DOI: 10.11817/j.issn.1672-7207.2015.07.020

节理三维形貌参数的采样效应与峰值抗剪强度准则

唐志成1, 2,刘泉声1,夏才初2

(1. 武汉大学 土木建筑工程学院,湖北 武汉,430072;

2. 同济大学 地下建筑与工程系,上海,200092)

摘 要:

3D型便携式岩石三维表面形貌仪对3组不同形貌的节理试件进行形貌测试,采用不同的采样间距获得形貌坐标的三维离散点数据。采用节理形貌描述方法计算节理的三维粗糙度,其值随采样间距的增大而逐步减少、最终趋于稳定,与采样间距呈对数函数的关系。根据3组节理在5级法向应力下的直剪试验结果,提出考虑采样间距影响的节理峰值抗剪强度公式,采样效应系数与采样间距呈幂函数关系。采用岩石节理的直剪试验结果对所提公式进行验证,计算值与试验值较吻合。

关键词:

中图分类号:TU821 文献标志码:A 文章编号:1672-7207(2015)07-2524-08

Investigation of three-dimensional roughness scale-dependency and peak shear strength criterion

TANG Zhicheng1, 2, LIU Quansheng1, XIA Caichu2

(1. School of Civil and Architectural Engineering, Wuhan University, Wuhan 430072, China;

2. Department of Geotechnical Engineering, Tongji University, Shanghai 200092, China)

Abstract: In order to obtain three-dimensional discrete points, three rock joint replicas were measured and digitized with TJXW-3D-typed portable rock surface topography by different sampling intervals. Three-dimensional roughness metric method was analyzed. The roughness decreases with the increasing sample interval, but stabilizes eventually. An empirical relationship between the sample interval and roughness was established and there was a logarithmic function. According to direct shear test of three joints over 5-level normal stresses, a peak shear strength criterion taking into account the sampling effect was proposed for rock joints. There was a power function between the sampling interval and the sampling coefficient. The published experimental datum was used to validate the proposed criterion. The results show that there is a good agreement between the calculated values and the experimental results. Thus, the peak shear strength of rock joints can be predicted by the proposed criterion.

Key words: rock joint; peak shear strength; three-dimensional morphology parameters; sampling effect

工程岩体中往往含有大量规模不同的节理。节理的存在破坏了岩体的完整性,大大降低了岩体的力学强度等。节理的力学性质在很多程度上影响岩体的力学性质,进而影响岩体工程的稳定与安全,因此,对节理的力学性质展开研究,具有极大的工程实践意义。剪切力学性质是节理最主要的力学性质,与表面的三维形貌特征有直接关系。如何测试并合理描述节理的形貌特征是研究节理力学性质的前提。目前,测试技术的发展使得精确描述节理的三维形貌成为可能[1-10]。Grasselli等[2-3]采用最大接触面积比A0、最大视倾角θ*max和视倾角分布参数C描述节理的形貌特征。A0,θ*max和C由形貌测试获得,不进行任何平均化处理,被认为是目前最为合适的描述节理三维形貌特征的参数[11],且能够反映节理形貌的各向异性性质[5]。在测试节理的形貌特征时,采样间距对最终的形貌参数的计算结果有很大影响[12],进而影响峰值抗剪强度公式的计算值。目前,就节理的三维形貌参数而言,分析采样间距影响的文献较少。分析节理表面形貌特征的主要目的是为了建立起形貌参数与峰值抗剪强度的联系。本文作者在3组不同形貌节理的基础上,首先进行三维形貌参数与采样间距关系的研究,然后在直剪试验的基础上建立考虑采样间距影响的峰值抗剪强度公式,最后采用文献中报道的直剪试验数据进行验证。

1 形貌测试设备与描述方法

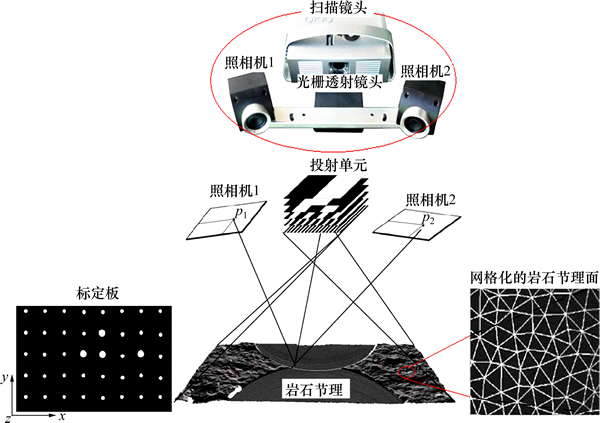

1.1 形貌测试设备

采用TJXW-3D 型便携式岩石三维表面形貌仪[4]测试节理的三维形貌。该测试系统采用立体视觉法、结构光法和双目成像原理,具有测试时间短,操作简单、方便等特点。摄像头的分辨率为1.44×106像素,最高分辨率为0.02 mm。对实验室尺度范围内的节理形貌的测试步骤(如图1所示)为:1) 标定设备,确定形貌仪系统内部参数;2) 投射栅距不同的一系列平行光栅到节理面,获得节理形貌的三维离散点坐标数据;3) 根据节理的三维离散点坐标数据,计算三维形貌参数。

1.2 形貌描述方法

将节理形貌的三维离散点坐标数据网格化后,每个网格的方位均可由方位角 、倾角

、倾角 确定,如图2所示[3]。节理的粗糙程度可用网格视倾角

确定,如图2所示[3]。节理的粗糙程度可用网格视倾角 的函数表示,每个网格的视倾角

的函数表示,每个网格的视倾角 表示该网格沿剪切方向相对于平均平面的起伏程度。视倾角

表示该网格沿剪切方向相对于平均平面的起伏程度。视倾角 表示网格倾角

表示网格倾角 在剪切方向

在剪切方向 上的分量可表示为

上的分量可表示为

(1)

(1)

累加节理面中视倾角θ*大于或等于某阀值的网格的面积并与整个节理面的面积相比,得到归一化的参量 ,在[0,

,在[0,  ]内不断改变视倾角的阀值从而得到相应的

]内不断改变视倾角的阀值从而得到相应的 ,随视倾角阀值

,随视倾角阀值 的增加,对应的接触面积比

的增加,对应的接触面积比 减少,通过对37组岩石节理的形貌进行分析,可用式(2)描述节理的形貌特征[3]:

减少,通过对37组岩石节理的形貌进行分析,可用式(2)描述节理的形貌特征[3]:

图1 TJXW-3D 型便携式岩石三维表面形貌仪的测试原理与流程

Fig. 1 Test principle and process of TJXW-3D-typed portable three-dimensional profilometer of rock

图2 沿剪切方向相对于平均平面的视倾角 的定义[3]

的定义[3]

Fig. 2 Geometrical identification of the apparent dip angle  measured along shear direction with respect to the average plane[3]

measured along shear direction with respect to the average plane[3]

(2)

(2)

式中:A0为沿剪切方向阀值为0°时的接触面积比,即节理面的最大接触面积比; 为剪切方向上视倾角

为剪切方向上视倾角 的最大值;C为粗糙度,表示剪切方向上视倾角

的最大值;C为粗糙度,表示剪切方向上视倾角 的分布,C越小,节理越粗糙。

的分布,C越小,节理越粗糙。

在[0,  ]内对下式积分[5]:

]内对下式积分[5]:

(3)

(3)

式(3)为由式(2)确定的形貌函数曲线与坐标轴围成的面积,面积越大,则节理面越粗糙;反之,面积越小,则节理面越平滑。式(3)可用于表征节理的三维粗糙程度[5]。

2 采样间距对形貌参数的影响

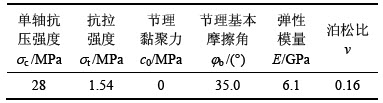

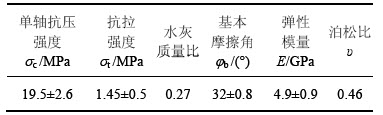

将适合剪切盒尺寸的若干岩石试件劈裂获得3个具有不同表面形貌的偶合节理(长×宽为300 mm×150 mm),以此作为模板采用水、砂、水泥质量比为1:2:3的水泥砂浆复制其形貌,共制备3组具有不同形貌的节理(J-Ⅰ,J-Ⅱ和J-Ⅲ)。在25 ℃的恒温下养护28 d后进行试验。采用TJXW-3D 型便携式岩石三维表面形貌仪对J-Ⅰ,J-Ⅱ和J-Ⅲ进行形貌测试,网格化后的节理形貌如图3所示(图示采样间距为1 mm)。与直剪试验相关的材料/节理面的基本物理力学性质参数见表1[13]。

表1 节理材料/节理面的基本力学参数[13]

Table 1 Mechanical property of joint material and joints[13]

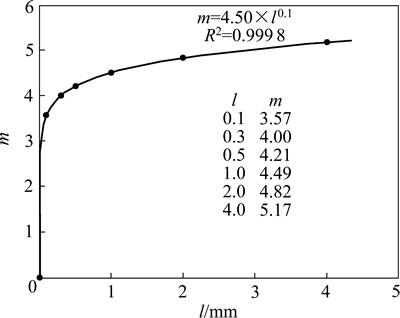

表2所示为不同采样间距下,根据Grasselli等[2-3]建议的方法计算得到的三维形貌参数。采样间距与三维形貌参数的关系如图4所示。参数 与网格尺度 l 的关系可表示为

与网格尺度 l 的关系可表示为

(4)

(4)

式中:a和b为拟合参数;l和L分别为采样间距、试件长度。

表2 不同采样间距下节理的三维形貌参数

Table 2 Three-dimensional parameters with different spacing point

图3 节理的三维形貌特征

Fig. 3 Three-dimensional surface morphologies of joints

图4 不同采样间距下节理的三维形貌参数

Fig. 4 Three-dimensional morphology parameters with different sampling intervals

3 峰值抗剪强度公式

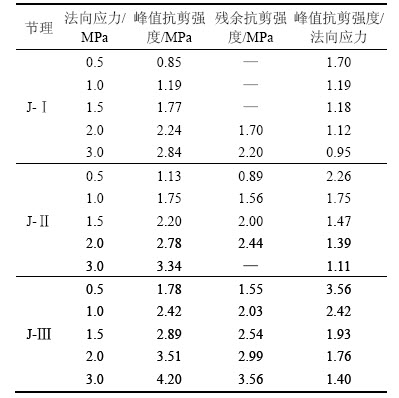

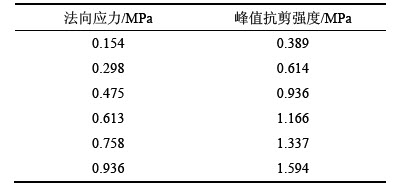

各组节理的5个试件分别在0.5,1.0,1.0,2.0和3.0 MPa 5级法向应力下进行直剪试验。先按荷载控制方式施加法向荷载直至预定的法向应力;再按变形控制方式施加切向荷载,加载速率为0.5 mm/min;设定的剪切位移为18 mm(保证出现峰值抗剪强度或至试件破坏)。共进行15组节理的直剪试验,得到的典型剪切强度值如表3所示。

表3 J-Ⅰ,J-Ⅱ和J-Ⅲ节理的直剪试验结果

Table 3 Experimental datum for J-Ⅰ, J-Ⅱ and J-Ⅲ joints

唐志成等[14-15]提出的含三维形貌参数的峰值抗剪强度公式为

(5)

(5)

式中:τp为峰值抗剪强度;σn为法向应力;σt为节理材料的抗拉强度;φb为节理的基本摩擦角。

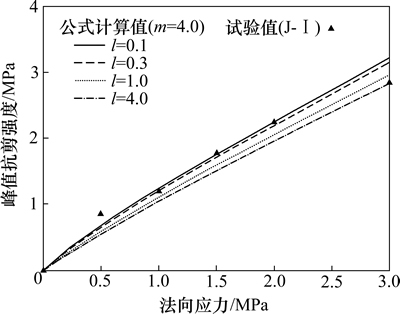

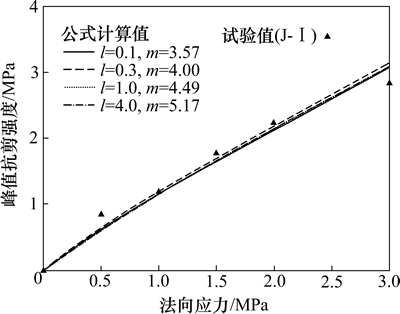

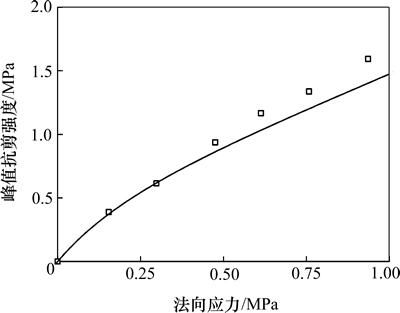

若不考虑采样间距的影响,采用0.3 mm采样间距下的形貌参数由式(5)计算节理的峰值抗剪强度(以J-Ⅰ为例)如图5所示。从图5可见:受形貌参数计算值的影响,峰值抗剪强度的计算值随采样间距的增大而减少。

图5 不同采样间距l时式(5)的计算值与试验值的比较

Fig. 5 Comparison between calculated peak shear strength by Eqn. (5) with different points spacing and measured peak shear strength

若考虑采样效应,可将式(5)改写为

(6)

(6)

式中:m为采样效应系数,反映采样间距的影响。

采用式(6)计算不同采样间距下节理的峰值抗剪强度,得到一系列不同的m,回归分析m与l的关系,如图6所示,二者的函数关系可表示为

(7)

(7)

由此,得到考虑采样间距影响的节理峰值抗剪强度公式,如式(8)所示。采用式(8)计算节理的峰值抗剪强度并与试验值进行比较,如图7所示(以J-Ⅰ为例)。

(8)

(8)

图6 m与l的关系

Fig. 6 m as a function of l

图7 式(8)的计算值与试验值的比较

Fig. 7 Comparison between calculated peak shear strength by Eqn. (8) and measured peak shear strength

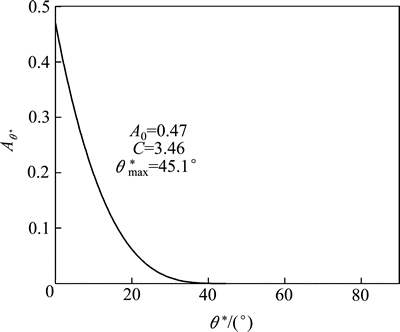

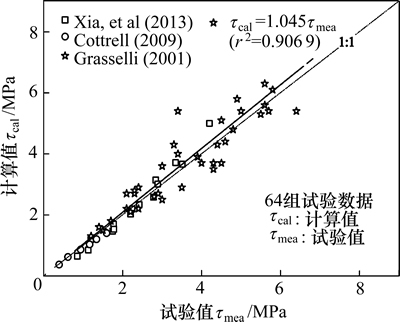

为进一步验证考虑采样间距影响的峰值抗剪强度公式,采用Cottrell的6组水泥砂浆节理试件的直剪试验数据[16]验证提出的公式。节理的基本物理力学性质参数如表4所示,由式(2)确定的形貌函数曲线如图8所示(采样间距为0.5 mm)。直剪试验得到的峰值抗剪强度值如表5所示。节理试件的制作流程、形貌测试方法及直剪试验步骤等见文献[16]。采样式(8)得到的抗剪强度计算值与试验值的比较如图9所示。

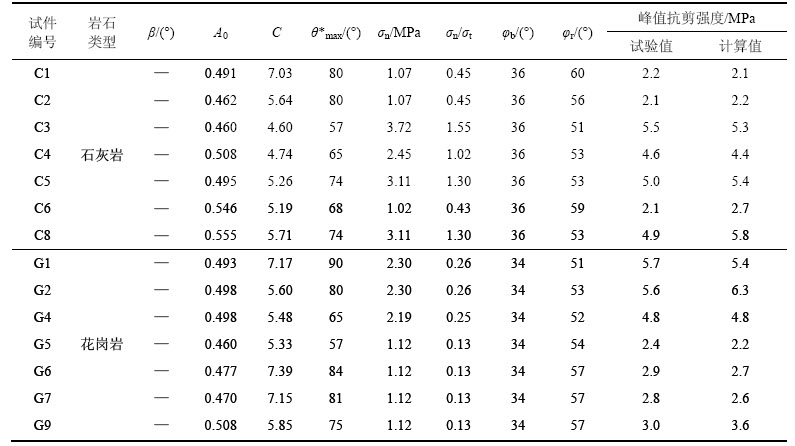

为验证新公式对岩石节理的适用性,采用Grasselli[2]的37组岩石节理的直剪切试验结果对式(8)进行验证,抗剪强度计算值与试验值如表6所示(表中:φr为残余摩擦角),平均偏差约为14.8%,可见新公式同样适用于分析岩石节理的峰值抗剪强度。

表4 Cottrell节理材料的基本力学参数[16]

Table 4 Mechanical parameters of Cottrell’s joints[16]

图8 Cottrell节理的形貌参数[16]

Fig. 8 Morphology parameters of Cottrell’s joints[16]

表5 Cottrell节理直剪试验结果[16]

Table 5 Experimental results of Cottrell’s joints[16]

图9 节理峰值抗剪强度试验值与式(8)的计算值比较

Fig. 9 Comparison between the measured peak shear strength and the calculated peak shear strength by Eqn. (8)

图10所示为上述64组节理试件的抗剪强度试验值与计算值的比较,总的抗剪强度平均偏差约为9.4%。从图10可见:抗剪强度计算结果与实验值保持了较好的一致性。考虑到新公式采用的形貌参数是基于形貌测试的结果,不含任何拟合参数以及平均化的处理,因此,可用本文作者提出的式(8)预测节理的峰值抗剪强度。

表6 岩石节理峰值抗剪强度的试验值[2]与计算值的比较

Table 6 Comparison between the measured peak shear strength[2] and calculated peak shear strength of rock joints

续表6

图10 节理峰值抗剪强度试验值与计算值比较

Fig. 10 Comparison between the measured peak shear strength and the calculated peak shear strength by proposed criterion

4 结论

1) 采用不同的采样间距分析节理的三维形貌参数,形貌参数计算值随采样间距的增加而减少,但逐步趋于稳定,二者之间呈对数函数关系。

2) 采样间距影响形貌参数的计算结果,最终影响到节理峰值抗剪强度的计算值;提出了考虑采样间距影响的峰值抗剪强度公式,由多组试验数据对其进行了验证,节理峰值抗剪强度计算值与试验值吻合较好。

3) 采样效应系数与采样间距呈幂函数关系,随采样间距的增大而增大。

参考文献:

[1] Fardin N, Feng Q, Stephansson O. Application of a new in-situ 3D laser scanner to study the scale effect on the rock joint surface roughness[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(2): 329-335.

[2] Grasselli G. Shear strength of rock joints based on quantified surface description[D]. Switzerland: Swiss Federal Institute of Technology, 2001: 49-55.

[3] Grasselli G, Wirth J, Egger P. Quantitative three-dimensional description of a rough surface and parameter evolution with shearing[J]. International Journal of Rock Mechanics and Mining Sciences, 2002, 39(6): 789-800.

[4] 夏才初, 王伟, 丁增志. TJXW-3D型便携式岩石三维表面形貌仪的研制[J]. 岩石力学与工程学报, 2008, 27(7): 1505-1512.

XIA Caichu, WANG Wei, DING Zengzhi. Development of three-dimensional TJXW-3D-typed portable rock surface topography[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(7): 1502-1512.

[5] Tatone B S A, Grasselli G. A method to evaluate the three- dimensional roughness of fracture surfaces in brittle geomaterials[J]. The Review of Scientific Instruments, 2009, 80(12): 125110-10.

[6] Tatone B S A, Grasselli G. An investigation of discontinuity roughness scale dependency using high-resolution surface measurements. Rock Mechanics and Rock Engineering, 2013, 46(4): 657-681.

[7] 范祥, 曹平, 张春阳. 节理体积的计算方法[J].中南大学学报(自然科学版), 2012, 43(11): 4420-4425.

FAN Xiang, CAO Ping, ZHANG Chunyang. A computational method of joint volume[J]. Journal of Central South University (Science and Technology), 2012, 43(11): 4420-4425.

[8] Gao Y, Wong L N Y. A modified correlation between roughness parameter Z2 and the JRC[J]. Rock Mechanics and Rock Engineering, 2015, 48(1): 387-396.

[9] Alameda-Hernández P, Jiménez-Perálvarez J, Palenzuela J A, et al. Improvement of the JRC calculation using different parameters obtained through a new survey method applied to rock discontinuities[J]. Rock Mechanics and Rock Engineering, 2014, 47(6): 2047-2060.

[10] Ge Y, Kulatilake P H S W, Tang H, et al. Investigation of natural rock joint roughness[J]. Computers and Geotechnics, 2014, 55(1): 290-305.

[11] Yang Z Y, Taghichian A, Huang G D. On the applicability of self-affinity concept in scale of three-dimensional rock joints[J]. International Journal of Rock Mechanics and Mining Science, 2011, 48(7): 1173-1187.

[12] 夏才初, 孙宗颀. 工程岩体节理力学[M]. 上海: 同济大学出版社, 2002: 100-101.

XIA Caichu, SUN Zongqi. Joint mechanics of engineering rock mass[M]. Shanghai: Tongji University Press, 2002: 100-101.

[13] 唐志成, 夏才初, 宋英龙, 等. 人工模拟节理峰值剪胀模型及峰值抗剪强度分析[J]. 岩石力学与工程学报, 2012, 31(s1): 3038-3044.

TANG Zhicheng, XIA Caichu, SONG Yinglong, et al. Analysis of peak dilation strength and model of peak dilation angle for artificial joint[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(s1): 3038-3044.

[14] 唐志成, 夏才初, 宋英龙, 等. Grasselli 峰值抗剪强度再探[J]. 岩石力学与工程学报, 2012, 31(2): 356-364.

TANG Zhicheng, XIA Caichu, SONG Yinglomg, et al. Discussion about Grasselli’s peak shear strength criterion for rock joints[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(2): 356-364.

[15] XIA Caichu, TANG Zhicheng, XIAO Weiming, et al. New peak shear strength criterion of rock joints based on quantified surface description[J]. Rock Mechanics and Rock Engineering , 2014, 47(2): 387-400.

[16] Cottrell B E. Updates to the GG-shear strength criterion[D]. Toronto, Canada: University of Toronto, 2009: 25-45.

(编辑 罗金花)

收稿日期:2014-11-20;修回日期:2015-01-25

基金项目(Foundation item):国家自然科学青年基金资助项目(41402247);国家自然科学基金重点资助项目(41130742);国家重点基础研究发展计划(973项目)(2014CB046904);湖北省自然科学基金重点项目(创新群体)(2011CDA119);国家自然科学面上基金资助项目(40972178) (Project(41402247) supported by the National Natural Science Foundation for Young Scientists of China; Project(41130742) supported by the Key Program of the National Natural Science Foundation of China; Project(2014CB046904) supported by the National Basic Research Program (973 Program) of China; Project(2011CDA119) supported by the Key National Science Foundation of Hubei Province; Project(40972178) supported by the General Program of the National Natural Science Foundation of China)

通信作者:唐志成,博士,从事岩石力学方面的研究;E-mail: tangzhichengok@126.com

摘要:采用TJXW-3D型便携式岩石三维表面形貌仪对3组不同形貌的节理试件进行形貌测试,采用不同的采样间距获得形貌坐标的三维离散点数据。采用节理形貌描述方法计算节理的三维粗糙度,其值随采样间距的增大而逐步减少、最终趋于稳定,与采样间距呈对数函数的关系。根据3组节理在5级法向应力下的直剪试验结果,提出考虑采样间距影响的节理峰值抗剪强度公式,采样效应系数与采样间距呈幂函数关系。采用岩石节理的直剪试验结果对所提公式进行验证,计算值与试验值较吻合。

[4] 夏才初, 王伟, 丁增志. TJXW-3D型便携式岩石三维表面形貌仪的研制[J]. 岩石力学与工程学报, 2008, 27(7): 1505-1512.

[7] 范祥, 曹平, 张春阳. 节理体积的计算方法[J].中南大学学报(自然科学版), 2012, 43(11): 4420-4425.

[12] 夏才初, 孙宗颀. 工程岩体节理力学[M]. 上海: 同济大学出版社, 2002: 100-101.

[13] 唐志成, 夏才初, 宋英龙, 等. 人工模拟节理峰值剪胀模型及峰值抗剪强度分析[J]. 岩石力学与工程学报, 2012, 31(s1): 3038-3044.

[14] 唐志成, 夏才初, 宋英龙, 等. Grasselli 峰值抗剪强度再探[J]. 岩石力学与工程学报, 2012, 31(2): 356-364.