DOI: 10.11817/j.issn.1672-7207.2018.09.026

阶段嗣后胶结充填体矿柱强度模型研究与应用

杨磊1, 2,邱景平1,孙晓刚1,邢军1

(1. 东北大学 资源与土木工程学院,辽宁 沈阳,110819;

2. 皇家墨尔本理工大学 工程学院,澳大利亚 墨尔本,3000)

摘 要:

平衡理论,建立胶结充填体矿柱侧向滑移失稳模型,考虑采场结构参数、充填材料自身特性和充填体-矿岩(柱)接触面特性的影响,分别得出胶结充填体矿柱与矿壁和非胶结充填体矿柱接触时所需强度模型。以中关铁矿为工程分析实例,开展室内充填配比试验。研究结果表明:当胶结充填体矿柱后壁与矿壁和非胶结充填体矿柱接触时,胶结充填体矿柱所需强度随阶段高度的增加分别呈对数函数和线性函数增长;中关铁矿胶结充填体矿柱所需强度为0.78~0.82 MPa,经典强度设计模型计算值偏小,需选取安全系数为1.5~3.0;推荐中关铁矿使用的充填配比为灰砂比1:10、料浆质量分数70%,抗压强度、泌水率、塌落度和流动度均能满足采矿作业需求,水泥用量与原推荐方案相比可降低45.7%。

关键词:

阶段嗣后充填采矿法;胶结充填体矿柱;强度模型;全尾砂;充填配比;

中图分类号:TU863 文献标志码:A 文章编号:1672-7207(2018)09-2316-07

Research and application on strength model of cemented backfill pillar for stage subsequent filling mining method

YANG Lei1, 2, QIU Jingping1, SUN Xiaogang1, XING Jun1

(1. School of Resources and Civil Engineering, Northeastern University, Shenyang 110819 China;

2. School of Engineering, RMIT University, Melbourne, VIC 3000, Australia)

Abstract: Limit equilibrium theory of sliding wedge was used to build a lateral sliding destabilization model of cemented backfill pillar (CBP). And the required strength models of CBP in contact with the wall and the uncemented backfill pillar were established respectively, considering stope structure parameters, characteristics of backfill and contacts properties of backfill-pillar. Then taking Zhongguan Iron Mine as the engineering example, the experiments on cemented tailings backfill were conducted in laboratory. The results show that the required strength of CBP in contact with non-cemented backfill increases linearly with higher stope height, while logarithmically in contact with orebody. The required strengths of CBP in Zhongguan Iron Mine is in the range from 0.78 MPa to 0.82 MPa. The strength designed by the traditional strength models should be multiplied by a factor of safety from 1.5 to 3.0 as the calculation results are relatively smaller. Cemented tailings backfill with 1:10 cement-to-tailings ratio and 70% solid mass fraction is recommended for Zhongguan Iron Mine, as its strength, bleeding rate, collapsed slump, and fluidity can meet the requirements of mining operation. The consumption of cement can reduce by 45.7% compared with previous recommended backfilling ratio.

Key words: stage subsequent filling mining; cemented backfill pillar; strength model; unclassified tailings; filling blending ratio

阶段空场嗣后充填采矿法在减少矿石损失贫化、控制岩爆、缓解地表沉降、提高采充效率等方面具有重要作用,正逐渐成为国内外矿山回采倾斜或急倾斜厚大矿体的首选采矿方法[1-4]。在相邻矿房回采过程中,为确保矿石能顺利采出和不被贫化,需要胶结充填体矿柱在保持自立性的同时,还能有足够的强度抵抗爆破扰动[5]。胶结充填体强度过高易造成胶凝材料不必要的浪费,增加充填成本;强度过低难以保证回采作业安全高效进行。因此,对阶段空场嗣后充填体强度进行研究具有重要意义。为合理确定采矿作业中所需的胶结充填体强度,国内外学者进行了大量研究。TERZAGHI[6]将改进的MARSTON理论用于分析充填体内应力状态分布,但主要适用于水砂充填材料。MITCHELL等[7]基于滑楔体平衡理论提出了满足自立性的充填体强度设计模型,但忽略了充填体与矿岩壁间的摩擦效应。THOMAS[8]认为充填体内应力呈拱形分布,提出了适用于充填挡墙的强度设计模型,但并未考虑充填体自身强度特性。卢平[9]针对THOMAS模型[8]的不足进行了修正,但未考虑充填体长度对所需强度的影响。蔡嗣经[10]对国内外矿山进行归纳分析,得到了充填体强度与其高度的半立方抛物线关系式。LIU等[11-13]基于充填体的本构模型,根据围岩开挖释放能量与充填体积蓄应变能相近原则,得到了考虑原岩地应力的胶结充填体强度设计公式,但未研究充填体自身尺寸的影响。LI等[14]推导了胶结充填矿柱在极限侧压状态下的三维力学强度设计模型,并针对MITCHELL方法的不足,提出了修正MITCHELL模型[15]和广义解析解法[16]用于充填体强度设计,但主要适用于一步骤胶结充填体矿柱临空侧对立面与矿壁接触时的情况。由希等[17]提出了考虑顶板垂直压力的阶段胶结充填体矿柱强度模型,但在现场实际中,矿柱由于自身沉缩性难以充分接顶作为承载结构。曹帅等[18]基于弹性力学平面应变基本假设建立了金属矿山阶段胶结充填体矿柱模型,未考虑上、下盘围岩与阶段矿柱间的摩擦效应。综上所述,人们对胶结充填体强度设计模型的研究已取得丰富成果,但对多因素(如采场尺寸、接触特性等)协同作用下的阶段空场嗣后胶结充填体矿柱所需强度研究较少。因此,本文作者根据滑楔体极限平衡理论,考虑采场结构参数、充填材料自身特性和充填体-矿岩(柱)接触特性的影响,建立阶段空场嗣后充填法中一步骤采场胶结充填体矿柱所需强度数学计算模型。以中关铁矿为工程实例,计算矿山阶段胶结充填体矿柱所需强度,开展全尾砂胶结充填体室内试验,以抗压强度、流动性和泌水率为评价指标,确定满足矿山开采需求的合理充填配比,以便为类似金属矿山阶段空场嗣后充填采矿开采提供理论参考。

1 阶段胶结充填体矿柱力学模型理论分析

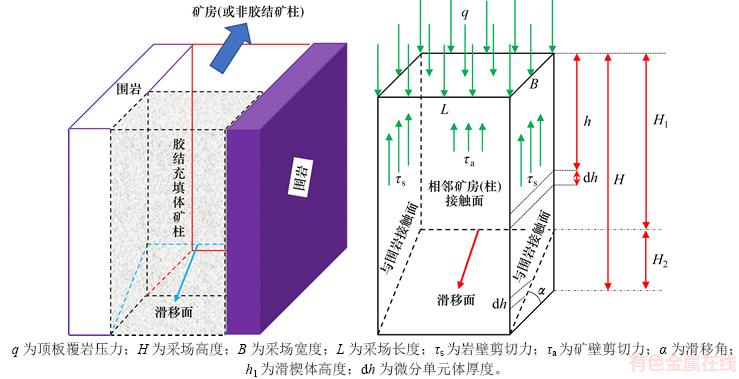

二步采矿房回采后,胶结充填体矿柱出现临空面,其破坏方式主要为表面脱落和在剪切力的作用下产生深部滑动面,相应的滑移失稳模型如图1所示。胶结充填体矿柱相对的2个面与上、下盘围岩接触,临空侧对立面(后壁)与相邻矿房或非胶结充填体矿柱接触。在黏结力和摩擦力的作用下,采场围岩与充填体产生剪切力[19]。

图1 充填体矿柱侧向滑移失稳力学模型

Fig. 1 Destabilization model of backfill pillar with an exposed face

1.1 后壁与相邻矿房接触

考虑到胶结充填体遵循摩尔-库仑破坏准则,并忽略矿壁水平应力对充填体之间的影响,则充填体与岩壁和与矿壁间的剪切力τs和τa分别为[16]:

(1)

(1)

(2)

(2)

式中:ca为充填体与矿壁之间的黏结力;cs为充填体与岩壁之间的黏结力; 为岩壁与充填体间的侧向水平应力;

为岩壁与充填体间的侧向水平应力; 为充填体与岩壁摩擦角,

为充填体与岩壁摩擦角, ≤

≤ ;

; 为充填体内摩擦角。

为充填体内摩擦角。

(3)

(3)

式中:ra为比例系数,ra=0~1;c为充填体内聚力。

(4)

(4)

式中:rs为比例系数,rs=0~1。

岩壁与充填体间的侧向水平应力 可表示为[20]

可表示为[20]

(5)

(5)

式中: 为充填体容重;K为朗肯主动侧压力系数,

为充填体容重;K为朗肯主动侧压力系数,  。

。

充填体与岩壁之间的剪切力Ss为

(6)

(6)

式中: ;

; 为滑移角,

为滑移角, 。

。

充填体与矿壁之间的剪切力Sa为

(7)

(7)

根据滑楔块平衡理论,在平行滑移面和垂直滑移面方向上充填体处于受力平衡状态。此时,安全系数FS的表达式为

(8)

(8)

则所需的充填体内聚力c为

(9)

(9)

式(8)和式(9)中的 为

为

(10)

(10)

当充填体与岩壁内摩擦角 趋于0时,

趋于0时,

(11)

(11)

内聚力与胶结充填体所需强度(SUC)满足

(12)

(12)

将式(9)代入式(12),可得胶结充填体矿柱与矿房接触时所需强度为

(13)

(13)

1.2 后壁与非胶结充填体矿柱接触

当胶结充填体矿柱后壁与非胶结充填体矿柱接触时,作用在后壁上的水平压力可由下式计算[21]:

(14)

(14)

式中: 为非胶结充填体容重。

为非胶结充填体容重。

胶结充填体矿柱与岩壁间的剪切力仍可用式(6)计算,此时安全系数FS表达式为

(15)

(15)

式中: ;

; 。

。

充填体内聚力为

(16)

(16)

将式(16)代入式(12)可得阶段胶结充填体矿柱与非胶结充填体矿柱接触时所需强度为

(17)

(17)

2 工程实例分析

中关铁矿隶属河北钢铁集团,地处河北省沙河市白塔镇中关村附近,地势标高+200~+270 m。矿山水文地质条件复杂,实施了帷幕注浆堵水工程,地表村庄较多、构建筑物密集。矿山以倾斜厚大矿体为主,平均品位(质量分数)高达46%,属大型优质铁矿山[22]。矿体上覆岩层为第四系松散沉积物、砂岩和结晶灰岩等,下盘围岩主要为蚀变闪长岩和大理岩、局部为矽卡岩。为保证注浆帷幕的稳定性和控制地表沉陷,南区一期开采范围(-350 m中段至-110 m中段)采用阶段空场嗣后充填采矿法进行回采,阶段高度为60 m,采场长度和宽度分别为50 m和18 m。原充填方案由工程类比法确定,设计灰砂比为1:5、料浆质量分数为73%。

2.1 中关铁矿胶结充填体矿柱强度设计

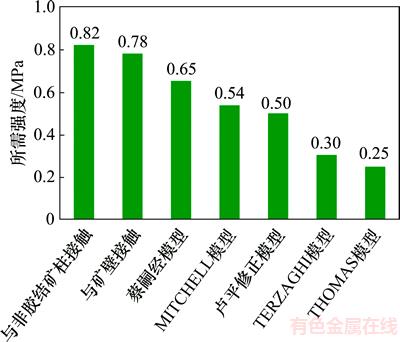

考虑到阶段胶结充填体矿柱后壁在回采过程中出现不同的接触情况,分别计算其所需强度。充填体容重为18 kN/m3,内摩擦角为30°,充填体与岩壁接触面摩擦角为15°,ra和rs分别取0.2和0.5,安全系数FS取1.5,非胶结充填体容重取16 kN/m3。现场实际中充填料浆因脱水沉缩难以完全接顶,设其顶部与采场顶板间留有0.5 m空区。将上述参数和采场尺寸分别代入式(15)和式(19)可得胶结充填体矿柱与矿房和非胶结充填体矿柱接触时的所需强度分别为0.78 MPa和0.82 MPa。图2所示为不同充填体强度模型计算结果,经典强度设计模型计算值为0.25~0.65 MPa,仍需选取1.5~3.0的安全系数。

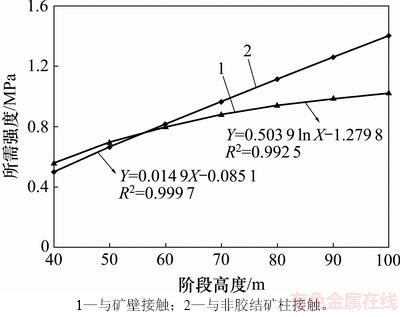

图3所示为考虑不同接触面特性时胶结充填体矿柱所需强度的变化曲线。由图3可知:当采场高度小于60 m时,2种接触特性所需的强度较接近;当阶段高度大于60 m时,与矿壁接触的强度增长趋势逐渐变缓,整体呈对数函数规律增长,而与非胶结充填体矿柱接触时所需强度呈线性函数规律增长;当阶段高度为100 m时,与矿壁接触所需强度为1.0 MPa,与非胶结充填体矿柱接触的强度为1.4 MPa。这是因为式(14)忽略了矿壁与充填体间的水平应力,且随着阶段高度的增加,胶结充填体与矿壁间接触面积增加,增大了摩擦阻力。

图2 不同模型所需强度计算结果对比

Fig. 2 Comparisons of required strength obtained from different models

图3 不同接触特性时胶结充填体矿柱所需强度变化图

Fig. 3 Required strength of cemented tailings backfill with different contacts

2.2 中关铁矿充填配比与强度试验

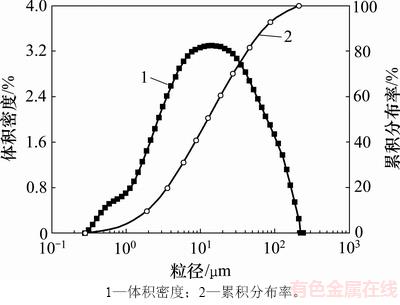

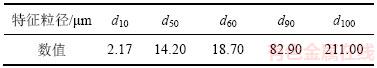

中关铁矿尾砂属超细全尾砂,粒径分布和特征粒径如图4和表1所示。采用全尾砂与硅酸盐水泥(GB 175—2007)制备料浆质量分数分别为65%,68%,70%和73%,灰砂比分别为1:10,1:8,1:6和1:4的16组胶结充填体试块,放入温度为(20±1) ℃、相对湿度为95%以上的YH-40B 型养护箱中养护28 d后,利用YAW-2000型压力试验机进行单轴抗压强度试验,结果如图5所示。

图4 中关铁矿全尾砂粒径分布图

Fig. 4 Particle size distribution of Zhongguan Iron Mine unclassified tailings

表1 中关铁矿全尾砂特征粒径

Table 1 Particle size characteristics of Zhongguan Iron Mine unclassified tailings

由图5可知:在充填体质量分数为65%~73%,灰砂比大于1:10时,充填体28 d单轴抗压强度为1.17~2.97 MPa,均高于所需强度(0.82 MPa);当灰砂比为1:10时,质量分数为65%的充填体28 d强度仅为0.75 MPa,略小于胶结充填体矿柱所需强度。考虑爆破扰动等采矿作业的影响及保证一定的堆放安全储备,可适当提高安全系数。因此,初步推荐中关铁矿充填灰砂比为1:10,料浆质量分数为68%~73%。

图5 28 d单轴抗压试验结果

Fig. 5 Results of 28 d uniaxial compressive tests

2.3 中关铁矿充填料浆输送性能试验

在实际中,不仅需要充填具有足够的强度满足回采需求,而且需要其具有良好的输送性能,从而顺利充填至采空区。为研究初步确定的充填配比方案的合理性,在28 d单轴抗压强度试验基础上,分别对其进行流动度、塌落度和泌水率试验,以确保上述配比方案能满足输送要求。

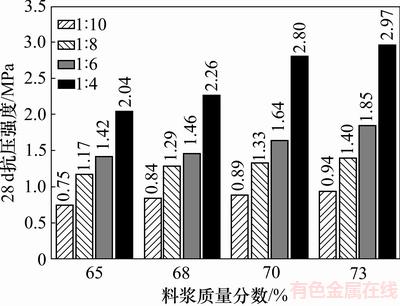

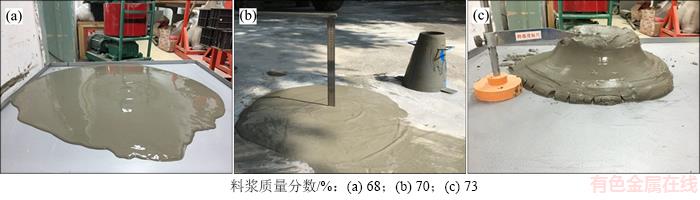

利用水泥胶砂流动度测试仪对灰砂比为1:10、质量分数为68%~73%的充填料浆进行流动度测试,结果如图6所示。由图6可知:当料浆质量分数为68%时,流动度为279.5 mm,浆体厚度为5 mm,流动性能很好,但出现轻微的离析现象;当料浆质量分数为70%时,充填体流动度为268.0 mm,浆体厚度为8 mm,流动性及均匀性较好;当料浆质量分数为73%时,中心堆积层高度为30 mm,流动性很差。一般认为,充填料浆流动度在200.0 mm以上是合理的。

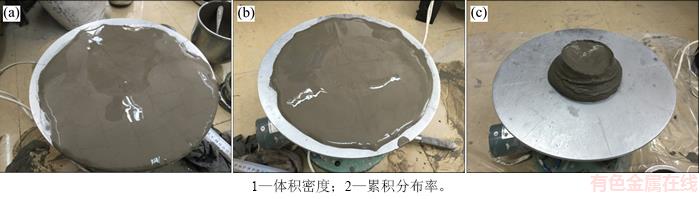

分别对初步确定的3种配比方案充填料浆进行塌落度试验,结果如图7所示,对应的塌落度分别为26.5,24.0和19.0 cm。由图7可知:结合国内外矿山生产经验,当充填料浆塌落度大于24 cm时,料浆输送性能良好,可实现自流输送;当小于24 cm时,需采用活塞泵加压方进行管道输送;充填体为68%~70%时的充填料浆保水性能较好,未出现明显的离析分层现象。

图6 充填料浆流动度试验结果

Fig. 6 Fluidity test results of backfilling slurry

图7 充填料浆塌落度试验结果

Fig. 7 Collapsed slump test results of backfilling slurry

图8 充填料浆自然沉降曲线

Fig. 8 Natural sedimentation curves of backfilling slurry

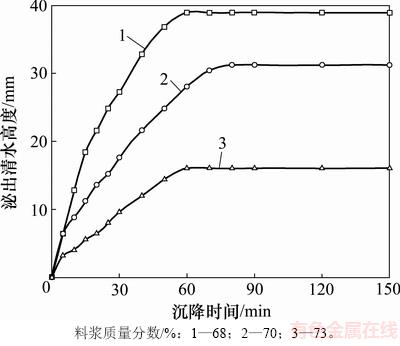

充填料浆在自然沉降的过程中因含水量和水泥量不同,表面出现程度不一的泌水现象。泌水率反映了充填料浆的析水性能,实际上也是其保水性能的体现。配制灰砂比为1:10、质量分数为68%~73%的充填料浆,充分混匀后注入500 mL的量筒中。为防止水分蒸发影响计算结果,在量筒口处包裹保鲜膜,自然沉降24 h 之后,吸出上层泌出清水并计算体积,泌水量与试验总含水量之比即为泌水率,对应的自然沉降曲线如图8所示。经计算可得,上述3种充填料浆的泌水率分别为7.29%,25.38%和12.56%。充填料浆进入采空区后泌水率要尽可能地小,从而提高充填接顶率并减少井下污染。国内外矿山充填采矿经验表明,泌水率应低于15%[23]。

综上可知,推荐灰砂比为1:10、料浆质量分数为70%的充填配比方案。该方案28 d抗压强度为0.89 MPa,流动度为268 mm,塌落度为24 cm,泌水率为12.56%。能够送采用自流输送的方式充填至采空区,保水性能良好,在相邻矿房的开挖扰动中能保持良好的稳定性。与原设计方案相比,节省水泥用量45.7%。

3 结论

1) 基于滑楔体极限平衡理论,考虑采场尺寸、充填材料自身特性和充填体-矿岩(柱)接触特性的影响,分别得出了阶段胶结充填体矿柱后壁与矿房和非胶结充填体矿柱相接时的强度设计数学模型。当后壁与矿房接触时,所需强度随阶段高度的增加呈对数函数增大;当后壁与非胶结充填体矿柱相接时,所需强度与阶段高度呈线性正相关。

2) 将计算模型用于中关铁矿工程实际,得到南区一期开采范围内阶段胶结充填体矿柱后壁与矿房和非胶结充填体矿柱接触时所需强度分别为0.78 MPa和0.82 MPa。经典充填体强度模型设计值为0.25~0.65 MPa,需选取1.5~3.0的安全系数。

3) 经中关铁矿全尾砂胶结充填体强度与输送性能试验验证,推荐使用的充填配比如下:灰砂比为1:10,料浆质量分数为70%。该配比充填体28 d单轴抗压强度为0.89 MPa,流动度、塌落度和泌水率分别为268 mm,24 cm和12.56%,能够满足回采和输送要求。水泥用量与原推荐方案相比降低了45.7%。

参考文献:

[1] GHIRIAN A, FALL M. Coupled thermo-hydro-mechanical- chemical behaviour of cemented paste backfill in column experiments (part I): physical, hydraulic and thermal processes and characteristics[J]. Engineering Geology, 2013, 164: 195-207.

[2] YILMAZ E, BELEM T, BENZAAZOUA M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill[J]. Engineering Geology, 2014, 168: 23-37.

[3] YIN Shenghua, WU Aixiang, HU Kaijia, et al. The effect of solid components on the rheological and mechanical properties of cemented paste backfill[J]. Minerals Engineering, 2012, 35: 61-66.

[4] CIHANGIR F, ERCIKDI B, KESIMAL A, et al. Utilisation of alkali-activated blast furnace slag in paste backfill of high-sulphide mill tailings: effect of binder type and dosage[J]. Minerals Engineering, 2012, 30: 33-43.

[5] QIU Jingping, YANG Lei, SUN Xiaogang, et al. Strength characteristics and failure mechanism of cemented super-fine unclassified tailings backfill[J]. Minerals, 2017, 7(4): 58.

[6] TERZAGHI K V. Theoretical soil mechanics [M]. New York: John Wiley and SonsInc, 1943: 1-49.

[7] MITCHELL R J, OLSEN R S, SMITH J D. Model studies on cemented tailings used in mine backfill[J]. Canadian Geotechnical Journal, 2011, 19(1): 14-28.

[8] THOMAS E G. Fill technology in underground metalliferous mines[D]. Vancouver: University of British Columbia. Department of Mineral Engineering, 1979: 10-50.

[9] 卢平. 胶结充填矿柱强度的设计[J]. 江西有色金属, 1990, 4(2): 48-53.

LU Ping. Strength design of cemented tailings backfill[J]. Nonferrous metals of Jiangxi, 1990, 4(2): 48-53.

[10] 蔡嗣经. 矿山充填力学基础[M]. 北京: 冶金工业出版社, 2009: 185-188.

CAI Sijing. Foundation of backfill mechanics in mine[M]. Beijing: Metallurgical Industry Press, 2009: 185-188.

[11] LIU Zhixiang, LAN Ming, XIAO Siyou, et al. Damage failure of cemented backfill and its reasonable match with rock mass[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 954-959.

[12] 柯愈贤, 王新民, 张钦礼, 等. 基于全尾砂充填体非线性本构模型的深井充填强度指标[J]. 东北大学学报(自然科学版), 2017, 38(2): 280-283.

KE Yuxian, WANG Xinmin, ZHANG Qinli, et al. Strength determination of crude tailings backfill in deep mine based on non-linear constitutive model[J]. Journal of Northeastern University(Natural Science), 2017, 38(2): 280-283.

[13] 贺桂成, 刘生龙, 黄炳香, 等. 废石胶结充填体与砂页岩合理匹配研究[J]. 采矿与安全工程学报, 2017, 34(2): 371-377.

HE Guicheng, LIU Shenglong, HUANG Bingxiang, et al. Reasonable matching for cemented waste rock backfill and sand shale[J]. Journal of Mining and Safety Engineering, 2017, 34(2): 371-377.

[14] LI L, AUBERTIN M, BELEM T. Erratum: formulation of a three dimensional analytical solution to evaluate stresses in backfilled vertical narrow openings[J]. Canadian Geotechnical Journal, 2006, 43(3): 338-339.

[15] LI L, AUBERTIN M. A modified solution to assess the required strength of exposed backfill[J]. Canadian Geotechnical Journal, 2012, 49(8): 994-1002.

[16] LI L. Generalized solution for mining backfill design[J]. International Journal of Geomechanics, 2013, 14(3): 04014006-1-04014006-11.

[17] 由希, 任凤玉, 何荣兴, 等. 阶段空场嗣后充填胶结充填体抗压强度研究[J]. 采矿与安全工程学报, 2017, 34(1): 163-169.

YOU Xi, REN Fengyu, HE Rongxing, et al. Research on compressive strength of cemented filling body in subsequent filling at the stage of open stope[J]. Journal of Mining & Safety Engineering, 2017, 34(1): 163-169.

[18] 曹帅, 杜翠凤, 谭玉叶, 等. 金属矿山阶段嗣后充填胶结充填体矿柱力学模型分析[J]. 岩土力学, 2015, 36(8): 2370-2376.

CAO Shuai, DU Cuifeng, TAN Yuye, et al. Mechanical model analysis of consolidated filling pillar using stage-delayed backfill in metal mines[J]. Rock and Soil Mechanics, 2015, 36(8): 2370-2376.

[19] LI L, AUBERTIN M. Numerical investigation of the stress state in inclined backfilled stopes[J]. International Journal of Geomechanics, 2009, 9(2): 52-62.

[20] LI L, AUBERTIN M. A three-dimensional analysis of the total and effective stresses in submerged backfilled stopes[J]. Geotechnical & Geological Engineering, 2009, 27(4): 559-569.

[21] YANG Zhiqiang, ZHAI Shuhua, GAO Qian, et al. Stability analysis of large-scale stope using stage subsequent filling mining method in Sijiaying iron mine[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2015, 7(1): 87-94.

[22] 师文豪, 杨天鸿, 常宏, 等. 中关铁矿工作面顶板突水机理及防治对策[J]. 采矿与安全工程学报, 2016, 33(3): 403-408.

SHI Wenhao, YANG Tianhong, CHANG Hong, et al. Water-inrush mechanism and countermeasure for the roof of working face in Zhongguan iron mine[J]. Journal of Mining & Safety Engineering, 2016, 33(3): 403-408.

[23] 杨磊, 王静波, 邱景平, 等. 基于正交试验的全尾砂胶结充填材料配比优化[J]. 矿产保护与利用, 2017(3): 21-25.

YANG Lei, WANG Jingbo, QIU Jingping, et al. Ratio optimization of unclassified tailings cemented backfill material based on orthogonal experiment[J]. Conservation and Utilization of Mineral Resources, 2017(3): 21-25.

(编辑 刘锦伟)

收稿日期:2017-09-13;修回日期:2017-11-21

基金项目(Foundation item):国家自然科学基金资助项目(51774066);十三五国家重点研发课题(2018YFC0604604)(Project(51774066) supported by the National Natural Science Foundation of China; Project(2018YFC0604604) supported by the National Key Point Research and Invention Program of the Thirteenth)

通信作者:邱景平,博士,副教授,从事充填采矿及资源综合利用研究;E-mail: qiujingping@mail.neu.edu.cn

摘要:利用滑楔体极限平衡理论,建立胶结充填体矿柱侧向滑移失稳模型,考虑采场结构参数、充填材料自身特性和充填体-矿岩(柱)接触面特性的影响,分别得出胶结充填体矿柱与矿壁和非胶结充填体矿柱接触时所需强度模型。以中关铁矿为工程分析实例,开展室内充填配比试验。研究结果表明:当胶结充填体矿柱后壁与矿壁和非胶结充填体矿柱接触时,胶结充填体矿柱所需强度随阶段高度的增加分别呈对数函数和线性函数增长;中关铁矿胶结充填体矿柱所需强度为0.78~0.82 MPa,经典强度设计模型计算值偏小,需选取安全系数为1.5~3.0;推荐中关铁矿使用的充填配比为灰砂比1:10、料浆质量分数70%,抗压强度、泌水率、塌落度和流动度均能满足采矿作业需求,水泥用量与原推荐方案相比可降低45.7%。

[6] TERZAGHI K V. Theoretical soil mechanics [M]. New York: John Wiley and SonsInc, 1943: 1-49.

[9] 卢平. 胶结充填矿柱强度的设计[J]. 江西有色金属, 1990, 4(2): 48-53.

[10] 蔡嗣经. 矿山充填力学基础[M]. 北京: 冶金工业出版社, 2009: 185-188.

[12] 柯愈贤, 王新民, 张钦礼, 等. 基于全尾砂充填体非线性本构模型的深井充填强度指标[J]. 东北大学学报(自然科学版), 2017, 38(2): 280-283.

[13] 贺桂成, 刘生龙, 黄炳香, 等. 废石胶结充填体与砂页岩合理匹配研究[J]. 采矿与安全工程学报, 2017, 34(2): 371-377.

[17] 由希, 任凤玉, 何荣兴, 等. 阶段空场嗣后充填胶结充填体抗压强度研究[J]. 采矿与安全工程学报, 2017, 34(1): 163-169.

[18] 曹帅, 杜翠凤, 谭玉叶, 等. 金属矿山阶段嗣后充填胶结充填体矿柱力学模型分析[J]. 岩土力学, 2015, 36(8): 2370-2376.

[22] 师文豪, 杨天鸿, 常宏, 等. 中关铁矿工作面顶板突水机理及防治对策[J]. 采矿与安全工程学报, 2016, 33(3): 403-408.

[23] 杨磊, 王静波, 邱景平, 等. 基于正交试验的全尾砂胶结充填材料配比优化[J]. 矿产保护与利用, 2017(3): 21-25.