文章编号:1004-0609(2014)05-1275-10

铜包铝复合材料研究进展

张建宇1, 2,姚金金1,曾祥勇1,韩艳秋1,吴春京1

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 河北工程大学 机电学院,邯郸 056038)

摘 要:

对铜包铝复合材料及其相关领域的研究现状进行评述。介绍铜包铝复合材料的主要制备方法、铜铝的界面结合机理、铜铝二元合金相图、金属间化合物相的形成与长大规律等方面的研究成果,并对铜包铝复合材料的发展进行展望。

关键词:

中图分类号:TB331 文献标志码:A

Research progress of copper cladding aluminum composites

ZHANG Jian-yu1, 2, YAO Jin-jin1, ZENG Xiang-yong1, HAN Yan-qiu1, WU Chun-jing1

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Mechanical and Electrical Engineering, Hebei University of Engineering, Handan 056038, China)

Abstract: The recent progress in the researches on copper cladding aluminum bimetallic composites and related research fields was reviewed. The review mainly includes the fabrication of copper cladding aluminum bimetallic composites, the bonding mechanism of Cu/Al interface, the Cu-Al binary alloy phase diagram, and the formation and growth rule of intermetallic compounds. Finally, the development trend was proposed.

Key words: copper cladding aluminum; composite; bonding mechanism; interfacial reaction

世界上铜资源的匮乏和市场价格较高,促使电工行业积极寻求代用材料。铝的资源丰富、价格低廉、密度小、导电率高,也是一种较好的导电材料。所以,在20世纪60年代就提出“以铝代铜”,用铝线作为电能传输线的导体。但是,铝的致命弱点是强度低、容易蠕变、耐蚀性能差、表面极易形成坚固的氧化膜,致使接头部分产生较大的接触电阻,难以牢固连接,从而限制了“以铝代铜”的进一步推广。铜包铝复合材料是利用复合技术使铜层和铝层在界面上实现牢固冶金结合的一种新型材料,不仅具有铜的电导率和热导率高、接触电阻低和外表美观等优点,还具有铝的密度低、价格低廉等优点[1]。铜包铝复合材料主要包括铜包铝线、铜包铝扁排、铜包铝薄带,可代替纯铜用于高频电力传输、电磁屏蔽等场合[2]。本文作者从铜包铝制备方法、铜铝界面结合机理、铜铝相图和金属间化合物,铜铝界面形成机制等几个方面,结合近年来国内外的研究成果,对铜包铝复合材料的研究现状进行了介绍,并对未来发展进行了展望。

1 铜包铝复合材料的制备方法

按照复合过程中界面是否生成液相可将铜铝复合分为两类:固相扩散复合和液相熔合复合。固相扩散复合主要是通过铜铝的固相反应扩散结合,扩散过程中没有液相生成。目前工业上广泛应用的铜包铝制备方法如轧制复合法、挤压复合法、拉拔复合法及爆炸焊复合法等都属于固相扩散复合。液相熔合结合主要是通过铜铝扩散形成的液相扩散层结合。主要制备方法包括低压铸造法和充芯连铸法,铜铝的接触反应焊接也属于液相熔合结合[3]。

1.1 轧制复合法

轧制复合法是将铜铝在一定的压力、温度作用下通过轧辊变形结合成一体。按照是否对坯料进行加热分为冷轧复合和热轧复合。这两种工艺都可以用于制备铜包铝复合材料[4-5],是目前生产铜包铝复合排/箔最主要的方法。轧制复合法具有成本低、效率高、设备少等优点。缺点是金属结合所需的轧制压下率较 大,一般在70%以上,对轧机的要求较高。为了降低轧制压下率,LI等[6]尝试将异步轧制工艺用于铜铝的复合,可在较低压下率下实现良好的界面复合。

1.2 挤压复合法

挤压复合法是对放在挤压筒内的坯料施加外力,使之从模孔流出,获得所需断面形状和尺寸的一种塑性成形方法。其中静液挤压法由于具有金属流动均 匀,产品质量好,模具磨损小等优点,在铜包铝棒坯的复合成形中得到了广泛的应用[7]。其主要缺点是生产效率低,成本高,不适合复杂断面形状材料的包覆,铜铝力学性能的较大差异,易导致波浪、竹节、芯材与包覆层容易破断等缺陷。近年来,又有研究者尝试用反向挤压、等通道角挤压等挤压方法来挤压铜包铝复合材料[8-9]。

1.3 拉拔复合法

拉拔方法是在外加拉力的作用下,使金属坯料通过模孔,从而获得相应形状和尺寸制品的塑性加工方法。主要用于其他方法制备的铜包铝复合坯的后续加工,其中包覆拉拔法[10-11]是目前国内生产铜包铝线的主要方法。由于拉拔加工时变形区内为轴向拉应力状态,故每一道次的变形量不能太大,否则容易拉断而无法实现正常加工,道次之间应实施软化退火处理。拉拔方法工艺简单,对设备要求不高且易于实现自动化。

1.4 爆炸焊复合法

爆炸焊复合法是利用炸药爆炸产生的能量,在微秒级时间内使两块金属板在碰撞点产生极高的应变速率和压力,从而实现异种材料的焊接。爆炸成形由于加载压力和界面高温持续时间极短,可避免脆性金属间化合物的生成;且其灵活性强,可实现各种异型件的复合,复合材料的结合强度高。其缺点是机械化程度低,劳动条件差,危险性高。爆炸焊可用于成形铜包铝复合板[12],也可以先制备铜包铝复合棒坯,经过后续的挤压-拉拔工艺制备铜包铝线[13]。

1.5 低压铸造法

低压铸造法是将壁厚均匀的铜管内壁进行清洗,然后在铜管内壁涂覆一层保护层,在惰性气体的保护下将铜管预热,在其内浇注铝液制备铜包铝复合坯[14]。骆俊廷等[15]用此方法制备的铜包铝复合坯经过冷挤压成功制备出铜包铝线,制品挤出后,界面相晶粒尺寸细小均匀,与铜铝两相结合良好。廖文俊等[16]将此方法制备的铜包铝复合坯经过轧制后获得铜包铝扁排。该工艺对设备要求不高,但存在的缺点如下:工艺流程长,且不连续,效率较低;界面易氧化,界面结合强度低;单根坯料长度受限,需去头尾,成材率较低等。

1.6 充芯连铸法

上述方法都存在着复杂的界面处理问题,所以均有生产流程长、成本高、环境负担大等缺点。谢建新等[17-18]提出了充芯连铸法(Core filling continuous casting,CFC)制备铜包铝复合材料,分为立式充芯连铸法和水平充芯连铸法。充芯连铸法是一种用于制备高熔点金属包覆低熔点金属复合材料的新工艺,是在连铸外层金属管壳中填充芯部金属液体并使之凝固,以实现两种金属的复合。铜包铝充芯连铸工艺过程[19]如下:外部铜层由熔铜坩埚加热和保温,并注入由结晶器和导流管构成的铸型中,凝固成外层金属管;芯部金属铝在熔铝坩埚中加热和保温,通过导流管同步浇注到外层铜管中,在一定的冷却条件和拉速下,实现铜与铝的冶金结合。充芯连铸法将芯线与覆层的成形过程以及复合过程集中在一个设备上完成,可以省略许多工序,如芯线与覆层的预成形、表面清理等。同时可以实现无氧化界面复合,获得良好的结合效果。

薛志勇等[20-21]开展了立式充芯连铸棒坯的实验研究,开发了立式充芯连铸的实验设备,并制备了d40 mm×7.5 mm的铜包铝棒坯,经过后续的静液挤压-拉拔工艺成功制备了铜包铝线,实验结果表明所制备的铜包铝线主要性能完全符合电子行业标准。臧勃林等[22]通过氮气对铜液加压,成功制备了d12 mm×2 mm的铜包铝棒坯,实验表明氮气加压可以提高铜层表面质量。苏亚军等[23]研制了水平充芯连铸设备,并制备了d30 mm×3 mm的铜包铝棒坯。罗奕兵等[24-25]用平辊轧制和带立辊的平辊轧制,将铜包铝坯料经过多道次轧制然后进行低温中间退火,再进行孔型轧制或拉拔制成铜包铝扁排。鉴于采用圆形坯料轧制生产扁排类产品时存在变形均匀性较差及轧制难度较大等问题,吴永福等[26-27]采用水平连铸法连铸了50 mm×30 mm×3 mm×R4的矩形断面铜包铝棒坯,配合3~5道次的平辊轧制,并配合拉拔精整以及退火工艺,制备了宽度60 mm、厚度8 mm的铜包铝复合扁排。本文作者[28]改进了实验室的立式充芯连铸设备,并成功制备了50 mm×14 mm×2 mm×R7的矩形扁排。

2 铜铝的界面结合机理

对于轧制、静液挤压、拉拔、爆炸焊等固相扩散结合方法,其工艺基本均分为3步[29]:首先进行结合表面的清理,包括去油,去氧化膜,使待结合表面保持清洁;然后进行塑性变形,使两组元金属的接触表面达到原子间的距离,进而形成有效结合点,此时双金属之间能够形成机械结合;最后进行扩散热处理,在该过程中通过原子的扩散形成牢固的结合。表面状况、塑性变形温度及变形程度、热处理制度是影响铜铝结合的主要因素[30-32]。

CHEN等[33]研究了冷轧铜铝板的界面断裂机制,认为铜铝界面结合强度是界面机械结合、界面相变及缺陷的综合作用结果。在热处理前阶段,金属在轧制压力下,金属表面的氧化薄膜开始破碎,露出的新鲜金属互相嵌合,当压力达到一定程度时,表面原子被激活,形成激活中心,而使新鲜质点间产生原子键结合,轧制压力越大,原子键结合面越大,孔洞越少,结合越强;在热处理阶段,原子通过扩散使结合界面在轧制过程中出现的孔洞发生闭合,原子通过化学相互作用形成化学结合键。虽然由于回复与再结晶,机械结合力降低,但总体而言,界面结合强度提高;随着扩散温度的提高和/或时间的延长,会在界面形成脆性金属间化合物,当厚度达到一定值时,会降低结合强度。另外,铜铝互扩散系数不同,导致柯肯达耳效应,进一步使结合强度下降。ABBASI等[34]研究了冷轧铜铝复合板界面金属间化合物厚度与界面结合强度的关系,发现当化合物厚度超过2.5 μm时,界面的结合强度开始下降。HUG等[35]研究发现,界面层厚度在0.5~2 μm时界面结合强度最高。

对于铸造法、连铸法等液相熔合结合,结合过程一般也可分为3步:铜铝的相互扩散、铜铝反应扩散形成金属间化合物及液态扩散层、冷却过程中界面层的相变。铜、铝的结合温度、冷却条件和表面处理方式等将影响到界面层的厚度及组织,从而影响界面结合强度[36-38]。同固相扩散结合相似,在液相熔合复合中,只当保证不是单纯机械复合时,一般情况下界面化合物层越薄,结合强度越高[38]。

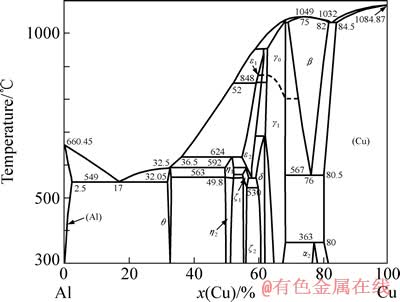

3 铜铝界面的相图与相组成

从材料连接的角度看,铜和铝是非相容性金属,在温度高于120 ℃时具有较大的亲和力,除了形成固溶体以外,还会形成各种金属间化合物。MURRAY[39]总结了铜铝之间的相平衡、相变及相结构。由于铜铝相图过于复杂,很多地方仍未确定。近年来,针对铜铝相图的研究取得了很大进展。GODECKE等[40]研究了31.5%~37.5%Cu(摩尔分数,下同)的铝铜合金,发现CuAl2通过包晶反应形成,包晶点温度为592 ℃。CuAl2的溶解度范围在549 ℃最大为32.05%~32.6%Cu,在250 ℃为32.4%~32.8%Cu。LIU等[41]利用扩散偶技术研究了40%~85% Cu的铜铝合金在500~1000 ℃的相平衡。研究发现,β0相在1000 ℃、70%Cu附近并不存在,γ1与γ0之间在62%~68%Cu、800~900 ℃时的转变不是一级相变而是二级有序相变。 共析反应γ0→β+γ1和包析反应γ0+ε1→γ1未被证实存在。RIANI等[42]结合上述数据绘出的铜铝二元合金相图如图1所示。从相图上可看出,在铜铝体系中存在14个相。(Cu)相和(Al)相是以Cu和Al为基体的2种固溶体,β(以Cu3Al为基的固溶体)、γ0、ε1、η1、θ(以CuAl2为基的固溶体),都是在液相参与下生成,γ1(以化合物Cu9Al4为基的固溶体)、α2、ε2、δ、ζ1、ζ2和η2是在固态下发生转变生成。

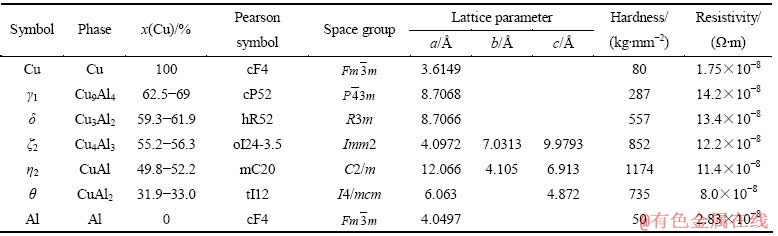

近年来,一些研究者[43-46]针对MURRAY报告中未确定的铜铝金属间化合物的晶体结构进行了测定。目前,除ε1相外,其他相的结构基本确定。另外,对其中一些金属间化合物的电、力、热等性能也进行了测量[47-49]。在铜包铝界面复合中,最常见的几种金属间化合物的晶体结构及常见性能列于表1。从表中可以看出,这些金属间化合物具有较高的硬度及脆性,过厚的脆性化合物会降低界面结合强度;另外,由于金属间化合物电阻率高于纯铜和铝的,这对材料的导电性能产生不利影响。因此为了保证获得的Cu/Al复合材料满足使用要求,在复合坯料制备与加工过程中,需要深入了解在具体制备工艺下,界面上化合物的种类、化合物生成的序列及生长动力学,才能更好地对其进行控制。

表1 Al-Cu系中金属间化合物的结构与性能[45, 47-49]

Table 1 Structure and properties of intermetallic compounds in Al-Cu system[45, 47-49]

图1 铜铝二元合金相图[42]

Fig. 1 Phase diagram of Cu-Al binary alloy[42]

4 界面相的形成机制

由A和B组成扩散偶,如果在A-B中不形成连续固溶体,扩散偶经一定时间扩散后会在A的固溶体(α相)和B的固溶体(β相)两相相遇的界面出现平衡,要求界面反应扩散才得以进行;若相图中存在中间相,则扩散偶经一定时间扩散后会形成化合物,出现化合物后扩散偶通过中间化合物层扩散要求连续的反应。这些扩散过程的连续进行都要求界面反应发生相变,这类扩散称为反应扩散或多相扩散[50]。铜包铝复合材料界面相就是通过反应扩散形成。

4.1 固相扩散结合的界面反应

铜铝扩散偶在某一温度保温并扩散一定时间后,在界面上会出现一系列相邻接相,其种类和顺序与该温度下相图中相的种类和顺序相对应。从铜铝二元合金相图看出,在363~549 ℃共晶温度范围,稳定存在5种相,从铜侧到铝侧依次为Cu9Al4、Cu3Al2、Cu4Al3、CuAl、CuAl2。FUNAMIZU等[51]在400~535 ℃温度下退火80 h后界面获得上述5种金属间化合物相。在室温363 ℃,合金中除了上述5种相外,还可能存在α2(Cu3Al)相。TAN等[52]将铜铝线键合试样在175 ℃退火1000 h后,检测发现界面上生成了以上6种相。

在实际生产条件下,固相结合的界面层厚度一般在几十微米甚至几微米以下,界面化合物层会出现某些相的缺失或生成相图上没有的相,种类和顺序随着热处理制度、原始材料及制备工艺等变化而不同。PENG等[53]对经过430 ℃热轧后的Cu/Al板在300~500 ℃和0.5~3 h范围内进行退火。在300 ℃、3 h退火条件下,在界面上只存在少量的CuAl2相,而在350 ℃、0.5 h时界面相由CuAl2和Cu9Al4组成。HENESS等[54]对相同轧制工艺的Cu/Al板在450 ℃退火,发现界面相种类随退火时间的延长而增加。处理1 h后,界面只出现CuAl2和Cu9Al4相,处理1.5 h后,在CuAl2和Cu9Al4之间又生成CuAl相,而处理3.0 h后,在变形量为60%的一些试样中,在Cu和Cu9Al4相间还发现了高温相β(Cu3Al)。CHEN等[55]将冷轧Cu/Al板在500 ℃退火3 h,发现在CuAl2和Cu9Al4之间生成CuAl和Cu4Al3。实验结果产生差异主要是各金属间化合物的生长速率差异及各相竞争生长的结果,一些相由于孕育期时间大于扩散时间没有来得及生成,或是一些相较薄,采用常规手段无法分辨。

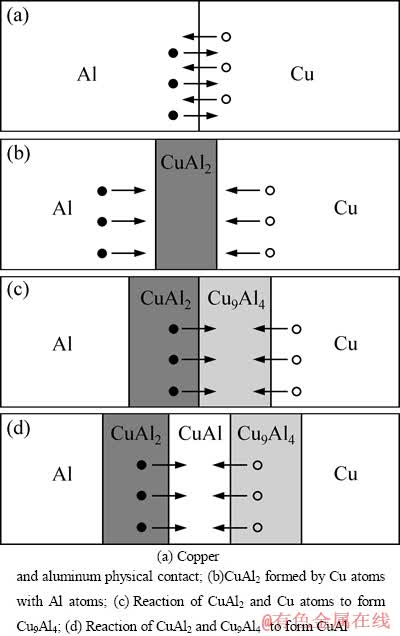

固态转变中相的生成顺序,是热力学与动力学共同作用的结果。PRETORIUS等[56]将系统的自由能变化与界面反应元素的浓度结合起来考虑,提出了有效生成热(Effective heat of formation, EHF)模型,用来预测反应界面上的最先生成相,其预测结果与实验结果比较吻合。郭亚杰等[57]用EHF理论计算了铜铝金属间化合物相的有效生成热,CuAl2的EHF值最大,因此,根据模型推测CuAl2相最先在界面上生成。对于后续相的生长,郭亚杰等认为随着扩散的进行以及CuAl2相的出现,热力学驱动力将逐渐超过动力学的限制,后续相的生成以CuAl2/Cu(Al)界面的热力学条件来推断,Cu9Al4的自由能最低,驱动力最大,作为第二相出现。最后在CuAl2与Cu9Al4之间生成CuAl相。这和众多的文献报道[53-55, 58]吻合。界面金属间化合物生长过程示意图如图2[58]所示。

图2 共晶温度以下铜铝界面反应示意图[58]

Fig. 2 Schematic diagram of interfacial reaction between copper and duminum below eutectic temperature[58]

固相结合金属间化合物生长动力学与界面化合物层厚有直接的关系,通常情况下,金属间化合物厚度x和反应时间t均符合经验公式[59]

(1)

(1)

式中:k和n分别为比例系数和时间指数。t0是单位时间,t/t0 可使指数函数无量纲化。n=1代表金属间化合物生长符合线性关系,化合物生长动力学由反应速率所控制;n=0.5代表金属间化合物生长符合抛物线关系,生长过程由元素体扩散规律控制。k与温度T的关系可以用Arrhenius公式表示

(2)

(2)

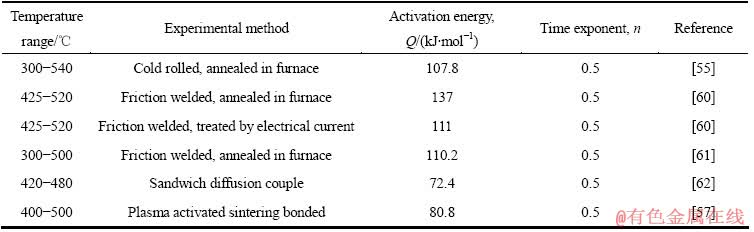

式中:k0、Q和R分别为指前因子、金属间化合物生长激活能和摩尔气体常数。表2所列为近期铜铝复合材料在300~540 ℃常见退火温度下,界面化合物生长动力学的研究结果,从表2中可看出:1) 各金属间化合物厚度与时间的关系遵循抛物线规律n=0.5,说明界面化合物生长主要由体扩散控制;2) 相同的温度范围内,不同的研究者得出的扩散激活能不同,这主要是由于原始材料、加工工艺以及测量精度的不同;3) 电场加热下的金属间化合物生长速度大于普通退火的生长速度,其机制目前仍不清楚。在铜包铝线电力传输中,由于过载经常导致温度超过200 ℃,所以电场对扩散的影响应引起高度重视。

4.2 液相熔合结合的界面反应

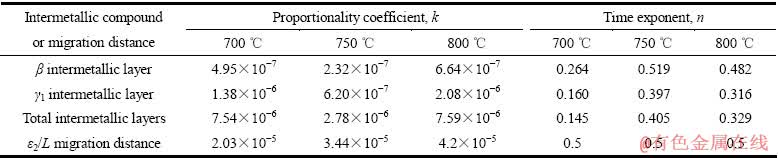

表2 铜铝固相扩散的动力学参数

Table 2 Kinetics parameter of solid diffusion between copper and aluminum

在共晶温度以上,铜铝的界面反应有液相参与或液相生成,同样遵循反应扩散规律。例如在700~800 ℃温度范围等温扩散,界面从铜侧依次为铜固溶体(Cu),金属间化合物β、γ1、ε2,铜铝液相扩散层[63]。在共晶温度549 ℃到铝熔点温度660 ℃范围内等温扩散,界面相从铜侧依次为(Cu)、铜铝液相扩散层、铜铝金属间化合物和(Al),其中金属间化合物种类与温度有关,温度不同,化合物种类不同[64]。界面层是高温反应扩散生成相在冷却过程中发生相变而形成的[59, 65],其形成过程如图3所示。

图3 共晶温度以上铜铝界面反应示意图

Fig. 3 Schematic diagram of interfacial reaction between above eutectic temperature (S: solid phase, L: liquid phase, CupAlq: copper aluminum intermetallic compound, DL: diffusion layer)

实际的铜铝液相熔合结合一般是变温过程,界面生成组织与具体的加热与冷却过程有关。KAWAKAMI等[66]将铜铝块用夹具固定好后,在氮气保护下进行高温扩散连接,从室温加热到630 ℃,加热速度为2 K/s,冷却速度为5 K/s,施加0.7 MPa的载荷,结合时间为0~900 s。得到的界面组织从铜侧为CuAl、CuAl2、(CuAl2+(Al))组织和(Al)。其中CuAl相很薄。其形成机理如下:在加热过程中,铜\铝原子在热激活下相互扩散。由于铜在铝中的扩散系数大于铝在铜中的扩散系数,铜首先向铝中扩散,界面开始出现α相,随着扩散反应的进行,当α相中Cu浓度超过固溶极限,开始出现液相。同时铜铝结合界面开始液化,铜铝发生反应扩散生成CuAl2和CuAl,当温度超过CuAl2相熔点较长时间后,CuAl2相会溶解。液相随着时间的推移,浓度梯度逐渐减少而趋于均匀化。在随后的冷却过程中,液相发生凝固形成界面层。MORENO等[67]将温度为688 ℃铝液浇入预热温度为458 ℃的铜模中,随炉冷却,通过相分析发现,界面上在铜固溶体和(CuAl2+(Al))伪共晶组织之间生成了Cu9Al4、CuAl和CuAl2 3种金属间化合物。MORENO等[67]认为界面形成过程是首先发生铜的扩散与溶解,然后由于激冷作用在铜铝界面形成CuAl2相,在铜与CuAl2相之间,通过固态反应扩散形成CuAl和Cu9Al4,铜在液态铝中形成的扩散层在随后的凝固中形成CuAl2相和伪共晶组织。SU等[68]在充芯连铸界面结合良好的铜包铝排中发现在铜固溶体(Cu)与铝固溶体(Al)之间,依次存在Cu9Al4、CuAl2 和(Al)+CuAl2伪共晶等3层组织,他们用MORENO的机理解释了铜包铝充芯连铸复合层的形成过程。并认为CuAl由于时间短,没来得及生成。

对于液相熔合结合,其界面层厚度不仅与铜铝反应扩散形成的化合物有关,而且与铜在铝形成的液相扩散层凝固有关,其中后者形成的界面层厚度占主要地位。根据质量守恒定律,液相扩散层礅度与金属间化合物/液相界面的迁移距离成正比关系,所以界面层厚度生长动力学可以用金属间化合物和金属间化合物/液相界面迁移距离的动力学联合描述[69-70]。金属间化合物的厚度均可用式(1)和(2)表示。其在700~800 ℃的动力学参数如表3所示。从表中看出,金属间化合物生长的时间指数n小于0.5,说明金属间化合物的扩散不仅受体扩散控制,而且受晶粒边界扩散控制。铜溶解厚度遵循抛物线规律n=0.5,说明铜原子在液态扩散层中主要受体扩散控制。

表3 铜铝在700~800 ℃的动力学参数[63]

Table 3 Kinetics parameters between copper and aluminum at 700-800 ℃[63]

5 结语

铜包铝复合材料由于兼有铜铝的优点,目前正逐步批量应用于汽车、电力供应设备等行业上,其发展前景非常广阔。今后的研究方向应主要集中在以下几个方面:1) 制备工艺。目前存在的铜包铝制备工艺,都各有其无法回避的缺点,需要进行工艺的改善和新工艺的开发。2) 界面机理。关于界面的反应机理、界面反应的动力学等方面,研究还不深入。3) 铜包铝的回收利用。铜包铝制品的铜铝分离回收问题,至今还没有找到具有技术经济和环保效果的方法,如果铜包铝大量应用,为了节约能源,不影响材料再利用,这个问题必须解决。

REFERENCES

[1] GIBSON A. The economics of copper clad aluminum bimetallic cables[J]. Wire & Cable Technology International, 2005, 33(4): 82-83.

[2] PERRARD W. Strategies for optimizing cable design and performance through the use of bimetallic wire[J]. Wire Journal International, 2001, 34(7): 154-159.

[3] QIAN Yi-yu, DONG Zhan-gui, MA Xin. Penetrating behavior of eutectic liquid during Al/Cu contact reactive brazing[J]. Trans Nonferrous Met Soc China, 2001, 11(5): 664-666.

[4] SHENG L Y, YANG F, XI T F, LAI C, YE H Q. Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling[J]. Composites: Part B, 2011, 42: 1468-1473.

[5] LIN Z C, HUANG T G. Hot rolling of an aluminum-copper sandwich flat strip with the three-dimensional finite element method[J]. Journal of Material Processing Technology, 2000, 99: 154-168.

[6] LI Xiao-bing, ZU Guo-yin, DING Ming-ming, MU Yong-liang, WANG Ping. Interfacial microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding and annealing[J]. Materials Science and Engineering A, 2011, 529: 485-491.

[7] RHEE K Y, HAN W Y, PARK H J, KIM S S. Fabrication of aluminum/copper clad composite using hot hydrostatic extrusion process and its material characteristics[J]. Materials Science and Engineering A, 2004, 384: 70-76.

[8] KWON H C, JUNG T K, LIM S C, KIM M S. Fabrication of copper clad aluminum wire(CCAW) by indirect extrusion and drawing[J]. Materials Science Forum, 2004, 449/452: 317-320.

[9] ZEBARDAST M, TAHERI A K. The cold welding of copper to aluminum using equal channel angular extrusion(ECAE) process[J]. Journal of Materials Processing Technology, 2011, 211: 1034-1043.

[10] 戴玉梅, 马永庆, 吴云忠. 室温包覆拉拔铜包铝线双金属结合的微观分析[J]. 材料热处理学报, 2012, 33(3): 35-39.

DAI Yu-mei, MA Yong-qing, WU Yun-zhong. Study of bimetallic bonding of copper clad aluminum wire by clad-drawing at room temperature[J]. Transactions of Materials and Heat Treatment, 2012, 33(3): 35-39.

[11] 吴云忠, 马永庆, 张 洋, 刘世永. 铜包铝线材室温拉拔变形后的显微组织和力学性能[J], 中国有色金属学报, 2006, 16(12): 2066-2070.

WU Yun-zhong, MA Yong-qing, ZHANG Yang, LIU Shi-yong. Microstructure and mechanical properties of copper clad aluminum wire by drawing at room temperature[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2066-2070.

[12] MAMALIS A G, VAXEVANIDIS N M, SZALAY A, PROHASZKA J. Fabrication of aluminum/copper bimetallics by explosive cladding and rolling[J]. Journal of Materials Processing Technology, 1994, 44: 99-117.

[13] BERSKI S, DYJA H, MARANDA A, NOWACZEWSKI J, BANASZEK G. Analysis of quality of bimetallic rod after extrusion process[J]. Journal of Materials Processing Technology, 2006, 177: 582-586.

[14] 吴运忠. 制造铜包铝排的生产方法: 中国专利, 200710011271. 7[P]. 2007-05-09.

WU Yun-zhong. Production method of copper cladding aluminum bar: China, 200710011271.7[P]. 2007-05-09.

[15] LUO Jun-ting, ZHAO Shuang-jing, ZHANG Chun-xiang. Microstructure of aluminum/copper clad composite fabricated by casting-cold extrusion forming[J]. Journal of Central South University of Technology, 2011, 18: 1013-1017.

[16] 廖文俊, 刘新宽, 王宇鑫. 高性能铜/铝复合排的制备及界面机理[J]. 同济大学学报: 自然科学版, 2012, 40(8): 1234-1238.

LIAO Wen-jun, LIU Xin-kuan, WANG Yu-xin. Preparation of High-performance Cu-Al Composite row and its interface bonding mechanism[J]. Journal of Tongji University: Nature Science, 2012, 40(8): 1234-1238.

[17] 谢建新, 吴春京, 周 成, 王自东. 一种包覆材料一次铸造连续成形设备与工艺: 中国专利, ZL01109076[P]. 2003-09-03.

XIE Jian-xin, WU Chun-jing, ZHOU Cheng, WANG Zi-dong. Continuous direct composite cast forming equipment and technology of a cladding materials: China, ZL01109076.6[P]. 2003-09-03.

[18] 谢建新, 刘新华, 刘雪峰, 苏亚军. 一种包覆材料水平连铸直接复合成形设备与工艺: 中国专刊, 200610112817.3[P]. 2008-04-02.

XIE Jian-xin, LIU Xin-hua, LIU Xue-feng, SU Ya-jun. Horizontal continuous direct composite cast forming equipment and technology of a cladding materials: China , 200610112817.3[P]. 2008-04-02.

[19] XIE Jian-xin, WU Chun-jing, LIU Xue-feng, LIU Xin-hua. A Novel forming process of copper cladding aluminum composite materials with core-filling continuous casting[J]. Materials Science Forum, 2007, 539/543: 956-961.

[20] 薛志勇, 秦延庆, 吴春京. 铜包铝复合棒充芯连铸设备的开发[J]. 北京科技大学学报, 2005, 27(6): 706-709.

XUE Zhin-yong, QIN Yan-qing, WU Chun-jing. Continuous core-filling cast equipment for the bimetal composite material of copper cladding aluminum[J]. Journal of University of Science and Technology Beijing, 2005, 27(6): 706-709.

[21] LIANG He, XUE Zhi-yong, WU Chun-jing, LIU Qing, WU Yuan. Research on continuous core-filling casting forming process of copper-clad aluminum bimetal composite material[J]. Acta Metall Sin: Engl Lett, 2010, 23(3): 206-214.

[22] 臧勃林, 赵永龙, 梁 贺, 吴春京. 铜包铝气压连铸成形工艺[J]. 特种铸造及有色合金, 2011, 31(5): 447-449.

ZANG Bo-lin, ZHAO Yong-long, LIANG He, WU Chun-jing. Preparation of copper cladding aluminum wire by continuous casting with air pressure[J]. Special casting & Nonferrous Alloys, 2011, 31(5): 447-449.

[23] SU Ya-jun, LIU Xin-hua, HUANG Hai-you, WU Chun-jing, LIU Xue-feng, XIE Jian-xin. Effects of processing parameters on the fabrication of copper cladding Aluminum rods by horizontal core-filling continuous casting[J]. Metallurgical and Materials Transaction B, 2011, 42: 104-113.

[24] 罗奕兵, 刘新华, 谢建新. 铜包铝复合棒材平辊轧制宽展变形行为[J]. 中国有色金属学报, 2009, 19(11): 1976-1981.

LUO Yi-bing, LIU Xin-hua, XIE Jian-xin. Lateral spreading deformation behavior in flat rolling of copper cladding aluminum composite rods[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1976-1981.

[25] 谢建新, 刘新华, 刘雪峰, 罗奕兵. 一种高性能铜包铝矩形横断面复合导电母排及其制备工艺: 中国专刊, 200810057668.4[P]. 2008-02-04.

XIE Jian-xin, LIU Xin-hua, LIU Xue-feng, LUO Yi-bing. Horizontal continuous direct composite cast forming equipment and technology of a cladding materials: China, ZL200610112817.3[P]. 2008-02-04.

[26] 吴永福, 刘新华, 谢建新, 王连忠, 董晓文. 矩形断面铜包铝复合材料的水平连铸直接复合成形[J]. 中国有色金属学报, 2012, 22(9): 2500-2507.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin, WANG Lian-zhong, DONG Xiao-wen. Copper cladding aluminum composite materials with rectangle section fabricated by horizontal core-filling continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2500-2507.

[27] 吴永福, 刘新华, 谢建新. 矩形断面铜包铝连铸坯轧制成形导电扁排的工艺及性能[J]. 北京科技大学学报, 2012, 34(11): 1301-1307.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin. Rolling process and properties of copper cladding aluminum flat bars using continuous casting bars with the rectangle section[J]. Journal of University of Science and Technology Beijing, 2012, 34(11): 1301-1307.

[28] 张建宇, 王屹峰, 万长清, 曾祥勇, 蔡 鹏, 吴春京. 铜包铝复合扁排立式充芯连铸设备的研制[J]. 特种铸造及有色合金, 2013, 33(3): 265-268.

ZHANG Jian-yu, WANG Yi-feng, WAN Chang-qing, ZENG Xiang-yong, CAI Peng, WU Chun-jing. Continuous cast forming machine with vertical core-filling for copper cladding aluminum composite bars[J]. Special casting & Nonferrous Alloys, 2013, 33(3): 265-268.

[29] 张胜华, 郭祖军. 铝/铜轧制复合板的界面结合机制[J]. 中南工业大学学报: 自然科学版, 1995, 26(4): 509-513.

ZHANG Sheng-hua, GUO Zu-jun. Bonding mechanism of the boundary surface of Al/Cu rolling clad sheet[J]. Journal of University of Central South Technology: Natural science, 1995, 26(4): 509-513.

[30] PENG X K, HENESS G, YEUNG W Y. Effects of sintering conditions on the bond strength of roll bonded metal laminate composites[C]//Proceedings of ICCM-11. Gold Coast, Australia, 1997: 119-125.

[31] PENG X K, HENESS G, YEUNG W Y. Effect of rolling temperature on interface and bond strength development of roll bonded copper/aluminum metal laminates[J]. Journal of Materials Science, 1999, 34: 277-281.

[32] PENG X K, WUHRER R, HENESS G, YEUNG W Y. Rolling strain effects on the interlaminar properties of roll bonded copper/aluminum metal laminates[J]. Journal of Materials Science, 2000, 35: 4357-4363.

[33] CHEN C Y, CHEN H L, HWANG W S. Influence of Interfacial structure development on the fracture mechanism and bond strength of aluminum/copper bimetal plate[J]. Materials Transactions, 2006, 47(4): 1232-1239.

[34] ABBASI M, TAHERI A K, SALEHI M T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process[J]. Journal of Alloys and Compounds, 2001, 319: 233-241.

[35] HUG E, BELLIDO N. Brittleness study of intermetallic(Cu, Al) layers in copper-clad aluminum thin wires[J]. Materials Science and Engineering A, 2011, 528: 7103-7106.

[36] 吴永福, 刘新华, 谢建新. 连铸直接成形矩形断面铜包铝复合材料界面及其在轧制中的变化[J]. 中国有色金属学报, 2013, 23(1): 191-200.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin. Interface of copper cladding aluminum composite materials with rectangle section fabricated by horizontal core-filling continuous casting and its evolvement in rolling process[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 191-200.

[37] 苏亚军, 刘新华, 吴永福, 黄海友, 谢建新, 王连忠, 董晓文. 水平连铸直接复合成形铜包铝复合材料的组织与性能[J]. 特种铸造及有色合金, 2011, 31(9): 785-790.

SU Ya-jun, LIU Xin-hua, WU Yong-fu, HUANG Hai-you, XIE Jian-xin, WANG Lian-zhong, DONG Xiao-wen. Microstructure and properties of copper cladding aluminum rod fabricated by horizontal core-filling continuous casting[J]. Special casting & Nonferrous Alloys, 2013, 31(9): 785-790.

[38] 张红安, 陈 刚. 铜/铝复合材料的固-液复合法制备及其界面结合机理[J]. 中国有色金属学报, 2008, 18(3): 414-419.

ZHANG Hong-an, CHEN Gang. Fabrication of Cu/Al compound material by solid-liquid bonding method and interface bonding mechanism[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 414-419.

[39] MURRAY J L. The aluminum-copper system[J]. International Metals Reviews, 1985, 30(5): 211-233.

[40] GODECKE T, SOMMER F. Solidification behaviour of the Al2Cu Phase[J]. Zeitschrift Fur Metallkunde, 1996, 87(7): 581-586.

[41] LIU X J, OHNUMA I, KAINUMA R, ISHIDA K. Phase equilibria in the Cu-rich portion of the Cu-Al binary system[J]. Journal of Alloys and Compounds, 1998, 264: 201-208.

[42] RIANI P, ARRIGHI L, MARAZZA R, MAZZONE D, ZANICCHI G, FERRO R. Ternary rare-earth alumimum systems with copper: A review and a contribution to their assessment[J]. Journal of Phase Equilibria and Diffusion, 2004, 25(1): 22-52.

[43] GULAY L D, HARBRECHT B. The crystal structure of ζ2-Al3Cu4-δ[J]. Z Anorg Allg Chem, 2003, 629: 463-466.

[44] GULAY L D, HARBRECHT B. The Crystal structure of ζ1-Al3Cu4[J]. Journal of Alloys and Compounds, 2004, 367: 103-108.

[45] PONWEISER N, LENGAUER C L, RICHTER K W. Re-investigation of phase equilibria in the system Al-Cu and structural analysis of the high-temperature phase η1-Al1-δCu[J]. Intermetallics, 2011, 19: 1737-1746.

[46] KISI E H, BROWNE J D. Ordering and structural vacancies in non-stoichiometric Cu-Al γ brasses[J]. Acta Crystallographica Section B, 1991, 47(6): 835-843.

[47] KOUTERS M H M, GUBBELS G H M, YUAN C A. Characterization of intermetallic compounds in Cu-Al ball bonds: mechanical properties, delamination strength and thermal conductivity[C]//Proceedings of the 13th International Conference on Thermal, Mechanical and Multi-physics Simulation and Experiments in Microelectronics and Microsystems. Lisbon, Portugal Eurosime, 2012: 1-9.

[48] BRAUNOVIC M, ALEKSANDROV N. Intermetallic compounds at aluminum-to-copper and copper-to-tin electrical interfaces[C]//Proceedings of the 38th IEEE Holm Conference on Electrical Contacts. Philadelphia, USA, 1992: 25-34.

[49] BRAUNOVIC M, RODRIGUE L, GAGNON D. Nanoindentation study of intermetallic phases in Al-Cu bimetallic system[C]//Proceedings of the 54th IEEE Holm Conference on Electrical Contacts. Orlando, FL, USA, 2008: 270-275.

[50] 余永宁. 材料科学基础[M]. 2版. 北京: 高等教育出版社, 2012: 523-524.

YU Yong-ning. Foundations of materials science and engineering[M]. 2nd ed. Beijing: Higher Education Press, 2012: 523-524.

[51] FUNAMIZU Y, WATANABE K. Interdiffusion in the Al-Cu system [J]. Transactions of the Japan Institute of Metals, 1971, 12: 147-152.

[52] TAN Y Y, YONG F K. Cu-Al IMC micro structure study in Cu Wire bonding with TEM[C]//Proceedings of the 17th IEEE Conference on Physical and Failure Analysis of Integrated Circuits. Singapore, 2010: 1-4.

[53] PENG X K, WUHRER R, HENESS G, YEUNG W Y. On the interface development and fracture behavior of roll bonded copper/aluminum metal laminates[J]. Journal of Materials Science, 1999, 34: 2029-2038.

[54] HENESS G, WUHRER R, YEUNG W Y. Interfacial strength development of roll-bonded aluminum/copper metal laminates[J]. Materials Science and Engineering A, 2008, 483/484: 740-742.

[55] CHEN C Y, wang S H. Effect of annealing on the interfacial structure of aluminum-copper joints[J]. Materials Transactions, 2007, 48(7): 1938-1947.

[56] PRETORIUS R, MARAIS T K, THERON C C. Thin film compound phase formation sequence: An effective heat of formation model[J]. Materials Science and Engineering, 1993, 10: 1-83.

[57] GUO Ya-jie, LIU Gui-wu, JIN Hai-yun, SHI Zhong-qi, QIAO Gun-jun. Intermetallic phase formation in diffusion-bonded Cu/Al laminates[J]. Journal of Materials Science, 2011, 46: 2467-2473.

[58] HSIEH C C, SHI M S, WU W. Growth of intermetallic phases in Al/Cu composites at various annealing temperatures during the ARB process[J]. Metals and Materials International, 2012, 18(1): 1-6.

[59] XU B, TONG W P, LIU C Z, ZHANG H, ZUO L, HE J C. Effect of high magnetic field on growth behavior of compound layers during reactive diffusion between solid Cu and liquid Al[J]. Journal of Materials Science and Technology, 2011, 27(9): 856-860.

[60] BRAUNOVIC M, ALEXANDROV N. Intermetallic compounds at aluminum-to-copper electrical interfaces: Effect of temperature and electric current[J]. IEEE Transactions on Components, Packaging, and Manufacturing Technology A, 1994, 17(1): 78-84.

[61] LEE W B,BANG K S, JUNG S B. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing[J]. Journal of Alloys and Compounds, 2005, 390: 212-219.

[62] MEGURO K M O, KAJIHARA M. Growth behavior of compounds due to solid-state reactive diffusion between Cu and Al[J]. Journal of Materials Science, 2012, 47: 4955-4964.

[63] TANAKA Y, KAJIHARA M, WATANABE Y. Growth behavior of compound layers during reactive diffusion between solid Cu and liquid Al[J]. Materials Science and Engineering A, 2007, 445/446: 355-363.

[64] KAWAKAMI H, SUZUKI J, FUJIWARA M, JUNNA N. Effect of bonding conditions on Al/Cu Dissimilar bonding with liquefaction by reaction diffusion in air[J]. Quarterly Journal of the Japan Welding Society, 2007, 25(1): 24-30. (in Japanese)

[65] LI Dong-gang WANG Qiang, LIU Tie, LI Guo-jian, HE Ji-cheng. Growth of diffusion layers at liquid Al-solid Cu interface under uniform and gradient high magnetic field conditions[J]. Materials Chemistry and Physics, 2009, 117: 504-510.

[66] KAWAKAMI H, NAKAJIMA J, SUZUKI J. Bonding process of Al/Cu bonding with liquefaction after solid state diffusion in air[J]. Welding International, 2007, 21(12): 836-843.

[67] MERENO J. GARRETT J. EMBURY D. A technique rapid characterization of intermetallics and interfaces[J]. Intermetallics, 1999, 7: 1001-1009.

[68] SU Ya-jun, LIU Xin-hua, HUANG Hai-you, LIU Xue-feng, XIE Jian-xin. Interfacial Microstructure and bonding strength of copper cladding aluminum rods fabricated by horizontal core-filling continuous casting[J]. Metallurgical and Materials Transactions A, 2011, 42: 4088-4099.

[69] TANAKA Y, KAJIHARA M. Numerical Analysis for migration of interface between liquid and solid phases during reactive diffusion in the binary Cu-Al system[J]. Materials Science and Engineering A, 2007, 459: 101-110.

[70] TANAKA Y, KAJIHARA M. Evaluation of interdiffusion in liquid phase during reactive diffusion between Cu and Al[J]. Materials Transactions, 2006, 47: 2480-2488.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51274038)

收稿日期:2013-03-05;修订日期:2013-12-27

通信作者:吴春京,教授;电话:010-62332605;E-mail:cjwu@mater.ustb.edu.cn

摘 要:对铜包铝复合材料及其相关领域的研究现状进行评述。介绍铜包铝复合材料的主要制备方法、铜铝的界面结合机理、铜铝二元合金相图、金属间化合物相的形成与长大规律等方面的研究成果,并对铜包铝复合材料的发展进行展望。

[10] 戴玉梅, 马永庆, 吴云忠. 室温包覆拉拔铜包铝线双金属结合的微观分析[J]. 材料热处理学报, 2012, 33(3): 35-39.

[11] 吴云忠, 马永庆, 张 洋, 刘世永. 铜包铝线材室温拉拔变形后的显微组织和力学性能[J], 中国有色金属学报, 2006, 16(12): 2066-2070.

[14] 吴运忠. 制造铜包铝排的生产方法: 中国专利, 200710011271. 7[P]. 2007-05-09.

[16] 廖文俊, 刘新宽, 王宇鑫. 高性能铜/铝复合排的制备及界面机理[J]. 同济大学学报: 自然科学版, 2012, 40(8): 1234-1238.

[17] 谢建新, 吴春京, 周 成, 王自东. 一种包覆材料一次铸造连续成形设备与工艺: 中国专利, ZL01109076[P]. 2003-09-03.

[18] 谢建新, 刘新华, 刘雪峰, 苏亚军. 一种包覆材料水平连铸直接复合成形设备与工艺: 中国专刊, 200610112817.3[P]. 2008-04-02.

[20] 薛志勇, 秦延庆, 吴春京. 铜包铝复合棒充芯连铸设备的开发[J]. 北京科技大学学报, 2005, 27(6): 706-709.

[22] 臧勃林, 赵永龙, 梁 贺, 吴春京. 铜包铝气压连铸成形工艺[J]. 特种铸造及有色合金, 2011, 31(5): 447-449.

[24] 罗奕兵, 刘新华, 谢建新. 铜包铝复合棒材平辊轧制宽展变形行为[J]. 中国有色金属学报, 2009, 19(11): 1976-1981.

[25] 谢建新, 刘新华, 刘雪峰, 罗奕兵. 一种高性能铜包铝矩形横断面复合导电母排及其制备工艺: 中国专刊, 200810057668.4[P]. 2008-02-04.

[26] 吴永福, 刘新华, 谢建新, 王连忠, 董晓文. 矩形断面铜包铝复合材料的水平连铸直接复合成形[J]. 中国有色金属学报, 2012, 22(9): 2500-2507.

[27] 吴永福, 刘新华, 谢建新. 矩形断面铜包铝连铸坯轧制成形导电扁排的工艺及性能[J]. 北京科技大学学报, 2012, 34(11): 1301-1307.

[28] 张建宇, 王屹峰, 万长清, 曾祥勇, 蔡 鹏, 吴春京. 铜包铝复合扁排立式充芯连铸设备的研制[J]. 特种铸造及有色合金, 2013, 33(3): 265-268.

[29] 张胜华, 郭祖军. 铝/铜轧制复合板的界面结合机制[J]. 中南工业大学学报: 自然科学版, 1995, 26(4): 509-513.

[36] 吴永福, 刘新华, 谢建新. 连铸直接成形矩形断面铜包铝复合材料界面及其在轧制中的变化[J]. 中国有色金属学报, 2013, 23(1): 191-200.

[37] 苏亚军, 刘新华, 吴永福, 黄海友, 谢建新, 王连忠, 董晓文. 水平连铸直接复合成形铜包铝复合材料的组织与性能[J]. 特种铸造及有色合金, 2011, 31(9): 785-790.

[38] 张红安, 陈 刚. 铜/铝复合材料的固-液复合法制备及其界面结合机理[J]. 中国有色金属学报, 2008, 18(3): 414-419.

[39] MURRAY J L. The aluminum-copper system[J]. International Metals Reviews, 1985, 30(5): 211-233.