Eu和P复合变质对过共晶Al-Si合金微观组织和耐磨性能的影响

河南科技大学金属材料磨损控制与成型技术国家地方联合工程研究中心

长江大学机械工程学院

中北大学材料科与工程学院

摘 要:

研究了Eu和P复合变质对过共晶Al-16Si合金中微观组织和耐磨性能的影响,并研究了初生硅的复合细化机制。采用光学显微镜(OM)、扫描电镜(SEM)对试样微观组织进行观察,通过电子探针(EPMA)和能谱仪(EDX)进行成分分析,并对不同样品进行销盘式摩擦磨损实验。结果表明:Eu和P复合变质可以同时实现过共晶Al-16Si合金中的初生硅的细化和共晶硅的变质。当向Al-16Si-0.06P合金中添加0.15%的Eu,初生硅细化效果最好,Eu元素可以在P元素的基础上进一步细化初生硅,共晶硅的形貌由板片状转变为纤维状,初生硅的细化机制为AlP颗粒的异质形核机制和Eu元素的成分过冷机制。当向Al-16Si-0.06P合金中加入Eu的含量为0.2%时,Eu和P发生微弱毒化反应,初生硅尺寸增加。未变质Al-16Si合金的磨损形式主要包括氧化磨损、磨粒磨损和剥层磨损,Eu和P复合变质显著提高了Al-16Si合金的耐磨性能,当添加0.15%的Eu和0.06%P时,体积磨损率降低了35.9%,磨损形式转变为氧化磨损和磨粒磨损。

关键词:

中图分类号: TG146.21

作者简介:毛丰(1990-),男,河南洛阳人,博士,副教授,研究方向:合金的变质和细化、金属基复合材料凝固过程同步辐射实时成像,电话:18336712258,E-mail:maofeng718@163.com;

收稿日期:2020-09-03

基金:河南省重点研发与推广专项项目(192102210009);江苏省高端结构材料重点实验室开放基金项目(hsm103);国家自然科学基金项目(51701185);中北大学金属凝固控制与精确成形山西省重点实验室开放基金项目(MSPM201904)资助;

Microstructure and Wear Resistance of Hypereutectic Al-Si Alloy with Combined Eu and P Additions

Mao Feng Ou Liming Qiao Yongfeng Zhang Po Wang Yu

National Joint Engineering Research Center for Abrasion Control and Molding of Metal Materials,Henan University of Science and Technology

School of Mechanical Engineering,Yangtze University

School of Materials Science and Engineering,North University of China

Abstract:

Hypereutectic Al-Si alloys were widely used to produce pistons,engine blocks,cylinder heads,brake fraction plates,and rocker arms in the aerospace and automotive industry due to their low weight,low thermal expansion coefficient,excellent wear resistance,and castability. It was a common knowledge that the mechanical properties of hypereutectic Al-Si alloys were closely associated with the shape and size of the Si phase. Nevertheless,the stress concentration was easily generated by the coarse irregularly shaped primary Si and plate-like eutectic Si,which could adversely affect the mechanical properties of hypereutectic Al-Si alloys,particularly the plasticity. In order to achieve good mechanical properties,the primary Si refinement and eutectic Si modification should be achieved simultaneously,which could be realized by several methods including rapid solidification,melt overheating,ultrasonic vibration,electromagnetic field,and chemical modification. In these technologies,chemical modification had found wide application in the industry due to the advantages of simple operation and low cost. Effective refinement of primary Si in hypereutectic Al-Si alloys had been frequently obtained by adding AlP particles,which could act as the heterogeneous nuclei of primary Si crystals. However,the P element had no effect on the size and morphology of eutectic Si. With respect to eutectic Si,Na and Sr elements had been successfully used in industry production,which has efficiently transformed eutectic Si from plate-like to a fibrous structure. Nevertheless,they had little influence on the dimension of primary Si in hypereutectic Al-Si alloys. Unfortunately,after adding P and Na/Sr to the melt simultaneously,the refinement efficiency of primary Si would be reduced due to the mutual poisoning between them. So it was difficult to achieve coinstantaneous primary Si refinement and eutectic Si modification in hypereutectic Al-Si alloys. The effect of combined Eu and P additions on microstructure and wear resistance of hypereutectic Al-16 Si alloy,as well as the combined refinement mechanism of primary Si were studied. Firstly,the hypereutectic Al-16 Si-0.06 P base alloys were prepared. Next,the base alloys were melted in a resistance furnace at 750 ℃. Different contents of Eu and Sr elements were added into melts with 15 min holding,and the melt of720 ℃ was cast into a metal mold. The microstructures were observed by optical microscope(OM)and scanning electron microscope(SEM),and the compositions were analyzed by electron probe micro-analyzer(EPMA)and energy dispersive X-ray spectrometers(EDX). Their friction and wear properties were studied with help of a pin-disc type wear apparatus at dry friction and room temperature,and the wear rate were calculated. The rotation rate was 100 r?min-1,and the load applied vertically was 18 N,and the wear time was 60 min. When adding 0.15%Eu in hypereutectic Al-16 Si-0.06 P alloy,the refining efficiency of primary Si was the best and the eutectic Si transformed into a fibrous structure. The additions of 0.15%Eu could further refine the primary Si on the basis of P refinement and no intermetallic formation between Eu and P was observed in the microstructure. The refinement of primary Si was caused by the heterogeneous nucleation mechanism of AlP combined with the constitutional supercooling mechanism of Eu. When adding 0.2%Eu in hypereutectic Al-16 Si-0.06 P alloy,the average size of primary Si increased. Meanwhile,some black particles containing Al,P,O and Eu were discovered in the microstructure,indicating a weak poison reaction exists between Eu and P. In this condition the refinement of primary Si was still affected by the heterogeneous nucleation mechanism of AlP and the constitutional supercooling mechanism of Eu. When adding 0.04%Sr in hypereutectic Al-16 Si-0.06 P alloy,the refinement of primary Si by P element was eliminated by a few Sr addition. Many black particles containing Al,P,O and Sr were discovered in the microstructure,indicating a strong poison reaction existed between Sr and P. Wide and deep furrows,scaly flaking pits and Al2 O3 thin film were found in wear surface of unmodified hypereutectic Al-16 Si alloy,which indicated that the forms of wear were mainly oxidation wear,abrasive wear and delamination wear.When the content of Eu was 0.15% and the content of P was 0.06%,the narrow and shallow furrows,and less damage and peeling of oxide film were found in wear surface,which indicated that the forms of wear were oxidation wear and abrasive wear. The wear resistance of hypereutectic Al-16 Si alloy was significantly improved by combined Eu and P modification,and the wear rate decreased by35.9%. The results showed that a strong poison reaction existed between Sr and P,while a weak poison reaction existed between Eu and P. The simultaneous primary Si refinement and eutectic Si modification in hypereutectic Al-16 Si alloy and the improvedwear resistance could be obtained by controlling Eu and P contents,which provided a new idea to dual modify hypereutectic Al-Si alloys.

Keyword:

hypereutectic Al-Si alloy; primary Si; rare earth; modification; wear resistance;

Received: 2020-09-03

过共晶Al-Si合金具有诸多优点,例如耐磨性高、低密度、低热膨胀系数及高的硬度等,因此被广泛应用于汽车活塞、汽缸、连杆,近几年在电子封装壳体中的应用受到越来越多的关注

目前工业生产中效果最好、应用最为广泛的初生硅细化剂是P元素,P加入熔体后,与Al生成大量的Al P颗粒,Al P颗粒是初生硅理想的异质形核质点

跟传统的变质剂相比,稀土元素具有重熔性好,变质持续时间长,环境友好等优点,而且还具有除气除渣的作用

1 实验

首先在750°C电阻炉中熔炼工业纯铝,待铝完全熔化后分别加入工业纯硅和Al-5P中间合金,保温30 min后浇注制备Al-16Si-0.06P合金。随后将Al-16Si-0.06P合金在750°C重熔,待合金熔化后,将含有Eu和Sr的中间合金加入熔液中,将熔体置于750°C的电阻炉中保温15 min,在室温下待其温度降至720°C,浇入到事先准备好的金属模具中,冷却凝固得到样品。表1为Al-16Si合金的成分。

采用奥地利莱卡MEF-3型光学显微镜(OM)和Zeiss supra 55扫描电子显微镜(SEM)对微观组织进行观察和拍照,使用Image Pro Plus(IPP)软件对上述实验不同视野的10张500倍金相照片中的初生硅进行统计,获得初生硅的体积分数、数量、平均尺寸和圆度等数据;利用扫描电镜中的EDS(能谱)和EPMA-1600型电子探针检测样品的元素和成分。

在万能摩擦磨损机上进行摩擦磨损实验,对偶件试环由45号钢加工而成并进行淬火和防锈处理。图1为销盘式摩擦磨损实验的原理图,在室温干摩擦的情况下,将摩擦磨损机的转速调整为100r·min-1,试样在垂直方向上施加18 N的载荷,磨损时长为60 min。为了提高准确性,每一个样品均进行三次实验。在实验前后分别对试样进行测量称重,以便获得试样在实验过程中的磨损量,采用的是德国赛多利斯ME215P型电子天平,之后采用以下公式对磨损率进行计算:

表1 复合变质Al-16Si合金的成分 下载原图

Table 1 Nominal compositions of Al-16Si alloys with com-plex modification(%,mass fraction)

图1 销盘式磨损实验示意图

Fig.1 Schematic diagram of pin-on-disc wear test

式中,w是试样在单位距离上的体积磨损率,m0是磨损前试样的质量,m是磨损后试样的质量,ρ是磨损前试样的密度,L是试样的磨损距离。

2 结果及讨论

2.1 Eu和P复合变质对过共晶Al-16Si合金微观组织的影响

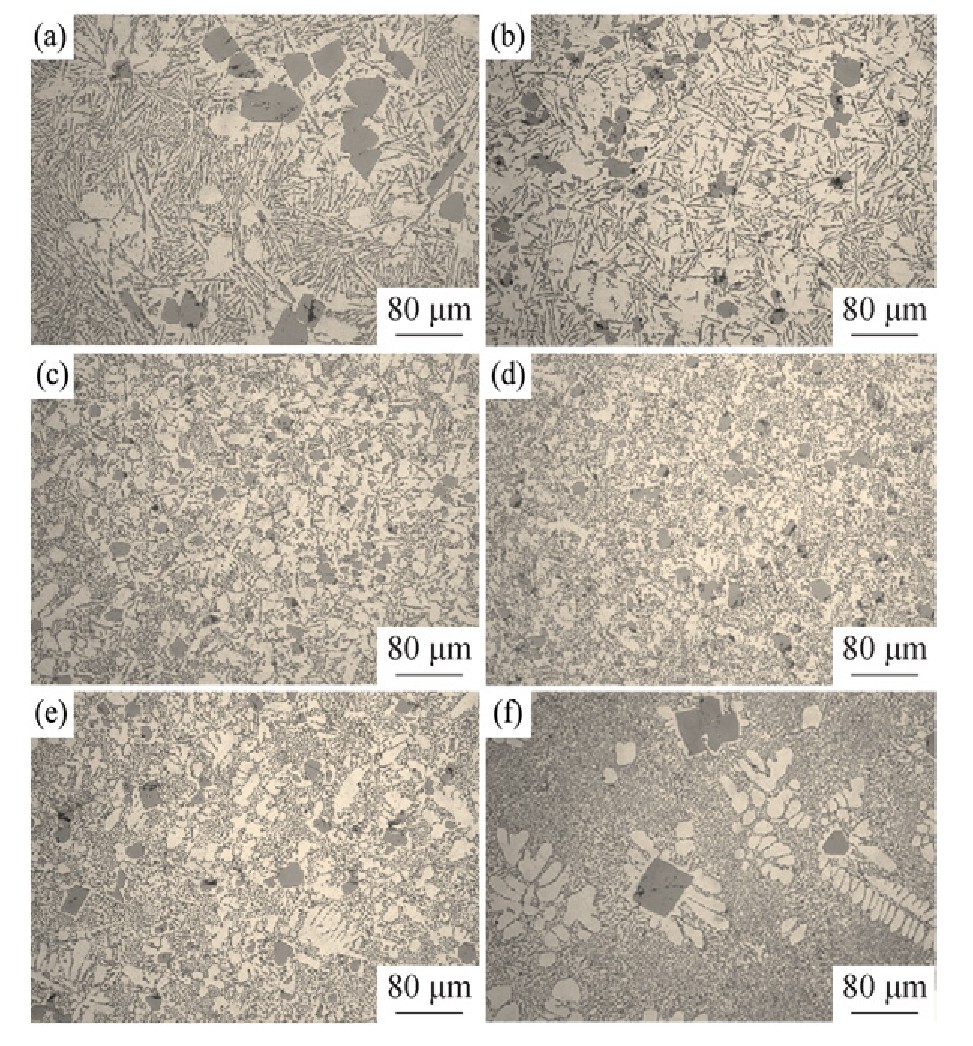

图2为Eu和P复合变质Al-16Si合金中初生硅的OM照片,其中初生硅的数量、平均尺寸和圆度如表2所示。当只加入0.06%P时,初生硅得到了很大程度的细化,同时初生硅数量增加,圆度变小(图2(a,b))。当向Al-16Si-0.06P合金中添加0.1%Eu时,初生硅的平均尺寸和圆度进一步减小(图2(c))。当添加Eu含量为0.15%时,初生硅的细化效果最好,其圆度也最小(图2(d))。值得注意的是,当Eu添加量为0.2%时,初生硅开始发生粗化,其数量也出现了减少(图2(e))。为了将Eu和Sr的变质效果进行对比,图2(f)为Al-16Si-0.06P合金中添加0.04%Sr时初生硅的金相照片,可以发现微量的Sr元素就使P元素对初生硅的细化作用失效,使初生硅尺寸增加至未细化水平。可见,Eu元素可以在P元素的基础上进一步细化初生硅,当Eu含量为0.15%,P含量为0.06%时,初生硅具有最好的细化效果。

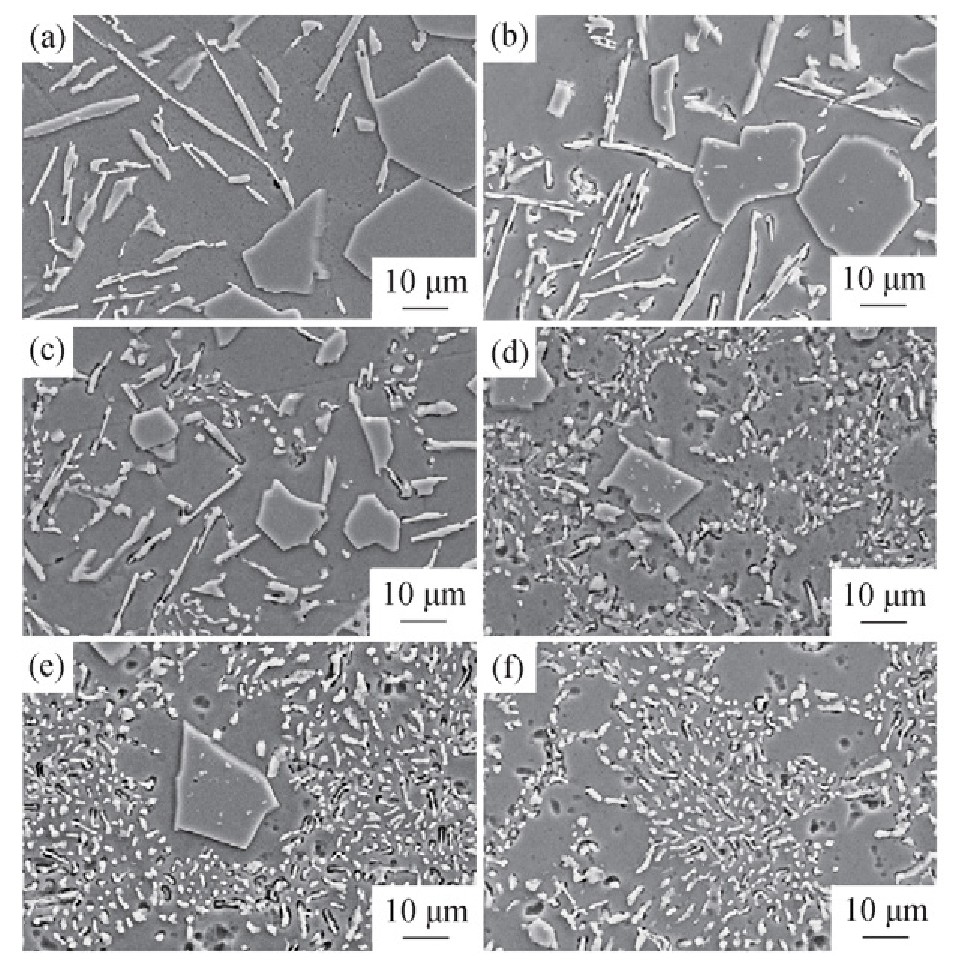

图3是Eu和P复合变质过共晶Al-16Si合金中共晶硅的SEM照片。未变质Al-16Si合金中共晶硅为片状(图3(a)),当添加0.06%的P元素后,共晶硅形貌并未发生改变,仍然为片状(图3(b))。当向Al-16Si-0.06P合金中添加0.1%的Eu元素后,大部分共晶硅开始由片状转变为纤维状,但是在组织中依然可以观察到片状共晶硅,呈现出部分变质的效果(图3(c))。当添加Eu元素含量至0.15%时,片状共晶硅基本转变成为纤维状(图3(d)),其变质效果与Sr元素对共晶硅的影响相似(图3(f))。继续添加0.2%的Eu元素后,没有出现过变质的现象,共晶硅仍然为纤维状(图3(e))。因此当稀土Eu的含量为0.15%时,P含量为0.06%时,初生硅不仅具有最小的平均尺寸和圆度,同时片状共晶硅完全转变成为纤维状。

图2 Eu和P复合变质对过共晶Al-16Si合金中初生硅形貌的影响(OM)

Fig.2 Effect of combined Eu and P additions on morphology of primary Si in hypereutectic Al-16Si alloys(OM images)

(a)Al-16Si,(b)Al-16Si-0.06P,(c)Al-16Si-0.06P-0.1Eu,(d)Al-16Si-0.06P-0.15Eu,(e)Al-16Si-0.06P-0.2Eu,(f)Al-16Si-0.06P-0.04Sr

表2 Eu和P复合变质对过共晶Al-16Si合金中初生硅的数量、平均尺寸和圆度的影响 下载原图

Table 2 Effect of combined Eu and P additions on num-ber,average size and roundness of primary Si crystals in hypereutectic Al-16Si alloys

图3 Eu和P含量对Al-16Si合金中共晶硅形貌的影响(SEM)

Fig.3 Effect of Eu and P contents on morphology of eutectic Si in Al-16Si alloys(SEM images)

(a)Al-16Si;(b)Al-16Si-0.06P;(c)Al-16Si-0.06P-0.1Eu;(d)Al-16Si-0.06P-0.15Eu;(e)Al-16Si-0.06P-0.2Eu;(f)Al-16Si-0.06P-0.04Sr

2.2 Eu和P复合变质机制分析

Li等

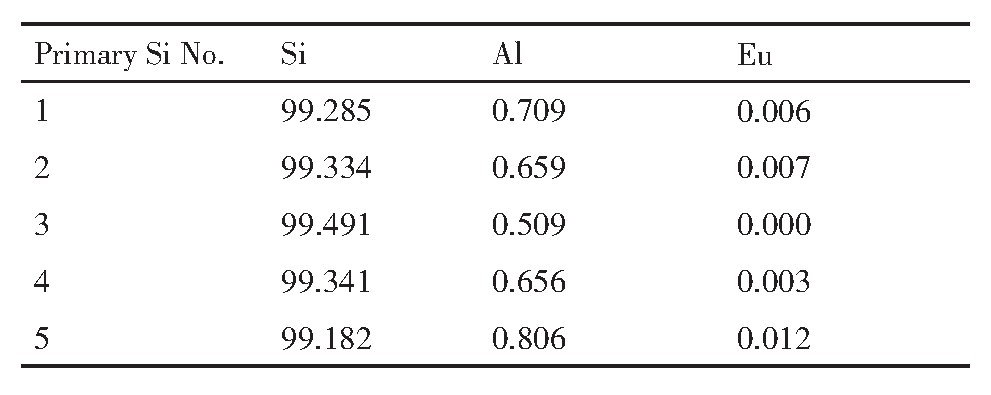

表3为0.15%Eu变质的Al-16Si-0.06P合金中初生硅的EPMA定量点分析结果(表中编号为初生硅的序号,在图3(d)中随机打了5个初生硅的EPMA点分析),结果表明初生硅中还含有少量的Al元素和Eu元素,其中Al元素的原子分数为0.5%~0.8%,而Eu元素的原子分数只有0~0.012%。由于Eu元素在初生硅中的固溶度很低,在凝固过程中Eu原子主要在初生硅的生长界面的前沿富集,使熔液在较大的过冷度下凝固,最终细化初生硅,这也与国内外报道的其他稀土元素对初生硅的影响和细化机制相同

表3 0.15%Eu变质的Al-16Si-0.06P合金中初生硅的EP-MA定量点分析 下载原图

Table 3 EPMA quantitative point analysis of primary Si in 0.15%Eu-modified Al-16Si-0.06P alloy(%,at-om fraction)

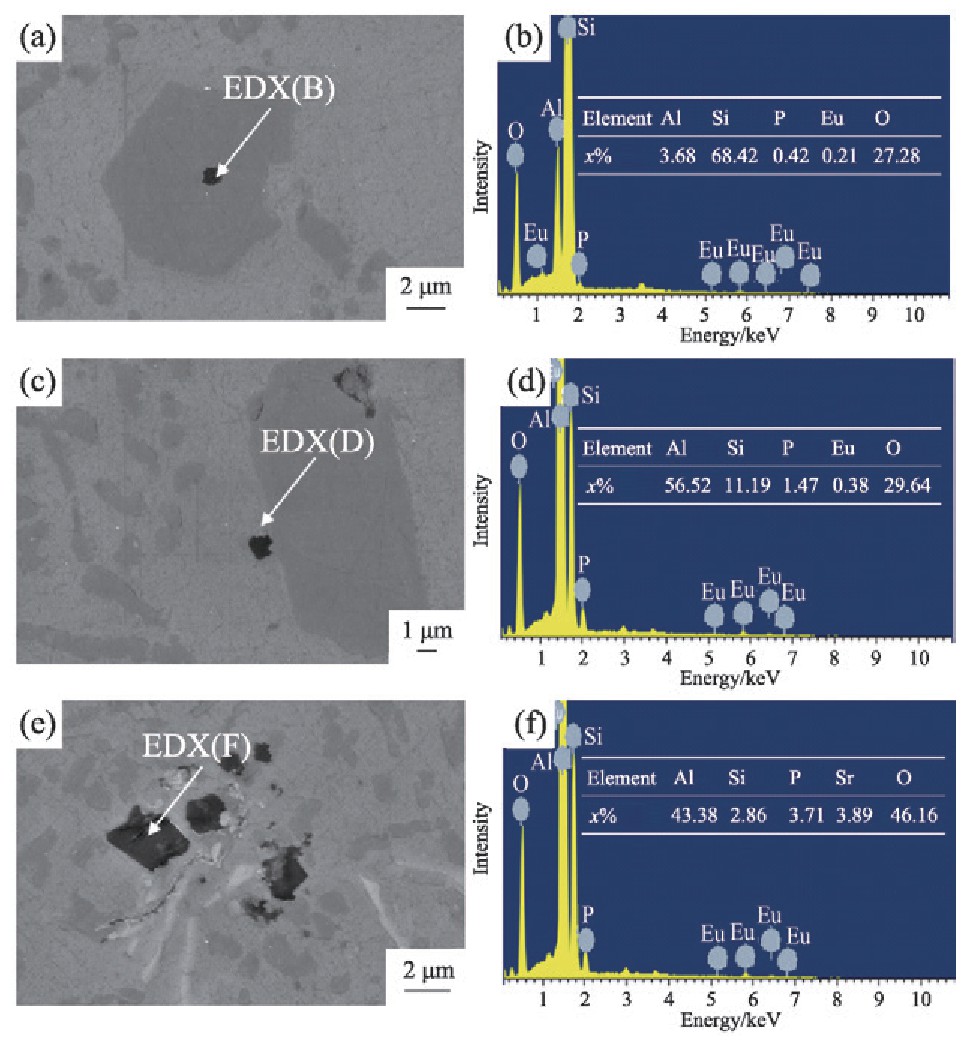

图4(a)为0.15%Eu变质的Al-16Si-0.06P合金中一个初生硅的SEM图片,常常在初生硅颗粒的内部观察到黑色颗粒。图4(b~f)是初生硅的EDX面扫描图,可以发现黑色颗粒富含Al,O和P元素,为初生硅的异质形核质点Al P颗粒。值得关注的是,0.1%Eu和0.15%Eu变质的Al-16Si-0.06P合金组织中并未发现Eu和P形成的金属间化合物,说明此时Eu和P元素并未发生毒化反应,Al P颗粒仍然能作为初生硅的异质形核质点,初生硅的细化机理为Eu元素的成分过冷机制和P元素的异质形核机制。

图5为0.2%Eu变质Al-16Si-0.06P合金的SEM图片。结果显示初生硅内部不仅含有黑色颗粒(图5(a)),共晶组织中也含有少量的黑色颗粒(图5(c))。EDX实验表明这些黑色颗粒中均含有Al,P,Eu和O元素(图5(b,d))。这可能是由于Eu与P元素发生了微弱的毒化反应,Eu固溶于Al P颗粒形成了(Al,Eu)P相,削弱了其对初生硅的异质形核能力,但仍然有较多的(Al,Eu)P相可以作为初生硅的形核质点,此时初生硅的细化机制仍为P元素的异质形核机制和Eu元素的成分过冷机制,但Eu对Al P的毒化使初生硅尺寸增大。作为对比,当向Al-16Si-0.06P合金中加入0.04%Sr时,很难在初生硅内部发现形核质点,却在共晶组织发现了大量含有Al,P,Sr和O元素的黑色颗粒(图5(e,f))。这说明此时Sr与P元素发生了强烈毒化反应,Al P颗粒不能再作为初生硅的异质形核质点,致使初生硅颗粒的尺寸大幅度增加。

2.3 Eu和P复合变质对过共晶Al-16Si合金耐磨性能的影响

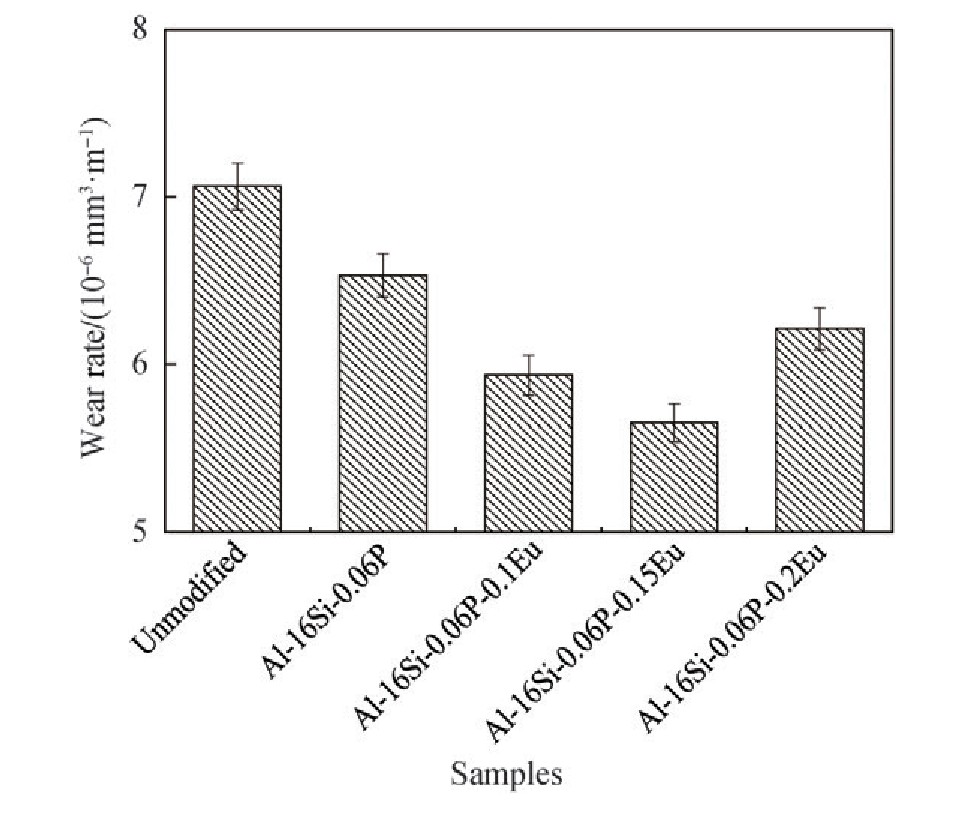

图6为Eu和P复合变质过共晶Al-16Si合金的体积磨损率。从中可以得出,单独加入P元素能提高合金的耐磨性,将Eu和P元素共同加入时,合金的耐磨性得到进一步的提高。当Eu含量为0.15%,P含量为0.06%时,合金有最小的体积磨损率。与未变质合金相比,其体积磨损率降低了35.9%。但继续增加Eu含量至0.2%时,体积磨损率反而升高。

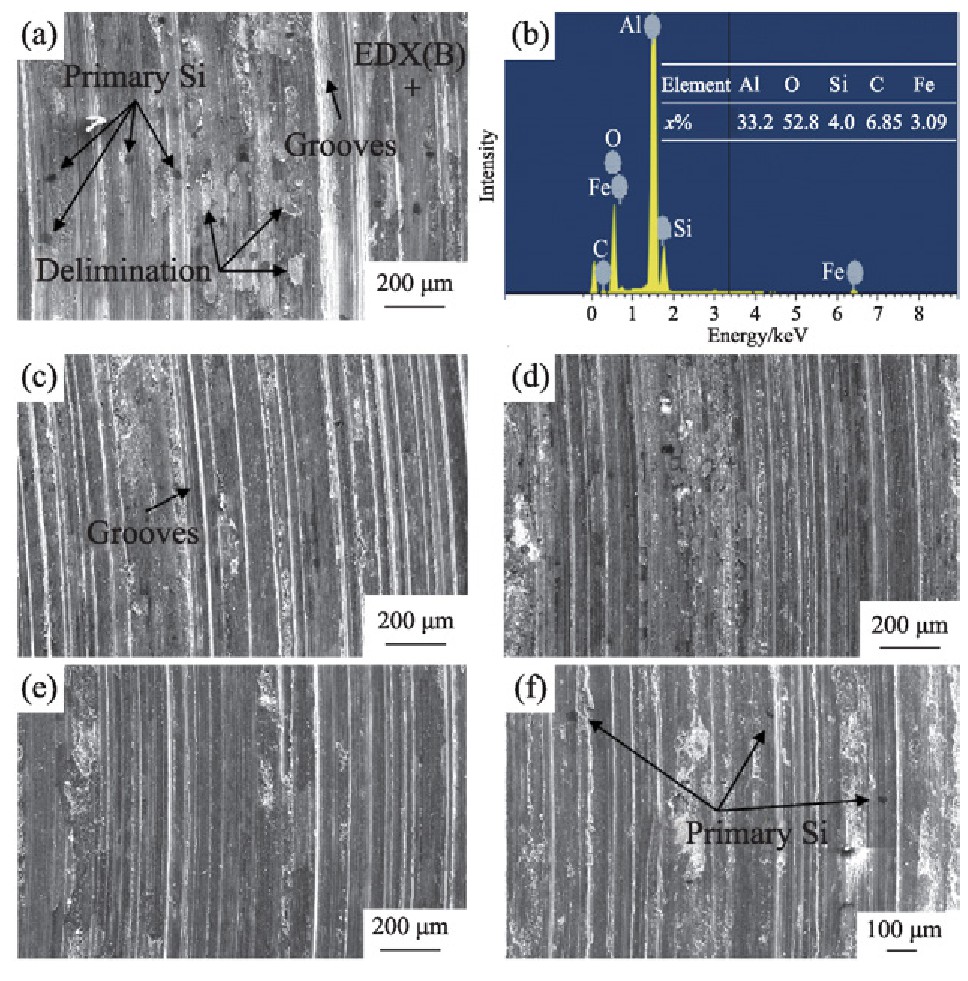

图7是Eu和P复合变质过共晶Al-16Si合金磨损面的SEM图片。可以发现未变质合金磨损表面含有宽而深的犁沟和鳞片状的剥落坑。由于未变质合金中粗大初生硅和片状共晶硅在磨损应力下容易与基体之间产生微裂纹或者自身发生断裂,初生硅颗粒从铝基体中部分或者全部脱离后在磨损表面留下凹坑(图7(a))。随后脱落的硅颗粒嵌入样品与对偶件之间,将原本的两体磨粒磨损转变为三体磨粒磨损

图4 含Eu量为0.15%的Al-16Si-0.06P合金中初生硅EDX分析

Fig.4 EDX analysis of primary Si particles in commercial Al-16Si-0.06P alloys with the addition of 0.15%Eu

(a)SEM image,(b)Al,(c)O,(d)P,(e)Si

图5 Al-16Si-0.06P-0.2Eu合金初生硅内部和共晶组织中富P黑色颗粒和EDX点分析,Al-16Si-0.06P-0.04Sr合金共晶组织中富P黑色颗粒和EDX点分析(SEM)

Fig.5 P enriched black particle within primary Si and its EDX point analysis(a,b)and within Al-Si eutectic(c,d)in Al-16Si-0.06P-0.2Eu alloy,P enriched black parti-cle within Al-Si eutectic and its EDX point analysis in Al-16Si-0.06P-0.04Sr alloy(e,f)

图6 Eu和P含量对工业Al-16Si合金的磨损率的影响

Fig.6 Effect of Eu and P contents on wear rate of commercial purity Al-16Si alloys

当只加入P元素细化后,磨损表面初生硅的脱落凹坑和剥层减少,犁沟宽度变小(图7(c))。初生硅颗粒的细化,使其与基体结合得更加紧密,因此初生硅颗粒不易脱落。然而板片状共晶硅不仅具有较低的承载能力,而且在外力作用容易发生应力集中,使共晶硅与基体产生微裂纹或自身开裂脆断,加剧磨损。当加入0.1%Eu和0.15%Eu进行复合变质后,不仅减小了初生硅的尺寸,还改变了共晶硅的形貌,其部分或者全部转变成为纤维状,初生硅和共晶硅在经过复合变质后,减小了合金内的应力集中,提高了合金的承载能力,使其磨损表面主要由细小而浅的犁沟构成,氧化膜的破损和剥落也极少(图7(d,e)),此时磨损形式主要为氧化磨损和磨粒磨损。继续增加其Eu含量至0.2%,由于初生硅的粗化,致使磨损表面又出现了剥层和宽的犁沟(图7(f))。

图7 Eu和P含量对工业Al-16Si合金的磨损面的影响(SEM)

Fig.7 Effect of Eu and P contents on wear sufraces of commer-cial purity Al-16Si alloys(SEM images)

(a)Al-16Si;(b)EDX point analysis in(a);(c)Al-16Si-0.06P;(d)Al-16Si-0.06P-0.1Eu;(e)Al-16Si-0.06P-0.15Eu;(f)Al-16Si-0.06P-0.2Eu

3 结论

1.当向Al-16Si-0.06P合金中添加0.15%的Eu,Eu元素可以在P元素的基础上进一步细化初生硅,共晶硅的形貌由片状转变为纤维状。此时初生硅的细化机制为Al P颗粒的异质形核机制和Eu元素的成分过冷机制。

2.当向Al-16Si-0.06P合金中加入Eu的含量为0.2%时,Eu和P发生微弱毒化反应,削弱了Al P颗粒对初生硅的异质形核作用,增大了初生硅的尺寸。

3.未变质Al-16Si合金主要磨损形式有3种,即氧化磨损、磨粒磨损和剥层磨损。在加入Eu和P元素对Al-16Si进行复合变质后,合金的耐磨性能得到了显著提高,当添加Eu含量为0.15%,P含量为0.06%时,体积磨损率降低了35.9%,磨损形式转变为氧化磨损和磨粒磨损。

参考文献