DOI: 10.11817/j.ysxb.1004.0609.2021-37905

TiC对Fe43Ni35Co22中熵合金微观组织与性能的影响

李睿锴1,陈维平1,王 浩1,陈 强2,曾大海1,付志强1

(1. 华南理工大学,广东省金属新材料制备与成形重点实验室,广州 510640;

2. 西南技术工程研究所,重庆400039)

摘 要:

本文系统研究了TiC含量对Fe43Ni35Co22中熵合金微观组织、力学性能以及磁性能的影响。添加5%和10%(摩尔分数)Ti至中熵合金Fe43Ni35Co22,通过原位自生反应形成TiC/Fe43Ni35Co22合金块体,制备方法为“机械合金化(MA)+放电等离子烧结(SPS)”。研究结果表明:经40h球磨后, Fe43Ni35Co22粉末相的组成为FCC主相+少量BCC,两种TiC/Fe43Ni35Co22粉末的相组成为BCC主相+FCC相。经SPS烧结后,Fe43Ni35Co22块体为单相FCC和少量的杂质;两种TiC/Fe43Ni35Co22块体均由FCC+TiC两相组成,其中FCC相呈现“微米晶+超细晶”构成的多尺度结构,且随着TiC含量的增加,超细晶区增多。性能上,TiC的添加大幅提高了Fe43Ni35Co22的压缩屈服强度和矫顽力,同时也导致了材料的塑性和饱和磁化强度的降低。Ti添加量为5%的TiC/Fe43Ni35Co22综合性能最优异,其压缩屈服强度为1352 MPa,压缩断裂应变为24.5%,矫顽力为12.4 Oe,饱和磁化强度为138.7 emu/g。

关键词:

文章编号:1004-0609(2021)-xx-- 中图分类号:TG113 文献标志码:A

引文格式:李睿锴, 陈维平, 王 浩, 等. TiC对Fe43Ni35Co22中熵合金微观组织与性能的影响[J]. 中国有色金属学报, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37905

LI Rui-kai, CHEN Wei-ping, WANG Hao, et al. Influence of TiC on microstructure and properties of Fe43Ni35Co22medium-entropy alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37905

随着科学技术的飞速发展,对材料的性能提出了更高的要求。例如,在混合动力汽车或纯电动汽车中,为了提高系统的工作效率,需要用到微型、高效的感应电动机以及对其充电的功率转换器[1]。而电机的微型化与效率的提高,关键在于电机中的软磁材料。一方面,软磁材料需要更高的饱和磁化强度,以减少电机中软磁材料的体积;另一方面,软磁材料需要更高的强度,以抵抗高频带来的更大的扭转力。此外,一定的塑性,既可以保证材料良好的加工成型性能,降低生产成本,也是材料服役性能要求。目前,现有的软磁材料在不同方面存在瓶颈,如:非晶合金较脆,晶化温度较低,使用温度受限[2];FeCo合金也较脆,且合金中Co含量高,价格昂贵[3];大块纳米晶软磁材料加工工艺复杂且热稳定性差[4]。因此,亟需开发新型软磁材料。

20 世纪 90 年代,YEH 等[5]提出了一个全新的合金设计理念—— 多主元高熵合金,极大地丰富了金属材料的设计策略。与传统合金的设计理念不同,高熵合金一般由4种及以上的主要元素组成,且每种元素的原子百分含量为 5%~35%。较高的混合熵抑制了金属间化合物的形成,使高熵合金形成简单的固溶体相[6-9]。同时,高熵合金具有许多优异的性能,如:高的强度和硬度、良好的抗辐射性、优异的低温断裂韧性、耐蚀性以及抗高温软化和特殊的磁性能[10-15],使得材料学家对其进行了广泛的研究。而关于高熵合金磁性材料的研究,主要集中在含Fe、Co、Ni的合金系统,力求兼具良好的力学性能与软磁性能[16-20]。作者前期[17]采用MA+SPS工艺制备TiC/Fe30Ni30Co29Mn5.5Cu5.5高熵合金,通过添加Ti元素,实现了TiC的原位自生,并在FCC基体中成功构建了多尺度结构,实现了优异力学性能和良好软磁性能的组合。此外,由于含Fe、Co、Ni的高熵合金在高温条件下有着良好的热稳定性,因而有望用作高温软磁材料[21-23]。

众所周知,铁磁性元素Fe,Co,Ni占比较大的高熵合金,饱和磁化强度通常会比较高[23, 24],并且根据FENG等的研究[25],Fe和Co可以更好地增强材料的磁饱和强度。GUO等研究发现[27],降低Ni的含量,会导致高熵合金中出现BCC相,将降低材料的塑性。此外,考虑到钴的价格昂贵,故本文适当提高Fe的含量、降低Co的含量,设计出具有单相FCC结构的Fe43Ni35Co22中熵合金。然后,通过添加Ti元素至该合金体系,采用MA+SPS的制备工艺,在Fe43Ni35Co22中原位生成TiC,并使FCC相构建多尺度结构,实现强韧化。通过改变Ti元素的添加量(0、5%、10%),实现TiC含量的调控,系统地研究TiC对Fe43Ni35Co22中熵合金微观组织、力学性能以及软磁性能的影响。

1 实验

本实验采用质量分数≥99.7%、粒度≤45μm的Fe、Co、Ni、Ti四种单质金属粉末为原料,按摩尔配比配制 (Fe43Ni35Co22)1-xTix(x=0、5、10)原始粉末,再将原始粉末置于混粉机混合5 h;之后,再将混合均匀的粉末置于不锈钢球磨罐中球磨40h,球料比为10:1,转速为300 r/min,使用环己烷作过程控制剂,并在球磨罐中冲入氩气进行保护。整个球磨过程在QM-3SP4型行星式球磨机上进行,并对球磨0h、20h、40 h的粉末进行XRD测试。最后,将球磨40 h的粉末置于真空干燥箱干燥,并使用SPS(Dr. Sinter 825, Sumitomo Coal Mining Co., Ltd., Japan)将干燥好的粉末烧结成d 20 mm×10 mm的块体材料。烧结过程中程序设置如下:首先,加热 1 min 将温度由室温升至100 ℃;随后,加热 8 min 将温度升高到 900 ℃;最后,再用 2 min 加热到 1000 ℃。并且在 1000 ℃下保温 10 min,烧结过程中保持恒压,压强为30 MPa。为方便阅读,下面将(Fe43Ni35Co22)1-x Tix(x=0、5%、10%)依次简写为HEA1、HEA2、HEA3。

本研究采用X 射线衍射仪(XRD,Bruker-D8 Advance, Germany)对不同球磨时间的粉末及烧结后的块体进行物相分析;采用扫描电子显微镜(SEM, NOVA NANOSEM 430, USA) 对合金块体的微观组织进行观察及成分分析;采用透射电镜(200 kV TEM, JEM-2100, JEOL, Tokyo, Japan)进一步的分析高熵合金的微观组织特征、晶体结构及成分;采用万能试验机(AG-100kNX, Shimadzu Corporation, Japan)进行压缩性能测试,样品尺寸为d 3 mm×4.5 mm,压头下压速率为 0.27 mm/min;采用振动样品磁强计(VSM,Lake Shore 7407, USA)测试材料的室温磁滞回线,试样尺寸为d 3 mm×1 mm。

2 结果与分析

2.1 XRD图谱分析

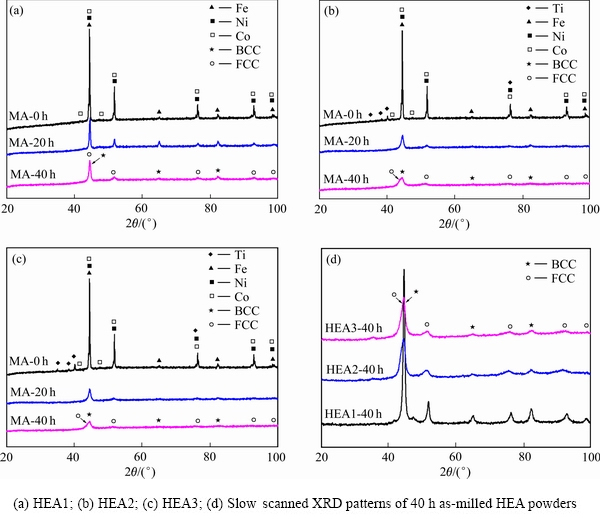

图1所示为不同球磨时间(Fe43Ni35Co22)1-xTix粉末的XRD谱。图 1(a)为HEA1粉末的 XRD谱。0 h时,各个元素的衍射峰清晰可见。当球磨时间增加到20 h,各元素衍射峰强度急剧降低,表明材料发生了合金化[28]。球磨时间增加至40 h时,衍射峰强度进一步降低。此时,粉末由FCC主相+少量BCC相组成。

图 1(b)、(c)所示为HEA2与HEA3粉末的XRD谱。与HEA1相比,其合金化行为略有不同。0 h时,各个元素的衍射峰清晰可见。随着球磨时间增加到20 h,衍射峰强度急剧降低,且衍射峰略微宽化,表明材料发生合金化和晶粒细化。当球磨时间增加至40 h,HEA2和HEA3衍射峰均明显宽化,表明材料的晶粒进一步细化[29];同时,各元素的衍射峰消失,表明此时的材料,已完全合金化,合金粉末均由FCC相和BCC主相组成。为了更好的表征球磨40 h之后粉末的相组成,对球磨40 h的合金粉末进行XRD慢扫,图谱如图1(d)所示,各个合金粉末中的FCC相与BCC相的特征峰清晰可见。

图1 不同球磨时间(Fe43Ni35Co22)1-x Tix粉末的XRD谱

Fig. 1 XRD patterns of (Fe43Ni35Co22)1-xTix powders with different milling times

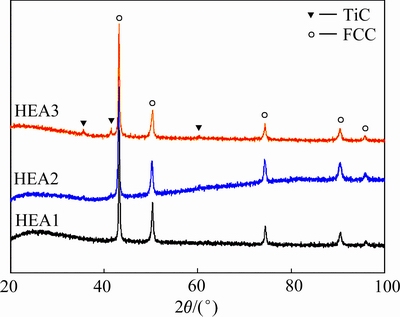

图2所示为1000 ℃烧结后三种合金块体的XRD谱。可以观察到,烧结后,三种合金中BCC相的衍射峰均消失。表明在SPS烧结过程中发生了相变。这是因为粉末的机械合金化是一个非平衡状态下的工艺过程,球磨后的粉末是一个亚稳态的过饱和固溶体;此外,在球磨的过程中产生了大量的纳米晶,导致晶界体积分数增大,而在晶界处储存了大量的畸变能,降低了相变所需的自由能。最终,高熵合金粉末在 SPS 烧结成形的过程中,在高温以及磁场、电场、等离子体场等多场效应的耦合作用下,转变为相对更稳定的FCC相。同时,在HEA2和HEA3中,还观察到了TiC的衍射峰,表明形成了TiC相。TiC主要是SPS烧结过程中原位自生形成的,其化学反应方程为Ti+C→TiC。其中,C主要来源于干燥后残留的过程控制剂环己烷的分解。Ti和C原子对的混合焓为-109 kJ/mol[30],在SPS烧结过程中,两者很容易发生原位自生成反应得到TiC。在HEA3中的TiC的峰强比增大,表明随着Ti含量的增加,HEA3中形成了更多的TiC。最终,HEA1为单相FCC结构,HEA2与HEA3的相组成相同,均为FCC+TiC,但HEA3中TiC的含量比HEA2高。

图2 (Fe43Ni35Co22)1-xTix块体的XRD谱

Fig. 2 XRD patterns of bulk (Fe43Ni35Co22)1-xTix

2.2 块体的相组成和微观组织

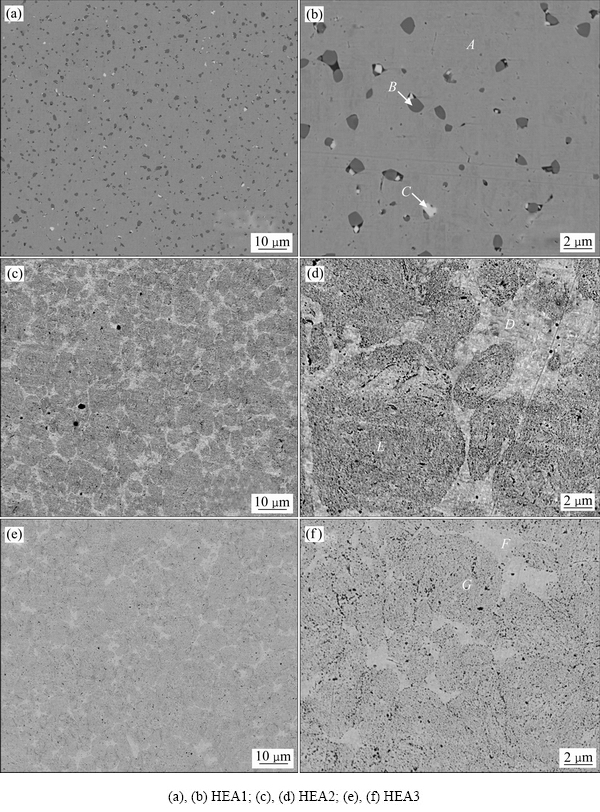

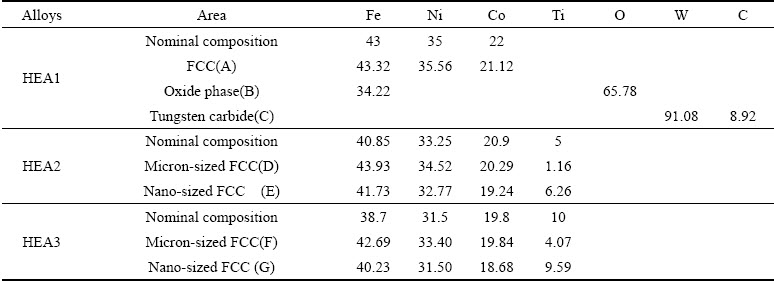

图3所示为三种高熵合金的背散射电子(BSE)照片。图3(a)~(b)所示为HEA1,可以看出,HEA1存在灰色区域(A),深色颗粒(B)以及白色颗粒(C),并且FCC基体与第二相颗粒的结合处存在孔洞。图3(c)~(d)所示为HEA2,材料的组织由白色区域(D)与灰色区域(E)组成,且存在少量的孔洞。图3(e)~(f)所示为HEA3,其组织与HEA2相似,由白色区域(F)与灰色区域(G)组成,存在较多的微观缺陷;但在HEA3中,灰色区域的占比明显提高。为了进一步分析三个材料中各个区域所表示的相,对图3中各个区域做能谱分析(EDS),每一块区域做5次能谱分析,取平均值,结果列于表1。

根据能谱分析结果, A区域含Fe、Co、Ni三种元素,其组成成分接近HEA1的名义成分;B区域含有氧和铁两种元素;C区域的主要元素为钨。由此推断,在HEA1中,灰色区域A为FCC基体,深色颗粒B与白色颗粒C,分别对应铁的氧化物和WC,是材料制备过程中引入的杂质。其中,铁的氧化物可能来源于粉末在空气中混粉时原始粉末的氧化[31];WC则是来自碳化钨磨球,在FeCoNi三元合金中也有出现[32]。对于HEA2,白色区域(D)与灰色区域(F)的Ti元素分布存在明显的差别;其中区域D的Ti元素含量较少,仅为1.16%,而区域(E)的Ti元素的含量较多,达到6.26%。在HEA3中,元素的分布与HEA2有相似规律。对于HEA2与HEA3,其相组成有待进一步的分析。

图3 (Fe43Ni35Co22)1-xTix的BSE图像

Fig. 3 BSE images of (Fe43Ni35Co22)1-xTix

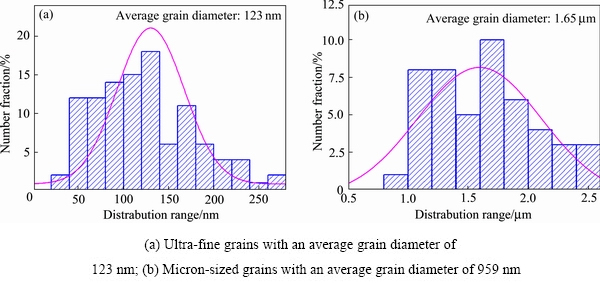

表1 (Fe43Ni35Co22)1-xTix的EDS/BSE分析结果

Table 1 Chemical compositions of bulk (Fe43Ni35Co22)1-xTix HEAs analyzed by EDS/BSE (mole fraction, %)

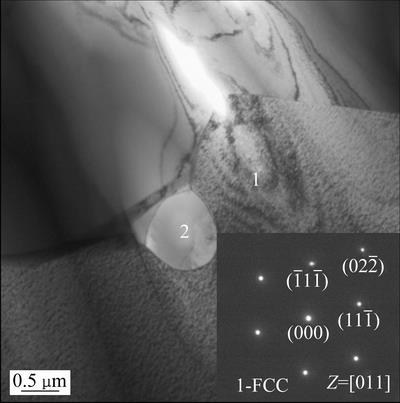

图4所示为HEA1的TEM明场像,以及晶粒1沿[011]轴的衍射斑点。可以确定晶粒1的晶体结构为FCC。HEA1的EDS/TEM结果列于表2,晶粒1中各元素都接近HEA1的名义成分,晶粒2主要含铁和氧,可以确定晶粒1为FCC基体,晶粒2为铁的氧化物,结合HEA1的SEM图像分析结果,可知HEA1包含FCC基体相、少量铁的氧化物和极微量的WC。其中,铁的氧化物与WC均为污染物。因此,HEA1的相组成可以描述为FCC相+少量杂质(铁的氧化物+WC)。

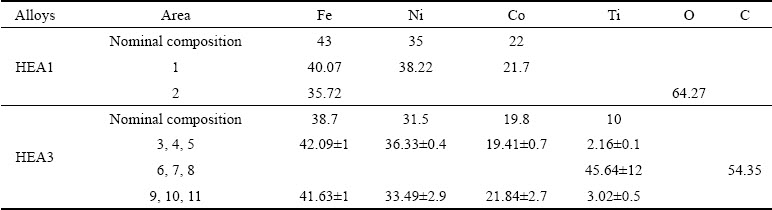

图5(a)为HEA3的明场像,以及晶粒3沿[011] 轴的衍射斑点,可知晶粒3为FCC结构;同时,可以观察到,在HEA3中形成了由超细晶区+微米晶区构成的多尺度结构。结合表2中 HEA3的EDS/TEM分析结果,可得出微米晶区为富Fe、Co、Ni的FCC相。图5(b)为HEA3超细晶区的明场像,结合EDS/TEM结果,可以判断细晶区中存在两个物相,即富Fe、Co、Ni的FCC相与TiC相。HEA3的相组成为FCC相+TiC,其中FCC相表现出多尺度结构。HEA2与HEA3有着相似的相组成和微观组织。由此推断,HEA2的相组成亦为FCC相+ TiC,且FCC为多尺度微观结构;与HEA3的区别是HEA2中的TiC更少,因此在烧结过程中阻碍晶粒长大的效果相对较弱,从而微米晶FCC相相对较多,并且超细晶的尺寸可能更大一点。

图4 HEA1的TEM照片及晶粒1的衍射斑点

Fig. 4 Bright-feld (BF) TEM images of HEA1 and SAED pattern corresponding to grain 1 (FCC)

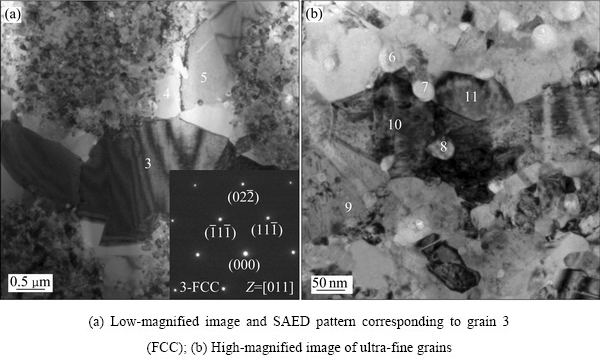

图6所示为HEA3晶粒中微米晶区和超细晶区中晶粒尺寸分布的统计直方图。根据统计结果,超细晶区晶粒的平均直径为123 nm,微米晶区晶粒的平均直径1.65 μm。与HEA1相比,HEA3的晶粒明显细化,并且出现了多尺度的结构。这主要是因为HEA3中原位生成了TiC。在烧结过程中,粉末颗粒相互接触,在粉末颗粒内部,由于TiC的存在,内部纳米晶粒的长大受阻,最终得到超细晶区。粉末颗粒之间,由于接触表面小,承受的电流过大而形成局部高温,促使晶粒快速长大,最终形成微米晶区。

表2 (Fe43Ni35Co22)1-x Tix的EDS/TEM分析结果

Table 2 Chemical compositions of bulk (Fe43Ni35Co22)1-x Tix HEAs analyzed by EDS/TEM

图5 HEA3的TEM照片及晶粒3的衍射斑点

Fig. 5 Bright-field (BF) TEM images of HEA3

图6 HEA3的晶粒粒径分布统计直方图

Fig. 6 Statistical grain diameter distribution histogram of bulk HEA3

2.3 高熵合金的力学性能与磁性能

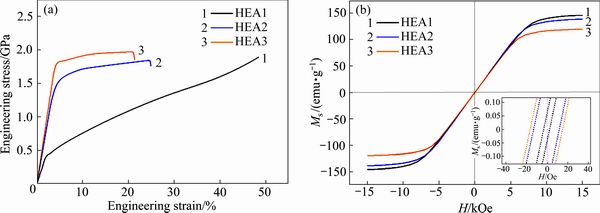

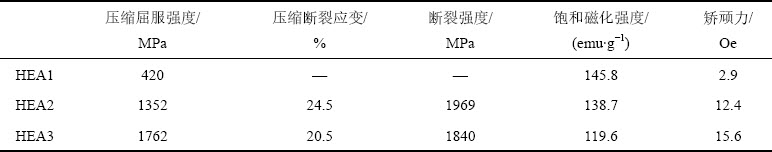

图7(a)为(Fe43Ni35Co22)1-xTix在室温下的压缩工程应力-应变曲线。从图中可以看出,HEA1塑性最好,但屈服强度仅为420 MPa。随着TiC含量的增加,材料的塑性降低,但屈服强度得到大幅提升。当Ti含量为5%时,材料的屈服强度提升221%,达到1352 MPa;当Ti含量为10%时,材料的屈服强度提升319%,高达1762 MPa。这主要归因Ti的添加使得材料中原位生成TiC颗粒,细小的TiC颗粒弥散分布于基体中,变形过程中会阻碍位错的运动,有着弥散强化的效果;同时,在烧结过程中,细小的TiC颗粒阻碍了晶粒的长大,使得材料出现大量的超细晶,晶粒的细化增加了晶界的体积分数,使得位错运动阻力增加,强度提升(晶界强化)。随着Ti含量的添加,原位生成TiC的量增加,对基体的强化效果更加显著。此外,由于材料同时存在微米晶区和超细晶区,会使得材料获得背应力强化,进一步提高材料的强度,这种强化现象在多尺度(异构)材料中都有报道[33, 34]。

图7(b)为(Fe43Ni35Co22)1-xTix室温下的磁滞回线。由磁滞回线可知,HEA1具有最高的饱和磁化强度以及最低的矫顽力,即HEA1的软磁性能最好。随着TiC含量的增加,材料的饱和磁化强度略有下降,同时材料的矫顽力急剧增加,导致软磁性能恶化。添加5%Ti使得材料的矫顽力提升327%,为12.4 Oe;当添加10%Ti时,材料的矫顽力提升438%,为15.6 Oe。这主要是因为饱和磁化强度是一个本征参数,其值主要取决于材料的组成元素及晶体结构等,而矫顽力受晶粒大小、位错、第二相等因素的影响[35, 36]。在(Fe43Ni35Co22)1-xTix中,随着Ti元素的添加,材料中原位生成TiC含量增加,铁磁性元素占比降低,导致饱和磁化强度略有下降。同时,原位生成的TiC促使晶粒细化,并形成了微米晶区和超细晶区。一方面,晶粒细化有助于畴壁的运动,使得材料的矫顽力降低;另一方面,第二相颗粒的添加,会阻碍畴壁的运动,使得材料的矫顽力增大[3, 37-38]。显然,本文中TiC颗粒对畴壁运动阻碍效果更为显著,使得材料的矫顽力增加。综合考虑,HEA1的强度过低,HEA3的矫顽力太大而导致磁性能不佳,故HEA2具有最为优异的综合性能,其压缩屈服强度为1352 MPa,矫顽力为12.4 Oe,饱和磁化强度为138.7 emu/g,压缩断裂应变为24.5%,抗压强度为1969 MPa。

图7 (Fe43Ni35Co22)1-x Tix的室温压缩性能曲线与磁滞回线

Fig. 7 Room-temperature compressive curve (a) and hysteresis loop (b) of (Fe43Ni35Co22)1-x Tix

表3 (Fe43Ni35Co22)1-x Tix的性能总结

Table 3 Compressive and soft magnetic properties of (Fe43Ni35Co22)1-x Tix

3 结论

1) HEA1高熵合金粉末在球磨40 h粉末的相组成为FCC主相+少量BCC相;HEA2和HEA3高熵合金粉末球磨40 h后粉末的相组成为BCC主相+FCC相。

2) 经过1000 ℃的SPS烧结后,HEA2和HEA3原位生成了TiC,且随着Ti添加量的增加,TiC的含量增多。最终HEA1的相组成为FCC相+少量杂质;HEA2和HEA3则由单相FCC+TiC组成,其中FCC相为超细晶+微米晶的多尺度结构。

3) HEA2表现出最优异的综合性能。HEA1具有良好的塑性和软磁性能,但屈服强度较低。随着TiC含量的增加,材料的强度与矫顽力显著提高,当Ti添加量为5%时,材料的屈服强度提升221%,达到1352 MPa;矫顽力提升327%,达到12.4 Oe;当Ti添加量为10%时,材料的屈服强度提升319%,达到1762 MPa,矫顽力则提升至15.6 Oe。强度的提升,主要来源于弥散强化、细晶强化以及背应力强化;矫顽力的增高则是因为TiC颗粒对磁畴的阻碍作用。

REFERENCES

[1] GUTFLEISCH O, WILLARD M A, BR?CK E, et al. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient[J]. Advanced Materials, 2011, 23(7): 821-842.

[2] MCHENRY M E, WILLARD M A, LAUGHLIN D E. Amorphous and nanocrystalline materials for applications as soft magnets[J]. Progress in materials science, 1999, 44(4): 291-433.

[3] SOURMAILT. Near equiatomic FeCo alloys: Constitution, mechanical and magnetic properties[J]. Progress in Materials Science, 2005, 50(7): 816-880.

[4] JILES D C. Recent advances and future directions in magnetic materials[J]. Acta Materialia, 2003,51(19): 5907-5939.

[5] YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303.

[6] ZHANG Zi-jiao, MAO M M, WANG Jiang-wei, et al. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi[J]. Nature Communications, 2015, 6(1).

[7] TAKEUCHI A, AMIYA K, WADA T, et al. High-entropy alloys with a hexagonal close-packed structure designed by equi-atomic alloy strategy and binary phase diagrams[J]. JOM, 2014, 66(10): 1984-1992.

[8] ZHANG Wei-ran, LIAW P K, ZHANG Yong. A novel low-activation VCrFeTaxWx (x=0.1, 0.2, 0.3, 0.4, and 1) high-entropy alloys with excellent heat-softening resistance[J]. Entropy (Basel), 2018, 20(12).

[9] 龙 雁, 梁小彪, 苏 凯, 等. 粉末冶金FeCoNiCu0.4Al0.4高熵合金的热处理组织与性能[J]. 中国有色金属学报, 2020, 30(1): 88-93.

LONG Yan, LIANG Xiao-biao, SU Kai, et al, Microstructure and mechanical properties of heat treated FeCoNiCu0.4Al0.4 high entropy alloy prepared by powder metallurgy[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(1): 88-93.

[10] BERND G, ANTON H, DHIRAJ C, et al. A fracture- resistant high-entropy alloy for cryogenic applications[J]. Science, 2014, 6201(345): 1153-1158.

[11] CHEN Shu-ying, LI Wei-dong, XIE Xie, et al. Nanoscale serration and creep characteristics of Al0.5CoCrCuFeNi high-entropy alloys[J]. Journal of Alloys and Compounds, 2018, 752: 464-475.

[12] FU Zhi-qiang, CHEN Wei-ping, WEN Hai-ming, et al. Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25- Al7.5Cu17.5 high-entropy alloy[J]. Acta Materialia, 2016, 107: 59-71.

[13] LI Ze-zhou, ZHAO Shi-teng, ALOTAIBI S M, et al. Adiabatic shear localization in the CrMnFeCoNi high-entropy alloy[J]. Acta Materialia, 2018, 151: 424-431.

[14] QIU Xing-wu. Corrosion behavior of Al2CrFeCo CuNiTi high-entropy alloy coating in alkaline solution and salt solution[J]. Results in Physics, 2019, 12: 1737-1741.

[15] 王 勇, 李明宇, 孙丽丽, 等. FeCrNiCo(Cu/Mn)高熵合金组织及腐蚀性能[J]. 中国有色金属学报, 2020, 30(1): 94-102.

WANG Yong, LI Yu-ming, SUN Li-li, et al. Microstructure and corrosion properties of FeCrNiCo(Cu/Mn)high entropy alloy[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(1): 94-102.

[16] CHEN Chen, ZHANG Hang, FAN Yan-zhou, et al. A novel ultrafine-grained high entropy alloy with excellent combination of mechanical and soft magnetic properties[J]. Journal of Magnetism and Magnetic Materials, 2020, 502: 166513.

[17] FU Zhi-qiang, MACDONALD B J, DUPUY A D, et al. Exceptional combination of soft magnetic and mechanical properties in a heterostructured high-entropy composite[J]. Applied Materials Today, 2019, 15: 590-598.

[18] LI Pan-pan, WANG An-ding, LIU C T. A ductile high entropy alloy with attractive magnetic properties[J]. Journal of Alloys and Compounds, 2017, 694: 55-60.

[19] ZHANG Hang, YANG Yao-xuan, LIU Lei, et al. A novel FeCoNiCr0.2Si0.2 high entropy alloy with an excellent balance of mechanical and soft magnetic properties[J]. Journal of Magnetism and Magnetic Materials, 2019, 478: 116-121.

[20] ZUO Ting-ting, GAO M C, OUYANG L, et al. Tailoring magnetic behavior of CoFeMnNiX (X=Al, Cr, Ga, and Sn) high entropy alloys by metal doping[J]. Acta Materialia, 2017, 130: 10-18.

[21] HOU Jin-xiong, ZHANG Min, MA Sheng-guo, et al. Strengthening in Al0.25CoCrFeNi high-entropy alloys by cold rolling[J]. Materials Science and Engineering A, 2017, 707: 593-601.

[22] TARIQ N H, NAEEM M, HASAN B A, et al. Effect of W and Zr on structural, thermal and magnetic properties of AlCoCrCuFeNi high entropy alloy[J]. Journal of alloys and compounds, 2013, 556: 79-85.

[23] ZUO Ting-ting, REN Song-bo, LIAW P K, et al. Processing effects on the magnetic and mechanical properties of FeCoNiAl0.2Si0.2 high entropy alloy[J]. International Journal of Minerals, Metallurgy, and Materials, 2013, 20(6): 549-555.

[24] LI Pan-pan, WANG An-ding, LIU C T. Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl) x high entropy alloys[J]. Intermetallics, 2017, 87: 21-26.

[25] ZHANG Yong, ZUO Ting-ting, CHENG Yong-qiang, et al. High-entropy alloys with high saturation magnetization, electrical resistivity and malleability[J]. Scientific Reports, 2013, 3(1).

[26] FENG Wen-qiang, QI Yang, WANG Shao-qing. Effects of short-range order on the magnetic and mechanical properties of FeCoNi(AlSi)x high entropy alloys[J]. Metals, 2017, 7(11): 482.

[27] GUO Sheng, NG C, LU Jian, et al. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys[J]. Journal of Applied Physics, 2011, 109(10): 103505.

[28] YEH J W, CHANG S Y, HONG Y D, et al. Anomalous decrease in X-ray diffraction intensities of Cu-Ni-Al-Co-Cr-Fe-Si alloy systems with multi-principal elements[J]. Materials Chemistry and Physics, 2007, 103(1): 41-46.

[29] ZHANGA K B, FUZ Y, ZHANGA J Y, et al. Characterization of nanocrystalline CoCrFeNiTiAl high- entropy solid solutionprocessed by mechanical alloyin[J]. Journal of Alloys and Compounds, 2010, 495: 33-38.

[30] TAKEUCHI A, INOUE A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element[J]. Materials Transactions, 2005, 46(12): 2817-2829.

[31] MORAVCIK I, KUBICEK A, MORAVCIKOVA-GOUVEA L, et al. The origins of high-entropy alloy contamination induced by mechanical alloying and sintering[J]. Metals, 2020, 10(9): 1186.

[32] 吴炳勇. FeNiCoCu系高熵合金及其复合材料的微观组织与力学性能研究[D]. 广州: 华南理工大学, 2017.

WU Bing-yong. Research on the microstructure and mechanical properties of FeNiCoCu series high-entropy alloy and its composite materials[D]. Guangzhou: South China University of Technology, 2017.

[33] FU Zhi-qiang, MACDONALD B E, LI Zhi-ming, et al. Engineering heterostructured grains to enhance strength in a single-phase high-entropy alloy with maintained ductility[J]. Materials Research Letters, 2018, 6(11): 634-640.

[34] YANG Mu-xin, PAN Yue, YUAN Fu-ping, et al. Back stress strengthening and strain hardening in gradient structure[J]. Materials Research Letters, 2016, 4(3): 145-151.

[35] FU Zhi-qiang, MACDONALD B E, MONSON T C, et al. Influence of heat treatment on microstructure, mechanical behavior, and soft magnetic properties in an fcc-based Fe29Co28Ni29Cu7Ti7 high-entropy alloy[J]. Journal of Materials Research, 2018, 33(15): 2214-2222.

[36] HOU Chong-qiang, SHAN Yi-jiao, WU Hai-chen, et al. Effect of a small addition of Cr on soft magnetic and mechanical properties of Fe-49Co-2V alloy[J]. Journal of Alloys and Compounds, 2013, 556: 51-55.

[37] SUNDAR R S, DEEVI S C. Soft magnetic FeCo alloys: alloy development, processing, and properties[J]. International materials reviews, 2005, 50(3): 157-192.

[38] HERZER G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets[J]. IEEE Transactions on Magnetics, 1990, 26(5): 1397-1402.

Influence of TiC on microstructure and properties of Fe43Ni35Co22medium-entropy alloy

LI Rui-kai1, CHEN Wei-ping1, WANG Hao1, CHEN Qiang2, ZENG Da-hai1, FU Zhi-qiang1

(1. Guangdong Key Laboratory for Advanced Metallic Materials Processing, South China University of Technology, Guangzhou 510640, China;

2. Southwest Institute of Technology and Engineering, Chongqing 400039, China)

Abstract: This paper systematically studied the influence of TiC on the microstructure, mechanical and magnetic properties of Fe43Ni35Co22 medium-entropy alloy (MEA). Adding 5% or 10% (mole fraction) Ti to theFe43Ni35Co22 MEA, the bulk TiC/Fe43Ni35Co22composite was achieved via in-situ reaction, using the combination of mechanical alloying (MA) and spark plasma sintering (SPS). The results showed that after 40hof ball milling, Fe43Ni35Co22 MEA powder was composed of a major face-centered cubic (FCC) phase and a small amount of body-centered cubic (BCC) phase, and the two TiC/Fe43Ni35Co22 powders were composed of a primary BCC phase and an FCC phase. Following by SPS, the bulk Fe43Ni35Co22MEA showed a single FCC phase with a small amount of contamination, and the two bulk TiC/Fe43Ni35Co22 consisted of a primary FCC phase with some TiC. Note that the FCC phase in the two bulk TiC/Fe43Ni35Co22 exhibited a multi-scale structure consisting of micron grains and ultra-fine grains. In addition, the volume fraction of ultra-fine grains increased as the TiC increased. In terms of properties, the addition of TiC evidently improved the compressive yield strength and coercivity of Fe43Ni35Co22, there by leading to a decrease in the plasticity and magnetic saturation of the material simultaneously. The bulk TiC/Fe43Ni35Co22 with 5% Ti addition showed the best performance, in detail, showing a compressive yield strength of 1352 MPa and a compressive fracture strain of 24.5%, along with a coercivity of 12.4 Oe and a saturation magnetization of 138.7emu/g.

Key words: medium-entropy alloys; mechanical alloying; spark plasma sintering; mechanical properties;

soft magnetic properties

Foundation item: Project(2020A1515111104) supported by Guangdong Basic and Applied Basic Research Foundation; Project supported by the Guangzhou Science and Technology Bureau

Received date: 2021-03-04; Accepted date: 2021-07-19

Corresponding author: FU Zhi-qiang; Tel: +86-20-87113832; E-mail: zhiqiangfu2019@scut.edu.cn

(编辑 )

基金项目:广东省基础与应用基础研究研究联合基金-青年基金项目(2020A1515111104);广州市科技局支持

收稿日期:2021-03-04;修订日期:2021-07-19

通信作者:付志强;电话:020-87113832;E-mail:zhiqiangfu2019@scut.edu.cn

摘 要:本文系统研究了TiC含量对Fe43Ni35Co22中熵合金微观组织、力学性能以及磁性能的影响。添加5%和10%(摩尔分数)Ti至中熵合金Fe43Ni35Co22,通过原位自生反应形成TiC/Fe43Ni35Co22合金块体,制备方法为“机械合金化(MA)+放电等离子烧结(SPS)”。研究结果表明:经40h球磨后, Fe43Ni35Co22粉末相的组成为FCC主相+少量BCC,两种TiC/Fe43Ni35Co22粉末的相组成为BCC主相+FCC相。经SPS烧结后,Fe43Ni35Co22块体为单相FCC和少量的杂质;两种TiC/Fe43Ni35Co22块体均由FCC+TiC两相组成,其中FCC相呈现“微米晶+超细晶”构成的多尺度结构,且随着TiC含量的增加,超细晶区增多。性能上,TiC的添加大幅提高了Fe43Ni35Co22的压缩屈服强度和矫顽力,同时也导致了材料的塑性和饱和磁化强度的降低。Ti添加量为5%的TiC/Fe43Ni35Co22综合性能最优异,其压缩屈服强度为1352 MPa,压缩断裂应变为24.5%,矫顽力为12.4 Oe,饱和磁化强度为138.7 emu/g。