文章编号:1004-0609(2007)08-1266-07

不同环境条件下铝合金微弧氧化陶瓷膜的摩擦磨损性能

王 远1,王美玲2,周 飞1,丁红燕1,戴振东1

(1. 南京航空航天大学 高新技术研究院 仿生结构及材料防护研究所,南京 210016;

2. 南京航空航天大学 材料科学与技术学院,南京 210016)

摘 要:

在2A12铝合金表面通过微弧氧化制备氧化铝陶瓷膜。用X射线衍射仪分析薄膜的相构成,用涡流测厚仪测量膜层的厚度,用自动转塔显微硬度计测量薄膜的显微硬度,利用微摩擦磨损试验机研究Al2O3薄膜/Si3N4球在干摩擦及水润滑下的摩擦磨损特性,用非接触表面三维形貌仪测量薄膜的磨损体积,并采用扫描电镜观察磨痕的表面形貌。结果表明:2A12铝合金微弧氧化陶瓷膜主要由α-Al2O3相和γ-Al2O3相组成;干摩擦时,薄膜主要发生磨粒磨损和疲劳磨损,摩擦因数随法向载荷和滑行速度的增大分别从0.79和0.82增加到0.87,磨损率则分别从4.07×10?5mm3/(N?m)和4.36×10?5mm3/(N?m)增加到9.69×10?5mm3/(N?m);水润滑时,薄膜主要发生摩擦化学磨损和疲劳磨损,摩擦因数随法向载荷和滑行速度的增大分别从0.69和0.67下降到0.65,磨损率则分别从3.84×10?5mm3/(N?m)和2.89×10?5mm3/(N?m)增加到4.47×10?5mm3/(N?m);薄膜在干摩擦时的摩擦因数和磨损率都大于相同实验参数下水润滑时的摩擦因数和磨损率,表明水介质有效地改善了体系的摩擦条件,降低了薄膜的磨损。

关键词:

中图分类号:TG 174.45 文献标识码:A

Tribological properties of ceramic coating prepared by

micro-arc oxidation for aluminum alloys in various environments

WANG Yuan1, WANG Mei-ling2, ZHOU Fei1, DING Hong-yan1, DAI Zhen-dong1

(1. Institute of Bio-inspired Structure and Surface Engineering, Academy of Frontier Science,Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. School of Materials Science and Engineering,Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: The alumina ceramic coating was prepared by micro-arc oxidation (MAO) technique on 2A12 Al alloy. The phase structure of Al2O3 coating was analyzed by X-ray diffractometry, its thickness was measured using MINITEST1100 equipment, and its micro-hardness was determined using micro-hardness equipment. The friction and wear properties of Al2O3 coatings sliding against silicon nitride ceramic ball were carried out under dry and water-lubricated conditions using tribo-meters. The wear volume of Al2O3 coatings was measured using non-contact surface profilometer, and the worn surface of Al2O3 coatings was observed by scanning electron microscopy (SEM). The results show that the alumina ceramic coating on 2A12 Al alloy is mainly composed of α-Al2O3 and γ-Al2O3 phase. Under dry condition, the wear mechanism of Al2O3 coatings is mainly abrasive wear and fatigue wear. With an increase in normal load and sliding speed, the friction coefficient of Al2O3 coatings increases from 0.79 and 0.82 to 0.87, and the specific wear rate of Al2O3 coatings increases from 4.07×10?5mm3/(N?m) and 4.36×10?5mm3/(N?m) to 9.69×10?5 mm3/(N?m), respectively. Under water-lubricated condition, the wear mechanism of Al2O3 coatings is mainly tribo-chemical wear and fatigue wear. With an increase in normal load and sliding speed, the friction coefficient of Al2O3 coatings decreases from 0.69 and 0.67 to 0.65, respectively, and the specific wear rate of Al2O3 coatings increases from 3.84×10?5mm3/(N?m) and 2.89×10?5mm3/(N?m) to 4.47×10?5mm3/(N?m), respectively. Moreover, the friction coefficient and specific wear rate of Al2O3 coatings under dry condition are lower than those under water-lubricated condition, which indicates that water-lubrication availably improves the friction condition and decreases the wear loss of Al2O3 coatings.

Key words: Al alloy; micro-arc oxidation; lubrication; friction; wear

铝合金由于具有密度小、比强度高及易于切削加工等优异性能,已被广泛应用于航空航天、汽车、电子电气等工业领域。但是,作为摩擦学材料,铝合金存在表面硬度低、摩擦因数高、耐磨性和耐蚀性差、容易拉伤和难以润滑等缺点[1?2]。微弧氧化技术不但能在铝合金表面原位生成一层硬度高、耐磨耐蚀、耐高压绝缘和高温冲击等优异性能的氧化铝陶瓷薄膜[3],而且它还能将铝合金的金属性能和氧化铝的陶瓷性能有机地结合在一起,这有效地克服了铝合金表面质软、硬度低、易磨损和在介质中易腐蚀的缺陷[4],从而拓宽铝合金的应用领域,延长铝合金制件的使用寿命。尽管铝合金微弧氧化陶瓷膜具有如此多的优异性能,但是它在干摩擦条件下显示出较高的摩擦因数(0.64~ 0.68,0.68~0.86对偶件分别为轴承钢和碳化钨球[5]),易使对偶件产生磨损而失效。因而,寻找一种适合氧化铝陶瓷膜的润滑介质尤为重要。水润滑介质因其对环境无污染、来源广泛、价格低廉,节省能源和使用安全等一系列优点,满足了人们日益强烈的环保要求,因而应用领域广泛[6],如在切削、磨削、拉拔、轧制、液压传动和陶瓷轴承等方面得到了实际的应用[7]。目前,关于铝合金微弧氧化陶瓷膜在水润滑下的摩擦学性能尚未见报道。因此,本文作者研究Al2O3薄膜/Si3N4球在水润滑下的摩擦学性能,并与干摩擦下的摩擦学性能进行对比分析。

1 实验

1.1 Al2O3薄膜的制备

样品材料为2A12铝合金,其组成(质量分数,%)为:Cu 3.8~4.9;Mg 1.2~1.8;Mn 0.3~0.9;Fe<0.5;Si<0.5;余量为Al。样品被加工成尺寸为d 30 mm× t 6 mm的圆盘,经表面清洗、去离子水漂洗后,进行微弧氧化处理。微弧氧化是在西安理工大学自行研制的MAO750/30?Ⅱ设备中进行,该设备使用直流脉冲电源,最大输出电压为750 V,最大输出电流为30 A[8]。电解液为去离子水配制的磷酸盐体系碱性溶液(10 g/L (NaPO3)6,8 g/L Na2SiO3,2 g/L NaOH,及一定量的添加剂),微弧氧化过程中通过循环冷却系统维持电解液温度30~50 ℃,处理时间30 min,所制取氧化膜为黑色。微弧氧化处理过的样品,用自来水冲洗干净后,使用烘箱低温烘干。烘干后的样品统一用SiC砂纸打磨抛光至表面粗糙度为0.6~0.8 μm,接着在丙酮中超声清洗20 min。

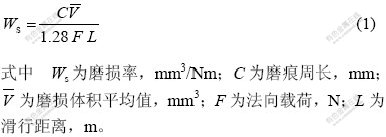

1.2 Al2O3薄膜的相构成、膜厚及显微硬度

用D8?AdvanceX射线衍射仪分析薄膜的相组成,扫射角度10?~110?,使用Cu靶材。用MINITEST1100涡流测厚仪测量打磨抛光前后的Al2O3薄膜的厚度。用HXD?1000TM自动转塔显微硬度计测量Al2O3薄膜的显微硬度,载荷4.9 N,保压时间10 s,测量3次取平均值。

1.3 Al2O3薄膜的摩擦磨损实验

用UMT?2型微摩擦磨损试验机研究Al2O3薄膜/Si3N4球的摩擦磨损特性。运动方式为球?盘的圆周运动,摩擦对偶件为d 4 mm的Si3N4陶瓷球,显微硬度为HV 3 100。实验参数如下:当法向载荷F=10 N时,分别为0.05、0.1和0.15 m/s;当v=0.15 m/s时,法向载荷(F)分别为5、7.5和10 N,相应的赫兹接触应力分别为1 869、2 139和2 355 MPa,滑行距离均为300 m。在干摩擦实验时,室内温度为25 ℃,相对湿度(RH)30%。在水润滑实验时,将水滴加到样品摩擦区,并保证整个摩擦区内的水在整个实验中都能浸没磨球三分之一以上的体积。用丙酮超声清洗实验后的样品20 min。

1.4 磨痕的体积测试及微观形貌分析

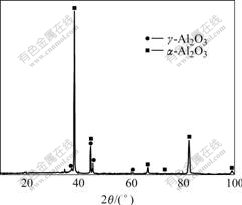

采用MicroXAMTM非接触表面三维形貌仪测试薄膜在不同实验参数下的磨损体积,测试扫描周长为1.28 mm,圆环磨痕大致取3等分进行测量,最后取3次测量结果的平均值。依据测量的磨损体积值计算Al2O3薄膜的磨损率(Ws)并作为评估其抗磨性能的指标,其计算公式如下:

用QUANTA200扫描电镜观察Al2O3薄膜磨痕的表面微观形貌。

2 结果与讨论

2.1 Al2O3薄膜的相组成、厚度及显微硬度

图1所示为Al2O3薄膜的XRD谱,通过X射线衍射分析可知:陶瓷膜层主要由α-Al2O3和γ-Al2O3相组成。其中,α-Al2O3相中,O2?为六方紧密堆积,Al3+对称分布在O2?围成的八面体配位中心,晶格能很大,故硬度、熔点和沸点都很高。γ-Al2O3相中,O2?近似为立方面心紧密堆积,Al3+不规则地分布在O2?围成的八面体和四面体空隙之中,且γ-Al2O3相为一种多孔性物质,故其性能不如α-Al2O3相的优异。YANG等[9]曾指出:铝合金微弧氧化陶瓷膜层只含有α-Al2O3和γ-Al2O3相。其实,在微弧氧化过程中,产生弧光发电微区的瞬间高温使Al2O3处于熔融状态,而熔融Al2O3在高冷却速率时易形成γ-Al2O3相,在低冷却速率时易形成α-Al2O3相,且在1 200 ℃高温下,γ-Al2O3相转变为α-Al2O3相[10]。抛光前Al2O3薄膜膜厚为35 μm,显微硬度为HV 1 211,抛光后的Al2O3薄膜膜厚为25 μm,显微硬度为HV 1 740。这是因为从外到内氧化铝陶瓷膜中的γ-Al2O3相含量逐渐减少,而α-Al2O3相含量逐渐增加[11],且α-Al2O3相为超硬相[12]。

图1 Al2O3薄膜的XRD谱

Fig.1 XRD pattern of Al2O3 coating

2.2 Al2O3薄膜的摩擦磨损特性

2.2.1 Al2O3薄膜/Si3N4球摩擦行为

图2所示为Al2O3薄膜/Si3N4球在2种摩擦环境下的摩擦因数随滑行距离的变化曲线。图2(a)所示为法向载荷对摩擦因数的影响。可以看出:在F=5 N下,2种摩擦环境下的摩擦因数曲线都经过几次波动后进入稳定状态,其中干摩擦下波动幅度为0.75~0.79,水润滑下为0.69~0.71,进入稳定状态下的滑行距离大约都为150 m;在F=7.5 N和10 N时,干摩擦下的摩擦因数曲线在滑行距离大约为50m处进入稳定状态,水润滑下的大约在20 m处就进入了稳定状态。图2(b)所示为F=10 N时,滑行速度对摩擦因数的影响,可以看出:干摩擦下的摩擦因数曲线在0.05 m/s时,出现先升后降的情况,进入稳定状态的滑行距离大约为100 m;0.1 m/s和0.15 m/s时,干摩擦下的摩擦因数曲线都是经过磨合阶段上升后直接进入稳定状态的,进入稳定状态下的滑行距离大致分别为100 m和50 m。而水润滑下的摩擦因数曲线在3种滑行速度下都是先经过磨合阶段后进入稳定状态的,进入稳定状态的滑行距离大约都为75 m。此外,干摩擦下摩擦因数明显大于水润滑下的摩擦因数,并且在2种摩擦环境下,摩擦因数曲线都未出现突变,表明Al2O3薄膜在经历300 m的滑行距离后仍未磨损失效。

图2 Al2O3薄膜/Si3N4球的摩擦行为

Fig.2 Friction behaviors of Al2O3 coating/Si3N4 ball system

图3所示为平均稳态摩擦因数随实验参数的变化关系。在0.15 m/s时(见图3(a)),Al2O3薄膜/Si3N4球干摩擦下的摩擦因数随法向载荷的增大近似线性地从0.79增加到0.87,而水润滑下则从0.69下降到0.65。在F=10 N时(见图3(b)),随滑行速度的增大,Al2O3薄膜/Si3N4球干摩擦下的摩擦因数平缓地从0.82增加到0.87,而水润滑时在0.1 m/s时出现波动,其值为0.67。而且,水润滑下的最大和最小摩擦因数分别为干摩擦下的79%和82%。干摩擦下的最大摩擦因数出现在高速重载下,水润滑时高速重载下则出现最小摩擦因数,可见水润滑有利于制品在高速重载下工作,同时可降低对偶件因磨损而失效的可能性。

图3 Al2O3薄膜/Si3N4球平均稳定摩擦因数随载荷和滑行速度的变化趋势

Fig.3 Mean steady-state friction coefficients of Al2O3 coating/Si3N4 ball system affected by normal load and sliding speed

2.2.2 Al2O3薄膜的磨损特性

Al2O3薄膜的磨损率随摩擦环境和实验参数的变化关系如图4所示。由图4(a)可知:在较小法向载荷F=5 N时,Al2O3薄膜在2种摩擦环境下的磨损率相差并不明显,但是随法向载荷进一步增大到7.5 N,干摩擦下的磨损率出现陡变现象,其值为9.27×10?5 mm3/(N?m),是此时水润滑下磨损率的2倍多。然而水润滑下的磨损率随法向载荷的增大却近似线性地增加。由图4(b)可知:2种摩擦环境下的Al2O3薄膜磨损率随滑行速度增大的变化关系与法向载荷增大的变化趋势相似,且在v=0.1 m/s时,干摩擦下的Al2O3薄膜磨损率也出现陡变,其值为8.93×10?5mm3/(N?m),并且是此时水润滑下磨损率的近3倍。而且,干摩擦下Al2O3薄膜的最大磨损率是水润滑下最大磨损率的2.2倍,最小磨损率是水润滑下最小磨损率的1.4倍。可见,水介质有效地改善了体系的摩擦条件,降低了Al2O3薄膜的磨损。

图4 Al2O3薄膜磨损率随载荷和滑行速度的变化趋势

Fig.4 Specific wear rate of Al2O3 coating affected by normal load and sliding speed

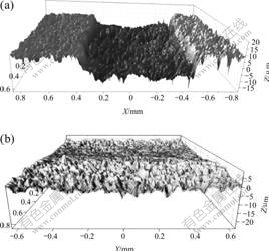

2.3 Al2O3薄膜的磨痕形貌

2.3.1 Al2O3薄膜磨痕宏观形貌

图5所示为用MicroXAMTM非接触表面三维形貌仪扫描的Al2O3薄膜在2种摩擦环境下的磨痕宏观形貌。由图可知:在相同的实验参数(F=10 N,v=0.1 m/s) 下,干摩擦下磨痕的深度与宽度都大于水润滑下的磨痕深度和宽度。这也是Al2O3薄膜在水润滑下的磨损率小于干摩擦下的一个原因。

图5 Al2O3薄膜磨痕的三维形貌图

Fig.5 3D photographs of wear scar of Al2O3 coating: (a) Dry friction; (b) Water-lubrication

2.3.2 Al2O3薄膜磨痕微观形貌

图6所示为干摩擦时,不同实验参数下的薄膜磨痕的微观SEM像。比较图6(a)和(c)可知:法向载荷增大时,薄膜发生片状脱落的区域增大,即磨损趋于严重。比较图6(b)和(c)可知:滑行速度增大时,薄膜表面发生与法向载荷增大时的相似情形。这是因为随着法向载荷与滑行速度的增大,样品摩擦区内产生的微小磨屑急剧增多,同时,磨屑产生、脱离的频率增大,脱离过程中的作用力也增大,从而致使薄膜的磨损趋于严重。而且,法向载荷和滑行速度增大时,球?盘摩擦副间产生的摩擦热急剧增加,使摩擦表面的温度升高,薄膜表层发生变形及化学变化等[13],从而引起薄膜的磨损加剧。薄膜在磨损过程中产生的大量片状脱落使薄膜表面粗糙度增加,从而导致摩擦因数和薄膜的磨损率都随法向载荷和滑行速度的增大而增加。

图7所示为水润滑时,不同实验参数下薄膜磨痕的微观SEM形貌。由图7(a)和(c)可知:随着法向载荷的增加,磨损表面的微小针孔(氧化铝陶瓷膜的特点:外层为疏松多孔层,内层为致密层[14])孔径减小,数量减少,这表明磨损趋于严重。因为法向载荷增大时,接触面间的正压力增大,球?盘相互嵌入的深度增加,故此磨损率随之增大,即薄膜表面发生的磨损加重。由图7(b)和(c)可知:滑行速度增大引起磨痕形貌发生的变化与法向载荷增大磨痕形貌的变化情形相似。不管是法向载荷的增大,还是滑行速度的增加,从磨痕的SEM形貌都可以看出磨痕表面变得更加光滑平整。

图6 干摩擦时Al2O3薄膜磨痕的SEM像

Fig.6 SEM images of wear scar of Al2O3 coating under dry condition: (a) F=7.5 N, v=0.15 m/s; (b) F=10 N, v=0.1 m/s; (c) F=10 N, v=0.15 m/s

图7 水润滑时Al2O3薄膜磨痕的SEM像

Fig.7 SEM images of wear scar of Al2O3 coating under water-lubricated condition:

(a) F=5 N, v=0.15 m/s; (b) F=10 N, v=0.05 m/s; (c) F=10 N, v=0.15 m/s

2.3.3 讨论

在干摩擦和水润滑下(F=10 N、v=0.1 m/s)Al2O3薄膜的磨痕微观形貌比较如图8所示。由图8(a)可以看出:干摩擦下的磨痕表面出现片状脱落和裂纹现象,即Al2O3薄膜主要发生了磨粒磨损和疲劳磨损。实验过程中,样品摩擦面不停地受到来自对偶件的作用力,使样品摩擦面产生疲劳裂纹。同时,样品摩擦区在实验过程中产生大量的微小磨屑,没有润滑介质的存在,这些微小磨屑被挤压在球?盘摩擦副间随圆盘一起转动,新的磨屑又不断产生,使一部分先前被挤压在球?盘摩擦副间的磨屑脱离原先所在位置,脱离过程中,薄膜表面受到磨屑脱离过程所产生力的作用,使发生疲劳裂纹区域内的薄膜部分脱落。在水润滑下,磨痕表面有微小裂纹,但较光滑平整,也未出现类似干摩擦下的片状脱落(见图8(b)),即薄膜主要发生了疲劳磨损和摩擦化学磨损。在水中,Si3N4球在摩擦氧化作用下形成非晶Si(OH)4后分解于水中[15],亦或转移到样品摩擦面形成固体润滑,产生摩擦化学磨损,因而水润滑下Al2O3薄膜的磨损率低于干摩擦下的磨损率。另外,Al2O3薄膜同样承受来自对磨件的周期性载荷,使薄膜表面产生疲劳磨损。

图8 在干摩擦和水润滑下Al2O3薄膜的磨痕SEM像

Fig.8 SEM images of wear scar of Al2O3 coating under dry condition (a) and water-lubricated condition (b)

3 结论

1) 干摩擦时,Al2O3薄膜主要发生了磨粒磨损和疲劳磨损,摩擦因数随法向载荷和滑行速度的增大分别从0.79(F=5 N,v=0.15 m/s)和0.82(F=10 N,v=0.05 m/s)增加到0.87(F=10 N,v=0.15 m/s);磨损率则分别从4.07×10?5mm3/(N?m)和4.36×10?5mm3/(N?m)增加到9.69×10?5mm3/(N?m)。

2) 水润滑时,Al2O3薄膜主要发生了摩擦化学磨损和疲劳磨损,摩擦因数随法向载荷和滑行速度的增大分别从0.69和0.67下降到0.65;磨损率则分别从3.84×10?5mm3/(N?m)和2.89×10?5mm3/(N?m)增加到4.47×10?5mm3/(N?m)。

3) Al2O3薄膜在干摩擦时的摩擦因数和磨损率都大于相同实验参数下水润滑时的摩擦因数和磨损率,表明水介质有效地改善了体系的摩擦条件,降低了Al2O3薄膜的磨损。

[1] Sheng X Y, Callahan D L, Barrera E V. The degradation of optical properties in a sulfuric acid anodized aluminum coating system exposed to vacuum or vacuum-ultraviolet radiation[J]. Materials and Manufacturing Process, 1997, 12(2): 215?228.

[2] Zhang W, Bay N. Cold welding-theoretical modeling of the weld formation[J]. Welding Journal, 1997, 76(10): 326?330.

[3] 来永春, 施修龄, 华 铭. 铝合金表面等离子微弧氧化处理技术[J]. 电镀与涂饰, 2003, 22(3): 1?3.

LAI Yong-chun, Shi Xiu-ling, HUA Ming. Plasma enhanced micro arc oxidation on the surface of aluminum alloys[J]. Electroplating & Finishing, 2003, 22(3): 1?3.

[4] Awad S H, Qian H C. Deposition of duplex Al2O3/TiN coating on aluminum alloys for tribological applications using a combined micro-plasma oxidation (MPO) and arc ion plating (AIP)[J]. Wear, 2006, 260: 215?222.

[5] Nie X, Leyland A, Song H W, Yerokhin A L, Dowey S J, Matthews A. Thickness effects on the mechanical properties of micro-arc discharge oxide coatings on aluminum alloys[J]. Surface and Coatings Technology, 1999, 116/119: 1055?1060.

[6] 唐向阳. 纯水液压系统的设计及动态特性研究[M]. 昆明: 昆明理工大学出版社, 2001.

TANG Xiang-yang. Design of pure water hydraulic transmission system and research to its dynamic properties[M]. Kunming: Kunming University of Science and Technology Press, 2001.

[7] 黄 平. 双电层对润滑薄膜厚度与压力的影响[J]. 机械工程学报, 2002, 12(4): 9?13.

HUANG Ping. Influences of electric double layer on thin lubrication film thickness and pressure[J]. Chinese Journal of Mechanical Engineering, 2002, 12(4): 9?13.

[8] 李均明, 朱 静, 白力静. 铝合金微弧氧化陶瓷层的磨损特性[J]. 材料保护, 2005, 38(1): 27?29.

LI Jun-ming, ZHU Jing, BAI Li-jing. Wear resistance of micro arc oxidation layer on aluminum alloy[J]. Materials Protection, 2005, 38(1): 27?29.

[9] YANG Guang-liang, L? Xian-yi, BAI Yi-zhen, CUI Hai-feng, JIN Zeng-sun. The effects of current density on the phase composition and microstructure properties of micro-arc oxidation coating[J]. Journal of Alloys and Compounds, 2002, 345: 196?200.

[10] TIAN Jun, LUO Zhuang-zi, QI Shang-kui, SUN Xiao-jun. Structure and anti-wear behavior of micro-arc oxidized coatings on aluminum alloy[J]. Surface and Coatings Technology, 2002, 154(1): 1?7.

[11] 薛文彬, 邓志威. 铝合金微弧氧化陶瓷膜的形貌及相组成分析[J]. 北京师范大学学报(自然科学版), 1996, 32(1): 67?70.

XUE Wen-bin, DENG Zhi-wei. Analysis of morphology and phase composition of ceramic films formed by the micro-arc oxidation of aluminum alloy[J]. Journal of Beijing Normal University (Natural Science), 1996, 32(1): 67?70.

[12] 辛铁柱, 赵万生, 刘晋春. 铝合金表面微弧氧化陶瓷膜的摩擦学性能及微观结构研究[J]. 航天制造技术, 2005, 8(4): 5?8.

XIN Tie-zhu, ZHAO Wan-sheng, LIU Jin-chun. Research on tribological properties and microstructure of alumina ceramic coating by micro-arc oxidation on aluminum alloy[J]. Journal of Manufacturing Technique on Astronautics, 2005, 8(4): 5?8.

[13] 温诗铸, 黄 平. 摩擦学原理[M]. 第2版. 北京: 清华大学出版社, 2002: 285?286.

WEN Shi-zhu, HUANG Ping. Theory of tribology[M]. 2nd ed. Beijing: Tsinghua University Press, 2002: 285?286.

[14] Yerokhina A L, Shatrovb T A, Samsonovb V, Shashkov P, Pilkington A, Leyland A, Matthews A. Oxide ceramic coatings on aluminum alloys produced by a pulsed bipolar plasma electrolytic oxidation process[J]. Surface and Coatings Technology, 2005, 199: 150?157.

[15] ZHOU Fei, Koshi A, Koji K. Friction and wear property of α-CNx coatings sliding against ceramic and steel balls water[J]. Diamond and Related Materials, 2005, 14: 1711?1720.

基金项目:国家自然科学基金资助项目(50675102); 南京航空航天大学高级人才启动资金资助项目(4015-905381-S0581-GXY)

收稿日期:2006-11-01;修订日期:2007-03-02

通讯作者:周 飞,教授;电话:025-84892581-803;E-mail:fzhou@nuaa.edu.cn

摘 要:在2A12铝合金表面通过微弧氧化制备氧化铝陶瓷膜。用X射线衍射仪分析薄膜的相构成,用涡流测厚仪测量膜层的厚度,用自动转塔显微硬度计测量薄膜的显微硬度,利用微摩擦磨损试验机研究Al2O3薄膜/Si3N4球在干摩擦及水润滑下的摩擦磨损特性,用非接触表面三维形貌仪测量薄膜的磨损体积,并采用扫描电镜观察磨痕的表面形貌。结果表明:2A12铝合金微弧氧化陶瓷膜主要由α-Al2O3相和γ-Al2O3相组成;干摩擦时,薄膜主要发生磨粒磨损和疲劳磨损,摩擦因数随法向载荷和滑行速度的增大分别从0.79和0.82增加到0.87,磨损率则分别从4.07×10?5mm3/(N?m)和4.36×10?5mm3/(N?m)增加到9.69×10?5mm3/(N?m);水润滑时,薄膜主要发生摩擦化学磨损和疲劳磨损,摩擦因数随法向载荷和滑行速度的增大分别从0.69和0.67下降到0.65,磨损率则分别从3.84×10?5mm3/(N?m)和2.89×10?5mm3/(N?m)增加到4.47×10?5mm3/(N?m);薄膜在干摩擦时的摩擦因数和磨损率都大于相同实验参数下水润滑时的摩擦因数和磨损率,表明水介质有效地改善了体系的摩擦条件,降低了薄膜的磨损。