文章编号:1004-0609(2010)S1-s0274-06

Ti-47Al-2Cr-2Nb-0.2W-0.15B合金板材的制备

及其拉伸性能

王 刚,徐 磊,崔玉友,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:

采用感应熔炼气体雾化法制备Ti-47Al-2Cr-2Nb-0.2W-0.15B预合金粉末,对预合金粉末进行表征,通过热等静压工艺制备TiAl基合金坯料。应用包套叠轧的方法轧制出TiAl基合金板材,对轧制的TiAl基合金板材进行不同相区的热处理,分别得到双态组织和全片层组织,对热处理后的TiAl基合金进行拉伸性能测试。结果表明:TiAl基合金的预合金粉末主要由α2相和少量γ相组成,热等静压致密化处理后的板坯组织细小均匀。拉伸实验表明,双态和全片层组织的TiAl基合金板材在高于700 ℃时,其塑性大幅提高;双态组织TiAl基合金板材的断裂形式主要以韧性断裂为主,而全片层TiAl基合金板材的断裂形式仍为脆性断裂。

关键词:

中图分类号:TF 804.3 文献标志码:A

Fabrication and tensile property of

Ti-47Al-2Cr-2Nb-0.2W-0.15B alloy sheets

WANG Gang, XU Lei, CUI Yu-you, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The Ti-47Al-2Cr-2Nb-0.2W-0.15B prealloyed powder was fabricated by electrode induction melting gas atomization technical, the pre-alloyed powder was characterized. The compacts of the alloy were hot isostatically pressed and pack rolled, and then heat treated at different temperatures in order to obtain different microstructures. The tensile tests were carried out on the specimens machined from the sheets. The results indicate that the pre-alloyed powder consists of α2 phase and a slight of γ phase, after hot isostatic pressing treatment, the microstructure is fine and homogenous. The elongations of TiAl alloy sheet with duplex significantly increases at the temperatures higher than 700 ℃, the same mechanical phenomenon also happens in the TiAl alloy sheets with full-lamellar microstructure. At the temperature higher than 700 ℃, the TiAl alloy sheets with duplex microstructure demonstrates ductile fracture. Although the TiAl alloy sheets with full-lamellar microstructure exhibit high elongation in the tensile test, the brittle fracture occurs.

Key words: powder metallurgy; TiAl based alloy; heat treatment; tensile property

TiAl基合金因其密度低、比强度高和比模量高、蠕变抗力高和抗氧化等优点,在航空航天和汽车等领域具有广阔的应用前景。TiAl基合金板材可以直接用做结构材料,例如返回式航天器的回转体、弹壳体尾翼和弹体蒙皮等重要部件[1-5]。随着TiAl基合金实用化进程的发展,对TiAl基合金板材的需求越来越迫 切[6-7]。但是TiAl基合金的室温塑性低、加工性能差,导致TiAl基合金板材制备的难度增大。因此,必须选择合理的加工路线和合适的工艺参数方能制备出TiAl基合金板材[8]。对于铸锭冶金工艺,存在坯料组织粗大和宏观偏析等缺陷,同时材料利用率低和难以制备出大尺寸的板材。预合金粉末冶金工艺可解决板材的组织不均匀性等技术难题,获得显微组织细小均匀、无宏观偏析和热加工性能得到改善的轧制坯料。应用粉末冶金近净成型技术可以直接获得达到尺寸要求的原始坯料,简化采用铸态TiAl基合金所需要的均匀化和锻造等加工步骤,从而节约成本和能源。本文作者采用预合金粉末冶金方法制备TiAl基合金坯料,应用包套叠轧方法,选取合适的工艺参数,对TiAl基合金进行轧制,同时研究轧制TiAl基合金板材的微观组织与性能。

1 实验

研究所用TiAl基合金名义成分为Ti-47Al-2Cr- 2Nb-0.2W-0.15B(摩尔分数,%)。TiAl基合金板材的制备工艺如下:采用无坩埚感应熔炼气体雾化法制备TiAl基合金预合金粉末。将预合金粉末装入长方形钛合金包套内,在450 ℃真空除气12 h,随后进行封焊处理,然后在150 MPa经1 260 ℃,4 h热等静压处理。应用线切割去掉外部包套,表面进行光洁处理,随后将试样封焊于TC4合金包套内,进行包套轧制。开轧温度1 260 ℃,道次变形量8%~10%,每道次保温2 min,总变形量为60%。应用日本岛津粒度测试仪对预合金粉末进行粒度分析。采用D/MAX 2400型X射线衍射分析仪测定预合金粉末相组成。室温拉伸试验在TMS材料实验机上进行,高温拉伸试验在700~850 ℃温度下进行,拉伸试验机型号为SANS- CMT5205,拉伸应变速率为1×10-4 s-1。为了消除表面状态的影响,试样工作段做精磨处理。用JSM6301型扫描电镜对室温拉伸高温拉伸试样进行断口形貌分析。

2 结果与讨论

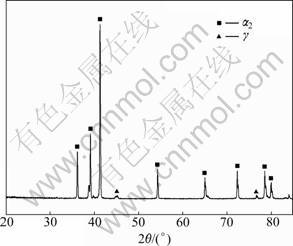

图1所示为Ti-47Al-2Cr-2Nb-0.2W-0.15B合金粉末的XRD谱。由图1可看出,预合金粉末主要由是α2相构成,其中含有少量的γ相。

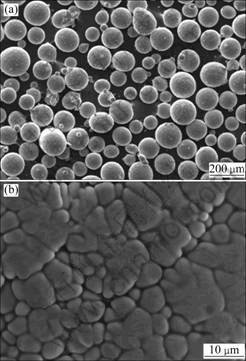

图2所示为预合金粉末的SEM像。从图2中可以看出,预合金粉末主要呈球形,少数粉末为椭球形。有行星球形粉末形成,其原因是在粉末制备过程中大颗粒和小颗粒发生碰撞、粘接所致。粉末的表面存在发达的树枝晶。

图1 预合金粉末的XRD谱

Fig.1 XRD patterns of TiAl pre-alloyed powder

图2 预合金粉末的SEM像

Fig.2 SEM images of pre-alloyed powder: (a) Low magnification; (b) High magnification

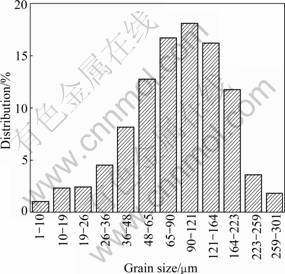

图3所示为预合金粉末的粒度分布。由3可看出,经过250 μm的筛后,小于190 μm的粉末占粉体的90%左右,粉末粒度主要分布在50~190 μm之间,小于50 μm的粉体颗粒占20%左右。

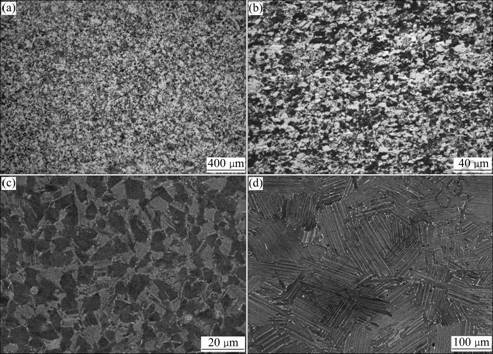

图4所示为Ti-47Al-2Cr-2Nb-0.2W-0.15B预合金粉末致密化后的显微组织。由图4可看出,预合金粉末经过热等静压后,得到了细小均匀的等轴晶组织。细小均匀的组织有利于降低韧性-脆性转变温度,从而降低板材的轧制温度[9-10]。图4(b)所示为TiAl基合金板材的轧制态组织,轧制后晶粒沿着轧制方向略微伸长,晶粒尺寸略大于原始热等静压态组织的,这可能是由于在轧制过程中,道次间保温过程中静态再结晶的发生,导致晶粒的长大。图4(c)所示为TiAl基合金板材经1 280 ℃、2 h热处理得到的双态组织的BSE显微组织。图中黑色相为γ相,灰色相为α2相。图4(d)所示为TiAl基合金板材经过1 360 ℃、10 min、FC热处理得到的全片层组织的BSE显微组织照片,其晶粒尺寸约为100 μm。

图3 预合金粉末粒度分布

Fig.3 Grain size distribution of TiAl pre-alloyed powder

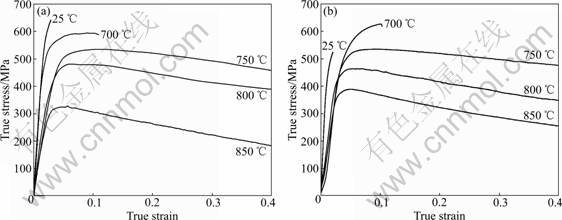

图5所示为双态和全片层组织的TiAl基合金板材在不同温度拉伸的应力—应变曲线。从图5中可以看出:TiAl基合金板材的拉伸应变行为对温度敏感;当温度低于700 ℃时,TiAl基合金板材的塑性很低,表现出脆性失稳行为;当温度升高到750 ℃时,塑性大幅提高。

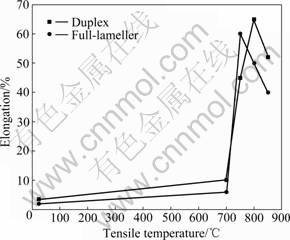

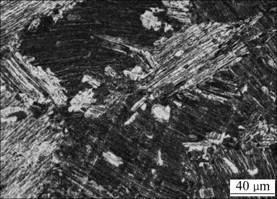

图6所示为TiAl基合金板材经过不同热处理后,伸长率与温度之间的关系。由图6可以看出,对于双态组织的TiAl基合金板材,最大伸长率出现在800 ℃。对于全片层组织的TiAl基合金板材,其最大伸长率出现在750 ℃。当温度大于700 ℃时,应力—应变曲线的初始阶段为加工硬化区,达到极值后应力逐渐降低进入稳态阶段。在稳态流变阶段,应力的软化是由于动态回复与动态再结晶的发生,从而伸长率显著提高[11]。图7所示为全片层组织的TiAl合金板材经800 ℃拉伸变形后的显微组织,再结晶晶粒形成于片层之间。

图4 不同状态时TiAl基合金的显微组织

Fig.4 Microstructures of TiAl based alloys at different states: (a) Hipped TiAl alloy; (b) Rolled sheet; (c) Rolled sheet with duplex; (d) Rolled sheet with full-lamellar

图5 TiAl合金板材在不同温度拉伸时的应力—应变曲线

Fig.5 True stress—stain curves of TiAl sheets tensiled at different temperatures: (a) Duplex; (b) Full-lameller

图6 TiAl合金板材伸长率与拉伸温度之间的关系

Fig.6 Relationship between elongation and tensile temperature

图7 TiAl合金板材拉伸过程中形成的再结晶晶粒

Fig.7 Recrystallization grains during tensile test

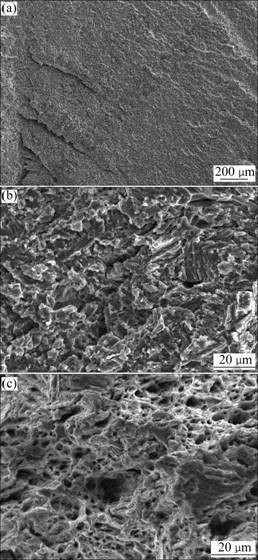

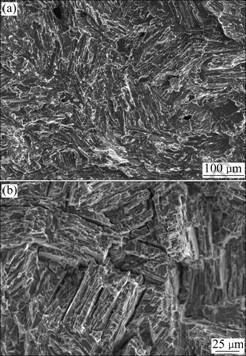

图8(a)和(b)所示为双态组织的TiAl基合金板材室温拉伸断口的SEM像。图8(a)所示为低倍断口形貌。由图8(a)可以看出,室温拉伸断口表面有台阶状花纹。通过高倍形貌像观察发现断口上存在纤维状的晶间裂纹,呈现准解理断裂特征(见图8(b))。图8(c)所示为双态组织的TiAl基合金板材750 ℃拉伸断口形貌。由图8(c)可看出,断口中有表征韧性断裂特征的韧窝存在,但同时又呈现一定的脆性准解理断裂特征[12-15]。

图8 双态TiAl合金板材拉伸断口形貌

Fig.8 Fractographs of TiAl sheets with duplex microstructure: (a), (b) Room temperature; (c) 750 ℃

图9所示为全片层组织的TiAl基合金板材室温和750 ℃拉伸断口形貌。由图9可看出,在整个断口表面分布着沿TiAl合金片层断裂的小面。在拉伸过程中,由于片层与片层之间相互脱离,导致微孔洞的形成。随着拉伸过程的发展,这些微孔洞聚集为微裂纹,微裂纹沿晶界扩展导致晶间断裂。

图9 全片层TiAl合金板材的拉伸断口形貌

Fig.9 Tensile fractographs of full-lamellar TiAl sheets: (a) Room temperature; (b) 800 ℃

3 结论

1) TiAl基合金的预合金粉末主要由α2相和少量γ相组成,预合金粉末颗粒主要呈球形,表面存在发达的树枝晶。

2) TiAl基合金的拉伸行为对温度敏感。在高温拉伸过程中,应力的软化主要是由于动态回复与动态再结晶的发生。

3) 拉伸温度在700 ℃以上时,对于具有双态组织的TiAl基合金板材,其断裂形式主要以韧性断裂为主;对于具有全片层组织的TiAl基合金板材,尽管具有很高的伸长率,但其断裂形式仍为脆性断裂。

REFERENCES

[1] KIM Y W, DIMIDUK D M. Designing Gamma TiAl alloys: Fundamentals, strategy and production [C]// NATHAL M V, DAROLIA R, LIU C T, MARTIN P L, MIRACLE D B, WAGNER Y R M. Warrendale, PA: TMS, 1997: 531.

[2] CLEMENS H, KESTLER H, EBERHARDT N, KNABL W. Processing of γ-TiAl-based alloys on an industrial scale[C]// KIM Y W, DIMIDUK D M, LORETTO M H. Gamma titanium aluminides 1999. Warrendale, PA: TMS, 1999: 209-223.

[3] HEMKER K J, DIMIDUK D M, CLEMENS H, DAROLIA R, INUI H, LARSEN J M. Structural intermetallics. Warrendale, USA: TMS; 2001.

[4] APPEL F, BROSSMANN U, CHRISTOPH U. Recent progress in the development of γ-titanium aluminide alloys [J]. Adv Eng Mater, 2002, 2(11): 699-720.

[5] SHIH D S, HUANG S C, SCARR G K, JANG H, CHESNUTT J C. The microstructural dependence of mechanical properties of Ti-48Al-2Cr-2Nb [C]// KIM Y W, BOYER R R. Microstructure- Property Relationships in Titanium Aluminides and Alloys. Warrendale, PA: TMS, 1991: 135-148.

[6] GOPAL D, KESTLER H, CLEMENS H, BARTOLOTTA H, P A, Sheet gamma TiAl: Status and opportunities[J]. Journal of the Minerals Metals and Materials Society, 2004, 56: 42-45.

[7] GOPAL D, BARTOLOTTA H P A, KESTLER H, CLEMENS H. The development of sheet gamma TiAl technology under the enabling propulsion materials/high speed civil transport [C]// KIM Y W, CLEMENS H, ROSENBERGER A H. Gamma Titanium Aluminides. Warrendale, PA: TMS, 2003: 33-45.

[8] WEGMANN G, GERLING R, SCHIMANSKY F P, CLEMENS H, BARTELS A. High-temperature mechanical properties of hot isostatically pressed and forged gamma titanium aluminide alloy powder [J]. Intermetallics, 2002(10): 511-517.

[9] IMAYEV V M, IMAYEV R M, SALISHCHEV G A. On two stages of brittle-to-ductile transition in TiAl intermetallic [J]. Intermetallics, 2000, 8: 1-6.

[10] IMAYEV R M, SALISHCHEV G A, SENKOV O N, IMAYEV V M, SHAGIEV M R, GABDULLIN N K, KUZNETSOV A V, FROES F H. Formation of a submicrocrystalline structure in TiAl and Ti3Al intermetallics by hot working [J]. Materials Science and Engineering A, 2001, 300: 263-277.

[11] BYSTRZANOWSKI S, BARTELS A, CLEMENS H, GERLING R. Characteristics of the tensile flow behavior of Ti-46Al-9Nb sheet material—Analysis of thermally activated processes of plastic deformation [J]. Intermetallics 2008, 16: 717-726

[12] SEETHARAMAN V, SEMIATIN S L. Microstructures and tensile properties of Ti-45.5Al-2Nb-2Cr rolled sheets [J]. Materials Science and Engineering A, 2001, 299: 195-209

[13] LIU C T, MAZIASZ P J. Microstructural control and mechanical properties of dual-phase TiAl alloys [J]. Intermetallics, 1998(6): 653-661.

[14] KIM J H, HA T K, CHANG Y W, LEE C S. High temperature deformation behavior of a γ-TiAl alloy determined using the load-relaxation test [J]. Materials Science and Engineering A, 2003, 344: 146-157.

[15] SEETHARAMAN V, SEMIATIN S L, LOMBARD C M, FREY N D. Deformation and fracture characteristics of a Gamma titanium aluminide at high temperature[C]// BAKER I, DAROLIA R, WHITTENBERGER J D, YOO M H. High temperature ordered intermetallic alloys V. Pittsburgh, PA: Materials Research Society, 1993: 513-518.

(编辑 李艳红)

通信作者:崔玉友;电话:024-23971961;E-mail: yycui@imr.ac.cn