有机负荷对单级UASB-A/O处理晚期垃圾渗滤液短程脱氮的影响

刘牡,彭永臻,王淑莹,刘甜甜,委燕

(北京工业大学 北京市水质科学与水环境恢复工程重点实验室,北京,100124)

摘 要:

SB-A/O组合工艺”处理实际晚期城市生活垃圾渗滤液,考察不同有机负荷(OLR, organic loading rate)条件下氮与有机物的转化和去除及其产生的综合影响。研究结果表明:厌氧与好氧系统的动态缓冲能力使得COD总去除率均在90%以上;OLR过低与过高时,氨氮去除率分别因碱度回收不足与异养菌竞争作用而下降;总氮去除率随OLR的提升而升高,而当OLR过低时,受反硝化碳源与氨氮降解效率的双重限制,其去除率明显偏低;同时甲烷化反硝化UASB中挥发性脂肪酸(VFA, volatile fatty acid)与碱度的比值始终低于 0.3,OLR在6.15~15.58 kg/(m3·d)范围内时反硝化菌与产甲烷菌活性能维持动态平衡;在应对OLR变化方面,DO与pH曲线作为实时控制的电化学参数时各有特点,应当针对不同水质研究其变化规律并使两者结合运用;A/O亚硝积累率随着OLR的增加而呈现小幅度上升。

关键词:

中图分类号:X703.1 文献标志码:A 文章编号:1672-7207(2014)04-1347-07

Effect of organic loading rate on shortcut nitrification-denitrification of mature landfill leachate in single-stage UASB-A/O system

LIU Mu, PENG Yongzhen, WANG Shuying, LIU Tiantian, WEI Yan

(Key Laboratory of Beijing Water Quality Science and Water Environment Recovery Engineering,

Beijing University of Technology, Beijing 100124, China)

Abstract: A combined system consisting of an up-flow anaerobic sludge blanket (UASB) and anoxic/oxic bioreactor was adopted for treating mature municipal landfill leachate. The transition behavior of nitrogen and organic matter and the comprehensive effects in the combined system were systematically analyzed at different organic loading rates (OLR) (3.78-20.25 kg/(m3·d)). The results show that the total COD removal rate is above 90% due to the dynamic buffer ability of anaerobic and aerobic system; ammonia nitrogen (NH4+-N) removal rate decreases due to the lack of alkalinity with low OLR and the competition of heterotrophic bacteria with high OLR; total nitrogen removal rate ascends with the increase of OLR, and when OLR is too low, total nitrogen removal rate decreases obviously with the double restriction of carbon source for denitrifying and low efficiency of NH4+-N degradation; in the anaerobic simultaneous denitrification and methanogenesis reactor, volatile fatty acid (VFA)/alkalinity value is lower than 0.3 and denitrifying bacteria and methane-producing bacteria are maintained at dynamic balance in the OLR range of 6.15-15.58 kg/(m3·d); there are different features while using DO and pH curve as electrochemical parameters of real-time control, and it is necessary to combine these two methods according to variation rule; and the nitrite accumulation rate in A/O presents a modest increase with the increase of OLR.

Key words: organic loading rate; landfill leachate; methanogenesis; shortcut nitrification-denitrification; nitrite accumulation rate

目前,我国90%左右的城市固体废弃物采用填埋法处理,填埋产生的渗滤液危害十分严重。垃圾渗滤液往往有机物组分众多,氨氮含量较高,营养元素比例失调,这些特征决定了常规的、单一的渗滤液处理方法并不可行[1-2]。已有学者研究了不同反应器如厌氧消化池[3]、流化床反应器[4]、厌氧膜生物反应器[5]、厌氧过滤器(AF)[6]、序批式反应器[7]和升流式厌氧污泥床反应器(UASB)[8-11]等处理垃圾渗滤液的可行性。传统厌氧生物处理具有能耗低、污泥产量少、有机负荷(OLR, organic loading rate)高且能够回收能源等优点[8-12],但是,同时也存在反应速率慢、出水氨氮含量较高等缺点。厌氧与好氧组合工艺往往成为处理垃圾渗滤液的较佳选择。Agdag等[13]采用两级UASB-CSTR系统处理垃圾渗滤液,COD与氨氮去除率分别可达98%和99.6%。An等[14]采用UASB和好氧MBR组合工艺,TOC和总氮去除率分别可达98%和80%。此外,在单一厌氧反应器中实现同时产甲烷与反硝化既可以实现有机物与氮的同步去除,又能进一步改善厌氧出水水质[15]。与传统的硝化反硝化相比较,短程脱氮能节约25%的能耗与40%的碳源,且能够获得更高的反硝化效率以及较低的污泥产量[16],因而,具有同步产甲烷反硝化功能的厌氧反应器与具有短程硝化功能的好氧反应器的组合无疑具有更大的优势。由于雨雪、气温等自然因素以及人为因素都会导致垃圾渗滤液中有机物浓度发生大幅度变化,而不论是对厌氧还是好氧生化系统,OLR对系统的处理效率以及处理性能的稳定性均存在直接或间接影响。已有学者对有关OLR对单独的好氧或者厌氧反应器的影响进行了较为深入的研究[17-19],但关于OLR对厌氧与好氧组合工艺的综合影响方面仍缺乏系统考察,而OLR对以短程脱氮为基础的组合系统的影响研究则更为鲜见。基于上述背景,本文作者采用“单级UASB-A/O组合工艺”处理实际晚期高氨氮城市生活垃圾渗滤液,考察以改变进水有机物质量浓度为基础的OLR变化对氮与有机物的转化和去除及其他综合效果产生的影响,以期为厌氧与好氧组合类工艺的运行控制提供理论和技术指导。

1 试验材料与方法

1.1 试验装置及运行条件

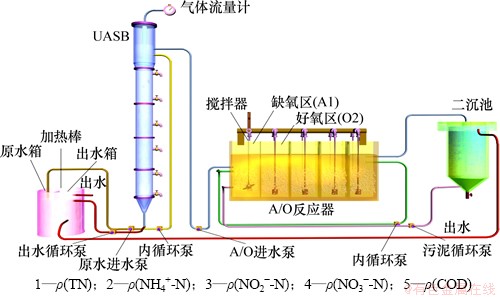

图1所示为单级UASB+A/O系统流程图。由图1可见:UASB-A/O生化系统由缺氧/厌氧UASB和A/O连接组成。UASB与A/O的有效容积为分别为4.25 L和15 L,其中A/O均分为10个格室,第1格室为缺氧区(标记为A1),其余9个格室为好氧区(依次为O2~O10)。A/O在室温下运行。渗滤液从原水水箱通过蠕动泵与按一定比例回流的A/O出水一起进入UASB,进行缺氧、厌氧反应。UASB的出水与A/O内循化回流的硝化液进入A/O,在A1池进行反硝化,然后在好氧池完成硝化反应。UASB-A/O系统进水流量为5.0 L/d。UASB采用预热加保温的方式控制反应温度为32 ℃,用加热泵维持A/O为26 ℃。取样点如下:原渗滤液(raw),UASB进水即原渗滤液与回流处理水的混合液(mix),UASB进水(Ui)与出水(Ue),A/O的缺氧区(A1),好氧区的不同格室(O2~O10)。

在水力停留时间(HRT,hydraulic retention time)不变的情况下,进水有机物的质量浓度与OLR直接相关,本文在原渗滤液的基础上,通过往进水原液中添加葡萄糖、碱度、氯化铵以及稀释的方式,在保证仅有机物浓度变化的前提下,依次使有机物负荷从3.78 kg/(m3·d)提高至20.25 kg/(m3·d),每个阶段稳定运行5个水力停留时间,共125 d,并以每阶段的第5个周期各反应器采样数据为准。

图1 单级UASB+A/O系统流程图

Fig. 1 Flow diagram of single-stage UASB+A/O system

1.2 试验水质及分析方法

试验用水取自北京市六里屯垃圾填埋场调节池,其平均水质为(g/L):COD,7.806;BOD5,6.300;NH4+-N,1.974;浊度SS,2.600;总氮TN,2.077;碱度,8.100;总磷TP,0.011。pH 为8.1。

COD采用COD快速测定仪测定;NH4+-N 采用纳氏试剂光度法测定;NO2--N采用N-(1-萘基)-乙二胺光度法测定;NO3--N采用麝香草酚分光光度法测定;TN通过TN/TOC分析仪(multi N/C3000,德国耶拿)测定;采用WTW测定仪及相应探针在线监测液相内DO、温度和pH。碱度采用电位滴定法测定。生物气总体积通过排水集气法收集并测量。生物气中甲烷体积分数采用气相色谱(GC)(Agilent,6890N,USA)测量。CO2在生物气中的体积含量通过碱液吸收法测量。将生物气均匀缓慢的通过4 mol/L的氢氧化钠(NaOH),以减少的气体体积为CO2体积。甲烷气体的体积由总体积与体积分数的乘积计算得到的。在确定了生物气中CH4和CO2的体积分数之后,残余的气体体积定义为N2的体积。

2 试验结果与讨论

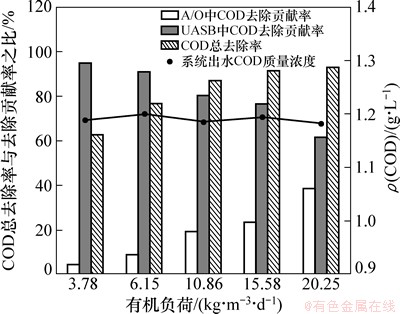

2.1 UASB-A/O组合工艺中COD的降解规律

COD首先在UASB中通过厌氧产甲烷以及反硝化进行去除,随后流入A/O中的缺氧段进行反硝化,若仍然有COD剩余则通过A/O的好氧段进行好氧降解。图3所示为不同OLR条件下组合系统COD去除性能。由图3可见:OLR从3.78 kg/(m3·d)提高到20.25 kg/(m3·d)的过程中,组合系统整体COD出水质量浓度均在1.2 g/L左右,这部分COD均为难降解COD,而总去除率从62.5%提高到93.0%,这表明该组合系统在COD降解方面具有较高的抗OLR能力。此外,虽然在不同OLR下,组合系统均以UASB中的厌氧降解及反硝化为主要COD降解途径,但是,COD在UASB和A/O中各自的去除速率呈现出不同程度的变化,在6.15 kg/(m3·d)的条件下,A/O对COD的去除贡献率仅为5%,而在20.25 kg/(m3·d)的条件下增加为38.5%。这主要是由于随着OLR的提高UASB出水与回流液混合流入A/O中的COD浓度明显增加,厌氧与好氧系统的动态缓冲能力保证了COD的有效去除。

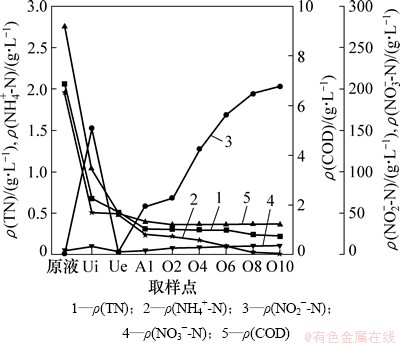

图2 OLR为10.86 kg/(m3·d)时氮与COD的转变规律

Fig. 2 Variations of COD and nitrogen concentration with OLR of 10.86 kg/(m3·d)

图3 不同OLR条件下组合系统COD去除性能

Fig. 3 Performance of COD removal in combined system at different OLR

2.2 UASB-A/O组合工艺中氮的转化与去除

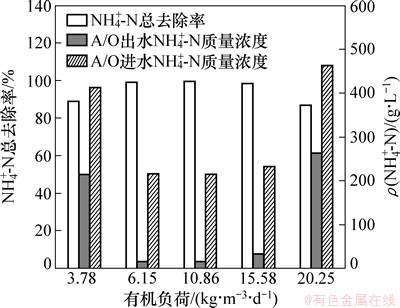

2.2.1 氨氮的去除

氨氮在本组合工艺中主要在A/O通过硝化作用而被降解。图4所示为不同OLR条件下组合系统氨氮去除性能。由图4可见:当OLR为3.78 kg/(m3·d)时,由于组合系统通过反硝化所回收的碱度不足导致A/O硝化过程中pH迅速下降,在好氧第8格pH即下降到6.4,此时pH过低严重抑制硝化活性,组合系统氨氮总去除率仅为89.1%;当OLR在6.15~15.58 kg/(m3·d)范围内时,组合系统氨氮去除率在98.2%~99.2%之间波动。因为降解氨氮的自养菌比降解COD的异养菌的比增长速率小一个数量级以上,且异养菌在反应器中竞争底物和溶解氧,当OLR提高到20.25 kg/(m3·d)后,UASB中COD的出水浓度升高导致A/O进水COD质量浓度增加,硝化效率下降,氨氮总去除率降低为86.6%。

图4 不同OLR条件下组合系统氨氮去除性能

Fig. 4 Performance of NH4+-N removal in combined system at different OLR

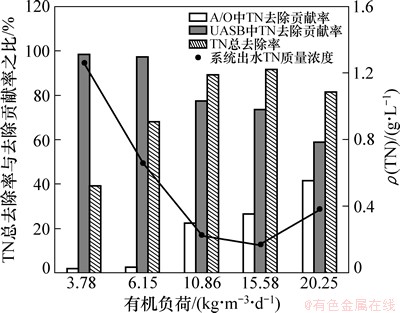

2.2.2 总氮的去除

图5所示为不同OLR条件下组合系统总氮去除性能。由图5可见:OLR为3.78 kg/(m3·d)时,一方面由于用于反硝化的碳源不足,另一方面,此条件下氨氮降解效率不高,导致UASB进水亚硝态氮以及硝态氮的浓度也相应较低,因而总氮去除率仅为39%。OLR从3.78 kg/(m3·d)提升到20.25 kg/(m3·d)的过程中,由于提供了更多的反硝化碳源,组合工艺总氮去除率从68.1%提高到91.8%。而当OLR提高到20.2 kg/(m3·d)时,虽然OLR的提高为反硝化提供到了更多的碳源,但是,由于氨氮去除率下降间接导致UASB进水亚硝态氮以及硝态氮的质量浓度下降,总氮去除率反而下降为81.5%。

图5 不同OLR条件下组合系统总氮去除性能

Fig. 5 Performance of TN removal in combined system at different OLR

此外,组合工艺内各反应器对总氮去除的贡献率也随着OLR的提高而呈不同的变化,在3.78~20.25 kg/(m3·d)的范围内,随着OLR的提高,从UASB中流入A/O的COD质量浓度增加,促进了A/O缺氧段的反硝化作用,UASB对总氮去除的贡献率从 98.5%下降到58.5%,A/O对总氮的去除率则相应提高。当OLR为20.25 kg/(m3·d)时,A/O好氧段还出现了一定比例的同步硝化反硝化。

2.3 UASB同时反硝化与甲烷化过程

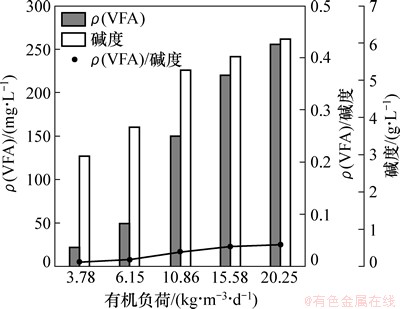

2.3.1 VFA变化规律

图6所示为不同OLR条件下UASB中VFA与碱度变化规律。由图6可知:随着OLR的提高,UASB中挥发性脂肪酸(VFA,volatile fatty acid)质量浓度呈上升趋势,OLR为20.25 kg/(m3·d)时出水VFA质量浓度均达到256 mg/L,但VFA质量浓度与碱度比值的最大值仅为0.04远低于0.3,这表明在本组合系统中的UASB在不同OLR下均具有较高的抗酸化能力。适当范围的反硝化可以缓和由产酸菌所引起的pH下降从而有利于提高厌氧生物反应器的稳定性。在较高pH条件下,有利于VFA的氧化,以及CO2和H2的吸收利用或吹脱[20]。因此,富含NOx--N的出水回流能够促进VFA和CO2的去除,减少对产甲烷反应可能存在的负面影响,从而维持产甲烷菌和反硝化菌的活性[21]。从定量关系上看,若渗滤液的平均氨氮质量浓度为1.960 g/L,因为1 g氨氮硝化需要消耗7.14 g碱度(CaCO3),1.960 g/L氨氮全部硝化需要消耗碱度13.994 g/L,而原水碱度为10.190 g/L。若不进行充分的反硝化,碱度就会被全部消耗或因为不足而需要投加碱度,而UASB中反硝化的进行在很大程度上保证了碱度的回收。

图6 不同OLR条件下UASB中VFA与碱度变化规律

Fig. 6 Variations of VFA and alkalinity in UASB at different OLR

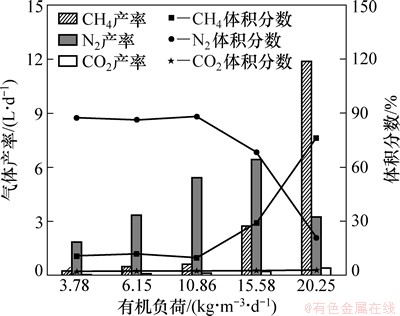

2.3.2 气体变化规律

UASB产生的生物气由N2,CH4和CO2组成,图7 显示了不同OLR条件下生物气各组分的产率及其体积分数。由图7可知:随着OLR的提高,气体总产率从3.78 kg/(m3·d)时的2.134 L/d提高到20.25 kg/(m3·d)时的15.576 L/d,产气量提高,能够促进UASB混流,从而有利于功能菌群对基质的利用。当OLR在3.78~15.58 kg/(m3·d)范围内时,N2产率随着流入UASB中的有机物浓度的增加而从1.820 L/d增加到6.420 L/d,而当OLR为20.25 kg/(m3·d)时,由于相当部分的NOx--N在A/O中被去除,并且由于氨氮降解效率的影响导致流入UASB的NOx--N质量浓度降低,N2产率降低为3.265 L/d。OLR从3.78 kg/(m3·d)提高到10.86 kg/(m3·d)的过程中,由于绝大部分COD均被用于反硝化,因而N2所占百分比均在86.2%以上,而当OLR从15.58 kg/(m3·d)提高到20.25 kg/(m3·d)时,由于甲烷产率的提升从而导致N2所占百分比降低为20.9%。

图7 不同OLR条件下UASB中N2,CH4和CO2产率及其体积分数的变化规律

Fig. 7 Variations of production and percentage of N2, CH4 and CO2 in UASB at different OLR

在OLR提升的过程中,甲烷产率整体呈上升趋势,而当OLR在3.78~10.86 kg/(m3·d)的范围时,同样由于可利用COD的限制,导致CH4体积分数均在9.7%以下,这也说明在反硝化与甲烷化的竞争过程中,反硝化细菌将优先利用有机碳源。当OLR达到15.58 kg/(m3·d)以上时,CH4体积分数开始有大幅度提高;当OLR达到20.25 kg/(m3·d)时,CH4体积分数达到76.4%。产甲烷细菌是严格厌氧细菌,NOx--N 会导致氧化还原电位升高,不利于产甲烷菌的生长与活性发挥,但通过改善原有反应器形态,利用微生物自固定技术形成高效优质的颗粒污泥以及污泥驯化等方法在宏观条件下可以达到较理想的有机碳与氮的去除效果[15]。

当OLR从3.78 kg/(m3·d)提高到20.25 kg/(m3·d)时,CO2的产率和体积分数均很少但是有一定的增幅,其最大产率和体积分数分别为411 mg/L和2.6%。主要是由于在较高的pH环境下,UASB中游离的CO2浓度占HCO3-,CO32-和CO2总浓度的百分比很低。

2.4 A/O实时控制参数与亚硝酸积累率

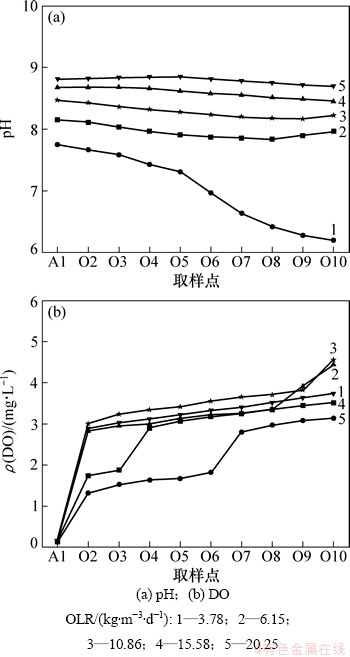

2.4.1 实时控制参数的变化规律

图8所示为不同OLR条件下A/O中pH与DO曲线变化规律。由图8可知:当OLR为3.78 kg/(m3·d)时,由于碱度较低,pH曲线没有出现任何拐点而是呈现出持续下降的趋势;当OLR为6.15和10.86 kg/(m3·d)时,pH曲线与氨氮降解仍有很好的相关性,在pH曲线上均出现了氨谷点,都较好地指示了硝化反应终点,但是,UASB中COD的出水质量浓度升高导致A/O进水COD质量浓度增加,后者出现pH曲线拐点的时间有所延后。而当OLR为15.58和20.25 kg/(m3·d)时,pH曲线在COD降解过程中不断大幅度上升,当COD降解停止时,pH曲线出现转折点,开始不断下降但是由于氨氮受到氨氮降解效率的影响pH曲线不再出现氨谷点。

当OLR为3.78 kg/(m3·d)时,DO呈现缓慢上升趋势,没有出现任何特征点;当OLR为10.86和15.5 kg/(m3·d)时,DO曲线在硝化结束时候出现突越点;当OLR为15.58和20.25 kg/(m3·d)时,DO曲线随着COD降解而出现平台;当COD降至难降解部分时,DO突然迅速大幅上升,自养菌开始进行硝化反应,由于硝化效率受COD降解的影响,反应过程中DO不断上升没有出现第2次跳跃。

在不同OLR条件下,DO曲线与pH曲线作为实时控制的电化学参数时各有特点,针对不同水质研究其变化规律并使两者结合运用,能更好地指示生物硝化反应进程。

2.4.2 亚硝酸积累率的变化规律

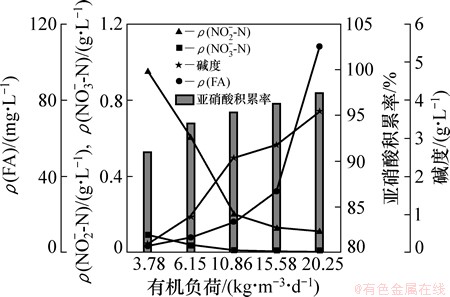

游离氨(FA,free ammonia)通过对氨氧化菌(AOB) 和亚硝酸盐氧化菌(NOB)的选择性抑制实现对硝化反应速率的控制,因而能成为实现短程硝化的决定性因素之一[22]。图9所示为不同OLR条件下平均FA质量浓度、碱度、出水NO2--N质量浓度以及亚硝酸积累率的变化规律。由图9可见:在不同OLR条件下,A/O出水亚硝酸积累率均在90%以上,这表明AOB成为了系统中的主要硝化菌属,主要是A/O长期受到高FA抑制(均在1 mg/L以上),使得AOB成为了硝化细菌的主要菌群,而NOB逐渐从活性污泥中淘洗所致。但随着负荷的不断增加,亚硝积累率仍有小幅上升,从OLR为3.78 kg/(m3·d)时的92.9%上升到OLR为20.25 kg/(m3·d)时的97.4%。

图8 不同OLR条件下A/O中pH与DO曲线变化规律

Fig. 8 Profiles of pH and DO at different OLR in A/O

图9 不同OLR条件下平均FA质量浓度、碱度、出水NO2--N质量浓度以及亚硝酸积累率的变化规律

Fig. 9 Variations of average FA, alkalinity, NO2--N, NO2--N accumulation ratio at different OLR

3 结论

(1) 不同OLR条件下,COD在UASB和A/O中各自的去除速率呈现出不同程度的变化,COD总去除率均在90%以上,厌氧与好氧系统的动态缓冲能力保证了COD的有效去除。

(2) OLR过低时,由于回收的碱度不足导致A/O硝化过程中pH迅速下降,氨氮降解率为89.1%,此时,受反硝化碳源与氨氮降解效率的双重限制,总氮去除率相对较低;OLR提高到20.25 kg/(m3·d)后,虽然反硝化碳源充足,但由于此时氨氮去除率仍然较低,间接导致总氮去除率的增幅很小。

(3) 甲烷化反硝化UASB在不同OLR下均具有较高的抗酸化能力,VFA质量浓度与碱度之比始终低于 0.3,适当范围的反硝化可以缓和由产酸菌所引起的pH下降从而有利于提高厌氧生物反应器的稳定性。

(4) 在应对OLR变化方面,DO曲线与pH曲线作为实时控制的电化学参数时各有特点,针对不同水质研究其变化规律并使两者结合运用,能更好地指示生物硝化反应进程。A/O亚硝积累率随着OLR的提高呈现小幅度上升。

参考文献:

[1] Aziz S Q, Aziz H A, Yusoff M S, et al. Landfill leachate treatment using powdered activated carbon augmented sequencing batch reactor (SBR) process: optimization by response surface methodology[J]. Journal of Hazardous Materials, 2011, 189(1/2): 404-413.

[2] Renou S, Givaudan J G, Poulain S, et al. Landfill leachate treatment: Review and opportunity[J]. Journal of Hazardous Materials, 2008, 150(3): 468-493.

[3] Kheradmand S, Karimi-Jashni A, Sartaj M. Treatment of municipal landfill leachate using a combined anaerobic digester and activated sludge system[J]. Waste Management, 2010, 30(6): 1025-1031.

[4] Gulsen H, Turan M. Startup of an anaerobic fluidized bed reactor for landfill leachate treatment[J]. Environmental Technology, 2004, 25(10): 1107-1114.

[5] Bohdziewicz J, Neczaj E, Kwarciak A. Landfill leachate treatment by means of anaerobic membrane bioreactor[J]. Desalination, 2008, 221(1/3): 559-565.

[6] Dacanal M, Beal L L. Anaerobic filter associated with microfiltration membrane treating landfill leachate[J]. Engenharia Sanitaria E Ambiental, 2010, 15(1): 11-18.

[7] Timur H, Ozturk I. Anaerobic sequencing batch reactor treatment of landfill leachate[J]. Water Research, 1999, 33(15): 3225-3230.

[8] Kennedy E J, Lentz E M. Treatment of landfill leachate using sequencing batch and continuous flow upflow anaerobic sludge blanket (UASB) reactors[J]. Water Research, 2000, 34(14): 3640-3656.

[9] Agdag O N, Sponza D T. Anaerobic/aerobic treatment of municipal landfill leachate in sequential two-stage up-flow anaerobic sludge blanket reactor (UASB)/completely stirred tank reactor (CSTR) systems[J]. Process Biochemistry, 2005, 40(2): 895-902.

[10] Calli B, Mertoglu B, Roest K, et al. Comparison of long-term performances and final microbial compositions of anaerobic reactors treating landfill leachate[J]. Bioresource Technology, 2006, 97(4): 641-647.

[11] Parawira W, Murto M, Zvauya R, et al. Comparative performance of a UASB reactor and an anaerobic packed-bed reactor when treating potato waste leachate[J]. Renewable Energy, 2006, 31(6): 893-903.

[12] Zhou W L, Imai T, Ukita M, et al. Effect of loading rate on the granulation process and granular activity in a bench scale UASB reactor[J]. Bioresource Technology, 2007, 98(7): 1386-1392.

[13] Agdag O N, Sponza D T. Anaerobic/aerobic treatment of municipal landfill leachate in sequential two-stage up-flow anaerobic sludge blanket reactor (UASB)/completely stirred tank reactor (CSTR) systems[J]. Process Biochemistry, 2005, 40(2): 895-902.

[14] An Y Y, Yang F L, Wong F S, et al. Simultaneous bioenergy (CH4) production and nitrogen removal in a combined upflow anaerobic sludge blanket and aerobic membrane bioreactor[J]. Energy & Fuels, 2008, 22(1): 103-107.

[15] Huang J S, Chou H H, Chen C M. Effect of recycle-to-influent ratio on activities of nitrifiers and denitrifiers in a combined UASB–activated sludge reactor system[J]. Chemosphere, 2007, 68(2): 382-388.

[16] Gu S B, Wang S Y, Yang Q, et al. Start up partial nitrification at low temperature with a real-time control strategy based on blower frequency and pH[J]. Bioresource Technology, 2012, 112: 34-41.

[17] Huilinir C, Hernandez S, Aspe E, et al. Simultaneous nitrate and organic matter removal from salmon industry wastewater: The effect of C/N ratio, nitrate concentration and organic load rate on batch and continuous process[J]. Journal of Environmental Management, 2012, 101: 82-91.

[18] Johir M A H, Vigneswaran S, Sathasivan A, et al. Effect of organic loading rate on organic matter and foulant characteristics in membrane bio-reactor[J]. Bioresource Technology, 2012, 113(SI): 154-160.

[19] Latif M A, Ahmad A, Ghufran R. Effect of temperature and organic loading rate on upflow anaerobic sludge blanket reactor and CH4 production by treating liquidized food waste[J]. Environmental Process & Sustainable Energy, 2012, 31(1): 114-121.

[20] Zitomer D H. Stoichiometry of combined aerobic and methanogenic COD transformation[J]. Water Research, 1998, 32(3): 669-676.

[21] Peng Y Z, Zhang S J, Zeng W, et al. Organic removal by denitritation and methanogenesis and nitrogen removal by nitritation from landfill leachate[J]. Water Research, 2008, 42(4/5): 883-892.

[22] Zanetti L, Frison N, Nota E, et al. Progress in real-time control applied to biological nitrogen removal from wastewater: A short-review[J]. Desalination, 2012, 286: 1-7.

(编辑 杨幼平)

收稿日期:2013-05-25;修回日期:2013-08-08

基金项目:国家自然科学基金资助项目(21177005) ;北京市教委科技创新平台项目(2013年);北京工业大学第十一届研究生科技基金资助项目(ykj-2012-8458)

通信作者:彭永臻(1949-),男,黑龙江哈尔滨人,博士,教授,从事污水处理与过程控制、脱氮除磷等研究;电话:010-67392627;E-mail:pyz@bjut.edu.cn

摘要:采用“单级UASB-A/O组合工艺”处理实际晚期城市生活垃圾渗滤液,考察不同有机负荷(OLR, organic loading rate)条件下氮与有机物的转化和去除及其产生的综合影响。研究结果表明:厌氧与好氧系统的动态缓冲能力使得COD总去除率均在90%以上;OLR过低与过高时,氨氮去除率分别因碱度回收不足与异养菌竞争作用而下降;总氮去除率随OLR的提升而升高,而当OLR过低时,受反硝化碳源与氨氮降解效率的双重限制,其去除率明显偏低;同时甲烷化反硝化UASB中挥发性脂肪酸(VFA, volatile fatty acid)与碱度的比值始终低于 0.3,OLR在6.15~15.58 kg/(m3·d)范围内时反硝化菌与产甲烷菌活性能维持动态平衡;在应对OLR变化方面,DO与pH曲线作为实时控制的电化学参数时各有特点,应当针对不同水质研究其变化规律并使两者结合运用;A/O亚硝积累率随着OLR的增加而呈现小幅度上升。