文章编号:1004-0609(2011)08-1808-06

渗注磷酸盐对AZ31镁合金疲劳裂纹扩展的影响

贺显聪1, 2,王章忠1,白允强1,巴志新1,李晓泉1,沈鸿烈2

(1. 南京工程学院 材料工程学院,南京 211167;

2. 南京航空航天大学 材料科学与技术学院,南京 210016)

摘 要:

交变载荷作用下在AZ31镁合金疲劳裂纹尖端渗注磷酸盐转化液,研究磷酸盐的沉积行为及其对AZ31镁合金疲劳裂纹扩展速率的影响。采用扫描电镜(SEM)、能谱仪(EDS)、X射线衍射仪(XRD)观察分析裂纹尖端的形貌和物相组成,并采用贴应变片方法确定渗注磷酸盐转化液前后应力强度因子的变化。结果表明:渗注的磷酸盐转化液在AZ31镁合金疲劳裂纹尖端形成Zn3(PO4)?4H2O及MgZnP2O7复合覆层,能改变疲劳裂纹尖端的应力大小和分布状态,使应力强度因子降低约30%,从而有效地增强疲劳裂纹闭合效应,降低或延滞AZ31镁合金疲劳裂纹的扩展。

关键词:

中图分类号:TG 146.2 文献标志码:A

Effects of immersing phosphate on

fatigue crack propagation in AZ31 magnesium alloy

HE Xian-cong1, 2, WANG Zhang-zhong1, BAI Yun-qiang1, BA Zhi-xin1, LI Xiao-quan1, SHEN Hong-lie2

(1. School of Material Engineering, Nanjing Institute of Technology, Nanjing 211167, China;

2. College of Material Science and Technology, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China)

Abstract: Under alternate loads, a phosphate liquid was immersed into the fatigue crack tip of AZ31 magnesium alloy, the phosphate deposition behavior and effects of the phosphate film on the fatigue crack propagation rate at the fatigue crack tip of AZ31 magnesium alloy were investigated. The morphologies and phase constitutions of the phosphate deposition at the fatigue crack tip were characterized by scanning electron microscopy (SEM), energy spectrum analysis (EDS) and X-ray diffractometry (XRD), respectively. The stress-intensity factor values at the fatigue crack tip were compared with and without inmersing phosphate liquid by taking advantage of strain gauge. The results show that the phosphate( Zn3(PO4)?4H2O and MgZnP2O7) films can be formed at the fatigue crack tip of AZ31 alloy through inmersing phosphate liquid, and the stress magnitude and distribution change after inmersing phosphate liquid at the fatigue crack tip of AZ31 alloy. The stress-intensity factor value decreases by about 30%, which effectively improves the fatigue crack closure, and reduces or arrearage the fatigue crack propagation.

Key words: AZ31 magnesium alloy; phosphate; fatigue crack propagation; fatigue crack closure

镁合金是最轻的结构材料之一,具有优良的物理性能和力学性能[1],被誉为“2l世纪绿色工程材料”,在航空、航天、汽车、计算机、通讯和家电等领域具有广阔的应用前景,目前已成为材料界学者研究的热点[2-4]。然而具有密排六方结构的镁合金的塑性变形能力差、易开裂,实际加工的镁合金材料内部不可避免地存在一些既存的或后生的微裂纹或类裂纹缺陷,在疲劳载荷的作用下,裂纹是否会进一步扩展决定了构件的使用安全性和服役寿命[5-8]。因此,对已出现微裂纹的结构件进行及时修复就显得极为重要。利用电磁 热[9-12]、应力波加载[13-16]、激光熔覆[17]和渗透填充 法[18]等技术均可有效地阻止疲劳裂纹的进一步扩展,显著提高材料的疲劳寿命。但以上技术理论复杂、设备要求高、对合金整体影响较大或很难达到微细裂纹尖端部位。在裂纹尖端采用渗注磷酸盐转化液技术止裂的研究尚未见报道,因此,本文作者选用AZ31镁合金,在交变载荷作用下,首先确定疲劳门槛值,研究优化磷酸盐转化液的工艺配方,然后通过研究渗注磷酸盐对疲劳裂纹扩展速率的影响,观察该磷酸盐在裂纹尖端的沉积行为,并初步探讨其对延缓或延滞裂纹扩展的作用机理,为提高AZ31镁合金疲劳使用寿命提供理论依据。

1 实验

实验材料为d 40 mm×1 000 mm AZ31镁合金棒材,主要成分(质量分数)为5.70%Al、2.0%Zn、余量为镁。按单边缺口试样标准[19]用线切割机切取尺寸为130 mm×24 mm×12 mm的试样,表面磨光清洗待用。

采用三点弯曲的方法,正弦波加载;频率70~90 Hz,试验环境为室温、空气介质,应力比R=0.2;在Amsler 100 HFP-5100型高频疲劳试验机上进行试验。参照国家标准[20],用降载、逐步逼近法测定AZ31镁合金疲劳门槛值?Kth。

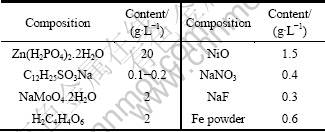

优化磷酸盐转化液工艺配方如下:按表1所列比例称取均为分析纯的试剂,配置成500 mL磷酸盐溶液,保持温度为40 ℃,15 min左右就能在AZ31镁合金上形成转化膜层。

表1 磷酸盐转化液配方

Table 1 Chemical liquid formula of phosphate liquid

首先预制裂纹长度为7.50 mm,然后选取应力强度因子高于疲劳门槛值约30%进行加载,研究渗注磷酸盐转化液前后疲劳裂纹的扩展速率。裂纹长度采用pro-microscan 5888型可移动的80倍数字显微镜与电脑相连,由电脑直接读数,精度为0.01 mm。在裂纹尖端表面贴应变片以电测法确定裂纹尖端应力强度因子变化。用JSM-6360LV型扫描电镜观察疲劳裂纹尖端的形貌特征,加速电压为20 kV,并用能谱仪GENESIS2000 XMS60对裂纹尖端进行成分分析。最后采用Bruker D8-Advance型X射线衍射仪对裂纹尖端的沉积物进行物相分析,Cu Kα,λ=0.154 nm,加速电压为30 kV,测量角度(2θ)的范围在0~105°,步长为0.02°,扫描速度为1 (°)/min。

2 结果与讨论

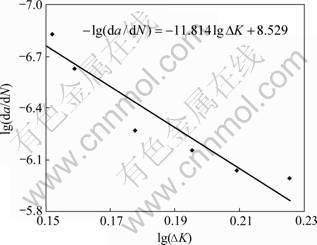

根据AZ31镁合金抗拉强度(85 MPa)确定预加载荷,然后逐步降低载荷,起初降载的速度较快,随后以5%~10%的速度降低应力强度因子(?K)。取 10-7 mm/cycle≤da/dN≤10-6 mm/cycle之间一组实验数据,利用线性回归的方法拟合lg(da/dN)—lg(?K)数据,得到图1所示的直线。通过图1拟合直线确定出该AZ31镁合金材料疲劳裂纹扩展门槛值(?Kth)为?Kth=1.35 MPa?m1/2。

图1 lg(da/dN)—lg(?K)线性回归曲线

Fig.1 lg(da/dN)—lg(?K) linear regression curve

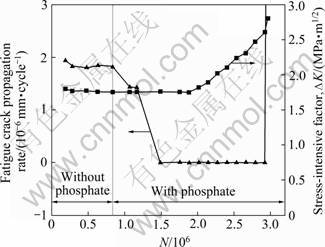

未渗注磷酸盐转化液前后AZ31镁合金疲劳裂纹扩展速率、应力强度因子与疲劳循环周次关系曲线如图2所示。从图2可以看出,保持应力强度因子?K≈1.75 MPa?m1/2不变,试样未渗注磷酸盐阶段,随着疲劳循环周次的增加,裂纹的扩展速率基本保持不变。向裂纹尖端不断渗注磷酸盐溶液后(应力强度因子不变),在831 780~1 488 300之间疲劳裂纹扩展速率随循环周次增加较快速降低,当循环周次在1 488 300后,裂纹已经不再扩展。由此可见,在保持?K不变时,渗注磷酸盐转化液可有效降低疲劳裂纹的扩展速率。持续渗注磷酸盐转化液,在2 014 860周次后,?K开始增大,从?K=1.75 MPa?m1/2增大到2.60 MPa?m1/2,即使疲劳循环周次增加到2 965 680,疲劳裂纹也不扩展,直到?K≈2.81 MPa?m1/2时,疲劳裂纹才开始快速扩展。而未渗注磷酸盐转化液时,?K≈1.75 MPa?m1/2时裂纹开始明显扩展。由此可知,渗注磷酸盐转化液同时亦可起到提高门槛值的作用。

图2 渗注磷酸盐前后裂纹扩展速率、应力强度因子与疲劳循环周次关系曲线

Fig.2 Relationships among fatigue crack propagation rate, stress-intensity factor and fatigue cycle without and with inmersing phosphate

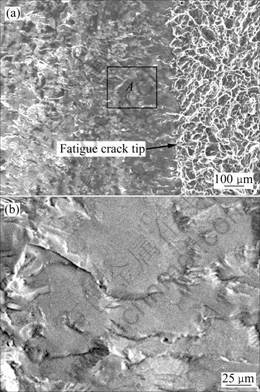

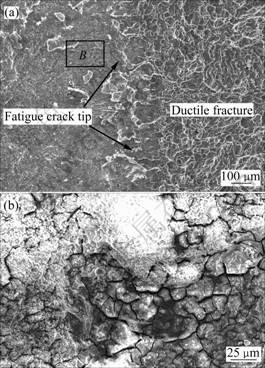

未渗注磷酸盐转化液的疲劳裂纹扩展试样裂纹尖端的微观形貌如图3所示。图3(a)所示为裂纹尖端的整体微观形貌,从图中可以看到,疲劳裂纹尖端和瞬断面有明显的分界,在裂纹尖端附近,疲劳条纹清晰可见;将图3(a)中A区域放大后得到图3(b),清楚显示疲劳断裂的解理面。

渗注磷酸盐转化液疲劳裂纹尖端的微观形貌如图4所示。从图4(a)可以清楚地看到,裂纹面与瞬断面的差异,在裂纹面上有颗粒物和覆层,见不到疲劳条纹,同时可以看出裂纹尖端的形貌发生了变化,裂纹面和瞬断面有一个明显的钝化台阶。裂纹尖端B区的放大形貌如图4(b)所示,从图中更清楚地看到,在疲劳裂纹面上形成了膜层,掩盖了疲劳断裂解理面。比较图3(a)和图4(a)可以确定,渗注磷酸盐转化液后在裂纹尖端产生磷酸盐的沉积物覆层。

图3 未渗注磷酸盐转化液裂纹尖端的微观形貌

Fig.3 Morphologies of samples at fatigue crack tip without inmersing phosphate: (a) Whole zone; (b) Magnification of area A in Fig.3(a)

图4 渗注磷酸盐转化液疲劳裂纹尖端微观形貌

Fig.4 Morphologies of samples at fatigue crack tip with inmersing phosphate: (a) Whole zone; (b) Magnification of area B in Fig.4(a)

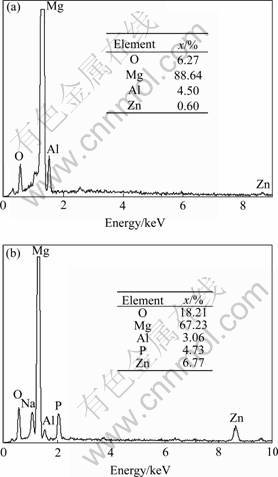

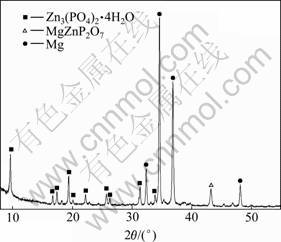

对图3(a)中裂纹尖端A区和图4(a)中裂纹尖端B区进行能谱分析,分别得到图5(a)和(b)。比较图5(a)和(b)的成分差异,未渗注磷酸盐的裂纹尖端A区成分基本和AZ31镁合金材料的一致,而在渗注磷酸盐的裂纹尖端B区的成分中含有P元素,其含量高达4.73%,Zn的含量6.77%也远高于A区Zn的含量(0.60%)。对渗注磷酸盐的裂纹尖端进一步做物相分析,其结果如图6所示。由图6可知,在8°~35°出现Zn3(PO4)?4H2O的衍射峰,并且在43.16°出现MgZnP2O7复盐衍射峰,由此可见,在交变载荷作用下,磷酸盐转化液在裂纹尖端产生了沉积行为,并形成了Zn3(PO4)?4H2O和 MgZnP2O7磷酸盐膜层。

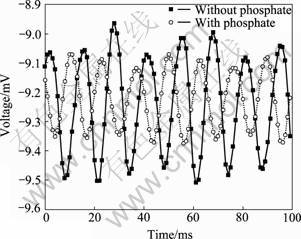

图7所示为渗注磷酸盐转化液前后应力应变仪输出的疲劳裂纹尖端附近电压随时间的变化曲线。从图7可以看出,渗注磷酸盐转化液之后,裂纹尖端电压值的振幅降低约30%。根据试验中所用电测法的一般原理,?φ的下降使得电阻?R/R下降,进而使得裂纹尖端应变量减小,这是应力强度因子降低所致。结合裂纹尖端沉积磷酸盐覆层的形貌和物相成分分析结果,可以认为该应力强度因子降低的原因应该是在疲劳裂纹尖端磷酸盐转化液腐蚀和转化产物的堆积、填充,使得裂纹尖端区域力学状态发生了变化,因而,裂纹扩展的有效驱动力降低或扩展阻力增加,造成疲劳裂纹的闭合效应。

图5 渗注磷酸盐转化液前后裂纹尖端不同区域的EDS谱

Fig.5 EDS spectra of different areas at fatigue crack with or without immersing phosphate liquid: (a) Area A in Fig.3(a); (b) Area B in Fig.4(a)

图6 裂纹尖端磷酸盐沉积物的XRD谱

Fig.6 XRD patterns of phosphate deposits at fatigue crack tip

图7 渗注磷酸盐前后裂纹尖端附近电压随时间的变化

Fig.7 Change of voltage with time at fatigue crack tip without and with phosphate

引起疲劳裂纹闭合的机制主要有塑性诱导、氧化物诱导、粗糙诱导、相变诱导和粘性液体诱导等。对于本研究可以排除塑性诱导和氧化物诱导机制。从图4(a)中明显看到,在裂纹尖端有渗注磷酸盐沉积的颗粒物存在,这些颗粒物使得裂纹表面粗糙度增大,导致在裂纹尖端造成额外的应力;在裂纹尖端,由于沉积了磷酸盐膜层,该膜层与基体材料发生物质相的变化,相变的发生必然导致体积的收缩或膨胀,同样在裂纹尖端也额外产生应力;这些额外产生的应力致使裂纹尖端的应力状态改变,从而使裂纹尖端的应力强度因子降低,疲劳裂纹闭合效应增强,或者认为提高了疲劳门槛值。另外,磷酸盐复合膜层本身具有一定强度,在裂纹尖端沉积可以将张开的镁合金基体连接起来,由于这种膜层本身的力学特性也可能起到提高疲劳门槛值的作用。比较图3和4可知,磷酸盐转化液对裂纹尖端镁合金基体有一定的腐蚀作用,使裂纹尖端有所钝化,从而影响到裂纹尖端的应力分布状态,降低裂纹尖端应力强度因子。由此可知,在裂纹尖端渗注磷酸盐转化液使裂纹尖端的应力强度因子降低,产生了较强的疲劳闭合效应,最终使疲劳裂纹扩展速率降低或延滞扩展。当应力强度因子?K再度增大,足以克服磷酸盐转化液在裂纹尖端沉积及腐蚀作用造成的应力强度因子降低的影响时,疲劳裂纹将以较大的扩展速率再度扩展。

3 结论

1) 采用逐步降低载荷法确定AZ31变形镁合金的疲劳门槛值为?Kth=1.35 MPa?m1/2。

2) 在交变载荷作用下,磷酸盐溶液能有效地在AZ31镁合金的疲劳裂纹尖端产生明显沉积作用,并形成Zn3(PO4)?4H2O和 MgZnP2O7磷酸盐复合膜层。

3) 裂纹尖端沉积的磷酸盐复合膜层和裂纹尖端形貌的钝化导致应力强度因子降低约30%,能有效增强疲劳裂纹闭合效应,降低或延滞疲劳裂纹的扩展。

REFERENCES

[1] ZENG R C, HAN E H, KE W, DIETZEL W, KAINER K U, ATRENS A. Influence of microstructure on tensile properties and fatigue crack growth in extruded magnesium alloy AM60[J]. International Journal of Fatigue, 2010, 32: 411-419.

[2] NAN Z, ISHIHARA S, GOSHRNA L, NAKANISHI R. Scanning probe microscope observations of fatigue process in magnesium alloy AZ3l near the fatigue limit[J]. Scr Mater, 2004, 50(4): 429-434.

[3] MARA M, GHECTOR L, VERMA T. Microstructural effects of AZ31 magnesium alloy on its tensile deformation and failure behavior[J]. Mater Sci Eng A, 2006, 418(1/2): 341-356.

[4] ZENG RC, HAN EH, KE W. Effect of temperature and relative humidity on fatigue crack propagation behavior of AZ61 magnesium alloy[J]. Mater Sci Forum, 2007, 409(12): 546-549.

[5] SUNG H P, HONG S G, BANG W Y, LEE C S. Effect of anisotropy on the low-cycle fatigue behavior of rolled AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2010, 527(3): 417-423.

[6] NASCIMENTO L, YI S, BOHLEN J, FUSKOVA L, LETZIG D, KAINER K U. High cycle fatigue behaviour of magnesium alloys[J]. Procedia Engineering, 2010, 2(l): 743-750.

[7] BEGUM S, CHEN D L, XU S. Effect of strain ratio and strain rate on low cycle fatigue behavior of AZ31 wrought magnesium alloy[J]. Materials Science and Engineering A, 2009, 517(1/2): 334-343.

[8] ISHIHARA S, NAN Zhen-yu, GOSHIMA T. Effect of microstructure on fatigue behavior of AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2007, 468/470(15): 214-222.

[9] 范华林, 陈 平. 电磁热效应理论在薄板止裂技术上的应用[J]. 兵工学报, 2005, 26(6): 791-794.

FAN Hua-lin, CHEN Ping. Crack arrest effect in thin plates[J]. Acta Armamentarii, 2005, 26(6): 791-794.

[10] 白象忠, 胡宇达, 谭文锋. 电磁热效应裂纹止裂研究的进展[J]. 力学进展, 2000, 30(4): 546-557.

BAI Xiang-zhong, HU Yu-da, TAN Wen-feng. Advance of the study of crack prevention by the electromagnetic heat effect[J]. Advances in Mechanics, 2000, 30(4): 546-557.

[11] 肖福仁, 白象忠, 乔桂英. 电磁热效应对35钢裂纹尖端组织及止裂效果的影响[J]. 材料热处理学报, 2001, 22(2): 56-59.

XIAO Fu-ren, BAI Xiang-zhong, QIAO Gui-ying. Influence of electromagnetic heat effect on microstructure and crack arrest of 35 steel[J]. Transactions of Metal Heat Treatment, 2001, 22(2): 56-59.

[12] 付宇明, 郑丽娟, 白象忠. T10钢金属模具中裂纹电磁热止裂的实验研究[J]. 实验力学, 2004, 19(4): 488-492.

FU Yu-ming, ZHENG Li-juan, BAI Xiang-zhong. Experimental research on crack arrest in metal die using electromagnetic heating[J]. Journal of Experimental Mechanics, 2004, 19(4): 488-492.

[13] 沙桂英, 刘瑞堂, 刘殿魁. 应力波加载条件下907A钢-20 ℃时的动态断裂与止裂研究[J]. 哈尔滨工程大学学报, 2001, 22(1): 96-101.

SHA Gui-ying, LIU Rui-tang, LIU Dian-kui. Fracture and arrest in 907A steel under stress wave loads at -20 ℃[J]. Journal of Harbin Engineering University, 2001, 22(1): 96-101.

[14] ISHIHARA S, GOSHIMA T. The influence of the stress ratio on fatigue crack growth in a cermet[J]. Journal of Materials Science, 2000, 35(22): 5661-5665.

[15] ZENG R C, XU Y B, KE W, HAN E H. Fatigue crack propagation behavior of an as-extruded magnesium alloy AZ80[J]. Materials Science and Engineering A, 2009, 509: 1-7.

[16] ZENG RC, KE W, HAN E H. Influence of load frequency and ageing heat treatment on fatigue crack propagation rate of as-extruded AZ61 alloy[J]. International Journal of Fatigue, 2009, 31: 463-467.

[17] 任爱国, 王晓静, 丁 静. 激光熔覆止裂技术研究[J]. 表面技术, 2006, 35(2): 69-81.

REN Ai-guo, WANG Xiao-jing, DING Jing. Research of laser-melt-repairing technology[J]. Surface Technology, 2006, 35(2): 69-81.

[18] SHIN C S, CAI C Q. A model for evaluating the effect of fatigue crack repair by the infiltration method[J]. Fatigue & Fracture of Engineering Materials & Structures, 2000, 23(10): 835-845.

[19] 邹广平, 张学义. 一种大量程疲劳试验机实现小试样预制裂纹的方法[J]. 应用科技, 2004, 31(1): 49-53.

ZOU Guang-ping, ZHANG Xue-yi. A method of implementing pre-cast crack of small specimen with wide scale fatigue-testing machine[J]. Applied Science and Technology, 2004, 31(1): 49-53.

[20] GB/T 6398—2000. 金属材料疲劳裂纹扩展速率试验方法[S].

GB/T 6398—2000. Standard test method for fatigue crack growth rates of metallic materials[S].

(编辑 龙怀中)

基金项目:江苏省高校自然科学基础研究项目(07KJB430036);江苏省自然科学基金资助项目(BK2009354);南京工程学院基金资助项目(KXJ08053, KXJ08003)

收稿日期:2010-07-05;修订日期:2010-11-05

通信作者:贺显聪,讲师,博士;电话:025-86118278;E-mail: hexiancong@njit.edu.cn