Trans. Nonferrous Met. Soc. China 23(2013) 1435-1441

Identification of material parameters from punch stretch test

Xiao-qiang LI1, De-hua HE1,2

1. School of Mechanical Engineering and Automation, Beijing University of Aeronautics and Astronautics, Beijing 100191, China;

2. Beijing Hangxing Machinery Manufacturing Company, Beijing 100013, China

Received 9 May 2012; accepted 10 November 2012

Abstract:

To accurately describe the mechanical properties of aluminium alloy sheet during deformation, an inverse identification was presented to deal with material parameters from the popular punch stretch test. In the identification procedure, the optimization strategy combines finite element method (FEM), Latin hypercube sampling (LHS), Kriging model and multi-island genetic algorithm (MIGA). The proposed approach is used on material parameter identification of aluminium alloy sheet 2D12. The anisotropic yield criterion Hill’90 is discussed. The results show that the Hill’90 anisotropic yield criterion with identified anisotropic material parameters has a good potential in describing the anisotropic behaviours. It provides a way to obtain the material parameters for FE simulations of sheet metal forming.

Key words:

parameter identification; punch stretch test; aluminium alloy sheet; Hill’90; Kriging model;

1 Introduction

Currently, FEM provides an appreciable help in handling sheet metal forming process. It could significantly reduce the time and cost of product development in the design stage. However, the reliability of FE simulations depends largely on the accuracy of the input data such as material parameters, geometry and contact conditions [1]. Among these factors, the material parameters that characterize the deformation behaviors are of great importance to achieve a sufficiently accurate FE simulation, particularly for a substantial anisotropy [2].

Generally, the standard uniaxial tensile test is used to determine the sheet metal material parameters. Other standard tests, such as the shear test, are also required for enhanced material models [3-5]. However, complex models require a considerable number of parameters to be determined, which leads to a high cost and a slow process. On the other hand, the results obtained from the standard tests are often inconsistent with the deformation behaviours in practice, due to many restricting assumptions [6,7], such as the homogeneity of the deformation fields. Sometimes, it is even difficult to determine material parameter through the standard tests, such as thin-walled tube with a small radius.

An alternative to the standard tests is to perform an inverse identification, which can be used to identify elastoplastic material parameters [2,8]. Inverse identification has a wider range of applications and can deal with large strain, non-uniform deformation and complex deformation states. Some works have reported in this direction [4,9-16]. Since the punch stretch test can be introduced to evaluate the effect of material on inhomogeneous and bend type forming [17], the test is adopted for identification of material parameters in the present study. For the optimization solution, the Kriging model coupled with MIGA is applied as an alternative to FE simulations in obtaining the best combination of material parameters. Then, the parameter identification of Hill’90 anisotropic yield criterion for aluminium alloy sheet is discussed.

2 Material models

In order to better describe the sheet metal anisotropy, enhanced constitutive models are proposed to improve the yielding description of sheet metal behaviours. In this work, the well-known anisotropic yield criterion Hill’90 is discussed.

2.1 Anisotropic yield criterion Hill’90

HILL [18] presented a yield criterion that describes both in-plane anisotropy and accommodated anomalous behaviour. In terms of intrinsic variables, the criterion can be represented as

(1)

(1)

where m is the non-integer power that accommodates anomalous behaviour, with m>1; A, B and C are non-dimensional parameters; α is the counterclockwise angle between the first principal stress and the material orthotropy; σb is the yield stress under equibiaxial tension.

Two common parameter identification methods, based on the material yield strengths and R-values, respectively, were given by HILL [18] and by LIN and DING [19]. The yield strengths method works well for the corresponding yield strengths data but poorly for the R-values data. While the R-values identification method works well for R-values data but poorly for yield strengths data [20]. Beside these two common parameter identification methods, the third option is the development of the inverse identification method.

2.2 Strain hardening law

For the sheet metal tested in this work, the strain hardening is assumed to be isotropic, characterized by the commonly used Swift law. It is expressed as

(2)

(2)

where σ is the equivalent yield stress; k and n are the hardening coefficient and the hardening exponent, respectively; ε0 and εp are the strain hardening parameter and the equivalent plastic strain, respectively.

3 Optimization problem description

3.1 Experimental setup

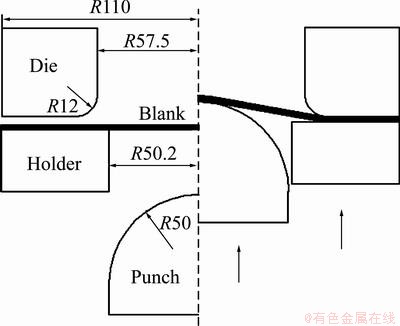

A key point of the inverse identification method is to perform a viable experiment. The proposed plan includes the testing of type and the choice of sample. Earlier works already proposed the uniaxial tensile test with non-standard samples [12,14], and the heterogeneous biaxial tensile tests with cruciform specimens [15]. Later, identification method from metal forming processes was considered [4], which exhibits a great advantage in evaluating material parameters of sheet metals under real situations. In this study, the punch stretch test is adopted for it provides the possibility to consider the deformation complexity. This is much closer to deformation fields occurring in real forming operations. In addition, it is simple to perform and standard test equipments can be used. The punch stretch test used is illustrated in Fig. 1. The circular sheet sample 2D12 has a thickness of 3.5 mm and a radius of 110 mm. Contact between the sheet and the punch was well lubricated, so the friction could be neglected.

Fig. 1 Punch stretch test (Unit: mm)

During the punch stretch test, the punch was pressed into the sheet, and no fracture occurred to the sheet. The applied force on the punch and the displacement of the sheet’s central point were continuously monitored and automatically recorded. The recorded force was considered the boundary condition of FE simulation, and the observed experimental displacements were compared with the calculated ones.

3.2 Optimization objective

The identification of material parameters is considered an optimization problem. The aim of optimization is to get the optimal material parameters that make the calculated data match the experimental ones as closely as possible. According to the experimental displacements obtained from the punch stretch test and the calculated ones, the least square cost-function is expressed as

(3)

(3)

where  is the objective function in a least square sense; P is the material parameter; q is the number of measured points;

is the objective function in a least square sense; P is the material parameter; q is the number of measured points;  and

and  are the experimental and calculated displacements under the same boundary condition, respectively.

are the experimental and calculated displacements under the same boundary condition, respectively.

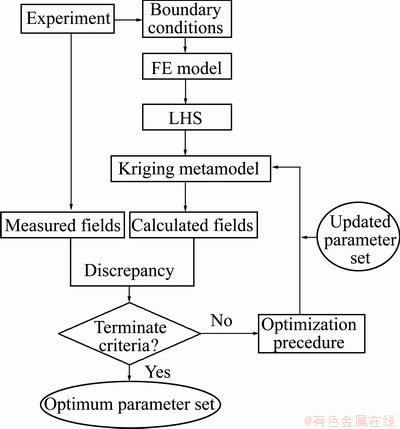

4 Optimization strategy

During the optimization process, a number of FE simulations are needed to obtain the optimum material parameters, which is a time-consuming task. To reduce the computational cost, a Kriging model is taken as an alternative analysis tool to improve the computational efficiency. The design flow for the inverse problem is shown in Fig. 2.

Fig. 2 Flow chart of inverse identification

4.1 Kriging model

4.1.1 Mathematical form

Kriging model in deterministic simulation developed by SACK et al [21,22] is represented as a combination of a regression model and a stochastic process:

(4)

(4)

where y(x) is the unknown function of interest; β is a set of polynomial regression coefficients; f(x) is a set of pre-specified functions; the first term f T(x)β provides a global approximation in the design space, whereas the second term z(x) generates localized deviations, so the Kriging model interpolates the sampling points.

Kriging model, as an approximate model, is an interpolation method. It is well suitable for I/O data of deterministic simulation case, such as FE simulation. At present, Kriging model has been widely applied in the optimization areas to surrogate FE simulations. More details about Kriging model could be found in Refs. [21,22].

4.1.2 Accuracy measurement

The approximate performance of the Kriging model considers the maximum absolute error (MAE) and the root mean square error (RMSE) as accuracy measurements. MAE represents local deviations and RMSE provides a global error measure. They are given, respectively, by

(5)

(5)

and

(6)

(6)

where k is the number of additional test points to verify the approximate model;  is the predicted value for the observed value yi. The smaller the value of MAE and/or RMSE is, the more accurate the Kriging model is.

is the predicted value for the observed value yi. The smaller the value of MAE and/or RMSE is, the more accurate the Kriging model is.

4.2 Latin hypercube sampling

As a sampling technique, LHS is a space-filling type of design and each level of a factor is considered only once. LHS allows one to select the number of designs to run according to requirements as long as it is greater than the number of factors. Thus, it can use a relatively small number of design points to investigate how inputs affect outputs. Moreover, LHS is well suitable for computer experiments, which can cope with more levels and more combinations for each factor while using fewer testing trails. In light of its excellent features, LHS is widely applied to designing and analyzing engineering problems and is helpful to understanding process characteristics with less cost. Here, LHS is used to select design points to build the Kriging approximate model.

4.3 Multi-island genetic algorithm

To find the best combination for the optimization problem, many algorithms have been developed, among which genetic algorithm (GA) has been applied to dealing with a diverse range of scientific and engineering problems, including process optimization of sheet metal forming [23] and identification of material parameters [7,10,24].

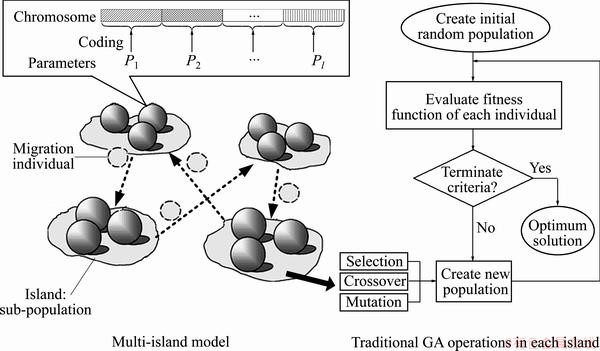

GA is well suited to handling complex optimization problems with nonlinear, discrete and constrained search spaces. A more efficient GA, termed ‘MIGA’, is now being used. Figure 3 displays the operation descriptions of MIGA, which involves a distributed GA and makes use of parallel processing. One main feature of the method, different from traditional GA, is that the population in one generation is divided into several sub-populations called ‘islands’, and all traditional genetic operations are performed separately on each island. An exchange of individual information, termed ‘migration’, is carried out periodically between sub-populations. This outstanding feature enables the calculation to avoid converging to partially optimal solutions. In the view of its capacity and efficiency, MIGA is adopted as the optimization strategy here.

Fig. 3 Schematic view of MIGA operation principle

5 Results and discussion

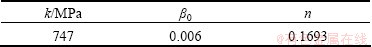

5.1 Determination of hardening parameters

The uniaxial tensile tests along the rolling direction were carried out to obtain the typical equivalent stress-equivalent strain behaviour. The obtained stress versus strain data were then fitted with the Swift law as already represented in Eq. (2). The computed results are listed in Table 1. Besides, an additional equibiaxial tensile test was required for comparative analysis. The yield stress obtained under equi-biaxial tensile state was 339.45 MPa.

Table 1 Hardening coefficients for aluminium alloy sheet of 2D12

5.2 Identification of anisotropic material parameters

5.2.1 Optimization procedure

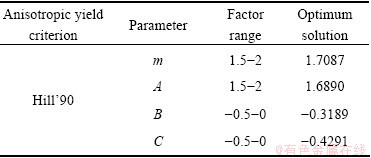

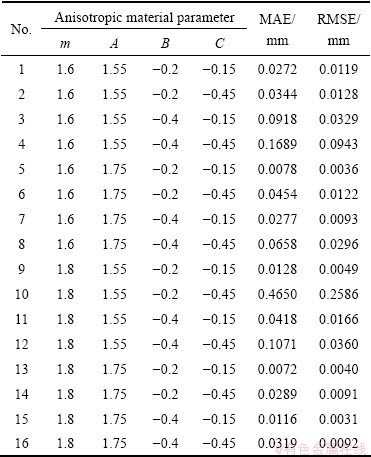

Certainly, an enhancement of the Kriging model accuracy can be reached by increasing the number of sampling points, but it will lead to a significant increase in computational cost. To determine the number of sampling points, one has to find a trade-off between the accuracy of the approximate model and the computational expense. Although the minimum number of designs is not limited by LHS as long as it is greater than the number of factors, it is recommended that the number of sampling points is 12 times the number of inputs in the Kriging model in order to establish an accurate approximate model [25]. As stated in the previous section, four of the Hill’90 anisotropic material parameters, m, A, B, C, needed to be considered. Lower and upper bounds of the anisotropic material parameters were given with mathematical considerations on the anisotropic yield criterion, as well as some research and physical considerations. They are reported in Table 2. Then, 48 simulations were run based on the LHS. The calculated inputs (m, A, B, C) and outputs (20 displacement response points) were used to establish the response relations with the Kriging model.

In order to test the accuracy of the fitted approximate model, additional simulations were required to verify the reliability of the approximate model. Here, a full-factorial design with two levels of each factor was applied (16 simulations in total). The accuracy assessment allows for the MAE and RMSE as a check standard. The error analysis results of the test are shown in Table 3. The computed MAE and RMSE, compared to the displacements of measured points, are very small. It is thought that the constructed Kriging model achieves a satisfactory accuracy in approximating analysis. Thus, it could be used as an alternative to FE simulations.

Based on the approximation model already developed, the optimization procedure MIGA was used to search for the optimum solution. The initial population was randomly generated among the design ranges. 1200 runs in total were carried out in the optimization process, while only several minutes were spent. And the optimization procedure converges quickly to the optimum parameter set.

Table 2 Optimization description and optimum solution of anisotropic material parameters

Table 3 Error analysis of Kriging model

5.2.2 Identified results

The identified anisotropic material parameters of Hill’90 yield criterion are given in Table 3.

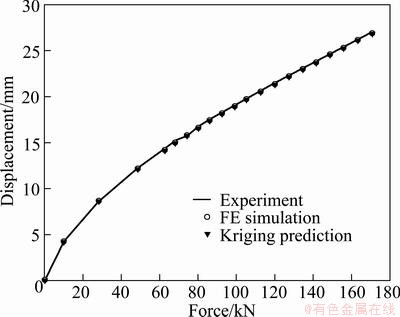

Figure 4 represents the displacement responses with respect to the applied force of the identified optimum parameter set. It is shown that the responses predicted by the Kriging model are very close to the experimental ones. In order to further check with the displacement responses, the corresponding FE simulation was implemented for comparison. Results show that the responses calculated from FE simulation agree well with the experimental ones. Again, this demonstrates that the Kriging model has a strong capacity for accurate prediction.

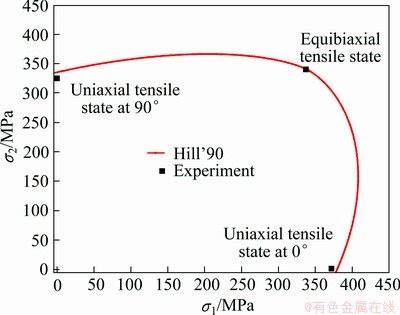

Figure 5 depicts the yield surface of Hill’90 with the identified anisotropic material parameters. The uniaxial tensile yield stresses predicted by the Hill’90 criterion at 0° and 90°, respectively, are very close to those from the experimental observations.

Fig. 4 Experimental, simulated and predicted displacement responses

Fig. 5 Identified yield surface

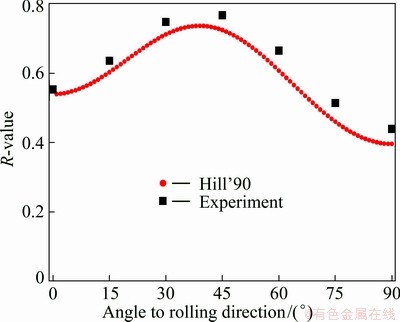

Figure 6 represents the predicted and experimental R-values distribution at various angles to the rolling direction. In general, a similar variation trend of R-values is found between the predicted distributions by the Hill’90 criterion and the experimental ones. Besides, the experimental R-values closely follow those predicted by the Hill’90 criterion. There are of course a few discrepancies between the predicted and the experimental R-values. This is because the deformation based on the punch stretch test is in a strong and non-uniform field. It is apparently different from standard test. Also, the strain measurement is distinct. The predicted R-values are expressed based on strain rate, whereas the experimental ones are macroscopic strains.

5.2.3 Verification tests

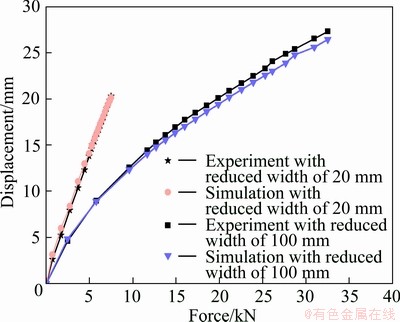

The verification procedure was similarly conducted based on the punch stretch test. Instead, two different samples designed with a radius of 110 mm and a reduced width of 20 mm and 100 mm, respectively, were considered, which correspondingly involves the uniaxial tensile and plane strain paths. The experimental and calculated results are illustrated in Fig. 7. In general, the calculated displacement responses with the optimum parameter set are consistent with the corresponding experimental ones, especially under the uniaxial tensile strain path.

Fig. 6 Comparison of experimental and predicted directional R-values

Fig. 7 Comparison of experimental and simulated displacement responses under uniaxial tensile and plane strain paths

In summary, Hill’90 anisotropic yield criterion with the identified material parameters has a great capacity in characterizing the anisotropic behaviours of aluminium alloy sheet 2D12.

6 Conclusions

1) Identification of material parameters was developed directly from the punch stretch test.

2) An optimization strategy for the identification of anisotropic material parameters was presented, which combines FEM, LHS, Kriging and MIGA.

3) The Hill’90 anisotropic yield criterion was used to perform the material parameter identification of aluminium alloy sheet 2D12. Results show that observed data results with the obtained optimum parameters agreed well with calculated ones, meaning that the method has a high reliability in performing the identification.

4) The optimization procedure indicates that the Kriging model has a strong capacity for highly accurate prediction. On the other hand, the use of the Kriging model significantly improves the computation efficiency.

References

[1] KLEINERMANN J, PONTHOT J. Parameter identification and shape/process optimization in metal forming simulation [J]. Journal of Materials Processing Technology, 2003, 139(1-3): 521-526.

[2] COOREMAN S, LECOMPTE D, SOL H, VANTOMME J, DEBRUYNE D. Elasto-plastic material parameter identification by inverse methods: Calculation of the sensitivity matrix [J]. International Journal of Solids and Structures, 2007, 44(13): 4329-4341.

[3] GAHBICHE A. Experimental characterization of stamping sheets: Application to the identification of the behaviour laws [D]. Tunisia: Ecole National D’lingéenieurs de Metz, 2005.

[4] GHOUATI O, GELIN J C. Identification of material parameters directly from metal forming processes [J]. Journal of Materials Processing Technology, 1998, 80-81: 560-564.

[5] GHOUATI O, GELIN J C. A finite element based identification method for complex material behaviours [J]. Computational Materials Science, 2001, 21(1): 57-68.

[6] CHAPARRO B M, ALVES J L, MENEZES L F, FEMNANDES J V. Optimization of the phenomenological constitutive models parameters using genetic algorithms [C]//Advanced Methods in Material Forming. Berlin: Springer Verlag, 2007: 35-54.

[7] KHALFALLAH A, BELHADJSALAH H, DOGUI A. Anisotropic parameter identification using inhomogeneous tensile test [J]. European Journal of Mechanics—A/Solids, 2002, 21(6): 927-942.

[8] HADDADI H, BOUVIER S, BANU M, MAIER C, TEODOSIU C. Towards an accurate description of the anisotropic behaviour of sheet metals under large plastic deformations: Modelling, numerical analysis and identification [J]. International Journal of Plasticity, 2006, 22(12): 2226-2271.

[9] HAMDI A, BELHADJSALAH H, HAMBLI R. Parameter identification of an elasto-plastic behaviour using artificial neural networks–genetic algorithm method [J]. Materials & Design, 2011, 32(1): 48-53.

[10] PONTHOT J P, KLEINERMANN J P. A cascade optimization methodology for automatic parameter identification and shape/process optimization in metal forming simulation [J]. Computer Methods in Applied Mechanics and Engineering, 2006, 195(41-43): 5472-5508.

[11] LANG Li-hui, LI Tao, ZHOU Xian-bin. Optimized constitutive equation of material property based on inverse modeling for aluminum alloy hydroforming simulation [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(6): 1379-1385.

[12] BELHABIB S, HADDADI H, GASPERINI M, VACHER P. Heterogeneous tensile test on elastoplastic metallic sheets: Comparison between FEM simulations and full-field strain measurements [J]. International Journal of Mechanical Sciences, 2008, 50(1): 14-21.

[13] LIU Di-hui, ZHONG Zhi-hua. Identification of material parameters of Barlat 1991 model by inverse method [J]. Chinese Journal of Mechnical Engineering, 2006, 42(4): 47-51. (in Chinese)

[14] MEUWISSEN M H H, OOMENS C W J, BAAIJENS F P T, PETTERSON R, JANSSEN J D. Determination of the elasto-plastic properties of aluminium using a mixed numerical-experimental method [J]. Journal of Materials Processing Technology, 1998, 75(1-3): 204-211.

[15] TEACA M, CHARPENTIER I, MARTINY M, FERRON G. Identification of sheet metal plastic anisotropy using heterogeneous biaxial tensile tests [J]. International Journal of Mechanical Sciences, 2010, 52(4): 572-580.

[16] LIU Jing, YANG He, ZHAN Mei, REN Ning. Material parameters identification of thin-walled seamed tube under biaxial stress state [J]. Steel Research International, 2010, 81(9-S): 1408-1411.

[17] DEMERI M Y. Strain analysis of the hemispherical stretch-bend test [J]. Journal of Applied Metalworking, 1986, 4(2): 183-187.

[18] HILL R. Constitutive modelling of orthotropic plasticity in sheet metals [J]. Journal of the Mechanics and Physics of Solids, 1990, 38(3): 405-417.

[19] LIN S B, DING J L. A modified form of Hill’s orientation-dependent yield criterion for orthotropic sheet metals [J]. Journal of the Mechanics and Physics of Solids, 1996, 44(11): 1739-1764.

[20] LEACOCK A G. A mathematical description of orthotropy in sheet metals [J]. Journal of the Mechanics and Physics of Solids, 2006, 54(2): 425-444.

[21] SACKS J, SCHILLER S B, WELCH W J. Design for computer experiments [J]. Technometrics, 1989, 31: 41-47.

[22] SACKS J, WELCH W J, MITCHELL T J, WYNN H P. Design and analysis of computer experiments [J]. Statistical Science, 1989, 4(4): 409-423.

[23] MEINDERS T, BURCHITZ I A, BONTE M H A, LINGBEEK R A. Numerical product design: Springback prediction, compensation and optimization [J]. International Journal of Machine Tools and Manufacture, 2008, 48(5): 499-514.

[24] AGUIR H, CHAMEKH A, BELHADJSALAH H, DOGUI A, HAMBLI R. Identification of constitutive parameters using hybrid ANN multi-objective optimization procedure [J]. International Journal of Material Forming, 2008, 1(s1): 1-4.

[25] ENGINEOUS SOFTWARE I. iSIGHT reference guide (v9.0) [M]. USA: Engineous Software, Inc, 2004.

基于凸模胀形试验的材料参数识别方法研究

李小强1, 何德华1,2

1. 北京航空航天大学 机械工程及自动化学院,北京 100191;

2. 北京航星机器制造有限公司,北京 100013

摘 要:为了准确地描述铝合金板料变形过程中的力学特性,采用参数识别的方法研究材料参数的确定问题。该方法基于凸模胀形试验,通过优化方法获取材料参数。优化计算采用了有限元方法、拉丁方抽样、Kriging近似模型以及多岛遗传算法。对铝合金板2D12的材料参数识别研究表明,经参数识别的Hill’90各向异性屈服准则能更好地描述板料的力学行为。该方法为板料成形有限元分析中材料参数的获取提供了一种有效的途径。

关键词:材料参数识别;凸模胀形;铝合金板;Hill’90;Kriging近似模型

(Edited by Hua YANG)

Foundation item: Project (2011YSKF01) supported by the Henan Key Laboratory of Advanced Non-ferrous Metals, China; Project (50905008) supported by the National Natural Science Foundation of China

Corresponding author: De-hua HE; Tel: +86-10-82316584; E-mail: hedehua@me.buaa.edu.cn

DOI: 10.1016/S1003-6326(13)62614-X

Abstract: To accurately describe the mechanical properties of aluminium alloy sheet during deformation, an inverse identification was presented to deal with material parameters from the popular punch stretch test. In the identification procedure, the optimization strategy combines finite element method (FEM), Latin hypercube sampling (LHS), Kriging model and multi-island genetic algorithm (MIGA). The proposed approach is used on material parameter identification of aluminium alloy sheet 2D12. The anisotropic yield criterion Hill’90 is discussed. The results show that the Hill’90 anisotropic yield criterion with identified anisotropic material parameters has a good potential in describing the anisotropic behaviours. It provides a way to obtain the material parameters for FE simulations of sheet metal forming.