Trans. Nonferrous Met. Soc. China 24(2014) 158-163

Vapor-grown carbon fibers enhanced sulfur-multi walled carbon nanotubes composite cathode for lithium/sulfur batteries

Zhao-feng DENG1, Zhi-an ZHANG1,2, Hai LU2, Yan-qing LAI1,2, Jin LIU1, Jie LI1,2, Ye-xiang LIU1

1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Engineering Research Center of High Performance Battery Materials and Devices, Research Institute of Central South University in Shenzhen, Shenzhen 518057, China

Received 29 October 2012; accepted 5 March 2013

Abstract:

Vapor-grown carbon fibers (VGCFs) were introduced as conductive additives for sulfur-multiwalled carbon nanotubes (S-MWCNTs) composite cathode of lithium-sulfur batteries. The performance of S-MWCNTs composite cathodes with carbon black and VGCFs as sole conductive additives was investigated using scanning electron microscopy (SEM), galvanostatic charge-discharge tests and electrochemical impedance spectroscopy (EIS). The results show that the S-MWCNTs composite cathode with VGCFs displays a network-like morphology and exhibits higher activity and better cycle durability compared with the composite cathode with carbon black, delivering an initial discharge capacity of 1254 mA·h/g and a capacity of 716 mA·h/g after 40 cycles at 335 mA/g. The interconnected VGCFs can provide a stable conductive network, suppress the aggregation of cathode materials and residual lithium sulfide and maintain the porosity of cathode, and therefore the electrochemical performance of S-MWCNTs composite cathode is enhanced.

Key words:

lithium-sulfur batteries; carbon fiber; composite cathode; multiwalled carbon nanotube;

1 Introduction

Lithium-sulfur (Li-S) batteries have received great attention because they process high theoretical specific capacity of 1675 mA·h/g and specific energy of 2600 W·h/kg, which are much greater than those of any conventional lithium ion batteries [1]. In addition, sulfur as a cathode active material has advantages of non-toxicity, natural abundance and environmental friendliness.

However, Li-S batteries with organic liquid electrolytes are still facing some critical problems. The first is the insulating nature of sulfur (5×10-30 S/cm) that leads to poor electrochemical accessibility. The second is the solubility of intermediary reduction species (Li2Sx, 4≤x≤8). It can cause active mass loss and reduce coulombic efficiency [2]. The third is the irreversible insulating agglomerates of solid discharge product (Li2S). During the charge process, Li2S is oxidized to soluble polysulfides, but few Li2S is left even at fully charged state [3]. Thus, irreversible agglomerates are formed on surface of the cathode with increasing cycle, inhibiting the transmission of ions and electrons, and causing capacity fading [1]. In order to overcome these problems, various strategies were attempted, mainly in study on various sulfur-carbon composites [4-7], sulfur- conducting polymer materials [8], surface coating [9], electrolyte additives [10] and new binders [11]. Important progress has been made in recent years. In particular, JI et al [6] prepared polymer-modified nanostructured mesoporous carbon-sulfur composite as cathode material for Li-S battery. High initial capacity of 1320 mA·h/g at a current density of 168 mA/g and 83% capacity retention after 20 cycles were obtained. Nevertheless, the challenge brought by insulating agglomerates has still not been resolved.

In this study, we synthesized sulfur-multiwalled carbon nanotubes (S-MWCNTs) nanocomposite and introduced vapor-grown carbon fibers (VGCFs), with length in micrometer size and diameter in nanoscale, as conductive additives for cathode, and therefore proposed a network-like architecture for sulfur cathode. The electrochemical performance of S-MWCNTs composite cathodes with carbon blacks (CB) and VGCFs as sole conductive additives was investigated. The morphologies of S-MWCNTs composite cathodes before and after cycling were also characterized.

2 Experimental

2.1 Preparation of S-MWCNTs composite cathodes

S-MWCNTs nanocomposite was synthesized by a typical co-heating process. S-MWCNTs cathode slurry was made by mixing 80% S-MWCNTs nanocomposite, 10% graphitized vapor-grown carbon fibers (VGCFs, Showa Denko) and 10% polyvinylidene fluoride (PVDF) binder in N-methyl-2-pyrrolidinone (NMP) solvent. The slurry was spread onto aluminum foil and then dried at 60 °C under vacuum for 24 h. For comparison, S-MWCNTs composite cathode with 10% carbon black (CB, TIMCAL) was prepared in the same way. Cathodes were cut at a diameter of 10 mm and sulfur loadings were about 1.0 mg/cm2.

2.2 Characterization and measurements

Morphologies of samples were characterized using field emission scanning electron microscope (SEM, Nova NanoSEM 230) and transmission electron microscope (TEM, Tecnai G2 20ST). Coin-type (CR2025) cells were assembled in an argon-filled glove box (Universal 2440/750), in which oxygen and water contents were less than 1×10-6. The electrolyte used was 1.5 mol/L bis(trifluoromethane)sulfonamide lithium salt (LiTFSI, Sigma Aldrich) in a solvent mixture of 1,3-dioxolane and 1,2-dimethoxyethane (1:1, v/v) (Acros Organics). Lithium metal was used as the counter and reference electrodes and Celgard 2400 was used as the separator. Galvanostatic charge-discharge tests were carried out at a constant current density of 335 mA/g (0.2 C) in the potential range of 1.5 to 2.8 V at 25 °C on a LAND CT2001A charge-discharge system. Electrochemical impedance spectroscopy measurements were carried out using PARSTAT 2273 electrochemical measurement system (PerkinElmer Instrument USA) in the frequency range between 100 kHz and 10 mHz with a perturbation amplitude of 5 mV.

3 Results and discussion

3.1 Morphological characterization

Figure 1(a) shows the TEM image of the S-MWCNTs nanocomposite and the inset is the image of MWCNTs. It can be seen that MWCNTs have an internal diameter of around 10 nm and an external diameter of about 40 nm. During the co-heating process, molten sulfur could be embedded in the hollow tubes of MWCNTs due to the capillary force and deposit on the outer surface. Compared with these two images, there is no distinguishable morphological difference between MWCNTs and S-MWCNTs nanocomposite, which suggests a homogeneous distribution of sulfur in MWCNTs matrix. The SEM image of the S-MWCNTs nanocomposite is presented in Fig. 1(b). No visible sulfur particles can be observed, which further indicates the uniform distribution of sulfur. Besides, the S-MWCNTs nanocomposites intertwine together seriously because of nanometer effect and their tortuous structure.

Fig. 1 TEM image (a) and SEM image (b) of S-MWCNTs nanocomposite (The inset is the image of MWCNTs)

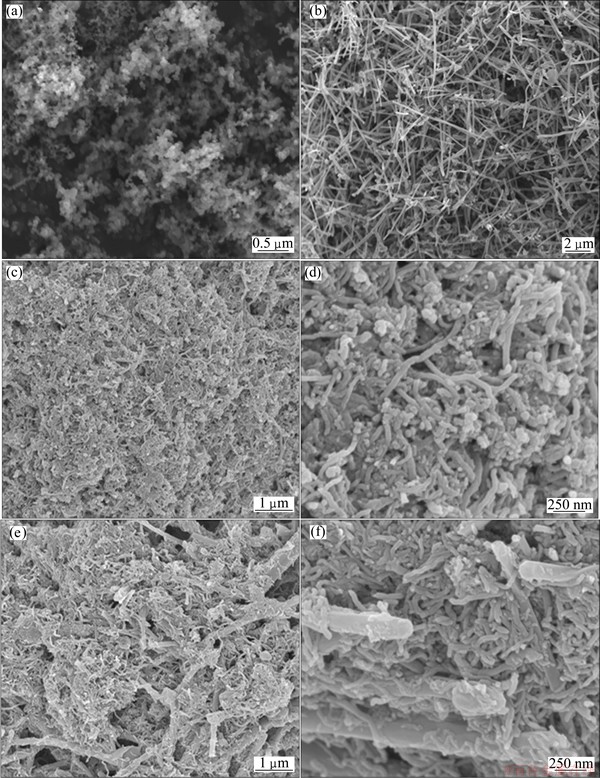

The morphologies of carbon black (CB), vapor-grown carbon fibers (VGCFs) and S-MWCNTs cathodes with CB and VGCFs as conducting agents are presented in Fig. 2. As shown in Figs. 2(a) and (b), carbon blacks are nanoscale particles (d40 nm), while VGCFs are linear fibers with a length in micrometer size (around 15 μm) and a diameter in nanoscale (around 150 nm). The linear VGCFs, with large aspect ratio, tend to interconnect and could construct a three-dimensional framework. The images of S-MWCNTs composite cathode with CB are shown in Figs. 2(c) and (d).

S-MWCNTs nanocomposites are intertwined with CB dispersing within them, and the surface of the S-MWCNTs composite cathode is compact, which was also observed in similar reports [12,13]. As for S-MWCNTs cathode with VGCFs, a network-like morphology is displayed. Interconnected VGCFs build a framework with S-MWCNTs nanocomposites filled in it. This structure of composite cathode could aid in maintaining the porosity of composite cathode and is expected to facilitate the transportation of ions and hinder the formation of agglomerates of residual lithium sulfide during cycling. Besides, it should be noted that most nanocomposites are intertwined without contacting with VGCFs because of the much larger size of VGCFs than the nanocomposite, as shown in Fig. 2(f).

Fig. 2 SEM images of carbon blacks (CB) (a), vapor-grown carbon fibers (VGCFs) (b), S-MWCNTs composite cathode with CB (c, d) and S-MWCNTs composite cathode with VGCFs (e, f)

3.2 Electrochemical properties

In order to study the electrochemical properties of the S-MWCNTs composite cathodes with VGCFs and CB, galvanostatic charge-discharge tests were performed at a current density of 335 mA/g (0.2C). Figure 3(a) displays the discharge-charge curves at the 1st and 40th cycle. The discharge curves display two typical potential plateaus at about 2.3 V and 2.1 V, corresponding to multiple-step reduction of sulfur. The high plateau is related to formation of intermediary polysulfides (Li2Sx, 4≤x≤8), and the low plateau corresponds to the conversion of lithium polysulfides to insoluble Li2S [1,6]. The initial discharge capacities of the S-MWCNTs composite cathodes with CB and VGCFs as conductive additives are 1175 and 1254 mA·h/g, respectively. The result that the initial discharge capacity of sulfur cathode with VGCFs is superior to the cathode with CB is in accordance with some reports about traditional lithium batteries [14,15]. The enhanced sulfur utilization could be attributed to the good conductivity and the network-like structure of composite cathode, which favors the penetration of the electrolyte into the cathode.

Fig. 3 Discharge-charge curves for S-MWCNTs composite cathode with CB and S-MWCNTs composite cathode with VGCFs at the first and 40th cycle at current density of 335 mA/g (a) and cycling performance of S-MWCNTs composite cathode with CB and S-MWCNTs composite cathode with VGCFs at current density of 335 mA/g (b)

Furthermore, as demonstrated in Fig. 3(b), the S-MWCNTs composite cathode with VGCFs presents a higher remained capacity after the 40th cycle and a lower capacity-fading rate compared with the composite cathode with carbon blacks. Specifically, the composite cathode with VGCFs shows a capacity of 716 mA·h/g after 40 cycles, while the capacity of the composite cathode with CB is 627 mA·h/g. Since agglomeration of residual Li2S will prevent ions from diffusing to the reaction sites and lower the conductivity of cathode, thus resulting in capacity fading [1]. The better cycle performance of composite cathode with VGCFs could be ascribed to the network-like cathode architecture that helps to hinder the formation of precipitation layer of Li2S.

Electrochemical impedance spectroscopy (EIS) measurements were conducted for S-MWCNTs composite cathodes before cycling and after 40 cycles. As shown in Fig. 4(a), for fresh cells, Nyquist plots of two cathodes are composed of a depressed semicircle in high frequency region and an inclined line in low frequency region. The semicircle is due to the sum resistance of surface layers, like the interphase electronic contact resistance on cathode and interface resistance of anode [16,17]. The resistance of the composite cathode with VGCFs is larger than that with CB probably because that some S-MWCNTs nanocomposites in the composite cathode with VGCFs are not contacted with conductive additives as shown in Fig. 2. After 40 cycles, as presented in Fig. 4(b), a new depressed semicircle emerges in the middle frequency range, which corresponds to charge-transfer resistance [2,5,16]. Note that resistances of the S-MWCNTs composite cathode with VGCFs are smaller than those of the composite cathode with CB. The result indicates that the composite with VGCFs has better electrical contact and ion transfer after 40 cycles than the composite cathode with CB because of the interconnected VGCFs, which can maintain a stable conductive network and help to suppress the formation of precipitation layer on the cathode surface during cycling.

Fig. 4 Impedance plots for S-MWCNTs composite cathode with CB and S-MWCNTs composite cathode with VGCFs before cycling (a) and after 40 cycles (b)

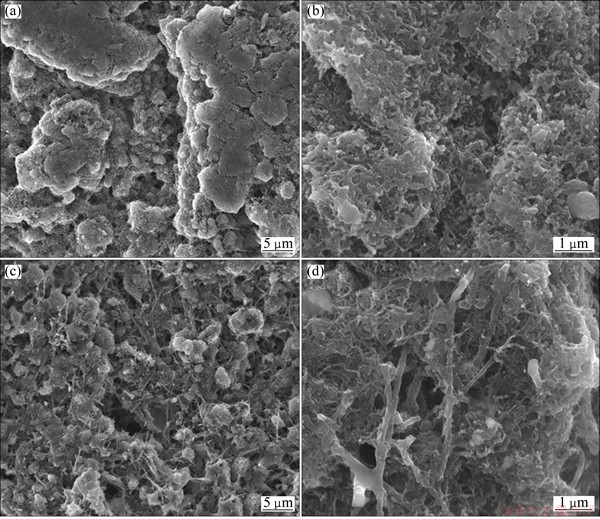

3.3 SEM of composite cathodes after cycling

To confirm the above interpretation, morphologies on composite cathodes with CB and VGCFs at the end of the 40th charge are recorded. From Figs. 2 and 5, it is observed that the surfaces of the two composite cathodes after the 40th cycle are covered with precipitation layer, which is identified as the residual irreversible lithium sulfide according with some literatures [3,11,12]. Moreover, the images of the two composite cathodes at the 40th cycle are also quite different. For the S-MWCNT composite cathode with CB (Figs. 5(a) and (b)), cathode materials agglomerate seriously and dense precipitation layer on the surface of cathode is clearly observed. On the contrary, as shown in Figs. 5(c) and (d), the composite cathode with VGCFs still displays a homogeneous and porous morphology and no severe precipitation layer appears. The result confirms that the conductive framework of VGCFs can effectively restrain the agglomeration of cathode materials and residual Li2S, and suppress the formation of precipitation layer. Additionally, the porous morphology of composite cathode with VGCFs could facilitate the access of electrolyte to the interior regions of the composite cathode, thus favors the active material utilization. These results further confirm the analysis in electrochemical properties.

4 Conclusions

1) S-MWCNTs nanocomposite was prepared by a co-heating process and VGCFs were introduced as conductive additives for S-MWCNTs composite cathode. The S-MWCNTs composite cathode with linear fibrous VGCFs presents a network-like architecture.

2) The S-MWCNTs composite cathode with VGCFs exhibits higher active material utilization and better cycle durability compared with the composite cathode with carbon blacks. It displays an initial discharge capacity of 1254 mA·h/g, and retains 716 mA·h/g after 40 cycles at 335 mA/g.

3) The interconnected VGCFs can provide a stable conductive network that helps to maintain the porosity of electrode and suppresses the aggregation of cathode materials and residual Li2S, and therefore contributes to better electrochemical properties.

Fig. 5 SEM images of S-MWCNTs composite cathodes with CB (a, b) and VGCFs (c, d) after 40 cycles

4) The strategy adopted could be helpful to not only S-MWCNTs composite cathodes but also many other sulfur-carbon nanocomposite electrodes.

References

[1] JI X L, Nazar L F. Advances in Li–S batteries [J], Journal of Materials Chemistry, 2010, 20: 9821-9826.

[2] Barchasz C,  J C, Alloin F, Patoux S. New insights into the limiting parameters of the Li/S rechargeable cell [J]. Journal of Power Sources, 2012, 199: 322-330.

J C, Alloin F, Patoux S. New insights into the limiting parameters of the Li/S rechargeable cell [J]. Journal of Power Sources, 2012, 199: 322-330.

[3] Cheon S E, Ko K S, Cho J H, Kim S W, Chin E Y, Kim H T. Rechargeable lithium sulfur battery I: Structural change of sulfur cathode during discharge and charge [J]. Journal of the Electrochemical Society, 2003, 150: A796-A799.

[4] Wang J L, Yang J, Xie J Y, Xu N X, Li Y. Sulfur-carbon nano-composite as cathode for rechargeable lithium battery based on gel electrolyte [J]. Electrochemistry Communications, 2002, 4: 499-502.

[5] Zhang B, Qin X, Li G R, Gao X P. Enhancement of long stability of sulfur cathode by encapsulating sulfur into micropores of carbon spheres [J]. Energy & Environmental Science, 2010, 3: 1531-1537.

[6] Ji X L, Lee K T, Nazar L F. A highly ordered nanostructured carbon–sulphur cathode for lithium–sulphur batteries [J]. Nature Materials, 2009, 8: 500-506.

[7] YUAN Ke-gou, WANG Wei-kun, YU Zhong-bao, WANG An-bang. Electrochemical performance of the exfoliated graphite containing sulfur cathode material for lithium sulfur battery [J]. Electrochemistry, 2009, 15(2): 202-205. (in Chinese)

[8] YUE Xin, LIU Jing-dong, LIU Hui. Study on electrochemical properties of triphosphazene-sulfur composites as cathode for Li/S batteries [J]. Chinese Battery Industry, 2011, 16(3): 180-183. (in Chinese)

[9] Cao Y L, Li X L, Aksay I A, Lemmon J, Nie Z M, Yang Z G, LIU J. A micro-mesoporous carbon with graphitic structure for high-rate stable sulfur cathode in carbonate solvent-based Li-S batteries [J]. Physical Chemistry Chemical Physics, 2011, 13: 7660-7665.

[10] XIONG Shi-zhao, XIE Kai , HONG Xiao-bin. Effect of LiNO3 as additive on electrochemical properties of lithium-sulfur batteries [J]. Chemical Journal of Chinese Universities, 2011, 32(11): 2645-2649. (in Chinese)

[11] He M , Yuan L X, Zhang W X, Hu X L, Huang Y H. Enhanced cyclability for sulfur cathode achieved by a water-soluble binder [J]. The Journal of Physical Chemistry C, 2011, 115: 15703-15709.

[12] Chen J J, Zhang Q, Shi Y N, Qin L L, Cao Y, Zheng M S, Dong Q F. A Hierarchical architecture S/MWCNT nanomicrosphere with large pores for lithium sulfur battery [J]. Physical Chemistry Chemical Physics, 2012, 14: 5376-5382.

[13] DU Rui, YUAN Zhong-zhi. Synthesis and characterization of sulfur-carbon nanotubes as cathode of lithium/sulfur rechargeable battery [J]. Electrochemistry, 2009, 15(3): 284-287. (in Chinese)

[14] Mizuno F, Hayashi A, Tadanaga K, Tatsumisago M. Effects of conductive additives in composite positive electrodes on charge-discharge behaviors of all-solid-state lithium secondary batteries [J]. Journal of the Electrochemical Society, 2005, 152: A1499-A1503.

[15] Endo M, Kim Y A, Hayashi T, Nishimura K, Matusita T, Miyashita K, Dresselhaus M S. Vapor-grown carbon fibers (VGCFs) basic properties and their battery applications [J]. Carbon, 2001, 39: 1287-1297.

[16] DENG Z F, ZHANG Z A, LAI Y Q, LIU J, LI J, LIU Y X. Electrochemical impedance spectroscopy study of a lithium/sulfur battery: modeling and analysis of fading capacity [J]. Journal of the Electrochemical Society, 2013, 160: A553-A558.

[17] FU Y Z, Manthiram A. Enhanced cyclability of lithium-sulfur batteries by a polymer acid-doped polypyrrole mixed ionic- electronic conductor [J]. Chemistry of Materials, 2012, 24: 3081-3087.

锂硫电池用气相生长碳纤维增强硫-多壁碳纳米管复合正极的影响

邓兆丰1,张治安1,2,卢 海2,赖延清1,2,刘 晋1,李 劼1,2,刘业翔1

1. 中南大学 冶金与环境学院,长沙 410083;

2. 中南大学 深圳研究院 深圳高性能电池材料与器件工程研究中心,深圳 518057

摘 要:制备了锂硫电池用硫-多壁碳纳米管纳米复合材料,并分别采用气相生长碳纤维(VGCFs)和导电炭黑作为复合正极的导电添加剂,通过形貌表征(SEM)、恒流充放电测试和交流阻抗分析(EIS)研究VGCFs对硫-多壁碳纳米管复合正极的影响。结果表明:采用VGCFs作添加剂的硫-多壁碳纳米管复合电极具有三维网状结构,其首次放电比容量为1254 mA·h/g,40次循环后容量保持在716 mA·h/g。与采用导电炭黑为添加剂的电极相比,采用VGCFs为添加剂的电极具有更高的活性物质利用率和更好的循环稳定性。相互搭接的纤维状VGCFs可形成稳定的导电网络,抑制正极材料及残存放电产物的团聚堆积,维持电极的多孔性,从而改善电池的电化学性能。

关键词:锂硫电池;碳纤维;复合正极;碳纳米管

(Edited by Xiang-qun LI)

Foundation item: Project (JCYJ20120618164543322) supported by Strategic Emerging Industries Program of Shenzhen, China; Project (2013JSJJ027) supported by the Teacher Research Fund of Central South University, China

Corresponding author: Zhi-an ZHANG; Tel/Fax: +86-731-88830649; E-mail: zza75@163.com

DOI: 10.1016/S1003-6326(14)63042-9

Abstract: Vapor-grown carbon fibers (VGCFs) were introduced as conductive additives for sulfur-multiwalled carbon nanotubes (S-MWCNTs) composite cathode of lithium-sulfur batteries. The performance of S-MWCNTs composite cathodes with carbon black and VGCFs as sole conductive additives was investigated using scanning electron microscopy (SEM), galvanostatic charge-discharge tests and electrochemical impedance spectroscopy (EIS). The results show that the S-MWCNTs composite cathode with VGCFs displays a network-like morphology and exhibits higher activity and better cycle durability compared with the composite cathode with carbon black, delivering an initial discharge capacity of 1254 mA·h/g and a capacity of 716 mA·h/g after 40 cycles at 335 mA/g. The interconnected VGCFs can provide a stable conductive network, suppress the aggregation of cathode materials and residual lithium sulfide and maintain the porosity of cathode, and therefore the electrochemical performance of S-MWCNTs composite cathode is enhanced.