J. Cent. South Univ. (2018) 25: 1870-1878

DOI: https://doi.org/10.1007/s11771-018-3876-7

Environmental impact assessment of magnesium alloy automobile hub based on life cycle assessment

YI Qiu-ping(易秋平)1, TANG Chang-ping(唐昌平)2

1. Institute for Hunan Innovation & Development Research, Hunan University of Science and Technology,Xiangtan 411201, China;

2. Key Defense Laboratory of High Temperature Wear-resisting Materials and Preparation Technology of Hunan Province, Hunan University of Science and Technology, Xiangtan 411201, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract:

In order to find out the impact of aluminum alloy hub replaced by the magnesium alloy hub on environment, the resource consumption, energy consumption and pollutant emission during hub production and their service life of the two types of hubs are investigated based on the life cycle assessment (LCA) theory. The results indicate that the adverse impact on environment can be effectively reduced by the application of magnesium alloy hubs. Compared with aluminum alloy hubs, the global warming potential (GWP) and human toxicity potential (HTP) are reduced by 39.6% and 24.0%, respectively. CO2 is the main pollutant in the life cycles of the two kinds of hubs, which is generated throughout the whole life cycle including the fabrication process and the service life, while the pollutants of particles mainly come from the fabrication stage. Compared with the aluminum alloy hubs, the green effect brought by magnesium alloy hubs is mainly due to the reduction of fuel consumption caused by weight loss.

Key words:

life cycle assessment theory; magnesium alloy; aluminum alloy; hub; environmental impact;

Cite this article as:

YI Qiu-ping, TANG Chang-ping. Environmental impact assessment of magnesium alloy automobile hub based on life cycle assessment [J]. Journal of Central South University, 2018, 25(8): 1870–1878.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-018-3876-71 Introduction

With the development of economy in China, the car ownership has sharply increased recently [1–3]. In 1990, the car ownership was about 5.5 million, which was only 4% of that in 2014 [4]. The increase in car ownership has greatly facilitated the people's travel. However, serious environment pollution caused by the significant exhaust emissions from massive fuel consumption also occurred [4–6]. For example, severe haze appeared in Beijing for 13 d consecutively in 2012. Factually, as early as 1943, the world's first photochemical smog event has already appeared in Los Angeles, USA, and then similar pollution events occurred in North America, Japan, Australia and parts of Europe [7]. Studies indicate that photochemical smog events are caused by hydrocarbons and nitrogen oxides emitted by vehicle exhaust, which is harmful to human life [8]. With the rapid growth of economy, the consumptions of resources and energy have increased, and people have paid more and more attention to the environmental problems [9, 10]. Therefore, a serious challenge is presented to the automobile industry due to the worsening in ecological environment. LI et al [11] showed that 60% of the fuel used in the automobile is consumed by the auto weight, and the fuel efficiency can be increased by 5%–8% for every 10% reduction in auto weight. Therefore, it is of great significance to solve the problem of energy saving and environmental pollution by reducing the weight of the automobile.

In general, there are three methods to reduce weight [12, 13]. Firstly, the auto weight can be reduced by structure design. For example, the unnecessary parts and components are reduced through structural design so as to save material consumption. Secondly, the advanced manufacturing processes can be applied to reducing the weight, such as thermoforming and laser welding. Thirdly, the new materials with high- performance and low-density can also be used. Thus, the use of light, weight, high-strength materials is an important way to achieve weight loss. Up to now, magnesium and its alloys are the lightest metal structural materials in engineering application [14]. The density of pure magnesium is just 1.738 g/cm3, and the density of magnesium alloy is usually less than 2.0 g/cm3. Due to low density, excellent machinability and good vibration damping performance, Mg alloys have broad application prospects in aerospace and automotive industry. Since the 1930s, magnesium castings have been used to fabricate transmission housing and air-cooled engine [15]. With the development of magnesium alloy preparation technology, magnesium alloys have been widely applied to producing other parts and components in recent years. For example, the production line of Henan Dowell Technology Company Limited was built in Changge, Henan Province in 2017. This production line is the first magnesium alloy hub production line in the world, and its production capacity is one million hubs per year [16]. As we know, the hub is an important rotating component in the driving system. It is also an important bearing component in a car. The use of magnesium alloy hub is of great significance to the weight reduction, and it can increase the ratio of the sprung mass to the unsprung weight. Hence, the stability of the car and the operating experience will also be promoted. However, whether the alternative of material is beneficial to environment in the whole life should be fully evaluated. The LCA method is an important environmental management tool, and it is widely used in many fields [15, 17–21]. In this paper, based on this theory, effects of magnesium alloy hub application on environment are evaluated.

2 Hub production processes

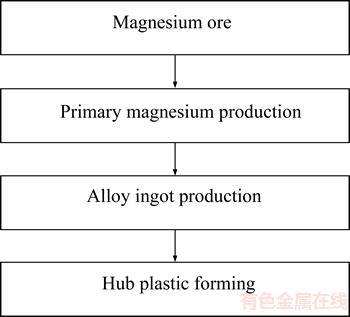

2.1 Production process of magnesium alloy hub

Figure 1 shows the production process of magnesium alloy hubs, including magnesium ore mining, smelting of primary magnesium, production of magnesium alloy ingots and hub plastic deformation. The specific process is described as follows.

Figure 1 Production process of magnesium alloy hub

Magnesium mainly exists in the form of salts in various minerals. At present, Pidgeon process is the main method for magnesium production in China. The raw materials used in this method are dolomite, fluorite and ferrosilicon. Firstly, the mixtures of roasted dolomite and ferrosilicon are ground into fine powders and pressed into bulks. Then, the bulks are placed in a distiller. The magnesium vapor is obtained by reduction reaction at the condition of 1423–1473 K and (10–2–10–1)×133.322 Pa. The reaction principle is listed as follows.

(1)

(1)

This magnesium production method is favored by most companies due to the short process, low investment, low cost and high product quality.

The solid magnesium is obtained by condensation crystallization, and then it is melted into ingots. As we know, the ultimate tensile strength of pure magnesium is only 120 MPa, which is too low to fabricate the main bearing component. Addition of alloying elements is an effective method to solve this problem. Generally, the amount of alloying elements is less than 10 wt%. So, the resources, energy consumption and pollutant emissions brought by alloying elements have been ignored in this work in order to simplify the calculation process.

On the basis of preparing the magnesium alloy ingot, the hub is processed by extrusion and forging to enhance its strength. The grains are refined during deformation through dynamic recrystallization because of the low stacking fault energy, which makes dynamic recrystallization easy to occur in magnesium alloy. The plastic deformation is applied to fabricate magnesium alloy hub due to the low strength of magnesium alloy castings, which is different from the aluminum alloy hub fabrication process.

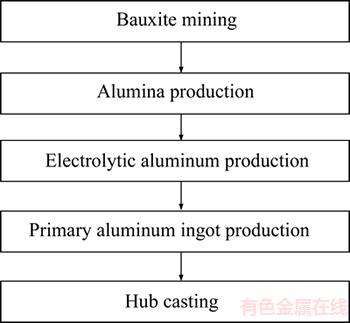

2.2 Production process of aluminum alloy hub

The cast aluminum alloy satisfies the requirements of car due to its high strength. In general, aluminum alloy hubs are mainly produced by means of die casting. Figure 2 shows the production process of aluminum alloy hubs. It mainly includes bauxite mining, alumina production, alumina electrolysis, aluminum ingot production and aluminum alloy hub casting.

Figure 2 Production process of aluminum alloy hub

China is rich in bauxite reserves, but its quality is poor. In the production of alumina, it is very difficult to refine because the bauxite in China belongs to the low-grade ore. The sintering process and combination process are the two main manufacturing methods in alumina production due to the poor quality of the mineral, which is different from the widely used process of Bayer method in the world. Complex production system, large capital investment and high energy consumption are disadvantages of the methods adopted in China. In primary aluminum production, the electrolytic method is widely used. ZL101A and A356 aluminum alloys are the two main alloys used for hub fabrication; their alloying elements are all less than 10%. In order to simplify the calculation process and to be consistent with magnesium alloy hubs, resources, energy consumption and pollutant emissions of alloying elements required for the production are ignored.

3 Effects of magnesium alloy hub production on environment

3.1 Goal and scope definition

The goal of this section is to quantitatively calculate the emission of pollutants during the production and service life of Mg alloy, then their impacts on the environment are evaluated. The system boundary of the study includes the entire life cycle, which is from the beginning of magnesium mining to the hubs scrapping.

3.2 Life cycle inventory analysis of magnesium alloy hub

In this work, the hub of a certain type of car is investigated. The total mass of the car is 1435 kg, and the standard fuel consumption is 7.6 L/100 km. The mass of an aluminum alloy hub is 11.1 kg, and it can be reduced to 5.6 kg when replaced by magnesium alloy. Five hubs that satisfy the needs of a car are selected for the functional unit in this paper. Thus, the total masses of the aluminum alloy hubs and the magnesium alloy hubs are 55.5 kg and 28 kg, respectively. Effects of the application of magnesium alloy hubs on resources, energy consumption and environmental impact are investigated. The statistical data used in this paper are originated from the Yearbook of China Nonferrous Metals Industry in 2016. Other non- statistical data come from correlated references in recent years [22–24].

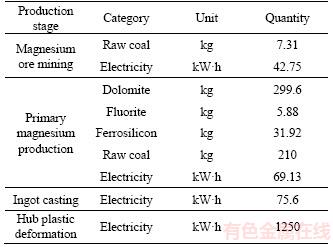

3.2.1 Resources, energy consumption list of magnesium alloy hub manufacturing process

In the primary magnesium production process, dolomite, fluorite and ferrosilicon are the main raw materials, as well as raw coal and electricity and other energy sources. In addition, waste residue of the Pidgeon process is harmless slag, and the discharge of waste water is also small. It is mainly circulating water used for cooling, and the circulating water is basically non-toxic. Therefore, the impacts of waste residue and waste water on the environment are not considered in this work.

Table 1 shows the resources and energy consumption in the production process of magnesium alloy hubs. It can be seen that the largest consumption of primary magnesium in the production process is dolomite, which is the main source of magnesium. Others such as fluorite and ferrosilicon are used as auxiliary materials with less dosage. According to the energy consumed during the smelting process, raw coal is the main energy source, followed by electricity. It is showed that the consumption of 0.393 kg standard coals is needed to produce 1 kW·h electricity according to the electricity production data of China. So, the electricity consumed for the production of the primary magnesium is equivalent to the indirect consumption of 27.17 kg standard coals.

Table 1 Resources, energy consumption inventory of magnesium alloy hubs fabrication

In addition to the resource and energy consumption, emissions such as CO2, SO2, NOx, CH4, HCl, HF and particles are also generated in the production process, which will cause environment pollution. The pollutant emissions during primary magnesium production are able to be calculated based on the consumption of resources and energy. According to Ref. [22], CO2 mainly comes from the consumption of raw coal burning, and the amount can be calculated by Eq. (2) [22]:

(2)

(2)

where ECO2 represents CO2 emissions (kg); M is raw coal consumption (kg); Q represents fuel heat (MJ/kg), which is 20.908 MJ/kg; K is carbon emission coefficient of coal (kg·C/MJ), which is 24.74×10–3 kg·C/MJ; α represents the carbon oxidation rate of the fuel, and the value is 0.90.

On the other hand, a large amount of CO2 will be generated during dolomite calcination process, and the emission can be calculated from the chemical equation of CaCO3·MgCO3 decomposition. If the content of dolomite is 98%, the amount of CO2 emission during magnesium alloy hubs fabrication will be 140.4 kg.

SO2 is another pollutant generated from coal burning, and the emissions are related to fuel sulfur content, fuel sulfur emission rates and the degree of desulfurization. It can be calculated according to Eq. (3) [22]:

(3)

(3)

where ESO2 is the discharge amount of SO2; M is the fuel consumption (kg); S indicates the sulfur content of the fuel (wt%), which is 1.12% according to the average sulfur content of coal resources in China; a represents the fuel emission factor, and the value is 1.74×10–3; g is the removal rate of SO2, which is related to the pollution control, and is set to be 0 in this work.

NOx emissions are also related to fuel consumption, emission factors and degree of denitrification. The amount of NOx emission can be calculated by Eq. (4) [22]:

(4)

(4)

where ENOx represents the amount of NOx emission (kg); M is the coal consumption (kg); α represents the NOx emission factor of the fuel (the NOx emission factor of raw coal burning is 7.5 kg/t); g indicates the NOx removal rate.

In addition, the amounts of CO and CH4 generated from raw coal burning are related to coal consumption, coal calorific value and the emission factor. The calculation formula is shown in Eq. (5) [22]:

(5)

(5)

where Ei represent the CO or CH4 emissions; M is the coal consumption; Q represents fuel heat (MJ/kg); αi is the CO or CH4 emission factor. The emission factors of CO and CH4 are 150×10–6 kg/MJ and 10×10–6 kg/MJ, respectively.

As a reductant in Pidgeon process, the amount of gaseous fluorine emissions produced by fluorite at high temperatures can be calculated as follows [22]:

(6)

(6)

where EHF represents the amount of HF emission (kg); M is the fluorite consumption; FH indicates the content of calcium fluoride in fluorite (taking 95%); FE is the emission rate of fluorine in fluorite during production, and the value is set to be 30%; hF represents the purification efficiency of gaseous fluoride, and the value is 0.

Particles produced during hub preparation mainly come from three parts: 1) coal dust, 2) fume generated from the decomposition of dolomite raw materials and 3) particles generated during rotary kiln operation.

First, the emission of coal dust is related to the fuel consumption, the ash content in the dust and the dust removal equipment. The calculation equation is shown in Eq. (7) [22]:

(7)

(7)

where Ecoal is the amount of soot emissions (kg); M is the fuel consumption (kg); a represents the coal ash (20%); dfh represents the percentage of dust in the flue gas (35%); h is the dust removal efficiency (76.1%); Cfh represents the percentage of combustibles in dust (20%).

Second, according to Ref. [22], the dust generated from dolomite decomposition can be calculated by Eq. (8):

(8)

(8)

where Edust represents the amount of dust emission (kg); Iq is the loss of raw materials (47%); the density of CO2 gas in the standard state is taken as 1.977 kg/m3; e represents the average dust density, and the value is taken as 16.76×10–3 m3/kg; h represents the dust removal rate, and the value is 76.1%.

Third, particles produced during the rotary kiln operation can be calculated by Eq. (9) [22]:

(9)

(9)

where Eparticle represents the amount of particle emission (kg); M represents the coal consumption (kg); Q represents the heating value of the fuel; a represents the excess air factor, and the value is taken as 1.14; h represents the dust removal rate, and the value is taken as 76.1%; e represents the average dust discharge density and the value is 16.76×10–3 m3/kg.

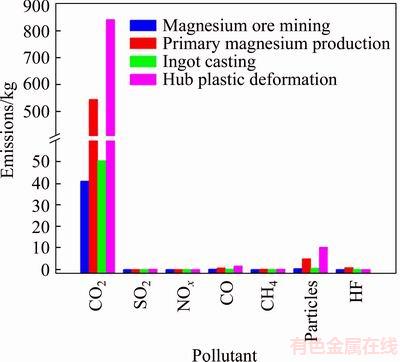

The emissions of pollutants during magnesium alloy hub production are shown in Figure 3. It indicates that CO2 is the main pollutant emission during each stage of production, followed by particles, HF and CO. It can be seen from the calculation that the generation of CO2 is mainly due to the hub plastic deformation and primary magnesium production. Comparing the emissions of each stage, it is indicated that the CO2 emission produced by the hub plastic deformation is much higher than that by mining and casting, which could attribute to the plastic deformation characteristic of magnesium alloy, whose crystal structure is hexagonal close-packed. Thus, only basal slip and twinning are able to be activated at room temperature, which leads to the poor plasticity. However, when the deformation temperature increases, the critical resolved shear stress (CRSS) of non-basal slip systems such as prismatic slip and pyramidal slip decreases rapidly, while the CRSS of basal slip is not significantly decreased, which leads to activation of more slip systems, and the plasticity of Mg alloys is greatly improved. On the other hand, magnesium alloys are prone to dynamic recrystallization at elevated temperatures due to its low stacking fault energy, which also improves the plastic deformation capability of the alloy. Therefore, the plastic deformation of magnesium alloy is usually carried out at high temperatures, which gives rise to more electricity and raw coal consumption, and leads to the increasing emissions of CO2 and particles.

Figure 3 Pollutant emissions during magnesium alloy hubs production

3.2.2 Energy consumption inventory of service life

The total mileage of a car is 600×103 km according to the “Mandatory Scrapping Standard for Motor Vehicles”. The service life of a hub can often satisfy the whole life of a car. Therefore, in this paper, the fuel consumption of a car in the life cycle is calculated with the mileage of 600×103 km. According to the standard fuel consumption of this type of car, the amount of gasoline consumed in the life is 45.6×103 L when using aluminum alloy hubs. The car will reduce 27.5 kg if the hubs are replaced by magnesium alloy, which is 2% reduction in weight, and 1.6% reduction in fuel consumption after replacement will achieve according to the experience that 8% fuel consumption reduction corresponds to per 10% reduction in weight [11]. Hence, the amount of gasoline consumption during the whole life would be 44×103 L.

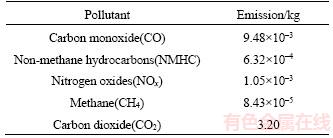

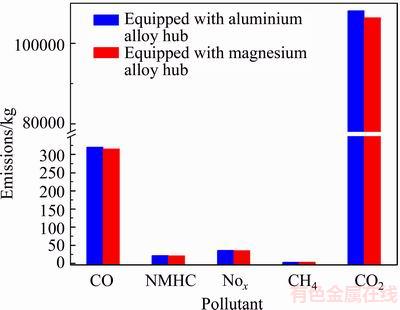

The main pollutants emitted by automobile during its service life are carbon monoxide, non- methane hydrocarbons, nitrogen oxides, methane and carbon dioxide according to Ref. [25]. The emissions corresponding to 1 kg gasoline are listed in Table 2. Therefore, the exhaust emissions of the automobile equipped with magnesium alloy and aluminum alloy hubs for the entire service life can be calculated, and the results are shown in Figure 4.

The weight of all the five magnesium alloy hubs is only 28 kg, which could lead to the sharp reduction of the car weight to 1407.5 kg. The pollutant emissions of magnesium alloy hubs during the service life are shown in Figure 5. The results indicate that CO2 is the most emitted pollutant in the entire service life of the hub, which is much higher than that in hub fabrication stage.

Table 2 Exhaust emissions inventory corresponding to 1 kg gasoline consumption

Figure 4 Pollutant emissions of automobile in service life

Figure 5 Pollutant emissions of magnesium alloy hubs through service life

4 Effects of aluminum alloy hub production on environment

4.1 Goal and scope definition

As a comparison, the research goal of this section is to quantitatively calculate the pollutants emissions and their environmental impacts during the life cycle of aluminum alloy hubs. The system boundary of the study is from the beginning of the mining of bauxite to the hub scrapping.

4.2 Life cycle inventory analysis of aluminum alloy hub

4.2.1 Resources, energy consumption list of aluminum alloy hub manufacturing process

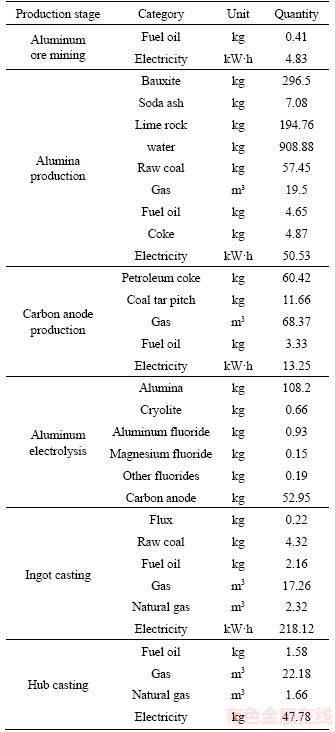

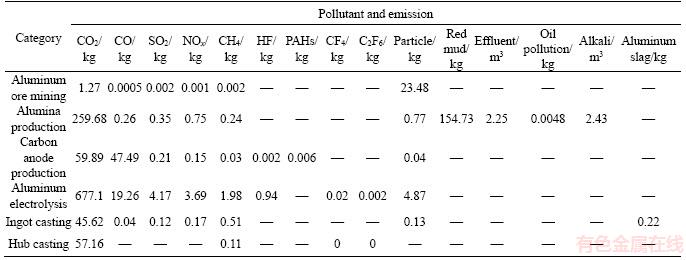

The resources, energy consumption and pollutant emissions of aluminum alloy hubs from mining to scrap are shown in Tables 3 and 4, respectively. The results indicate that CO2 is the main pollutants generated from aluminum alloy hubs production process, followed by dust and particles, which is consistent with that of the magnesium alloy hubs production. Comparing the emissions at different production stages, the CO2 generation of electrolytic aluminum production is the most in all stages and it reaches to 677.1 kg, followed by alumina production, which can generate 259.68 kg CO2.

Table 3 Resources, energy consumption inventory of aluminum alloy hubs fabrication

4.2.2 Energy consumption inventory of service life

The total weight of the aluminum alloy hubs is 55.5 kg, which accounts for 3.9% of the whole automobile weight. Figure 6 shows the pollutant emissions caused by hubs. It can be seen from the figure that CO2 is also the primary pollutant during the service life of aluminum alloy hubs, and the emissions reach 4215.71 kg. The second pollutant is CO, but the amount is much lower than the emission of CO2, and it is only 12.48 kg. By comparing with the pollutant emission at the production stage, it can be seen that the emission during service is much higher than that in production process.

5 Life cycle impact assessment

The internationally general impact types and environmental load classification methods are adopted to analyze the influence of emissions on environment [22]. The environment impact types and environmental load categories are listed in Table 5.

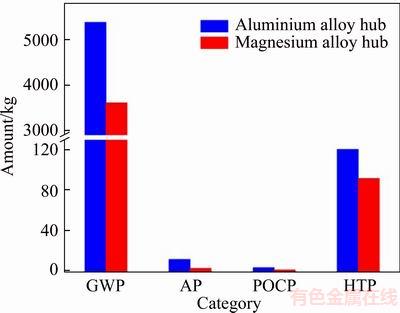

According to the emissions mentioned before and the characterization factors of different pollutants, the characterization results of magnesium alloy and aluminum alloy hubs in the life cycle are shown in Figure 7. The results indicate that the GWP is the main impact of the two types of hubs on environment, followed by the HTP. Comparing the characterization factors of the two alloy hubs, we can find that the GWP is reduced by 39.6% and the HTP is reduced by 24.0% after replacing the aluminum hubs by magnesium alloy hubs. This green effect is mainly induced by the reduction of fuel consumption in service life, which is caused by the weight loss effect brought by magnesium alloy. More significant green effect will be achieved if further optimization in magnesium alloy hub production process is realized. Moreover, magnesium alloy is much easier to be recycled, which may bring energy saving effect once again, and lead to green effect enhancement.

6 Conclusions

1) The adverse impact on the environment will be effectively reduced if the aluminum alloy hubs are replaced by magnesium alloy hubs. The global warming potential (GWP) over the entire life cycle will be reduced by 39.6%, and the human toxicity potential (HTP) will be reduced by 24.0%.

Table 4 Pollutant emissions of aluminum alloy hubs fabrication

Figure 6 Pollutant emissions of aluminum alloy hubs through service life

Table 5 Environmental impact types of pollutants and classification of environmental load in hub production

2) The major pollutants of magnesium alloy and aluminum alloy hubs during their life cycle are all CO2, followed by particles. CO2 is produced both in hub fabrication stage and the service life of the automobile, while the particles are mainly generated during hub fabrication.

Figure 7 Characterization results of hubs in life cycle

3) Comparing with aluminum alloy hub, the positive impact on environment brought by magnesium alloy hub is mainly due to the reduction in fuel consumption caused by car weight loss.

References

[1] WU Na, ZHAO Sheng-chuan, ZHANG Qi. A study on the determinants of private car ownership in China: Findings from the panel data [J]. Transportation Research Part A: Policy and Practice, 2016, 85: 186–195.

[2] YANG Zhen-shan, JIA Peng, LIU Wei-dong, YIN Hong-chun. Car ownership and urban development in Chinese cities: A panel data analysis [J]. Journal of Transport Geography, 2017, 58: 127–134.

[3] VINE S L, WU Chen-yang, POLAK J W. A nationwide study of factors associated with household car ownership in China [J]. IATSS Research, 2017. DOI: 10.1016/j.iatssr.2017. 10.001.

[4] WU Ye, ZHANG Shao-jun, HAO Ji-ming, LIU Huan, WU Xiao-meng, HU Jing-nan, WALSH M P, WALLINGTON T J, ZHANG K M, STEVANOVIC S. On-road vehicle emissions and their control in China: A review and outlook [J]. Science of the Total Environment, 2017, 574: 332–349.

[5] PU Yi-chao, YANG Chao. Estimating urban roadside emissions with an atmospheric dispersion model based on in-field measurements [J]. Environmental Pollution, 2014, 192: 300–307.

[6] LANG Jian-lei, ZHOU Ying, CHENG Shui-yuan, ZHANG Yan-yun, DONG Meng, LI Sheng-yue, WANG Gang, ZHANG Yong-lin. Unregulated pollutant emissions from on-road vehicles in China, 1999–2014 [J]. Science of the Total Environment, 2016, 573: 974–984.

[7] GUAN Wei-jie, ZHENG Xue-yan, CHUNG Kian-fan, ZHONG Nan-shan. Impact of air pollution on the burden of chronic respiratory diseases in China: Time for urgent action [J]. The Lancet, 2016, 388(10054): 1939–1951.

[8] WHITTEN G Z. The chemistry of smog formation: A review of current knowledge [J]. Environment International, 1983, 9(6): 447–463.

[9] YUAN Xue-liang, LIU Xin, ZUO Jian. The development of new energy vehicles for a sustainable future: A review [J]. Renewable and Sustainable Energy Reviews, 2015, 42: 298–305.

[10] WU Ya, ZHANG Li. Can the development of electric vehicles reduce the emission of air pollutants and greenhouse gases in developing countries? [J]. Transportation Research Part D: Transport and Environment, 2017, 51: 129–145.

[11] LI Yong-bing, CHEN Chang-nian, LANG Li-hui, XIE Hui, LI Luo-xing, FENG Zhi-jun. Research on key manufacturing technology of automobile aluminum body [J]. Automobile Technology and Material, 2013(3): 50–58. (in Chinese)

[12] SCHUBERT E, KLASSEN M, ZERNER I, WALZ C, SEPOLD G. Light-weight structures produced by laser beam joining for future applications in automobile and aerospace industry [J]. Journal of Materials Processing Technology, 2001, 115(1): 2–8.

[13] JHAVERI K, LEWIS G M, SULLIVAN J L, KEOLEIAN G A. Life cycle assessment of thin-wall ductile cast iron for automotive lightweighting applications [J]. Sustainable Materials and Technologies, 2018, 15: 1–8.

[14] CZERWINSKI F, TROJANOVA Z, SZARAZ Z, PALCEK P,CHALUPOVA M. Magnesium alloys-design, processing and properties [M]. Rijeka, Croatia: In Tech, 2011.

[15] THARUMARAJAH A, KOLTUN P. Is there an environmental advantage of using magnesium components for light-weighting cars? [J]. Journal of Cleaner Production, 2007, 15(11, 12): 1007–1013.

[16] The world’s first magnesium alloy automobile hub production line is put into operation in Changge City [N]. Henan Daily [2017–08–18]. https://www.henandaily.cn/ content/sh/yxz/ 2017/0818/60563.html. (in Chinese)

[17] GAO Feng, NIE Zuo-ren, WANGZhi-hong, GONG Xian-zheng, ZUO Tie-yong. Assessing environmental impact of magnesium production using Pidgeon process in China [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 749–754.

[18] KWON G R, WOO S H, LIM S R. Industrial ecology-based strategies to reduce the embodied CO2 of magnesium metal [J]. Resources, Conservation and Recycling: Part A, 2015, 104: 206–212.

[19] RAUGEI M, MORREY D, HUTCHINSON A, WINFIELD P. A coherent life cycle assessment of a range of lightweighting strategies for compact vehicles [J]. Journal of Cleaner Production: Part A, 2015, 108: 1168–1176.

[20] NIERO M, OLSEN S I. Circular economy: To be or not to be in a closed product loop? A life cycle assessment of aluminium cans with inclusion of alloying elements [J]. Resources, Conservation and Recycling, 2016, 114: 18–31.

[21] KHALIL Y F. Eco-efficient lightweight carbon-fiber reinforced polymer for environmentally greener commercial aviation industry [J]. Sustainable Production and Consumption, 2017, 12: 16–26.

[22] GAO Feng. Research on life cycle assessment and the application in China magnesium industry [D]. Beijing: Beijing University of Technology, 2008. (in Chinese)

[23] GAO Feng, NIEZuo-ren, WANGZhi-hong, GONG Xian- zheng, ZUO Tie-yong. Life cycle assessment of primary magnesium production using the Pidgeon process in China [J]. The International Journal of Life Cycle Assessment, 2009, 14(5): 480–489.

[24] China Nonferrous Metals Industry Yearbook Writing Group. Yearbook of China nonferrous metals industry in 2016 [M]. Beijing: China Nonferrous Metals industry Association, 2016. (in Chinese)

[25] SUN Xin, ZHANG Peng, ZHAO Ming-lan. Life cycle energy consumptions and environmental impact assessment of the gasoline engine [J]. Acta Scientiae Circumstantiae, 2016, 36(8): 3059–3065. (in Chinese)

(Edited by YANG Hua)

中文导读

基于生命周期评价的镁合金汽车轮毂环境影响评价

摘要:为了探明镁合金汽车轮毂替代铝合金汽车轮毂对环境的影响,本文基于生命周期评价理论研究了2种轮毂生产及使用过程中的资源、能源消耗及污染物排放情况。结果表明:采用镁合金轮毂替代铝合金轮毂,可有效降低对环境的不利影响,与铝合金轮毂相比,镁合金轮毂在整个生命周期中可使温室效应降低39.6%,对人体健康的损害程度降低24.0%;CO2是两种轮毂生命周期中的主要污染物,且贯穿于轮毂的生产及使用过程,颗粒物则主要产生于轮毂的制备阶段;与铝合金轮毂相比,镁合金轮毂的绿色效应主要归功于减重所带来的油耗降低。

关键词:LCA理论;镁合金;铝合金;轮毂;环境影响

Foundation item: Projects(51605159, 51475162) supported by the National Natural Science Foundation of China;Project(16B092) supported by the Hunan Education Department Outstanding Youth Foundation, China; Project(2016JJ5042) supported by the Natural Science Foundation of Hunan Province, China

Received date: 2018-02-10; Accepted date: 2018-06-30

Corresponding author: TANG Chang-ping, PhD, Lecturer; Tel: +86–731–58290782; E-mail: tcpswnu@163.com

Abstract: In order to find out the impact of aluminum alloy hub replaced by the magnesium alloy hub on environment, the resource consumption, energy consumption and pollutant emission during hub production and their service life of the two types of hubs are investigated based on the life cycle assessment (LCA) theory. The results indicate that the adverse impact on environment can be effectively reduced by the application of magnesium alloy hubs. Compared with aluminum alloy hubs, the global warming potential (GWP) and human toxicity potential (HTP) are reduced by 39.6% and 24.0%, respectively. CO2 is the main pollutant in the life cycles of the two kinds of hubs, which is generated throughout the whole life cycle including the fabrication process and the service life, while the pollutants of particles mainly come from the fabrication stage. Compared with the aluminum alloy hubs, the green effect brought by magnesium alloy hubs is mainly due to the reduction of fuel consumption caused by weight loss.