厚度在转鼓内壁表面上分布均匀,流膜流动稳定,可得到并保持高效的离心分离效果;水束流往复速度太大时(图5(c)),水束流快速移动,将转鼓内壁表面上薄流膜冲击卸落,离心分离过程失效。

往复速度/(mm?s-1): (a) 10; (b) 30; (c) 60

图5 SLon工业型离心机水束流往复速度对流膜流动的影响

Fig.5 Effect of reciprocating velocity of water sprays on flowing characteristics of flowing film in SLon full-scale centrifugal concentrator

3 结 论

a. 转鼓转速决定离心力场和颗粒受离心力,是推动颗粒离心沉降的基本作用力,因而对连续离心分离结果具有重要影响。实验结果表明,SLon实验型离心机用于处理高梯度磁选细粒赤铁矿尾矿得到的磁性产物,转鼓转速为450 r/min时再富集效果最佳。

b. 水束流往复速度对薄流膜底层富集层厚度分布和流膜流态具有重要影响,从而影响SLon连续离心分离效果。水束流往复速度适宜有助于提高大密度产品铁品位,而不对铁回收率造成明显影响。当水束流往复速度太小时,富集层厚度在转鼓内壁表面上分布不均,流膜轴向流动缓慢,大量连生体铁矿粒和脉石离心沉降,导致大密度产品铁含量降低;当水束流往复速度太大时,水束流快速移动将转鼓内表面上薄流膜冲击卸落,离心分离过程失效。

c. 当转鼓转速为450 r/min和水束流往复速度为36 mm/s时,大密度产品铁品位达到最高,为62.32%,此时铁回收率为65.02%。SLon离心机是一种新型连续式离心机,该机用于分离提纯高梯度磁选细粒赤铁矿尾矿得到的磁性产物,效果明显。

参考文献:

[1] Watson J H P, Beharrell P A. Extracting values from mine dumps and tailings[J]. Minerals Engineering, 2006, 19(15): 1580-1587.

[2] 毛益平, 黄礼富, 赵福刚. 我国铁矿山选矿技术成就与发展展望[J]. 金属矿山, 2005(2): 1-5.

MAO Yi-ping, HUANG Li-fu, ZHAO Fu-gang. Achievement and development prospect of mineral processing technology of China’s iron mines[J]. Metal Mine, 2005(2): 1-5.

[3] 陈禄政, 任南琪, 熊大和. 海钢尾矿强磁-离心分离再选试验研究[J]. 金属矿山, 2006(10): 75-77.

CHEN Lu-zheng, REN Nan-qi, XIONG Da-he. Test research on reconcentration of Hainan Steel’s tailings by high intensity magnetic separation-centrifugal separator[J]. Metal Mine, 2006(10): 75-77.

[4] 张淑会, 薛向欣, 刘 然, 等. 尾矿综合利用现状及其展望[J]. 矿冶工程, 2005, 25(3): 44-47.

ZHANG Shu-hui, XUE Xiang-xin, LIU Ran, et al. Current situation and prospect of the comprehensive utilization of mining tailings[J]. Mining and Metallurgical Engineering, 2005, 25(3): 44-47.

[5] Burt R. The role of gravity concentration in modern processing plants[J]. Minerals Engineering, 1999, 12(11): 1291-1300.

[6] Ergün L, Ersayin S. Studies on pinched sluice concentration. Part Ⅰ: The effects of operating variables and sluice geometry on the performance of pinched sluices[J]. Minerals Engineering, 2002, 15(6): 423-435.

[7] Coulter T, Subasinghe G K N. A mechanistic approach to modeling Knelson concentrators[J]. Minerals Engineering, 2005, 18(4): 9-17.

[8] Delfini M, Manni A, Massacci P. Gold recovery from jewellery waste[J]. Minerals Engineering. 2000, 13(6): 663-666.

[9] 温雪峰, 潘彦军, 何亚群, 等. Falcon选矿机的分选机理及其应用[J]. 中国矿业大学学报, 2006, 35(3): 341-346.

WEN Xue-feng, PAN Yan-jun, HE Ya-qun, et al. Study on separation mechanism of Falcon Concentrator and its application[J]. Journal of China University of Mining and Technology, 2006, 35(3): 341-346.

[10] 张金钟, 姜良友, 吴振祥, 等. 尼尔森选矿机及其应用[J]. 有色矿山, 2003, 32(3): 28-31, 37.

ZHANG Jin-zhong, JIANG Liang-you, WU Zhen-xiang, et al. Knelson concentrators and its application[J]. Nonferrous Mines, 2003, 32(3): 28-31, 37.

[11] Honaker R Q, Wang D, Ho K. Application of the Falcon concentrator for fine coal cleaning[J]. Minerals Engineering, 1996, 9(11): 1143-1156.

[12] Honaker R Q, Singh N, Govindarajan B. Application of dense-medium in an enhanced gravity separator for fine coal cleaning[J]. Minerals Engineering, 2000, 13(4): 415-427.

[13] 吕永信, 罗醒民, 杜懋德. SL型射流离心选矿机应用研究[J]. 有色金属, 1990, 42(4): 25-31, 37.

LU Yong-xin, LUO Xing-min, DU Mao-de. Separating ultrafines by SL-type continuous centrifugal separator with injection flow[J]. Nonferrous Metals, 1990, 42(4): 25-31, 37.

[14] 陈禄政, 任南琪, 熊大和. SLon连续式离心机回收微细粒级铁矿物工业试验[J]. 金属矿山, 2007(1): 63-66.

CHEN Lu-zheng, REN Nan-qi, XIONG Da-he. Industrial test on recovering microfine iron minerals by SLon continuous centrifugal separator[J]. Metal Mine, 2007(1): 63-66.

[15] Honaker R Q. High capacity fine coal cleaning using an enhanced gravity concentrator[J]. Minerals Engineering, 1998, 11(12): 1191-1199.

[16] Majumder A K, Lyman G J, Brennan M, et al. Modeling of flowing film concentrators. Part Ⅰ: Water split behavior[J]. International Journal of Mineral Processing, 2006, 80(1): 71-77.

[17] XIONG Da-he, LIU Shu-yi, CHEN Jin. New technology of pulsating high gradient magnetic separation[J]. International Journal of Mineral Processing, 1998, 54(2): 111-127.

[18] WANG Xue-song, Miles Nick J, Kingman Sam. Numerical study of centrifugal fluidized bed separation[J]. Minerals Engineering, 2006, 19(10): 1109-1114.

[19] Momber A W, Kovacevic R. Test parameter analysis in abrasive water jet cutting of rocklike materials[J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(1): 17-25.

[20] Ergün L, Ersayin S. Studies on pinched sluice concentration. Part ?I: Characterization of flow over pinched sluices[J]. Minerals Engineering, 2002, 15(6): 437-446.

[21] Udaya Bhaskar K, Govindarajan B, Barnwal J P, et al. Performance and modeling studies of an MGS for graphite rejection in a lead concentrate[J]. International Journal of Mineral Processing, 2002, 67(1/4): 59-70.

收稿日期:2008-03-01;修回日期:2008-05-07

基金项目:国家自然科学基金重点资助项目(50638020)

通信作者:任南琪(1959-),男,黑龙江哈尔滨人,博士,特聘教授,从事有机废水处理新技术与新设备研究;电话:0451-86282008;E-mail: rnq@hit.edu.cn