DOI:10.19476/j.ysxb.1004.0609.2017.05.003

新型Mg-Bi-Al-Zn变形镁合金的微观组织与力学性能

孟帅举1,余 晖1, 4,崔红卫2,张 静3,赵维民1,王志峰1,秦春玲1

(1. 河北工业大学 材料科学与工程学院,天津 300130;2. 山东理工大学 材料科学与工程学院,淄博 255049;

3. 江苏科技大学 冶金与材料学院,张家港 215600;4. 韩国材料科学研究院 轻合金组,韩国 昌原 51508)

摘 要:

基于开发低成本非稀土型变形镁合金的目的,利用XRD、SEM、EDS、TEM和EBSD等检测手段对新型Mg-7Bi-1Al-1Zn(质量分数,%,BAZ711)合金的微观组织进行相关表征,同时采用万能试验机测试了其铸态及挤压态试样的力学性能。结果表明:铸态BAZ711合金中粗大的Mg3Bi2相呈连续网状分布于α-Mg枝晶晶界处,其平均二次枝晶臂间距约为50 μm;挤压态BAZ711合金发生完全再结晶,平均晶粒尺寸减小为3 μm,微米级Mg3Bi2相沿挤压方向呈条带状断续分布,同时,基体中弥散分布有大量50~200 nm的近球状或短杆状Mg3Bi2相;挤压后合金表现出典型挤压织构特征。由于组织细化和微/纳双尺度第二相的综合强化作用,挤压态合金力学性能较铸态显著提高,其拉伸屈服强度、抗拉强度和伸长率分别达到244 MPa、305 MPa和14%。

关键词:

文章编号:1004-0609(2017)-05-0894-08 中图分类号:TG146.2 文献标志码:A

镁及其合金作为轻质金属结构材料的代表,具有比刚度比强度高、铸造加工性好、易切削加工及易于回收利用等一系列优点,广泛应用于汽车、轨道交通、电子通讯和航空航天等领域[1-2]。特别是Mg-Al系合金,诸如AZ91、AZ80、AM60等因具备良好加工成形性能及室温力学性能而得到广泛应用[3-4],但这些高铝含量合金中的主要强化相为Mg17Al12相,其熔点较低,使得合金在温度高于150 ℃的环境中因强度和蠕变性能急剧降低而极大地限制了其应用[5]。

近年来,Bi元素被加入AZ91[6]、AZ80[7]、AZ81[8]和ZK60[9]等商用镁合金中用以改善合金的显微组织并提高其室温和高温力学性能。特别是有研究[10-11]指出,Bi在Mg-Al合金中不但可细化Mg17Al12相并抑制其在时效过程中的不连续析出行为,同时,高熔点Mg3Bi2第二相(823 ℃)的存在还可提高合金抗蠕变性能,呈现出与添加稀土元素相媲美的效果。依据Mg-Bi二元相图[12],Bi在Mg中固溶度随温度下降而大幅降低,故Bi在镁合金中是一种典型的可沉淀强化元素[13]。基于此,国内外研究者[14-21]将Bi元素作为主要合金化元素,尝试开发Mg-Bi系新型合金。其中以快速凝固复合挤压法制备高延展性Mg-5Bi-1Ca和Mg-5Bi-1Si(质量分数,%)[20]和可热处理强化Mg-6.4Bi-1.3Zn(质量分数,%)[21]两类三元合金为典型代表。

可见,若对Mg-Bi基合金进行合理合金化设计并辅以塑形加工变形手段,有望通过晶粒细化和沉淀强化作用开发出强度较高的新型镁合金。本文作者在Mg-Bi二元合金基础上添加少量Al和Zn元素用于增强合金的固溶强化效果和塑性变形性能,通过合金熔炼,均匀化热处理和热挤压加工,成功制备出Mg-7Bi-1Al-1Zn(质量分数,%,BAZ711)合金,并详细对比研究了其挤压前后的微观组织演化规律和力学性能提高的主要原因。

1 实验

实验采用纯度均大于99.9%的纯Mg、Bi、Al和Zn为原料。合金熔炼采用不锈钢坩埚在井式电阻炉中进行,熔炼过程中采用SF6+CO2混合气氛保护,熔炼温度为760 ℃,待纯Mg熔化后加入纯Bi、纯Al和纯Zn,搅拌并静置20 min使熔体均匀。除渣后于熔体降至720 ℃时浇注到预热至200 ℃的金属模具中,获得尺寸为d 62 mm×180 mm合金铸锭。采用ICP法测量所得BAZ711铸锭合金的实际成分为Mg-7.08Bi- 1.12Al-1.02Zn(质量分数,%)。铸锭在500 ℃下保温5 h并温水淬火获得固溶态合金后机加工成d 60 mm×150 mm的待挤压坯料。随后热挤压工艺参数为挤压温度300 ℃、挤压速度1.5 m/min、挤压比36,最终制得d 10 mm的棒材。

铸态样品和固溶态样品经不同号砂纸粗磨后依次采用粒径为3、l和0.5 μm的金刚石膏进行抛光。抛光后样品经腐蚀液(10 mL醋酸+4.2 g苦味酸+70 mL乙醇+10 mL蒸馏水)腐蚀,采用INSPECTS50扫描电镜(SEM)进行微观组织观察;通过SmartLab型X射线衍射仪(XRD)和装配在SEM上的EDAX-TSL型能谱仪(EDS)对物相组成及合金元素进行分析。利用TecnaiG220透射电镜(TEM)观察挤压样品内的动态析出相,透射电镜试样采用金刚石刀片低速切割为l~2 mm厚薄片,机械研磨至约100 μm并冲成d 3 mm圆片后在电解双喷仪上进行减薄(0 ℃,20 V;电解液为600 mL甲醇+300 mL丙三醇+100 mL硝酸),试样在离子减薄仪(Gatan PLPS 691)减薄15~20 min后上机观察。电子背散射衍射(EBSD)试样在前述抛光步骤基础上采用自动抛光机辅以OPS悬浊液抛光40 min,酒精清洗表面后移至SU-6600场发射扫描电镜采集相关数据,通过TSLOIM7软件对置信度(CI)大于1的数据进行相关分析。

力学性能试样按照ASTM E8标准加工成拉伸试棒,引伸计标距25 mm,直径6 mm;利用SUNS-UTM5105X电子万能型拉伸试验机在拉伸速度为1 mm/min条件下测试铸态和挤压态BAZ711合金样品的室温(RT)拉伸性能。

2 结果与分析

2.1 合金物相分析

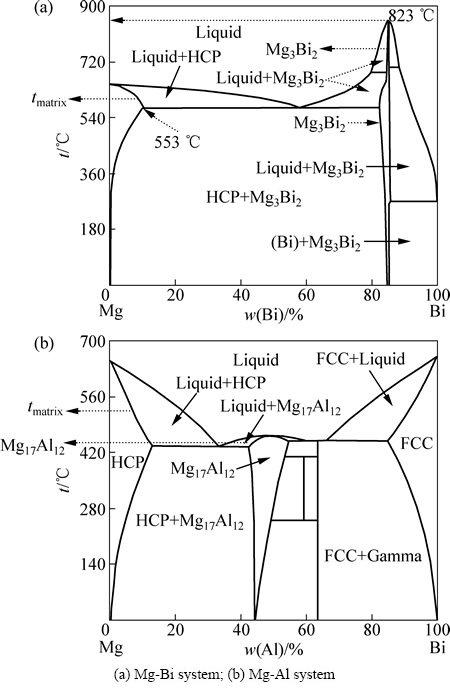

图1所示为Mg-Bi和Mg-Al二元合金的平衡相图。由图1可以看出,Mg-Bi相图与Mg-Al相图的左半部分相似,553 ℃时Bi在Mg中的固溶度为8.87%,其随温度的降低急剧减小,在200 ℃时降至1%以下,呈现典型可沉淀强化特点。由Mg-Bi相图可见:Mg-xBi(0<x<85%)合金的室温组织均由α-Mg和Mg3Bi2相组成,与Mg-Al合金中强化相Mg17Al12 (437 ℃)[12]相比,Mg3Bi2(823 ℃)具有更高的初溶温度。故固溶处理时需采用较高的温度,基于前期试验探索,确定BAZ711合金的固溶处理工艺为(500 ℃,5 h)。

图1 采用iPANDAT计算得到Mg-Bi和Mg-Al二元合金平衡相图

Fig. 1 Equilibrium phase diagrams calculated with iPANDAT

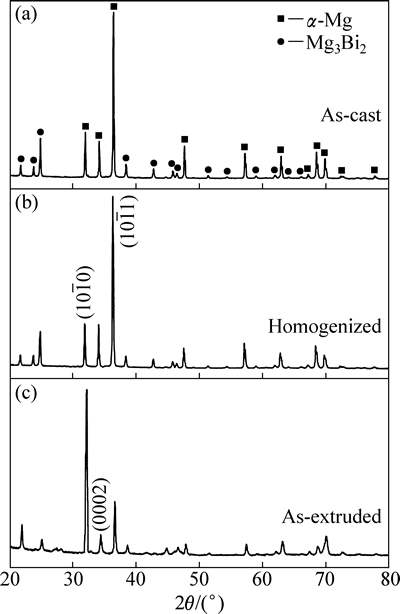

图2 铸态、固溶态和挤压态BAZ711合金的XRD谱

Fig. 2 XRD patterns of as-cast (a), homogenized (b) and as-extruded (c) BAZ711 alloys

图2所示为BAZ711合金铸态、固溶态和挤压态XRD谱。由图2可见,铸态、固溶态和挤压态合金物相组成相同(JCPDS α-Mg: #65-3365; Mg3Bi2: #65-1909),因Mg3Bi2相具有高热稳定性与熔点,固溶处理并未将其完全固溶。其中,挤压态试样与铸态、T4态在衍射峰相对强度上有所区别, 比值由铸态、固溶态约1.0变为挤压态0.25,说明挤压态合金中的晶粒取向与铸态和固溶态相比发生了显著变化,即晶粒基面倾向于与挤压方向一致,后续背散射电子衍射(EBSD)实验结果也验证了此变化。

比值由铸态、固溶态约1.0变为挤压态0.25,说明挤压态合金中的晶粒取向与铸态和固溶态相比发生了显著变化,即晶粒基面倾向于与挤压方向一致,后续背散射电子衍射(EBSD)实验结果也验证了此变化。

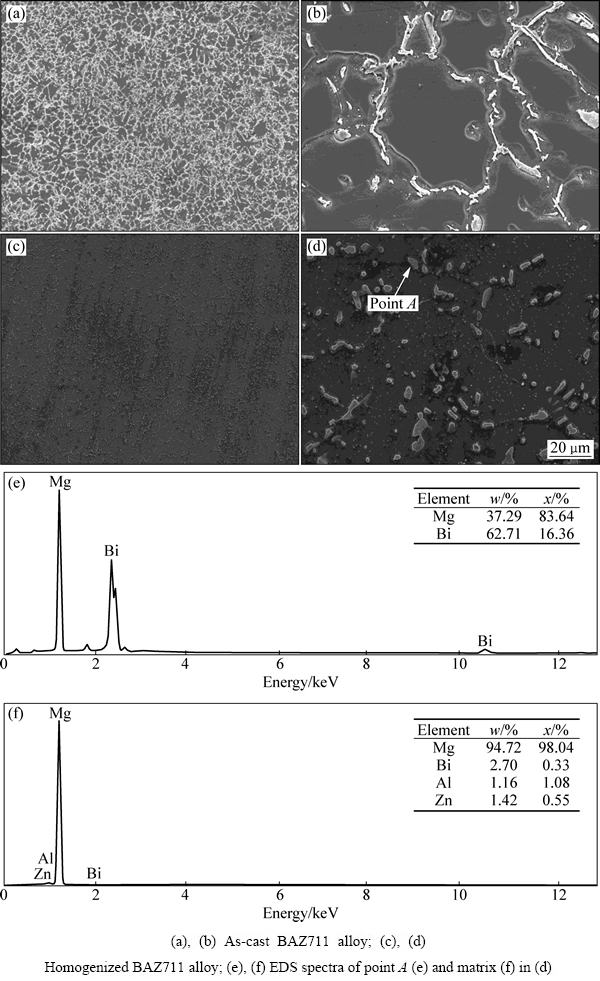

图3 BAZ711合金铸态和固溶态SEM像及EDS谱

Fig. 3 SEM images and EDS results of as-cast and homogenized BAZ711 alloy

2.2 不同状态下合金的显微组织分析

2.2.1 铸态与固溶态合金微观组织

图3(a)和(b)所示为BAZ711合金铸态的扫描电镜组织。由图3(a)和(b)可知,铸态BAZ711合金组织由等轴树枝状基体和呈连续网状分布于枝晶晶界上的金属间化合物构成,合金平均二次枝晶间距约为50 μm。铸态BAZ711合金中晶界处存在的大量硬脆相会割裂基体并限制合金的变形能力,故对其进行固溶处理。

图3(c)和(d)所示为BAZ711合金固溶态的微观组织。由图3(c)和(d)可知,其显微组织与铸态组织相比,固溶处理后部分晶间呈连续网状分布的第二相固溶进基体中且体积分数相应下降,未固溶进基体的第二相多呈短杆状或粒状断续分布于基体上。连续网状第二相的消除有利于减少其对合金的割裂作用并降低第二相对晶界移动的阻碍作用,从而有助于合金的挤压成形。

由图3(e)和(f)对应图3(d)的能谱分析结果。由图3(e)和(f)可知,金属间化合物含有较多Bi元素;结合前述XRD谱可知,此第二相为Mg3Bi2相;基体则为固溶有Al、Zn和Bi元素的α-Mg,此结论与文献[21]报道一致。

2.2.2 挤压态合金微观组织

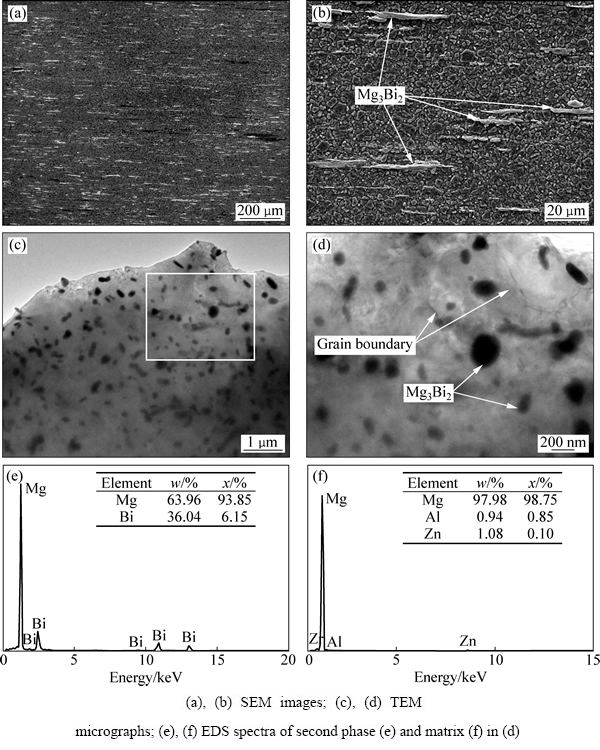

固溶态坯料经挤压的显微组织如图4(a)和(b)所示,水平方向为挤压方向(ED)。由图4(a)和(b)可见,原始粗大晶粒在挤压后均转变为细小等轴晶,截线法测量得到其平均晶粒尺寸约为3 μm,晶粒细化归因于动态再结晶。其中,未完全固溶于基体的硬质第二相在挤压过程中被破碎,并沿挤压方向呈断续条带状分布,形成清晰的挤压变形带[22]。一方面,这些微米级第二相可通过颗粒激发形核(PSN)机制[23]促进动态再结晶;另一方面,根据“Zener效应”[24],微米级Mg3Bi2相还可有效地阻碍再结晶晶粒生长过程中的晶界移动,从而细化晶粒。

图4 挤压态BAZ711合金的微观组织及EDS分析结果

Fig. 4 Microstructure of as-extruded BAZ711 alloy and corresponding EDS results

除上述未固溶进基体的Mg3Bi2相在热挤压过程中被破碎成微米级颗粒外,固溶于基体中的Bi元素也会随固溶度下降而在挤压过程中发生动态析出[12-13]。

图4(c)~(f)所示分别为挤压态BAZ711合金的TEM明场像及相应微区成分分析结果。由图4(c)~(f)可见,挤压态BAZ711合金中还存在大量细小第二相(50~200 nm),呈短棒状或近球状弥散分布在动态再结晶晶粒的内部及其晶界处。结合微区能谱成分分析结果可知,这些衬度较大的纳米级析出相由Mg和Bi构成,而其周边基体则主要由Mg、Al和Zn组成,结合前述XRD谱及SEM/EDS分析结果可判断这些析出相为Mg3Bi2相,此结果与有关报道[20-21]的研究结果一致,而Al和Zn元素仍固溶在基体中,这与Al和Zn元素在Mg中固溶度较大有关[12]。

文献[25-26]指出,在热挤压过程中,由于塑性变形产生的位错可以为第二相颗粒提供形核位置,并增加合金元素的扩散能力。从而增加第二相的析出动力,可见,大量细小Mg3Bi2颗粒的形成是挤压过程中过饱和溶质元素以第二相形式动态析出的结果。这些纳米级Mg3Bi2相可钉扎位错与再结晶晶粒晶界,从而阻碍再结晶晶粒长大。其与上述微米级Mg3Bi2相的共同作用是挤压态BAZ711合金获得细小均匀再结晶晶粒组织的主要原因。

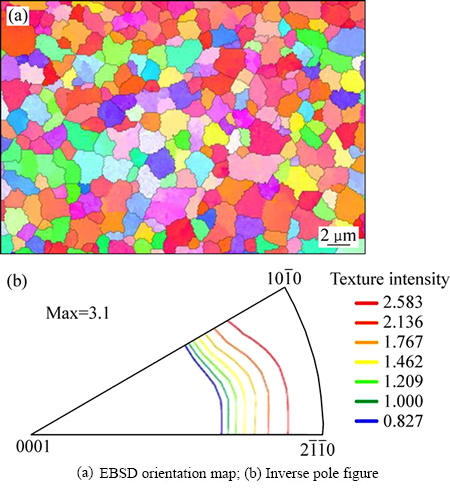

2.2.3 挤压态合金微观织构

图5(a)所示为挤压态BAZ711合金纵截面(沿挤压方向)的EBSD显微组织重构图。由图5(a)可见,挤压态合金发生了完全再结晶,平均晶粒尺寸约为2.9 μm,与前述SEM观察结果一致。相应的反极图(见图5(b))表明,挤压态合金呈现出典型的挤压纤维织构[27-28],其中大部分晶粒表现出基面取向特征,即晶粒的基面平行于挤压方向,最大织构强度为3.1。此织构的形成与挤压过程中基面滑移的塑性变形机制和动态再结晶有关[29]。部分相似变形镁合金的织构强度如表1[26, 30]所示,与已有研究结果报道相比,由于本试验中合金在挤压时发生了完全再结晶,再结晶晶粒取向随机化导致其织构强度较弱,这有助于改善合金的各向异性。

图5 挤压态BAZ711合金的EBSD显微组织重构图及对应的反极图

Fig. 5 EBSD analysis of as-extruded BAZ711 alloy

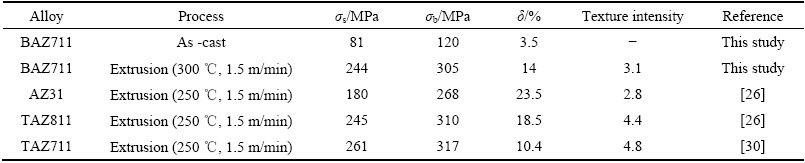

2.3 合金的铸态与挤压态室温拉伸性能

铸态和挤压态合金的室温拉伸性能总结于表1。其中,挤压态BAZ711合金的屈服强度σs,抗拉强度σb和伸长率δ分别为244 MPa、305 MPa和14%,与铸态合金(σs=81 MPa,σb=120 MPa,δ=3.5%)相比,显著提升。此外,新型低成本非稀土型BAZ711合金与部分已报道的Mg-Sn基挤压镁合金[26, 30]相比,具有与其接近的力学性能指标,特别是比相同条件下的商用AZ31镁合金具有更高的强度。

基于前述组织与织构演化规律分析可知,BAZ711合金力学性能提高的主要原因在于晶粒度变化和和微纳双尺度第二相的综合作用所致,具体可作如下分析:

1) 根据Hall-Petch(H-P)公式,σ=σ0+kd-1/2(其中σ0是摩擦应力,k是Hall-Petch系数,d为晶粒尺寸)可知合金的屈服强度与其晶粒尺寸(或者二次枝晶间距)的二次方根成反比,铸态合金的平均二次枝晶臂间距为50 μm,而挤压加工后合金的晶粒尺寸细化为3 μm,必然导致合金屈服强度大大提高。此外,还应指出上述H-P公式中的常数项σ0与Hall-Petch系数k具有取向(织构)依赖性[31-32],纤维织构强度越大(基面滑移处于硬取向),则σ0和k越大,相应屈服强度也越高,故具有典型纤维织构的挤压态BAZ711合金与具有随机取向的铸态合金相比亦对强度提高有所贡献;

2) 微纳双尺度第二相的弥散强化与析出强化作用也不容忽视,由图4微观组织的对比观察可发现固溶处理后BAZ711合金中依然有少量高熔点和高热稳定性微米级Mg3Bi2相未完全溶入基体,其在挤压中被破碎并沿着挤压方向分布,这些尺寸大小不一的微米级硬质相广泛的分布于较软的α-Mg基体上,可阻碍变形过程中位错的运动,进而提高合金的强度。与此同时,弥散分布于基体上的近球状纳米尺度Mg3Bi2颗粒的存在会致使位错在基体上第二相间滑动时需克服Orowan应力[13],从而提高合金的强度。

此外,铸态合金的塑性也在挤压后显著提高,这主要归因于以下两方面原因:

1) 铸态合金组织中在晶间呈网状分布的粗大Mg3Bi2相会造成第二相和基体之间的不连续性,当进行拉伸试验时,第二相周围易诱发位错聚集,导致裂纹源产生并扩展,从而降低合金塑性;而热挤压后BAZ711合金由于晶界周围第二相的网状形态被破坏,使得其对基体的割裂作用较铸态合金大为降低;

2) 挤压态合金中,由于晶粒均匀细小,晶界数目急剧增加,在受外力变形时,晶界附近的应力协调效应可在约束基面滑移的同时促进非基面滑移系,并且波及整个晶粒[33-36],继而有效减少晶界处的应力集中,提高伸长率。

表1 铸态与挤压态BAZ711合金力学性能与相关变形合金的对比

Table 1 Comparison of mechanical properties of extruded BAZ711 with previously reported wrought alloys

3 结论

1) 铸态BAZ711合金由在晶界呈连续网状的Mg3Bi2相和粗大的α-Mg基体组成,其平均二次枝晶臂间距约为50 μm。挤压后的合金组织则以沿挤压方向断续分布的条带状Mg3Bi2相和均匀细小的再结晶晶粒为基本特征,平均晶粒尺寸约为3 μm,同时,基体中弥散分布着大量纳米尺寸(50~200 nm)的Mg3Bi2相。

2) 与铸态合金相比,挤压态BAZ711合金的屈服强度,抗拉强度和伸长率都有显著提升,分别达到244 MPa、305 MPa和14%。

3) 挤压加工后合金强度的提升主要是细晶及微纳双尺度Mg3Bi2相共同强化作用的结果。塑性的显著改善则主要是消除晶界网状分布对基体的割裂作用和晶粒细化所致。

REFERENCES

[1] 丁文江, 付彭怀, 彭立明, 蒋海燕, 王迎新, 吴国华, 董 杰, 郭兴伍. 先进镁合金材料及其在航空航天领域中的应用[J]. 航天器环境工程, 2011, 28(2): 103-109.

DING Wen-jiang, FU Peng-huai, PENG Li-ming, JIANG Hai-yan, WANG Ying-xin, WU Guo-hua, DONG Jie, GUO Xing-wu. Advanced magnesium alloys and their applications in aerospace[J]. Spacecraft Environment Engineering, 2011, 28(2): 103-109.

[2] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[3] MATHAUDHU S N, LUO A A, NEELAMEGGHAM N R, NYBERG E A, SILLEKENS W H. Essential readings in magnesium technology[M]. New Jersey (U.S.A.): John Wiley & Sons, Inc., 2014: 333-395.

[4] AVEDESIAN M M, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys[M]. Materials Park, OH, ASM International, 1999: 274.

[5] 张新明, 彭卓凯, 陈健美, 邓运来. 耐热镁合金及其研究进展[J]. 中国有色金属学报, 2004, 14(9): 1443-1450.

ZHANG Xin-min, PENG Zhuo-kai, CHEN Jian-mei, DENG Yun-lai. Heat-resistant magnesium alloys and their development[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1443-1450.

[6] YUAN Guang-yin, SUN Yang-shan, DING Wen-jiang. Effects of bismuth and antimony additions on the microstructure and mechanical properties of AZ91 magnesium alloy[J]. Materials Science and Engineering A, 2001, 308(1/2): 38-44.

[7] WANG Ya-xiao, ZHOU Ji-xue, WANG Jie, LUO Tian-jiao, YANG Yuan-sheng. Effect of Bi addition on microstructures and mechanical properties of AZ80 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(4): 711-716.

[8] 任文亮, 李全安, 石雅静, 张兴渊. Bi 对 AZ81 镁合金组织和力学性能的影响[J]. 稀有金属与硬质合金, 2010, 38(3): 34-37.

REN Wen-liang, LI Quan-an, SHI Ya-jing, ZHANG Xing-yuan. Effect of bismuth addition on the microstructure and mechanical properties of AZ81 magnesium alloy[J]. Rare Metals and Cemented Carbides, 2010, 38(3): 34-37.

[9] HUANG Zheng-hua, LIU Wang-hanbo, QI Wen-jun, ZHOU Nan. Effects of Bi on the microstructure and mechanical property of ZK60 alloy[J]. Journal of Magnesium and Alloys, 2015, 3(1): 29-35.

[10] 张国英, 张 辉, 方戈亮, 李昱材. Bi, Sb 合金化对 AZ91 镁合金组织, 性能影响机理研究[J]. 物理学报, 2005, 54(11): 5288-5292.

ZHANG Guo-ying, ZHANG Hui, FANG Ge-liang, LI Yu-cai. A study on the mechanism of the influence of Bi, Sb alloying on microstructure and properties of AZ91 magnesium alloy[J]. Acta Physica Sinica, 2005, 54(11): 5288-5292.

[11] 周惦武, 刘金水, 卢远志, 张楚慧. Sb、Bi 合金化提高 Mg-Al 系合金抗蠕变性能的机理[J]. 中国有色金属学报, 2008, 18(1): 118-125.

ZHOU Dian-wu, LIU Jin-shui, LU Yuan-zhi, ZHANG Chu-hui. Mechanical of Sb, Bi alloying on improving heat resistance properties of Mg-Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 118-125.

[12] 刘楚明, 主修荣, 周海涛. 镁合金相图[M]. 长沙: 中南大学出版社, 2006: 256.

LIU Chu-min, ZHU Xiu-rong, ZHOU Hai-tao. Magnesium phase diagram[M]. Changsha: Central South University Press, 2006: 256.

[13] NIE Jian-feng. Precipitation and hardening in magnesium alloys[J]. Metallurgical and Materials Transactions A, 2012, 43(11): 3891-3939.

[14] 王 猛. 不同制备工艺下Mg-Bi合金及组织性能研究[D]. 沈阳: 沈阳航空航天大学, 2012.

WANG Meng. The study on the Mg-Bi alloy as well its microstructure and properties under different prepared states[D]. Shenyang: Shenyang Aerospace University, 2012.

[15] 张 辉. Mg-Bi 和 Mg-Bi-Sn 耐热镁合金的研究[D]. 太原: 太原理工大学, 2014.

ZHANG Hui. Study on as-cast Mg-Bi and Mg-Bi-Sn heat-resistant magnesium alloy[D]. Taiyuan: Taiyuan University of Technology, 2014.

[16] 张 辉, 韩 宝, 许春香, 刘 强, 王 淼. Sn 含量对二元 Mg-Bi 合金显微组织和力学性能的影响[J]. 铸造, 2014, 63(11): 1138-1141.

ZHANG Hui, HAN Bao, XU Chun-xiang, LIU Qiang, WANG Miao. Effect of Sn content on microstructure and mechanical properties of binary Mg-Bi magnesium alloy[J]. Foundry, 2014, 63(11): 1138-1141.

[17] 张 清, 李全安, 张兴渊, 周 伟. Bi合金化在耐热镁合金中的应用[J]. 铸造, 2011, 60(9): 857-859.

ZHANG Qing, LI Quan-an, ZHANG Xing-yuan, ZHOU Wei. Application of Bi alloying to heat resistant magnesium alloy[J]. Foundry, 2011, 60(9): 857-859.

[18] 赵玉华, 王 猛. Mg-Bi 合金的显微组织和力学性能[J]. 铸造, 2012, 61(7): 758-763.

ZHAO Yu-hua, WANG Meng. Microstructure and mechanical properties of Mg-Bi alloys[J]. Foundry, 2012, 61(7): 758-763.

[19] 孟恩强. 新型Mg-Bi和Mg-Bi-Ca合金的研制及组织与力学性能分析[D]. 西安: 西安理工大学, 2008.

MENG En-qiang. Development of Mg-Bi and Mg-Bi-Ca alloys and analysis of their microstructures and mechanical properties[D]. Xi’an: Xi’an University of Technology, 2008.

[20] REMENNIK S, BARTSCH I, WILLBOLD E, WITTE F, SHECHTMAN D. New, fast corroding high ductility Mg-Bi-Ca and Mg-Bi-Si alloys, with no clinically observable gas formation in bone implants[J]. Materials Science and Engineering B, 2011, 176(20): 1653-1659.

[21] SASAKI T T, OHKUBO T, HONO K. Precipitation hardenable Mg-Bi-Zn alloys with prismatic plate precipitates[J]. Scripta Materialia, 2009, 61(1): 72-75.

[22] HUMPHREYS F J. The nucleation of recrystallization at second phase particles in deformed aluminium[J]. Acta Metallurgica, 1977, 25(11): 1323-1344.

[23] YU Hui, PARK S H, YOU B S, KIM Y M, YU H S, PARK S P. Effects of extrusion speed on the microstructure and mechanical properties of ZK60 alloys with and without 1 wt% cerium addition[J]. Materials Science and Engineering A, 2013, 583: 25-35.

[24] LIU Hong-mei, CHEN Yun-gui, TANG Yong-bai, WEI Shang-hai, NIU Gao. The microstructure, tensile properties, and creep behavior of as-cast Mg-(1-10)% Sn alloys[J]. Journal of Alloys and Compounds, 2007, 440(1/2): 122-126.

[25] ROBSON J D, HENRY D T, DAVIS B. Particle effects on recrystallization in magnesium-manganese alloys: Particle- stimulated nucleation[J]. Acta Metallurgica, 2009, 57(9): 2739-2747.

[26] PARK S S, TANG W N, YOU B S. Microstructure and mechanical properties of an indirect-extruded Mg-8Sn-1Al-1Zn alloy[J]. Materials Letters, 2010, 64(1): 31-34.

[27] 丁文江, 靳 丽, 吴文祥, 董 杰. 变形镁合金中的织构及其优化设计[J]. 中国有色金属学报, 2011, 20(10): 2371-2381.

DING Wen-jiang, JIN Li, WU Wen-xiang, DONG Jie. Texture and texture optimization of wrought Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 20(10): 2371-2381.

[28] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[29] SHAHZAD M, WAGNER L. Influence of extrusion parameters on microstructure and texture developments, and their effects on mechanical properties of the magnesium alloy AZ80[J]. Materials Science and Engineering A, 2009, 506: 141-147.

[30] PARK S H, YOU B S. Effect of homogenization temperature on the microstructure and mechanical properties of extruded Mg-7Sn-1Al-1Zn alloy[J]. Journal of Alloys And Compounds, 2015, 637: 332-338.

[31] YUAN W, PANGIGRAHI S K, SU J Q, MISHRA R S. Influence of grain size and texture on Hall-Petch relationship for a magnesium alloy[J]. Scripta Materialia, 2011, 65(11): 994-997.

[32] WANG Y, CHOO H. Influence of texture on Hall-Petch relationships in an Mg alloy[J]. Acta Metallurgica, 2014, 81: 83-97.

[33] UEMATSU Y, TOKAJI K, KAMAKURA M, UCHIDA K, SHIBATA H BEKKU N. Effect of extrusion conditions on grain refinement and fatigue behaviour in magnesium alloys[J]. Materials Science and Engineering A, 2006, 434:131-140.

[34] YANG Q, GHOSH A K. Deformation behavior of ultrafine-grain (UFG) AZ31B Mg alloy at room temperature[J]. Acta Metallurgica, 2006, 54(19): 5159-5170.

[35] KOIKEA J, KOBAYASHIA T, MUKAIB T, WATANABE H, SUZUKI M, MARUYAMA K, HIGASHI K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys[J]. Acta Metallurgica, 2003, 51(7): 2055-2065.

[36] KOIKE J. New deformation mechanisms in fine-grain Mg alloy[J]. Materials Science Forum, 2003, 419(422): 189-194.

Microstructure and mechanical properties of new Mg-Bi-Al-Zn wrought magnesium alloy

MENG Shuai-ju1, YU Hui1, 4, CUI Hong-wei2, ZHANG Jing3, ZHAO Wei-min1, WANG Zhi-feng1, QIN Chun-ling1

(1. School of Materials Science and Engineering, Hebei University of Technology, Tianjin 300130, China

2. School of Materials Science and Engineering, Shandong University of Technology, Zibo 255049, China

3. School of Metallurgy and Materials Engineering, Jiangsu University of Science and Technology, Zhangjiagang 215600, China;

4. Light Metal Team, Korea Institute of Materials Science, Changwon 51508, Republic of Korea)

Abstract: In order to develop cost-effective Mg alloy without rare earth (RE) addition, the microstructural evolution of newly developed Mg-7Bi-1Al-1Zn (mass fraction, %, BAZ711) alloy was investigated by XRD, SEM, EDS, TEM and EBSD. The tensile test was also carried out to study corresponding mechanical properties. The results show that the as-cast BAZ711 alloy is consisted of α-Mg matrix with an average second dendrite arm space (SDAS) of about 50 μm and coarse Mg3Bi2 phases distributing in the grain boundaries. However, the average grain size is reduced to about 3 μm after extrusion. The extruded BAZ711 alloy with fully dynamic recrystallized (DRXed) grains contains strip-like fragmented Mg3Bi2 particles along the extrusion direction (ED), demonstrating a typical basal texture. In addition, a large amount of Mg3Bi2 precipitates with sizes ranging from 50nm to 200 nm were observed. The as-extruded BAZ711 alloy gives superior mechanical properties, a tensile yield strength of 244 MPa, an ultimate tensile strength of 305 MPa and an elongation of 14%, which is mainly due to grain refinement, and presence of micro/nano-size Mg3Bi2 particles.

Key words: magnesium alloy; extrusion; microstructure; mechanical property

Foundation item: Project(QN2015035) supported by the Research Foundation of Higher Education School Scientific Research Program from Hebei Education Department, China; Project(220056) supported by the Graduate Student Innovation Project of Hebei Province, China; Project(2015002) supported by the Outstanding Youth Scholar Science and Technology Innovation Program of Hebei University of Technology, China; Project(E2016202130) supported by the Natural Science Foundation for Excellent Young Scholars of Hebei Province, China; Project(208002) supported by the Research Foundation of Introduction Talent of Hebei University of Technology, China; Project(201510) supported by the Young Scientist Exchange Program between Korea and China of Science and Technology Department, China

Received date: 2016-02-24; Accepted date: 2016-07-19

Corresponding author: YU Hui; Tel: +86-18522233466; E-mail: yuhuidavid@126.com

(编辑 何学锋)

基金项目:河北省教育厅基金资助项目(QN2015035);河北省研究生创新项目(220056);河北工业大学优秀青年科技创新基金资助项目(2015002);河北省自然科学基金优秀青年科学基金资助项目(E2016202130);河北工业大学引进人才项目(208002);科技部“中韩青年科学家”交流计划资助项目(201510)

收稿日期:2016-02-24;修订日期:2016-07-19

通信作者:余晖,副教授, 博士;电话:18522233466;E-mail:yuhuidavid@126.com

摘 要:基于开发低成本非稀土型变形镁合金的目的,利用XRD、SEM、EDS、TEM和EBSD等检测手段对新型Mg-7Bi-1Al-1Zn(质量分数,%,BAZ711)合金的微观组织进行相关表征,同时采用万能试验机测试了其铸态及挤压态试样的力学性能。结果表明:铸态BAZ711合金中粗大的Mg3Bi2相呈连续网状分布于α-Mg枝晶晶界处,其平均二次枝晶臂间距约为50 μm;挤压态BAZ711合金发生完全再结晶,平均晶粒尺寸减小为3 μm,微米级Mg3Bi2相沿挤压方向呈条带状断续分布,同时,基体中弥散分布有大量50~200 nm的近球状或短杆状Mg3Bi2相;挤压后合金表现出典型挤压织构特征。由于组织细化和微/纳双尺度第二相的综合强化作用,挤压态合金力学性能较铸态显著提高,其拉伸屈服强度、抗拉强度和伸长率分别达到244 MPa、305 MPa和14%。

[1] 丁文江, 付彭怀, 彭立明, 蒋海燕, 王迎新, 吴国华, 董 杰, 郭兴伍. 先进镁合金材料及其在航空航天领域中的应用[J]. 航天器环境工程, 2011, 28(2): 103-109.

[2] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

[5] 张新明, 彭卓凯, 陈健美, 邓运来. 耐热镁合金及其研究进展[J]. 中国有色金属学报, 2004, 14(9): 1443-1450.

[8] 任文亮, 李全安, 石雅静, 张兴渊. Bi 对 AZ81 镁合金组织和力学性能的影响[J]. 稀有金属与硬质合金, 2010, 38(3): 34-37.

[10] 张国英, 张 辉, 方戈亮, 李昱材. Bi, Sb 合金化对 AZ91 镁合金组织, 性能影响机理研究[J]. 物理学报, 2005, 54(11): 5288-5292.

[11] 周惦武, 刘金水, 卢远志, 张楚慧. Sb、Bi 合金化提高 Mg-Al 系合金抗蠕变性能的机理[J]. 中国有色金属学报, 2008, 18(1): 118-125.

[12] 刘楚明, 主修荣, 周海涛. 镁合金相图[M]. 长沙: 中南大学出版社, 2006: 256.

[14] 王 猛. 不同制备工艺下Mg-Bi合金及组织性能研究[D]. 沈阳: 沈阳航空航天大学, 2012.

[15] 张 辉. Mg-Bi 和 Mg-Bi-Sn 耐热镁合金的研究[D]. 太原: 太原理工大学, 2014.

[16] 张 辉, 韩 宝, 许春香, 刘 强, 王 淼. Sn 含量对二元 Mg-Bi 合金显微组织和力学性能的影响[J]. 铸造, 2014, 63(11): 1138-1141.

[17] 张 清, 李全安, 张兴渊, 周 伟. Bi合金化在耐热镁合金中的应用[J]. 铸造, 2011, 60(9): 857-859.

[18] 赵玉华, 王 猛. Mg-Bi 合金的显微组织和力学性能[J]. 铸造, 2012, 61(7): 758-763.

[19] 孟恩强. 新型Mg-Bi和Mg-Bi-Ca合金的研制及组织与力学性能分析[D]. 西安: 西安理工大学, 2008.

[27] 丁文江, 靳 丽, 吴文祥, 董 杰. 变形镁合金中的织构及其优化设计[J]. 中国有色金属学报, 2011, 20(10): 2371-2381.

[28] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.