Production of 150 cm wide AZ31 magnesium sheet by twin roll casting

A. A. KAYA1, 2, O. DUYGULU1, S. UCUNCUOGLU1, G. OKTAY1, D. S. TEMUR1, O. YUCEL3

1. Materials Institute, TUBITAK MRC, Gebze, Kocaeli 41470, Turkey;

2. Engineering Faculty, Department of Metallurgy and Materials, Mugla University, Kotekli, Mugla 48000, Turkey;

3. Department of Metallurgical and Materials Engineering, Istanbul Technical University, Istanbul 34469, Turkey

Received 12 June 2008; accepted 5 September 2008

Abstract:

150 cm wide AZ31 magnesium alloy sheet was produced by twin roll casting. The sheets of 6 mm thickness were cast. The sheet material was characterized using various techniques including metallography and XRD. The mechanical properties were investigated by tensile tests and hardness measurements. The procedures were developed for thermomechanical treatment of cast sheet material. The products of these procedures were characterized and the results were discussed for possible potential applications.

Key words:

AZ31 magnesium alloy; twin roll casting; strip casting;

1 Introduction

There is increasing interest in using magnesium alloys for various applications in electronics and transportation industries[1-6]. The application of wrought magnesium alloys especially in the form of sheet is limited due to the price of conventional rolling product. However, the demand for decreasing the magnesium sheet prices is high and can be met through twin-roll casting[7].

With conventional magnesium sheet production, the starting material is a slab with thickness of 100-250 mm. The magnesium alloy slab has to be rolled many times with small amounts of deformation passes at each step and intermediate annealings to produce sheet material[8]. This multi-step process is not cost-effective in terms of time and energy. Therefore, twin roll casting (TRC) is focused on due to its potential for relatively low-cost production.

Universities, companies and institutes have performed some laboratory as well as pilot scale industrial trials using TRC technology. Investigations on strip casting have been mainly in Australia (CSIRO)[9-10], South Korea (POSCO Co. Ltd., RIST, Seoul National University, Pohang University of Science and Technology, University of Seoul)[11-15], Germany (Thyssen Krupp MgF Magnesium Flachprodukte GmbH in Freiberg/Saxony, Technical University Bergakademie Freiberg, University of Hanover)[16-20], Japan (Mitsubishi Aluminum Co. Ltd., Osaka Prefecture University, Gonda Metal Industry Co., Ltd., Advanced Technologies, Inc., Sumitomo Electric Industries, Ltd., Gunma University, Osaka Institute of Technology, Nippon Institute of Technology)[21-24], China (Luoyang Copper Co., Fuzhou Huamei New Technology Development Co. Ltd., Chongqing University, Northeast University, General Research Institute of Nonferrous Metals)[25-27] and Canada (McGill University)[28].

In CSIRO, magnesium alloy strips (AZ31, AZ61, AM60, and AZ91 alloys), with a width of 100-600 mm and thickness of 2.3-5.0 mm have been produced[9-10]. POSCO magnesium produces 530-600 mm wide, 0.4-4.3 mm thick AZ31 sheet or coils[11]. Thyssen Krupp MgF Magnesium Flachprodukte GmbH is producing strips up to 700 mm width and 4.5-7 mm thickness[16-20]. In Japan, AZ31, AZ61, AZ91, AM50 and AM60 strips are produced with 4-5 mm thickness and up to 250 mm width[21-28]. In China, 1.0-2.0 mm thick, 150 mm wide, 0.5-8 mm thick, 600 mm wide AZ31 strips are produced[8, 29-31].

Recently, an industrial scale magnesium twin roll casting plant has been set up in Turkey. The system is incorporated with a gas-fired chamber furnace with a maximum melting capacity of approximately 3 200 kg magnesium. Water-cooled steel twin-rolls of 1 600 mm wide and 1 125 mm diameter with 15? tilt angle, a pinch roll unit, a cross-cut shear and a coiler are incorporated into the system.

800 mm and 1 500 mm wide magnesium alloy AZ31 sheets of 6mm thickness have been successfully cast. To our knowledge, this is the widest AZ31 sheet that has been produced by this method in the world so far. The production has been continued for 10 s of meters and the sheet was coiled or sheared to test the system in process. The surfaces of the sheets were of good quality. No cracks or voids were observed other than some minor problems along the edges.

2 Experimental

The AZ31 magnesium alloy strips were cut to 5 cm×20 cm size samples. The sheet samples were homogenized at 400 ℃ for 1 h. After homogenization, the sheets have been warm/hot rolled using a laboratory scale rolling mill. Prior to the rolling, the rolls were heated by gas flame. The samples were preheated in a furnace for approximate 20 min before rolling. The temperature was controlled by a thermal camera and a thermocouple. AZ31 magnesium alloy sheets were rolled at 300 ℃ with 25% deformation at a single pass. In another trial, the samples were hot rolled at 450 ℃ and a maximum deformation of 50% reached in one rolling pass.

Metallographic samples were prepared to observe the microstructures in the length, width and thickness directions. The samples were mounted in epoxy and polished starting with SiC paper, followed by diamond slurry and colloidal silica. Etching was done using acetic picral acid solution (4.2 g picric acid, 10 mL acetic acid, 70 mL ethanol, 10 mL water) face up for 5 s immediately followed by washing with ethanol.

In order to evaluate the deformation behavior of the AZ31B sheet, tensile tests were preformed. Tensile samples were machined via EDM (Electric discharge machining) in accordance with ASTM standard B557M[33]. The samples were standard specimen sheet type for the as-received materials and subsize specimens for the rolled materials. A Zwick Z250 tensile testing machine at a strain rate of 1×10-3 s-1 was used for tensile testing.

Vickers microhardness measurements were performed with an applied load of 2 N using a Zwick ZHV10 device. For X-ray diffraction (XRD) studies, the specimens were polished and a Shimadzu XRD-6000 diffractometer producing Cu Kα radiation at 40 kV and 30 mA was used.

3 Results and discussion

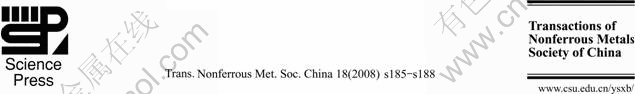

Photographs from the production and coiling of 1 500 mm and 800 mm wide AZ31 sheets are shown in Figs.1 and 2.

Fig.1 Photographs of 1 500 mm wide AZ31 magnesium alloy sheet during twin roll casting process(a) and coiling process(b)

Fig.2 Photograph of 800 mm wide AZ31 magnesium coil

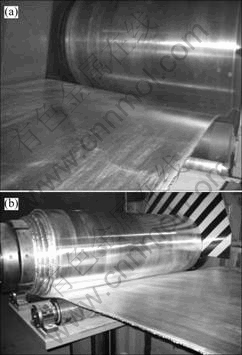

Dendritic structure throughout the thickness of sheet was observed as shown in Fig.3(a). In Fig.3(b) the plan view dendritic structure is seen more closely. It is observed that the dendritic grain size is approximately 300 ?m. As seen from Fig.3(a), a gross macrosegregation is not detected.

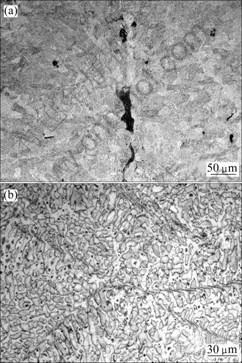

Fig.4 shows the microstructure after homo- genization at 400 ℃ for1 h. It is seen clearly that the dendritic structure is changed to equiaxed grains. The average grain size is measured to be around 25 ?m. After

Fig.3 Optical micrographs of AZ31 magnesium alloy plate produced by twin roll strip casting: (a) Side view; (b) Plan view of centerline

Fig.4 Optical micrograph of magnesium plate after homogenization at 400 ℃ for 1 h

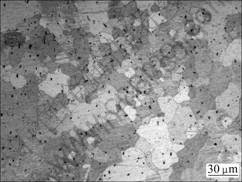

warm/hot rolling processes the grain size of less than 10 ?m has been achieved in some regions as shown in Fig.5.

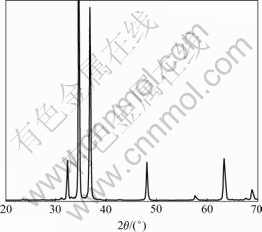

The XRD spectrum of AZ31 sheet is shown in Fig.6. It can be seen that no phase other than α-phase (Mg) is observed.

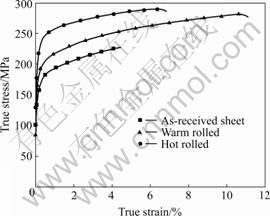

The tensile test results for the 1 500 mm wide as-received sheet and warm/hot rolled sheets are given in Fig.7. UTS values of the sheets are increased from 225 MPa to approximate 275 MPa by applying homogenization and rolling processes. Moreover, the elongation values are increased to more than 11%. The microhardness values are HVC 72 for the as-received sheet and HVC 74-76 for the rolled samples.

Fig.5 Optical micrographs showing microstructures after rolling at 300 ℃(a) and 450 ℃(b)

Fig.6 XRD spectrum of as twin-roll cast AZ31

Fig.7 Tensile test results for as-cast 1 500 mm wide AZ31 sheet and warm/hot rolled sheets

4 Conclusions

1) Continuous sheet castings of 6 mm thickness, 800 mm and 1 500 mm width are easily achieved by TRC method.

2) The conditions employed for thermomechanical processing showed that the atmospheric conditions for such processes can be used and that the microstructure and mechanical properties of the produced sheets can be improved significantly. Further processing for thinner sheets as well as casting of different magnesium alloys will be attempted using the same TRC plant in Turkey.

References

[1] AVEDESIAN M M, BAKER H. Magnesium and magnesium alloys: ASM specialty handbook[M]. Ohio: ASM International, 1999.

[2] EMLEY E F. Principles of magnesium technology[M]. Oxford: Pergamon, 1966.

[3] BECK E. The technology of magnesium and its alloys[M]. London: Hughes FA, Co. Ltd., 1943.

[4] AGHION E, ELIEZER D. Magnesium alloys, science, technology and applications[M]. Israel: Haifa, 2004.

[5] POLMEAR I J. Light alloys, metallurgy of the light elements [M]. London: Arnold, 1995.

[6] KAINER K U. Magnesium alloys and technologies[M]. Weinheim: WILEY-VCH, Verlag GmbH & Co., 2003.

[7] MOLL F, MEKKAOUI M, SCHUMANN S, FRIEDRICH H. Application of Mg sheets in car body structures[C]// KAINER K U. Magnesium, Proceedings of 6th International Conference Magnesium Alloys and their Applications. DGM, 2003: 936-942.

[8] DING P, JIANG B, WANG J, PAN F. Status and development of magnesium alloy thin strip casting[J]. Materials Science Forum, 2007, 546/549: 361-364.

[9] LIANG D, COWLEY C B. The twin roll strip casting of magnesium[J]. Journal of Materials Processing Technology, 2004, 56(5): 26-28.

[10] StJOHN D H. Overview of current international magnesium research and recent CAST CRC developments[J]. Advanced Materials Research, 2007, 29/30: 3-8.

[11] POSCO Co. Ltd web site: www.poscomagnesium.com.

[12] PARK S S, LEE J G, LEE H C, KIM N J. Development of wrought Mg alloys via strip casting[C]//Magnesium Technology 2004, Charlotte, North Carolina: TMS, 2004: 14-182.

[13] PARK S S, KIM Y M, KANG D H, KIM N J. Development of Mg alloy sheets via strip casting[J]. Materials Science Forum, 2005, 475/479: 457-462

[14] PARK S S, BAE G T, LEE J G, KANG D H, SHIN K S, KIM N J. Microstructure and mechanical properties of twin-roll strip cast Mg alloys[J]. Materials Science Forum, 2007, 539/543: 119-126.

[15] KANG S B, CHEN H, KIM H W, CHO J H. Effect of reheating and warm rolling on microstructure and mechanical properties of twin roll strip cast Mg-4.5Al-1.0Zn-0.4Mn-0.3Ca alloy sheet[C]// Magnesium Technology 2008. New Orleans, Louisiana: TMS, 2008: 147-152.

[16] ThyssenKrupp Magazine, 2004, web site: www.thyssenkrupp.com.

[17] KAWALLA R, OSWALD M, SCHMIDT C, ULLMANN M, VOGT H P, CUONG N D. Development of a strip-rolling technology for Mg alloys based on the twin-roll-casting process[C]//Magnesium Technology 2008. New Orleans, Louisiana: TMS, 2008: 177-182.

[18] BACH F W, RODMAN M, ROSSBERG A. High quality magnesium sheets for automotive applications[J]. Advanced Materials Research, 2005, 6/8: 665-672.

[19] ENGL B. Future aspects of magnesium sheet materials using a new production technology[C]//62nd Annual World Magnesium Conference. Berlin, 2005: 27-34.

[20] KAWALLA R, OSWALD M, SCHMIDT C, ULLMANN M, VOGT H P, CUONG N D. New technology for the production of magnesium strips and sheets[J]. Metalurgija, 2008, 47(3): 195-198

[21] NAKAURA Y, OHORI K. Properties of AZ31 magnesium alloy sheet produced by twin roll casting[J]. Materials Science Forum, 2005, 488/489: 419-426.

[22] WATARI H, DAVEY K, RASGADO M T, HAGA T, IZAWA S. Semi-solid manufacturing process of magnesium alloys by twin-roll casting[J]. Journal of Materials Processing Technology, 2004, 155/156: 1662-1667.

[23] HAGA T, WATARI H, KUMAI S. High speed twin roll casting of Mg alloy strip by a vertical twin roll caster[J]. Journal of Achievements and Manufacturing Engineering, 2006, 15(1/2): 186-192.

[24] WATARI H, HAGA T, DAVEY K, KOGA N, YAMAZAKI T. Effects of production parameters on characteristics of magnesium alloy sheets manufactured by twin roll casting[J]. Journal of Achievements and Manufacturing Engineering, 2006, 16(1/2): 171-175.

[25] WATARI H, HAGA T, SHIBUE Y, DAVEY K K, KOGA N. Twin roll casting of magnesium alloys with high aluminium contents[J]. Journal of Achievements and Manufacturing Engineering, 2006, 18(1/2): 419-422.

[26] WATARI H, HAGA T, PAISARN R, KOGA N, DAVEY K. Mechanical properties and metallurgical qualities of sheets manufactured by twin-roll casting[J]. Key Engineering Materials, 2007, 345/346: 165-168.

[27] WATARI H, HAGA T, KOGA N, DAVEY K. Feasibility study of twin roll casting process for magnesium alloys[J]. Journal of Materials Processing Technology, 2007, 192/193: 300-305.

[28] WATARI H, PAISARN R, HAGA T, NODA K, DAVEY K, KOGA N. Development of manufacturing process of wrought magnesium alloy sheets by twin roll casting[J]. Journal of Achievements in Materials and Manufacturing Engineering, 2007, 20(1/2): 515-518.

[29] YANG C, DING P, ZHANG D, PAN F. The microstructure and processing in twin roll casting of magnesium alloy strip[J]. Materials Science Forum, 2005, 488/489: 427-430.

[30] DI H, LI Y, NING Z, LI Z, LIU X, WANG G. New processing technology of twin roll strip casting of AZ31B magnesium strip[J]. Materials Science Forum, 2005, 488/489: 615-618.

[31] JIANG B, WANG J, DING P, YANG C, PAN F. Rolling of AZ31 magnesium alloy thin strip[J]. Materials Science Forum, 2007, 546/549: 365-368.

[32] JACKMAN J A, WOOD J, ESSADIQI E, LO J, SAHOO M, XU S, THOMSON J, LIU W. Overview of key R&D activities for the development of high-performance magnesium materials in Canada[J]. Materials Science Forum, 2005, 488/489: 21-24.

[33] ALLEN R F, BALDINI N C, et al. Annual Book of ASTM Standards. Section 3, Metals Test Methods and Analytical Procedures[M]. ASTM, Philadelphia, PA, 2001.

(Edited by LONG Huai-zhong)

Corresponding author: A. A. KAYA; E-mail: aakaya@mu.edu.tr

[2] EMLEY E F. Principles of magnesium technology[M]. Oxford: Pergamon, 1966.

[3] BECK E. The technology of magnesium and its alloys[M]. London: Hughes FA, Co. Ltd., 1943.

[5] POLMEAR I J. Light alloys, metallurgy of the light elements [M]. London: Arnold, 1995.

[6] KAINER K U. Magnesium alloys and technologies[M]. Weinheim: WILEY-VCH, Verlag GmbH & Co., 2003.

[11] POSCO Co. Ltd web site: www.poscomagnesium.com.

[16] ThyssenKrupp Magazine, 2004, web site: www.thyssenkrupp.com.