文章编号:1004-0609(2008)03-0457-08

涂层导体金属基带的研究进展

赵 跃,索红莉,刘 敏,何 东,祝永华,高忙忙,周美玲

(北京工业大学 材料科学与工程学院,北京 100022)

摘 要:

涂层超导材料是一种有着广泛应用前景和巨大潜在商业价值的高温超导材料之一。随着人们对高性能涂层超导带材研究的不断深入,基带材料作为涂层超导材料YBa2Cu3O7-x(YBCO)多层结构中重要的组成部分也呈现出新的科研成果,基底的研究在金属种类选择上和再结晶理论的研究方面都取得明显的进展。总结目前几种重要的金属及其合金基底,从材料的制备手段,织构形成的特点和性能,存在的优缺点以及未来的发展趋势等方面介绍了涂层导体中金属基带的研究现状。

关键词:

中图分类号:TM 26 文献标识码:A

A review of metal substrates for coated conductors

ZHAO Yue, SUO Hong-li, LIU Min, HE dong, ZHU Yong-hua, GAO Mang-mang, ZHOU Mei-ling

(College of Material Science and Engineering, Beijing University of Technology, Beijng, 100022, China)

Abstract: Coated conductor (CCs) with large potential commercial value, which is a promising candidate for wide HTS materials application, has been systematically studied for many years. Though choosing and combining varied metal materials, the metal substrate as the essential part in YBa2Cu3O7-x (YBCO) multi-layers structure has reached a series of the latest achievements on both fabrication method and the understanding of recrystallization theory. The development of different kinds of alloy substrates used in either rolling-assistant biaxially textured substrate technique or ion beam assistant deposition method was reviewed. Furthermore, from the view of cost-effect, several popular substrates were proposed.

Key words: metal substrate; Ag alloy; Ni alloy; Cu alloy; texture; recrystallization

近年来,人们广泛开展以第一代高温超导材料为主的高温超导电缆、超导限流器、超导变压器以及超导电动机等方面的试运行实验,这标志着高温超导已经逐渐从实验室研究阶段走向应用。但是由于第一代高温超导线带材存在无法克服的本征问题(低的不可逆场)和制造成本高的缺点,不能满足人们对材料性能和价格的要求,从而限制该材料真正走向市场应用。另一方面,近年来采用物理气相沉积方法和化学镀膜方法制备超导层及过渡层技术的发展使得第二代涂层超导材料,即以YBa2Cu3O7-x(YBCO)为主的稀土类高温超导材料,在经历较长时间的低靡后,重新成为各国竞相研究开发的热点,并取得一系列突破性进展。这使得人们看到高温超导线带材实现其大规模低成本工业化生产,走向市场应用的曙光。

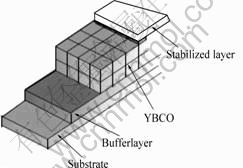

由于YBCO的临界电流密度(Jc)受晶界间夹角的严重限制,只有制备出像单晶一样具有双轴织构的材料才能获得高的超导性能[1-2]。另外,为了实现上述超导材料的大规模应用,必须将这种陶瓷超导氧化物制备出一定长度的韧性线带材。基于上述思路的考虑,如能制备出具有双轴织构的韧性基带,将“取向”直接或通过过渡层传递给超导层以外延获得YBCO薄膜是一种被人们普遍采用的方法,因此,制备具有双轴织构的金属韧性基板是获得高性能超导线材的关键。而金属基板在超导带材的结构中位于整个基板的底层(图1),其主要作用是外延生长过渡层和超导层,同时能够承受一定的应力应变。为了满足高性能超导带材的需求,高电导率、高织构度、较小交流损耗、较大屈服极限、抗氧化能力以及优良的表面粗糙度等性质的获得是制备高性能的金属基带的关键。

图1 涂层超导材料的基本结构示意图

Fig.1 Typical structure of coated conductors

在涂层超导带材的发展过程中,有很多种金属被选择作为涂层超导材料的基带材料。按照金属的种类划分主要有Ag及其合金基带,Ni及其合金基带,Cu及其合金基带,不锈钢基带等;按照金属的元素组元数量划分有纯金属基带,二元合金基带,多元合金基带;按照织构来划分,有多晶织构金属基带和无织构金属基带两大类。由此可见,人们根据不同的金属及其形成织构的情况可以设计出不同性能的基带,从而满足涂层超导体金属基带的使用需求。

本文作者全面概述了基带发展历史过程中受到人们广泛关注的几种金属基带,从合金的选择、材料制备手段、再结晶特点、基带的结构等方面介绍比较成熟的金属基带和该领域内国际上研究的热点。

1 Ag及其合金基板

Ag作为目前发现唯一不与YBCO反应的金属材料,可以简化诸如上述的多层超导结构,即可以直接在金属Ag基带上镀制YBCO超导薄膜而不需要过渡层。Ag的晶格常数为0.409 nm,熔点为961 ℃。早期有研究者在单晶Ag基底上用激光外延沉积出双轴织构的YBCO薄膜,提出用该种基带制备涂层导体的可能性[3-4]。此外;研究表明Ag的掺入可以改善高温超导体的力学性能和电性能[5-7]。20世纪90年代采用在多晶双轴织构Ag带上沉积YBCO的工作取得很大的进展,用脉冲激光溅射沉积(PLD)和化学气相沉积(CVD)在{110}<211>取向的多晶Ag带上制备YBCO薄膜,Jc达到1.2×105 A/cm2(77 K,0 T)[8-9]。研究发现{100}或{110}织构的Ag基带有利于YBCO超导层的双轴取向生长。本文作者所在的研究小组长期开展织构银基带的研究和在多晶和织构银基带上制备涂层超导材料的相关工作,继制备出{100}<001>双轴织构银带后,又制备出{110}<211>、{110}<001>和{110}<110>等双轴织构银基带[10-11]。在{110}<110>织构银基带上采用PLD方法直接沉积YBCO薄膜,其Jc达到7×105 A/cm2[12];并采用两种不同的化学办法,即金属有机盐热分解法(MOD)和超声喷雾热分解的方法在该织构基带上制备一定长度,Jc值超过104A/cm2的涂层超导带材[13-14]。

由于纯Ag基板机械性能差,成本高,本研究小组也制备出机械增强的且具有{110}<011>双轴织构的AgMg,Ag/Ni(或Ni合金)金属复合基带,这些复合基带的结构如图2所示。复合Ag基带外层为不与YBCO超导材料反应的纯Ag,而芯层则是高强度的合金,如AgMg,Ni或Ni合金[15]。值得一提的是这些金属复合带其Ag的用量仅为同样厚度的纯Ag基板的25%,这大大降低了成本,具有独特开创性。同时本文作者也将这种复合带用在制备YBCO涂层膜。

图2 复合Ag基带截面的SEM像

Fig.2 SEM cross-section image of Ag/NICrV composite tapes

另外在增强Ag基板的机械强度方面,Toshiba公司[16]在Ag基板中掺入Cu和Ni,其机械强度比纯Ag基板提高了3倍。最近,日本研究小组在无织构的Ag基带上用CVD方法制备出的涂层超导带材长度达到210 m,临界电流值为60~78 A[17],这也是目前在Ag基带上用化学方法制备涂层超导带材的最好结果。

但是由于Ag是贵金属,容易形成孪晶,不易获得单一锐利的双轴织构,机械强度较差,基带表面缺陷多,晶粒间沟槽深,同时由于Ag的熔点较低,在沉积YBCO薄膜时,难以控制生长条件阻止其向超导层的扩散。这些缺陷都成为超导层性能进一步提高的瓶颈,大大的限制Ag作为基带材料的使用。使用该种材料作为涂层超导的基带还需要进一步的研究以克服上述问题。

2 Ni及其合金基板

1996年,美国ORNL的Norton等[18]发现,金属Ni在较大变形量的冷轧以后,经过适当的热处理能够形成较强的立方织构。这种技术被称为压延辅助双轴织构技术(RABiTS)。Ni的晶格常数为0.352 4 nm,属于立方晶系,热膨胀系数(α)为(13.0~17.4)×10-6/℃,由于Ni与YBCO超导材料有严重的反应互扩散,必须在Ni和超导层之间插入一层或多层过渡层。研究表明Ni与可以作为YBCO隔离层的CeO2、STO、YSZ和LMO等具有萤石结构或钙钛矿结构的氧化物具有良好的晶格匹配性和热稳定性。继ORNL成功地用RABiTS 技术制备出Ni基带后,他们在这种基带制备了过渡层和YBCO薄膜,首次在金属韧性基带上获得Jc值高达3×105 A/cm2,接近以单晶为基底获得的YBCO超导层。这一令人兴奋的结果给人们勾勒出YBCO涂层导体的应用前景,同时也掀起利用(RABiTS)技术制备金属韧性基带和涂层导体在全世界研究的热潮。1999年MATSUMOTO[19]首先成功的在Ni基带表面制备出利于YBCO膜生长的双轴织构(SOE)NiO过渡层;2000年,CANTONI等[20-21]在研究时,发现表面干净的Ni金属基带上可以形成ab面内的(2×2)超结构,硫原子所在该结构中的晶格位置可以与多数氧化物过渡层材料(CeO2,YSZ等)结构中的氧占位形成良好的匹配,有利于过渡层的形核和生长。这些技术的开发和利用,极大地拓宽了Ni基带在涂层超导材料中的应用范围。

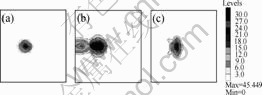

尽管高纯度的Ni基带容易通过RABiTS技术形成较强的立方织构,但是由于其具有的铁磁性(0 ℃饱和磁化强度为57.5 Gcm3/g)[22],屈服极限低(34 MPa,300 K),退火后晶界较深(几百纳米)等不可克服的本征缺点,因此不是作为涂层超导基带的最佳选择。于是,研究人员就提出了在Ni中固溶一定量的合金元素以解决上述问题。通过这种微合金的办法,减弱了有害杂质元素(如S、C、Mg)对织构的不利影响,使得Ni合金基带保持纯Ni基带具有较高织构度的同时在一定程度上弥补纯Ni的本征的缺点[23-24]。常用的微合金元素有W、V、Cr、Mo、Ta、Nb和Ag等。通常合金元素的加入将导致Ni层错能的下降,不同的元素影响Ni合金形成立方织构的极限含量不同,如W的摩尔分数超过5%时,退火后NiW合金带的立方织构就会明显的下降;对应的NiCr和NiV合金中,Cr元素的极限含量为13%,V的极限含量为10%[25-27]。基于以上研究,Ni合金是一种可以大规模工业化生产的应用于涂层导体中的金属基带,也是目前为止,研究最系统、最深入、成果最广泛的一类基带。传统的RABiTS方法研究主要集中在Ni-5%(摩尔分数)W合金方面。从初始铸锭的制备方法来分,主要有熔炼和粉末冶金两种方法。德国、美国、日本、韩国、意大利和中国等国家的不同研究小组通过对熔炼工艺、粉末粒度的控制,对冷轧变形量即总变形量和道次变形量的控制,以及对退火温度、时间和气氛的控制得到了成分均匀、取向单一、表面平整的立方织构Ni-5%W合金基带[28-37]。X射线衍射分析表明,这些基带的(111)φ扫描的半高宽(FWHM)达到5?~8?,(002)摇摆曲线的FWHM达到4?~6?。通过背散射电子衍射分析(EBSD)在微取向角10?的范围内,(001)<100>立方织构的含量接近100%;晶内粗糙度(RMS)在1 nm以下,σy在150 MPa以上。图3所示为一研究小组在制备该种基带的一些结果:通过极图、ODF和EBSD等现代分析手段表明基带具有高度的双轴立方织构,在微取向角小于8?的范围内{100}<001>立方织构度达到93.5%,晶内粗糙度小于0.9 nm,晶界深度在30~ 50 nm;同时研究揭示不同退火方式对基带织构及孪晶形成的影响[38]。

图3 Ni-5%W(摩尔分数)基带晶粒微取向角分布结果(a)和基带晶粒内的AFM像(b)

Fig.3 EBSD pattern(a) and AFM images(b) of Ni-5%W tape[38]

由于涂层超导带材将日渐实用化,Ni-5%W在磁性能和力学性能依然不能完全满足生产和应用的需求。人们试图通过以下方法来解决上述问题。

2.1 固溶强化和弥散强化金属基带

基于Ni-5%W合金优越的使用性能,制备更高W含量(≥5%)合金基带成为研究人员的首要选择,这是因为,随着W含量的不断增大,基带的一些性能有明显的提高,如合金带强度的提高,居里温度可下降到液氮沸点温度以下,基带表面抗热刻蚀的能力的提高;但是正如上文提及的,层错能的下降使得轧制退火后高W含量基带的立方织构含量明显减少,在这种情况下如何提高织构度成为人们研究的重点。美国ORNL最近的研究结果表明,通过改变轧制工艺,可以在Ni-9.3%W合金中获得和Ni-5%W相同的轧制织构(如图4所示),通过进一步优化的退火工艺,得到立方织构含量达到97%的Ni-9.3%W基带[39]。在弥散强化方面,德国的IFM Dresden研究小组,尝试用Al作为初始颗粒弥散在铸锭当中,轧制后的基带通过随后的内氧化处理得到了分散均匀的Al2O3,屈服强度达到了175 MPa以上,起到了弥散强化基带的效果,但是由于内氧化过程使得基带的织构受到了明显的影响,出现大量孪晶[40-41],采用这种弥散强化制备高强度的立方织构涂层超导基带还需要进一步的研究。在该方面,该研究小组也正在研究以NiW合金复合基带的关键技术问题,并取得阶段性的成果[42-43]。

图4 不同W含量NiW合金基带经轧制后的ODF图

(φ2=0)

Fig.4 ODF patterns of NiW alloy substrates with varied W contents after rolling (φ2=0): (a) Ni-5%W tape after standard cold rolling; (b) Ni-9.3%W substrate after standard cold rolling; (c) Ni-9.3%W after optimized rolling

2.2 制备三元合金或复合基带

考虑到W、Cr等合金元素的固溶强化作用,以及Al所能够形成Al2O3弥散强化的作用,不同的合金元素组合可用以制备满足强度和磁性要求的Ni基合金基带,目前比较成功的合金基带如表1所示。由于Cr和V等微合金元素在后续制备过渡层材料和超导层材料的高温条件下比较容易形成氧化物,从而使整个超导带材的性能下降。作为另外一种选择,复合基带同样受到研究者的关注。复合基带即作为外层的基带一般为容易形成强立方织构的Ni合金,而作为芯层的则是高强度无磁性的基带,如Ni-15%Cr[36]和Ni-15%Cr- 1.5%Al[44]等合金,制备这种基带的技术核心就是如何控制条件使得内外层具有相近的再结晶温度和相似的力学变形性能,保证复合基带的外层织构度、连接性以及良好的表面形貌。该研究小组采用“Layer by layer”的思路,成功制备一系列高强度低磁性的Ni基合金复合基带,同时保证基带的双轴织构,因此这种复合基带作为一种潜在的基带还有进一步的研究空间[45-47]。另外,ORNL在已经能够商业化生产的织构NiFe合金基带[48]的基础上,添加适量W,即Ni-3%W-1.7%Fe,克服了其抗氧化能力差的缺点,并获得了高度的织构,在该种基带上制备的YBCO的Jc达到1.9×106 A/cm2[49-50]。

表1 金属合金基带的强度及磁性[44, 49, 51]

Table 1 Strength and magnetic properties of metal substrates

3 Cu及其合金基带

Cu是一种廉价、高电导率、无磁性、高热容的、易于形成立方织构的金属材料,因此作为一种具有替代Ni合金潜力的基带逐渐成为目前人们研究的热点之一。但是由于Cu表面抗氧化能力较差,热膨胀系数高及力学性能低等缺点,其应用受到一定的限制。选择不同的过渡层结构以及合金材料的优化可以弥补Cu及其合金差的抗氧化性和高热膨胀系数所带来的不足,因此从Cu基带本身来讲就是如何获得高强度的Cu合金基带,同时保持其高的立方织构含量和无磁性等优点[52]。在较早的研究中,人们已经能够制备出双轴织构的CuNi合金[53-55],但是强度问题并没有得到很好的解决。近期,美国部分实验室作为一种技术储备,启动Cu及其合金作为涂层导体基带的研究计划。CHAKRAPANI 等[56]使用商业的Cu-Fe锭作为初始原料,利用RABiTS技术制备50 μm厚的具有双轴织构的基带(?φ=6.4?,?ω=5.9?),Fe作为弥散相使得基带强度比纯Cu基带提高一倍,同时保持基带的居里温度在液氮温区以下。另外,ORNL也通过弥散强化制备出Cu-48% Ni-1% Al合金基带,并在上面制备合适的过渡层,最终获得的YBCO超导层的Jc值达到3.5×106 A/cm2[57];同时,该小组依然继续寻找一种有效的弥散相和优化的退火工艺来制备强化的双轴织构Cu基带。据报道,选择适当的退火工艺后,Cu合金基带的屈服强度可以达到200 MPa以上,?ω也保持在5.5?[39]。尽管如此,Cu要想真正替代Ni合金基带还要在强度、织构、过渡层的选择等方面广泛探索,充分发挥其价格和性能优势,为制备高Ie的超导带提供条件。

4 不锈钢基带

上述的几种金属及其合金基带都是在RABiTS技术上发展应用的织构基带,除此以外,无织构的金属基带也可以作为另外一种涂层导体结构的选择。选择这种基板制备涂层导体带材的技术思路是在无织构的韧性金属基带上利用IBAD(离子束辅助沉积)和ISD(倾斜基板沉积)两种主要的物理沉积技术沉积具有双轴取向的过渡层,然后作为模板再提供给超导层。在无织构的金属基带中不锈钢合金以其低廉的价格、优越的性能一直受到人们的青睐。主要有以下几种合金用于涂层超导带材的金属基带材料[56-57],即Hastelloy C-276、Haynes 242、stainless steel SS304、Rene 41和Inconel 625。其中以Hastelloy C-276应用最为广泛,是目前主要使用的无织构金属基带[60-61]。其主要成分是Ni、Mo和Cr[62],有很高的屈服强度(360 MPa以上)和强的抗腐蚀抗氧化能力。由于使用这种基带的关键技术在于IBAD方法或ISD方法制备过渡层,在此不再赘述。

5 小结

总之,未来的十年是超导形成高新技术产业化的阶段,涂层超导材料是高温超导材料乃至整个超导材料研究和发展的热点。基带作为涂层超导材料重要的组成部分也要满足高性价比的发展趋势。随着不同学科和领域的相互渗透,特别是过渡层材料的不断推陈出新,给金属基带的选择和材料制备方法带来了广阔的研究和选择空间,即金属基板材料经历了由Ag合金向Ni合金,Cu合金发展的阶段;铸锭制备技术逐步从以熔炼方法为主拓宽粉末冶金和熔炼并重;此外,基带的抛光技术,表面硫化处理等技术的应用也将进一步提高基带的质量。这些都将为批量生产低成本的涂层超导工艺的研发奠定基础。

REFERENCES

[1] DIMOS D, CHAUDAHARI P, MANNHART J. Nonrandom percolation behavior of grain boundary networks in high-Tc superconductors[J]. Phys Rev, 1990, 41: 4038-4042.

[2] YANG F, NARUMI E, PATEL S, SHAW D T. In-plane texturing and its effect on critical current densities of YBa2Cu3O7-x thin films grown on polycrystalline substrates[J]. Physica C, 1995, 244: 299-303.

[3] BUDAI J D, YOUNG R T, CHAO B S. The study of nano-structures of ultrafine YBCO particles[J]. Appl Phys Lett, 1993, 62(7): 1836-1839.

[4] GENOUD J Y, SUO H L, SCHINDL M, BELLINGERI E, TYBELL T, WALKER E, FLUKIGER R. Preparation of {110} textured Ag ribbons for biaxially aligned superconducting tapes[J]. IEEE Trans Appl Supercond, 2001, 11: 3313-3316.

[5] KUMAR D, SHARON M, PINTO R, PAI S P. Large critical currents and improved epitaxy of Laser-ablated Ag-doped YBCO thin films[J]. Appl Phys Lett, 1993, 28: 3522-3524.

[6] SALAMATI H, BABAEI-BROJENY A A, SAFA M. Investigation of weak links and the role of silver addition on YBCO superconductors[J]. Supercond Sci Technol, 2001, 14: 816-819.

[7] GORUR O, TERZIOGLU C, VARILCI A, ALTUNBAS M. Investigation of some physical properties of silver diffusion- doped YBCO superconductors[J]. Supercond Sci Technol, 2005, 18: 1233-1237.

[8] YOSHINO H, YAMAZAKI M, THANH T D. Continuous deposition of YBCO film on Ag composite tape by PLD[J]. Physica C, 2002, 378: 917-921.

[9] WANG R, ZHOU Y, PAN S, HE M, CHEN Z, YANG G. A new direct process to prepare YBCO films on bi-axially textured Ag(110)<211>[J]. Physica C, 1999, 328: 37-43.

[10] SUO H L, GENOUD J Y, TRISCONE G, WALKER E, SCHINDL M, PASSERINI R, CLETON F, ZHOU M L, FLUKIGER R. Preparation and Characterization of {100}<001> cube textured Ag substrates for the fabrication of in-plane oriented HTS tapes[J]. Supercond Sci Tech, 1999, 12: 624-632.

[11] LIU D M, ZHOU M L, HU Y C, ZHOU M L, ZUO T Y. Preparation and formation mechanism of cube textured Ag substrate for coated high-Tc superconductor[J]. Physica C, 2000, 337: 75-78.

[12] ZHOU M, GUO H, LIU D M, ZUO T Y, ZHAI L H, ZHOU Y L, WANG R P, PAN S H, WANG H H. Properties of YBa2Cu3Ox-δ films on textured Ag tapes[J]. Physica C, 2000, 337: 101-105.

[13] LIU M, DONG J, LIU D M, SHEN J, ZHAO Y, ZHOU M L. Fabrication of YBCO Films on Ag Substrate by TFA-MOD Method[J]. Trans Nonferrous Met Soc China, 2004, 14(5): 992-995.

[14] LIU M, LIU D M, ZHOU M L, ZHAO Y, GAO X, LIANG J X. Fabrication of YBCO tapes on Ag substrates by the ultrasonic spray pyrolysis method[J]. Supercond Sci Technol, 2004, 17: 676-680.

[15] SUO H L, GENOUD J Y, SCHIND M, WALKER E, FLUKIGER R. Reinforced {110} textured Ag/Ni composite ribbons for biaxially oriented YBCO coated tapes[J]. Supercond Sci Technol, 2001, 14(10): 854-861.

[16] YOSHINA H, YAMAZAKI M, THANH T D, KUDO Y, KUBOTA H. Preparation of Ag-Cu Ni/Ag-Cu clad tapes for YBCO superconducting tape and its textured properties[J]. Physica C, 2001, 357/360: 923-930.

[17] KASHIMA N, NIWA T, MORI M, NAGAYA S, MUROGA T, MIYATA S, WATANABE T, YAMADA Y, IZUMI T, SHINHARA Y. YBCO coated conductor by multiple-stage CVD[J]. Physica C, 2005, 426/431: 887-892.

[18] NORTON D P, GOYAL A, BUDAI J D, CHRISTEN D K, KROEGER D M, SPECHT E D, HE Q, SAFFIAN B, PARATHAMAN M, KLABUNDE C E, LEE D F, SALES B C, LIST F A. Epitaxial YBCO on biaxially textured nickel (001): An approach to superconducting tapes with high critical current density[J]. Science, 1996, 274: 755-757.

[19] MATSUMOTO K, KIM S B, WEN J G, HIABAYASHI I, WATANABE T, UNO N, IKEDA M. Fabrication of in-plane aligned YBCO films on polycrystalline Ni tapes buffered with surface-oxidized NiO layers[J]. IEEE Trans Appl Supercond, 1999, 9(2): 1539-1542.

[20] CANTONI C, CHRISTEN D K, FEENSTRA R, GOYAL A, OWNBY G W, ZEHNER D M. Reflection high-energy electron diffraction studies of epitaxial oxide seed-layer growth on rolling-assisted biaxially textured substrate Ni(001): The role of surface structure and chemistry[J]. Appl Phys Lett, 2000, 79: 3077-3079.

[21] CANTONI C, CHRISTEN D K, GOYAL A, HEATHERLY L, LIST F A, OWNBY G W, ZEHNER D M, CHRISTEN H M, ROULEAU C M. Growth of oxide seed layers on Ni and other technologically interesting metal substrates: Issues related to formation and control of sulfur superstructures for texture optimization[J]. IEEE Trans Appl Supercond, 2003, 13: 2646-2650.

[22] IJADUOLA A O, THOMPSON J R, GOYAL A, THIEME C L H, MARKEN K. Magnetism and ferromagnetic loss in Ni-W textured substrates for coated conductors[J]. Physica C, 2003, 43: 163-171.

[23] EICKEMEYER J, SELBMANN D, OPITX R, BOER B D B, HOZAPFEL B, SCHULTZ L, MILLER U. Nickel-refractory metal substrate tapes with high cube texture stability[J]. Supercond Sci Technol, 2001, 14: 152-159.

[24] DE BOER B, EICHEMEYER J, REGER N, FERNADEZ L, RICHTER J, HOZAPFEL B, SCHULTZ L, PRUSSEIT W, BERBERICH P. Cube textured nickel alloy tapes as substrates for YBCO coated conductors[J]. Acta Materialia, 2001, 49: 1421-1428.

[25] SUBRAMANYA SARMA V, EICKEMEYER J, SCHULTZ L, HOZAPFEL B. Development of high strength and strongly cube textured Ni-5%W/Ni-10%W composite substrate tapes for coated conductor application[J]. Trans Indian Inst Met, 2004, 57: 651-657.

[26] PETRISOR T, BOFFA V, CELETANO G, CIONTEA L, FABBRI F, GALLUZZI V, GAMBARDELLA U, MANCINI A, RUFOLONI A, VARESI E. Epitaxial oxidation of Ni-V biaxially textured tapes[J]. Physica C, 2002, 377: 135-145.

[27] TUISSI A, VILLA E, ZAMBONI M, EVETTS J E, TOMOV R I. Biaxially textured NiCrX (X =W and V) tapes as substrates for HTS coated conductor applications[J]. Physica C, 2002, 372/376: 759-762.

[28] SARMA V S, BOER B, REGER N, EICKEMEYER J, OPITZ R. Ni and Ni-alloy tapes with a very strong cube texture as substrates for high temperature superconducting tapes[J]. Materials Science Forum, 2002, 408/412: 1561-1566.

[29] NAST R, OBST B, GOLDACKER W. Cube-textured nickel and Ni alloy substrates for YBCO coated conductors[J]. Physica C, 2002, 372/376: 733-737.

[30] ZHOU Y X, NAGUIB R, FANG H, FANG H, SALAMA K. Development of cube textured Ni-W alloy tapes using powder metallurgy along with high energy ball milling for HTS coated conductors[J]. Supercond Sci Technol, 2004, 17: 947-953.

[31] GOYAL A, BUDAI J D, KROEGER D M, NORTON D P, SPECHT E D, CHISTEN D K. Biaxially textured articles formed by powder metallurgy. US Patent No.5 739 086[P]. 1998.

[32] GOYAL A, PARANTHAMAN M. Strategic substrate development for coated conductors[EB/OL]. Superconductivity for Electric Systems 2007 Annual Peer Review.

[33] MATSUMOTO K, TAKECHI A, ONO T, HIRBAYASHI I, OSAMURA K. High critical current density YBCO films grown on mechanically polished surface-oxidized NiO/Ni substrates[J]. IEEE Trans Appl Supercond, 2003, 13: 2535-2538.

[34] KIM K T, LIM J H, KIM J H, JOO J, NAH W, JI B K, JUN B H, KIM C J, HONG G W. Development of cube-textured Ni-W alloy substrates for YBCO-coated conductor[J]. Physica C, 2004, 412/414: 859-863.

[35] CELENTANO G, VARESI E, PETRISOR T, BOFFA V,CIONTEA L,GALLUZZA V,GAMBARDELLA U, MANCINI A, RUFOLONI A,VANNOZZI A. Influence of the substrate microstructure on the superconducting properties of YBCO coated conductors[J]. IEEE Trans Appl Supercond, 2003, 13: 2591-2594.

[36] SHI D Q, DOU S X, KO R K, CHUNG J K, KIM H S, HA H S, SONG K J, PARK C. YBCO coated conductor using biaxially textured clad composite Ni-Mn/Ni-Cr substrate[J]. Supercond Sci Technol, 2005, 18: 1045-1049.

[37] LIU C F, WU X, WANG F Y, YANG Z J, FENG Y, ZHANG P X, WU X Z, ZHOU L. Preparation and evaluation of cube texture Ni substrate for YBCO-coated superconductor[J]. Physica C, 2000, 337: 83-86.

[38] ZHAO Y, SUO H L, LIU M, LIU D M, ZHANG Y X, ZHOU M L. Development of cube textured Ni-5%W alloy substrates using melting metallurgy for coated conductor application[J]. Physica C, 2006. 440: 10-16.

[39] SARMA SUBRAMANYA V, BOER B D, EICKEMEYER J, HOZAPFEL B. On the development of high strength and bi-axially textured Ni-3%W/Ni-10%Cr-1.5%Al composite substrate for coated conductor application[J]. Scripta Materialia, 2003, 48: 1167-1171.

[40] BOER B, SARMA V, REGER N, EICKEMEYER J, HOZAPFEL B. Strengthening of biaxially textured Ni-alloys as substrates for YBCO tape conductors[J]. Physica C, 2002, 372/376: 798-801.

[41] SARMA SUBRAMANYA V, EICKEMEYER J, SINGH A, SCHULTZ L, HOZAPFEL B. Development of high strength and strongly cube textured Ni-4.5%W/Ni-15%Cr composite substrate for coated conductor application[J]. Acta Materialia, 2003, 51: 4919-4927.

[42] ZHAO Y, SUO H L, LIU M, HE D, ZHANG YX, MA L, ZHOU ML. Investigation texture in Ni-W alloy substrates for coated conductors[J]. Materials Science Forum, 2007, 546/549: 2015-2018.

[43] ZHAO Y, SUO H L, LIU M, ZHU Y H, HE D, YE S, JI Y, ZHOU M L. Development of cube texture Ni-7%W tape for coated conductors applications[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(1): 208-211.

[44] GLOWACKI B A, VICKERS M E, RUTTER N A, MAHER E, PASOTTI F, BALDINI A, MAJOR R. Texture development in long lengths of NiFe tapes for superconducting coated conductor[J]. Journal of Materials Science, 2002, 37(1): 157-168.

[45] LIU M, SUO H L, ZHAO Y, HE D, ZHANG YX, MA L, FAN R F, ZHOU M L. A novel technique for developing composite substrates used in YBCO coated conductors[J]. Scripta Materialia, 2007, 56: 129-131.

[46] ZHAO Y, SUO H L, LIU M, HE D, ZHANG Y X, MA L, ZHOU M L. Mechanically reinforced and biaxially textured Ni alloy composite substrates developed by a hybrid route for coated conductors[J]. Acta Materialia, 2007(55): 2609-2614.

[47] SUO H L, ZHAO Y, LIU M, ZHANG Y X, HE D, MA L, JI Y, ZHOU M L. Technique for developing highly strengthened and biaxially textured composite substrates for coated super- conductor tapes [J]. Acta Materialia, 2008(56): 23-30.

[48] GOYAL A, FEENSTRA R, PARANTHAMAN M, THOMPSON J R, KANG B Y, CANTONI C, LEE D F, LIST F A, MARTIN P M, LARA-CURZIO E, STEVENS C, KROEGER D M, KOWALEWSKI M, SPECHT E D, AYTUG T, SATHYAMURTHY S, WILLIAMS R K,ERICSON R E. Strengthened, biaxially textured Ni substrate with small alloying additions for coated conductor applications[J]. Physica C, 2002, 382: 251-262.

[49] GOYAL A. RABiTS? substrates research & development. 2005[EB/OL].www.energetics.com/meetings/wire05/pdfs/session 6.

[50] SATHYAMURTHY S, PARANTHAMAN M, AYTUG T, KANG B W, MARTIN P M, GOYAL A, KROEGER D M, CHRISTEN D K. Chemical solution deposition of lanthanum zirconate buffer layers on biaxially textured Ni-1.7%Fe-3%W alloy substrates for coated-conductor fabrication[J]. Journal of Materials Research, 2002, 17(6): 1543-1549.

[51] GOYAL A, PARANTHAMAN M P, SCHOOP U. The RABiTS approach: using rolling-assisted biaxially textured substrates for high-performance YBCO superconductors[J]. MRS Bulletin, 2004: 552-561.

[52] AYTUG T, PARANTHAMAN M, THOMPSON J R, GOYAL A, RUTTER N, ZHAI H Y, GAPUD A A, IJADUOLA A O, CHRISTEN D K. Electrical and magnetic properties of conductive Cu-based coated conductors[J]. Appl Phys Lett, 2003, 83: 3963-3966.

[53] TUISSI A, CORTI R, VILLA E, BRAMLEY A P, VICKERS M E, EVETTS J E. Biaxially textured Ni and CuNi alloy substrate tapes for HTS coated conductor applications[J]. Inst Phys Conf Ser, 2000: 399-403.

[54] YUAN G, YANG J, SHI K. Epitaxial buffer layers on Ni and Cu-Ni substrates for Y-Ba-Cu-O film[J]. IEEE Trans Appl Supercond, 2001, 11: 3382-3385.

[55] SHI K, ZHOU Y, MENG J, YANG J, HU G Y, GU H W, YUAN G S. Fabrication of biaxially textured Cu-Ni alloy tapes for YBCO coated conductor[J]. Physica C, 2003, 386: 353-355.

[56] CHAKRAPANI V V, PAUL N B, NICHOLAS A Y. Biaxially textured copper and copper-iron alloy substrates for use in YBCO coated conductors[J]. Supercond Sci Technol, 2006, 19: 85-95.

[57] CANTONI C, CHRISTEN D K, SPECHT E D, VARELA M,THOMPSON J R, GOYAL A,THIEME C, XU Y, PENNYCOOK S J. Characterization of suitable buffer layers on Cu and Cu-alloy metal substrates for the development of coated conductors[J]. Supercond Sci Technol, 2004, 17: S341-S344.

[58] PHILLIPS J M. Substrate selection for high-temperature superconducting thin films[J]. J Appl Phys, 1996, 79: 1829-1848.

[59] YIN E, RUBIN M, DIXON M. Sputtered YBCO films on metal substrates[J]. Journal of Materials Research, 1992, 7(7): 1636-1640.

[60] YAMADA Y, WATANABE T, MUROGA T, MIYATA S, IWAI H, IBI A, SHIOHARA Y, KATOH T, HIRAYAMA T. Rapid production of buffered substrates and long length coated conductor development using IBAD, PLD methods and “self-epitaxial” ceria buffer[J]. IEEE Trans Appl Supercond, 2005, 15: 2600-2604.

[61] PRUSSEIT W, NEMETSCHEK R, HOFFMANN C, SIGL G, LUMKEMANN A, KINDER H. ISD process development for coated conductors[J]. Physica C, 2005, 426/431: 866-871.

[62] LIDE D. Handbook of chemistry and physics[M]. London: CRC, 1994.

基金项目:国家重大基础研究发展规划资助项目(2006CB601005);国家教委全国百篇优秀博士论文专项资金(200331);北京工业大学111人才工程基金资助项目;国家自然科学基金资助项目(50771003)

收稿日期:2007-06-01;修订日期:2008-01-07

通讯作者:索红莉,教授;电话:010-67392947;E-mail: zeuszhao@emails.bjut.edu.cn

摘 要:涂层超导材料是一种有着广泛应用前景和巨大潜在商业价值的高温超导材料之一。随着人们对高性能涂层超导带材研究的不断深入,基带材料作为涂层超导材料YBa2Cu3O7-x(YBCO)多层结构中重要的组成部分也呈现出新的科研成果,基底的研究在金属种类选择上和再结晶理论的研究方面都取得明显的进展。总结目前几种重要的金属及其合金基底,从材料的制备手段,织构形成的特点和性能,存在的优缺点以及未来的发展趋势等方面介绍了涂层导体中金属基带的研究现状。