网络首发时间: 2019-09-12 10:54

加剂方式对烧结钕铁硼磁体磁性能的影响

东北大学材料科学与工程学院

宁波启元新材料科技有限公司

东北大学冶金学院

摘 要:

钕铁硼永磁材料在民用、航空航天等众多领域得到广泛的应用。高档次烧结钕铁硼磁体具有良好的市场前景。商业磁体多是由大块烧结毛坯切割而成,磁性能一致性是市场的基本要求之一,润滑剂等化学试剂和磁粉混合不均匀是影响一致性的一个重要因素。钕铁硼磁粉化学性质活泼、容易氧化,制粉的全过程都在氮气气氛下进行,没有合适的设备,想均匀加入化学试剂困难很大。研究人员因设备条件不足无法开展进一步探索。针对这个问题,项目组自行开发了专利产品“自动雾化加剂设备”。通过改变化学试剂加入方式,改善了磁粉和化学试剂混合均匀性,提高了磁体取向度,生产过程中也更好地保护了磁粉,得到内部一致性更好、磁性能更高的烧结钕铁硼磁体:剩磁(Br)=1.426 T,内禀矫顽力(Hcj)=1373.1 kA·m-1,最大磁能积((BH)max)=406.99 kJ·m-3。毛坯内部磁性能一致性的提高对后期加工成小片的商业磁体很有意义。开发的“自动雾化加剂设备”已经在烧结钕铁硼行业中得到广泛应用。

关键词:

中图分类号: TM273

作者简介:宋小明(1973-),男,内蒙赤峰人,博士,高级工程师,研究方向:稀土永磁材料,E-mail:sunnynbsxm@163.com;;*张廷安,教授;电话:024-83687715,E-mail:zta2000@163.net;

收稿日期:2019-06-22

基金:国家自然科学基金项目(51871045)资助;

Magnetic Properties of Nd-Fe-B Sintered Magnets by Chemical Reagents Adding Method

Song Xiaoming Zhang Ting'an Dou Zhihe Pei Wenli Jv Xiangming Zhou Lian

School of Materials Science and Engineering,Northeastern University

Ningbo Qiyuan New Materials Technology Co.,Ltd

School of Metallurgy,Northeastern University

Abstract:

Nd-Fe-B materials were applied widely in civil,aerospace and other fields.High properties Nd-Fe-B sintered magnets were required sustainably in the market.Most commercial magnets were cut from large blocks.Magnetic consistency was one of the fundamental market requirements.There were many reasons that affected the internal consistency of blank magnets.One of the reasons was that magnetic powders and chemical agents were mixed uneven.Nd-Fe-B powder was chemically active and easy to oxidize.The whole process of making powders was carried out in nitrogen atmosphere.There was no proper equipment,so it was very difficult to add chemical reagent evenly.The researchers were unable to research further due to inadequate equipment.In order to improve the magnetic properties and internal consistency of sintered blank magnets,new chemical reagent addition technology and new additive equipment should be developed.According to the characteristics of Nd-Fe-B powders preparation,at present,it was feasible to add multiple times and add less each time,and atomize the reagent to further improve the mixing uniformity.After a lot of experiments,new atomizing additive technology and the patented product "the auto fog-doser" were developed.The dosage,frequency,interval time and times were adjusted through the special programmable logic controller(PLC).Specially designed spiral-percussion nozzle and the corresponding pipeline combination improved the atomization effect of the reagent.The auto fog-doser worked synchronously with the jet-mill to realize that the whole surface of magnetic powder adsorbed chemical reagent.At the same time,the mixing time was reduced from 5 h to 1 h,which reduced the oxygen absorption of magnetic powder in this process.In actual operation,the spraying frequency was set for one or several times according to the fixed frequency of the jet-mill.The magnets were obtained by the dual-alloy technology and the commonly techniques of strip-casting,hydrogen crushing,jet-mill grinding,orientation molding and vacuum sintering.The cylindrical magnet of Φ10 mm×10 mm was gotten out in the center and eight apexes angle of the rectangular magnets;the magnetic properties were tested for calculating the change of different locations in the same magnets.The auto fog-doser was used in the magnets preparation process.The mixing uniformity of magnetic powder and chemical reagent was greatly improved with the increase of dosing frequency and the increase of the reagent layers.The remanence Br increased from 1.403 T to 1.426 T,with an increase of 1.64%.The maximum magnetic energy product(BH)max increased from 394.66 to 406.99 kJ·m-3,with an increase of 3.12%.The coercivity Hcj decreased from 1377.9 to 1373.1 kA·m-1,with an decrease of 0.35%.The changes of magnetic properties of the cylindrical Φ10 mm×10 mm in the center and eight apex angles of the rectangular magnets were:ΔBr=0.77%,ΔHcj=0.76%,Δ(BH)max=0.84%,the values were all less than 1%.The internal magnetic properties of the magnet had good consistency.The new atomizing additive technology and the patented product "the auto fog-doser" could improve the mixing uniformity of magnetic powder and chemical reagent.The mixing time was reduced from 5 to 1 h to better protect the magnetic powder.Nd-Fe-B sintered magnets with better internal consistency and higher magnetic properties were obtained:Br increased 1.64%,(BH)max increased 3.12%,Hcj decreased 0.35%.The change values of magnetic properties in the same magnet were all less than 1%.The internal magnetic properties of the magnet had good consistency.The internal magnetic properties consistency improvement of the blank was significant for small commercial magnets.The auto fog-doser had been applied in Nd-Fe-B sintered magnets fields.

Keyword:

sintered Nd-Fe-B magnets; lubricating agent; adding method; consistency; magnetic properties;

Received: 2019-06-22

钕铁硼永磁材料在众多领域得到广泛的应用,尤其是新能源汽车、消费电子、信息通讯、航空航天等产业的发展,需要高档次烧结钕铁硼永磁材料。应用高性能烧结钕铁硼磁体,不仅可提高磁性器件的性能,亦可实现小型化、微型化和降低能耗

根据以上问题,项目组自行开发出“自动雾化加剂设备”(已申请发明专利)。通过改变化学试剂加入方式,研究了磁粉和化学试剂混合均匀性对磁体内部一致性、剩磁等磁性能的影响,得到内部一致性更好、磁性能更高的烧结钕铁硼磁体:剩磁Br=1.426 T,内禀矫顽力Hcj=1373.1 k A·m-1,最大磁能积(BH)max=406.99 k J·m-3。开发的“自动雾化加剂设备”有助于生产高性能、高稳定性烧结钕铁硼磁体,已经得到广泛应用。

1 实验

选用工业生产烧结钕铁硼通用的各种原材料分别配制:主相合金成分(Pr,Nd)29.4Tb0.8FebalTM1.87B0.97(%,质量分数),其中TM=Co,Cu,Zr,Al,Sn,Nb;辅相合金选用含重稀土的原材料Dy79.3Fe20.7(%,质量分数)合金。Liang等

采用HELOS-RODOS型激光粒度分析仪测定合金粉末的比表面积平均粒度(SMD)和粒度分布;应用HITACHIS-4800型扫描电子显微镜(SEM)观察磁体显微组织;应用BRUKER D8 Advance(Cu Kα)型X射线衍射仪(XRD)测定磁体的X射线衍射谱线,分析取向度变化;用NIM-2000型稀土永磁磁性能测量系统测定尺寸为Φ10 mm×10 mm磁体标样的Br,Hcj,(BH)max。

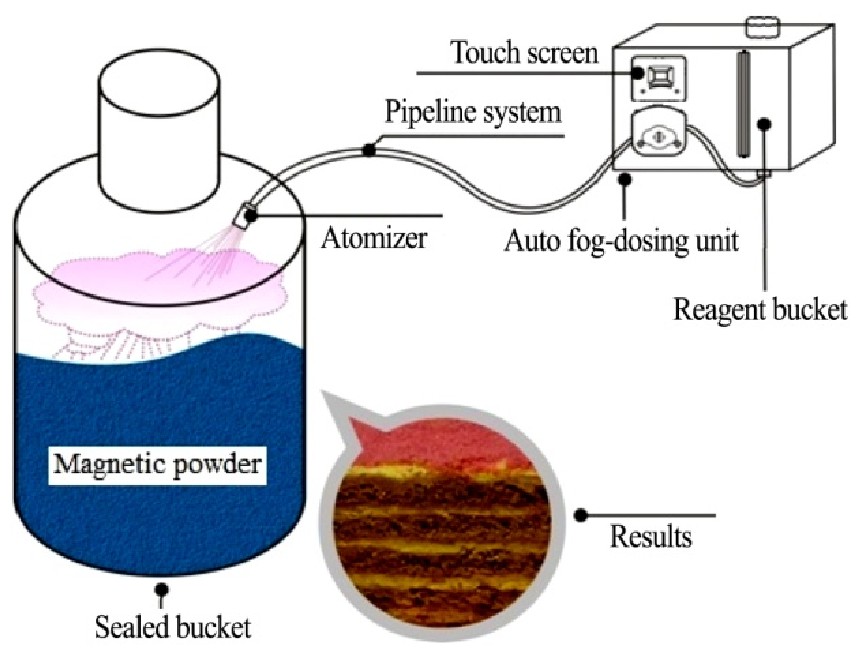

为了实现可设定的多次少量加入化学试剂的目的,项目组设计开发出“自动雾化加剂设备”,通过专有的可编程逻辑控制器(PLC)、喷嘴和管路等设计,可任意调节加剂量、频率和次数。实际工作中,根据气流磨的固定下料频率设定为:下1次料喷1次剂或者下几次料喷1次剂。其工作原理见图1。

图1 自动雾化加剂设备工作示意图

Fig.1 Schematics of auto fog-doser operating

根据项目组之前的实验结果,选取最佳细粉中加入总化学试剂的比例为0.6‰(质量分数),每次磨粉量为~150 kg。除了改变试剂加入方式和混料时间外,其他工艺条件保持不变。选用的三种试剂加入方式为:方式1:传统的制一罐粉倒一杯剂;方式2:自动雾化加剂设备与气流磨一起运行,将配好的化学试剂每62 s喷1次,喷剂量2 g/次,共喷45次;方式3:每31s喷1次,喷剂量1 g/次,共喷90次。其中31 s为该实验用气流磨的固定下料间隔时间。方式3与方式2比较,每次喷剂量减少一半,喷剂次数增加1倍。之后方式1的磁粉用三维混料机混料5 h,方式2和3混料1 h。3种粉在同等条件下继续后面的实验。

2 结果与讨论

2.1 微观结构分析

烧结钕铁硼磁体是一种结构敏感性的功能材料。成分相同的磁体,平均粒径、富Nd晶界相分布的完整性和连续性、局部大晶粒、杂质含量、取向度等因素都会影响整块烧结磁体的磁性能

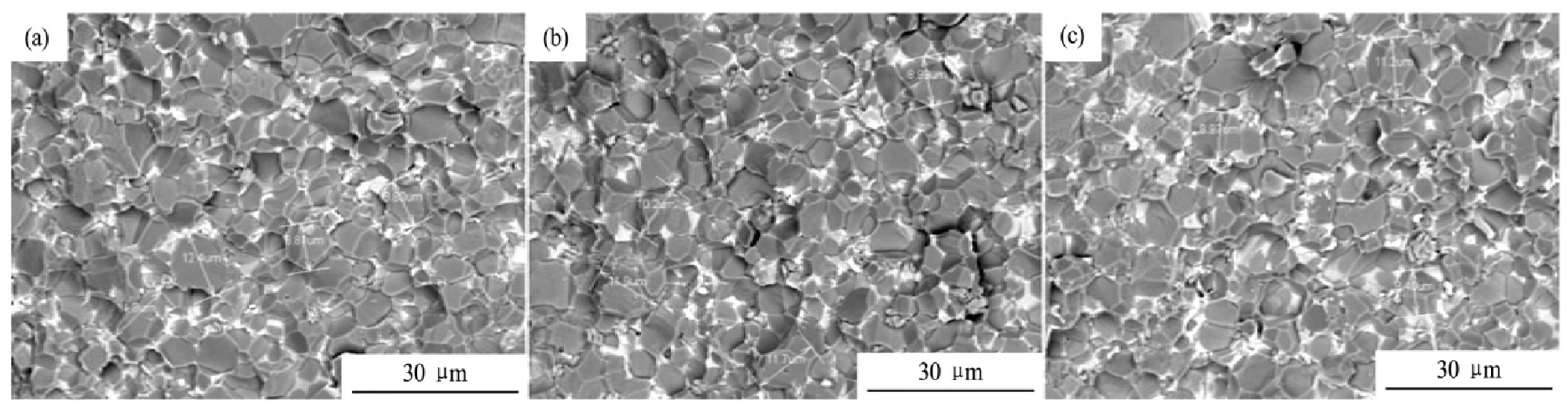

图2是3种加剂方式不同的烧结Nd-Fe-B磁体的合金断口SEM显微组织,图中亮的部分为晶界富Nd相,灰色部分为主相晶粒。对比看,3种合金的平均粒径、富Nd相分布都没有明显变化;杂质和孔洞含量很少;也都没有晶粒长大的迹象。说明加剂方式的改变没有影响磁体微观结构。

图2 不同加剂方式对应的样品SEM照片

Fig.2 SEM images of magnets prepared by different adding methods

(a)Method 1;(b)Method 2;(c)Method 3

2.2 取向度变化

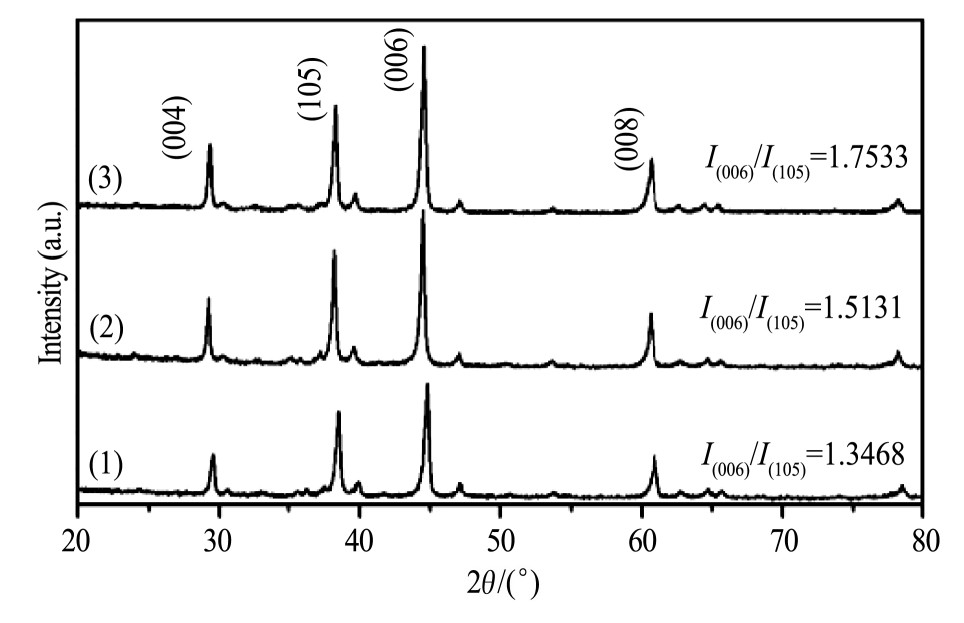

图3是3种加剂方式对应的烧结及时效处理后样品的XRD图谱,图3(1~3)谱线对应的加剂方式1,2和3。从图中可以看出主相晶体结构的衍射峰均具有较强特征峰(006),(105),各个衍射峰无明显分裂,说明烧结后磁体成分均匀。这里用(006)和(105)衍射峰强度比值I(006)/I(105)来评价各向异性烧结钕铁硼磁体的取向度

图3 不同加剂方式对应的磁体XRD图谱

Fig.3 XRD patterns of magnets prepared by different adding methods

(1)Method 1;(2)Method 2;(3)Method 3

2.3 取向度对磁性能影响

剩磁(Br)与取向度(f)等的函数关系式为:Br∝(Is?β)?{(ρρ0)?(1-α)}23?f,式中,Is是磁性相的饱和磁化强度,β是饱和磁化强度的温度系数,ρ是磁体的密度,ρ0是Nd2Fe14B的理论密度,α是非磁性相的体积分数,f是取向度

根据Br的关系式可以看出Br与f成正比。图4显示的是加剂方式1,2,3对应样品的Br,Hcj和(BH)max变化。随着加剂频率的提高:Br从1.403 T提高到1.426 T,提高了1.64%;(BH)max从394.66k J·m-3提高到406.99 k J·m-3,提高了3.12%;Hcj从1377.9 k A·m-1下降到1373.1 k A·m-1,只下降了0.35%。在取向成型工序中磁粉在磁场作用下向易取向方向转动,由于加剂频率的提高,使得化学试剂与磁粉混合均匀性更好,难取向的磁粉量减小,从而磁体取向度增加

图4 不同加剂方式对应的磁体磁性能

Fig.4 Magnetic properties of magnets prepared by different adding methods

(1)Method 1;(2)Method 2;(3)Method 3

实验得到样品的磁性能:Br=1.426 T,Hcj=1373.1 k A·m-1,(BH)max=406.99 k J·m-3。该性能的烧结钕铁硼磁体已经实现批量生产。

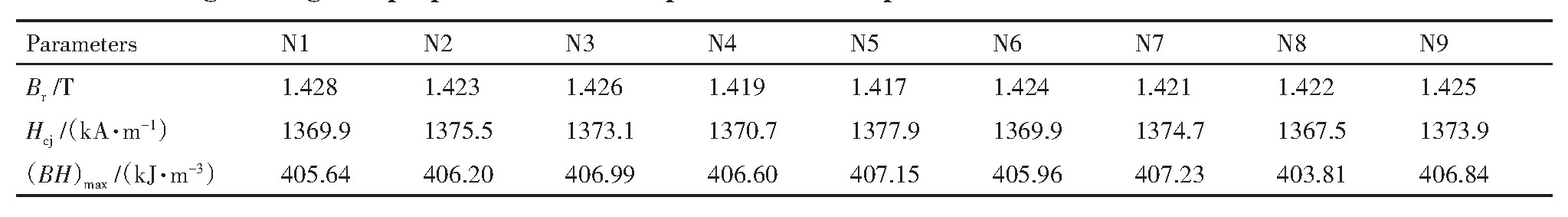

2.4 磁体内部磁性能一致性分析

为了查看同一块磁体内部磁性能的一致性,分别在长方形磁块体中心(N5)和8个顶角(N1~N4,N6~N9)的位置取出Φ10 mm×10 mm的圆柱进行磁性能测试(结果见表1)。从变化量和平均值的比值看:ΔBr=0.77%,ΔHcj=0.76%,Δ(BH)max=0.84%,均匀性较好。磁体不同位置的磁性能检测结果说明提高磁粉和化学试剂的混合均匀性有利于提高磁体内部一致性,毛坯内部磁性能一致性高对后期加工成小片商业磁体很有意义。

3 结论

开发出新型化学试剂加入技术,研制出专利产品“自动雾化加剂设备”,改善了磁粉和化学试剂混合均匀性和磁体取向度;混粉时间由5 h减少到1 h,更好地保护了磁粉,制备出内部一致性更好、磁性能更高的烧结钕铁硼磁体。制备出烧结钕铁硼磁体的磁性能中:Br提高了1.64%,(BH)max提高了3.12%,Hcj只下降了0.35%;同时磁性能波动小于1%,一致性较好。烧结毛坯内部磁性能一致性高对后期加工成小片商业磁体很有意义。研制出的“自动雾化加剂设备”已经在烧结钕铁硼行业得到批量应用。

表1 磁体中不同位置的磁性能变化 下载原图

Table 1 Change of magnetic properties at different positions of a sample

参考文献