文章编号:1004-0609(2010)06-1177-06

电沉积Ni-P/纳米Al2O3复合镀层的摩擦磨损与耐铝液侵蚀性能

彭成章,朱玲玲

(湖南科技大学 机械设备健康维护重点实验室, 湘潭 411201)

摘 要:

研究电沉积Ni-P/纳米Al2O3复合镀层的干摩擦磨损性能和耐铝液侵蚀性能,采用扫描电镜(SEM)观察Ni-P/纳米Al2O3复合镀层的磨损表面形貌以及铝与Ni-P/纳米Al2O3复合镀层的界面结构。结果表明:Ni-P/纳米Al2O3复合镀层(镀态)与淬火45钢对摩时的摩擦因数为0.45~0.55,磨损表现为疲劳剥落;经400 ℃热处理后,Ni-P/纳米Al2O3复合镀层与淬火45钢对摩的摩擦因数为0.20~0.24,磨损机理表现为轻微粘着和磨蚀;铝液在Ni-P/纳米Al2O3复合镀层表面的润湿角为109?,Ni-P/纳米Al2O3复合镀层具有良好的耐铝液侵蚀性能。

关键词:

Ni-P/纳米Al2O3复合镀层;脉冲电沉积;耐蚀性能;疲劳剥落;粘着;磨蚀;

中图分类号:TQ153.2 文献标志码:A

Tribological properties and erosion resistance of electroplated Ni-P/nano-Al2O3 composite coatings to aluminum liquid

PENG Cheng-zhang, ZHU Ling-ling

(Hunan Provincial Key Laboratory of Health Maintenance for Mechanical Equipment,

Hunan University of Science and Technology, Xiangtan 411201, China)

Abstract: The tribological properties under dry sliding condition and erosion resistance of Ni-P/nano-Al2O3 composite coatings pulse electroplated to aluminum liquid were investigated. The worn surface morphologies of the coatings and the interface structures between aluminum and Ni-P/nano-Al2O3 composite coatings were observed by scanning electron microscopy (SEM). The results demonstrate that the friction coefficient of the as-deposited composite coatings against quenched 45 steel is 0.45-0.55; its wear mechanism is fatigue flake. The friction coefficient of 400 ℃ heat-treated composite coatings against quenched 45 steel is 0.20-0.24; their worn surfaces exhibit slight adhesion and abrasion. The wetting angle of the aluminum liquid on the composite coatings is 109?, showing that the composite coatings present good erosion resistance to the aluminum liquid.

Key words: Ni-P/nano-Al2O3 composite coating; pulse electroplating; erosion resistance; fatigue flake; adhesion; abrasion

复合镀是通过在普通镀液中添加不溶性的固体颗粒,使基质金属与固体颗粒共同沉积而形成复合镀层的一种表面改性技术。复合镀层综合了基质金属和固体颗粒物质的性能,具有比单一基质金属或合金更优良的耐磨、减摩和耐蚀等特殊性能[1],例如,Ni/SiC[2]、Ni-P-SiC[3-4]、Ni-P/Cr2O3[5]、Ni-W-P-SiC[6] 、Ni-BN[7]耐磨复合镀层,Ni-P/BN(h)[8-9]、Ni-PS- MoS2[10]、Ni-P/PTFE [11]、Ni-graphite[12]减摩复合镀层。复合镀层已经在石油、化工、汽车、机械等行业中获得了广泛应用。

Al2O3的硬度高、化学稳定性好,具有优异的耐磨性能和抗金属熔体侵蚀性能。BADARULZAMAN等[13]研究了工艺参数对电沉积Ni/α-Al2O3复合镀层结构的影响。张卫国等[14-15]用化学镀制备了Ni-P/纳米Al2O3复合镀层,经400 ℃热处理后镀层硬度达到了1 185HV,耐磨损性能提高20%。周琦等[16]研究了表面活性剂对镍-磷-纳米氧化铝复合镀的影响,研究表明,用三乙醇胺阳离子表面活性剂对纳米Al2O3粒子进行分散,可以获得纳米Al2O3粒子的含量较多且分散均匀的复合镀层。高加强等[17]关于纳米氧化铝对化学镀镍-磷合金晶化行为的影响进行了研究,与Ni-P合金镀层相比,纳米氧化铝使其晶化温度降低。上述Ni-P/Al2O3复合镀层主要采用化学镀方法制备,关于电沉积方法制备Ni-P/Al2O3复合镀层的文献报道较少,而关于Ni-P/Al2O3复合镀层耐铝液侵蚀性能的研究鲜见报道。本文作者采用脉冲电沉积方法制备Ni-P/纳米Al2O3复合镀层,对Ni-P/ 纳米Al2O3复合镀层在干摩擦条件下的摩擦磨损性能和耐铝液侵蚀性能进行研究,试图提高在铝合金铸轧、铸造和高温挤压等成形过程中工模具的耐铝液侵蚀能力以及改善工模具与铝合金产品间的润滑状态。

1 实验

在XP-5型数控销-盘式摩擦磨损试验机上进行Ni-P/纳米Al2O3复合镀层的干摩擦磨损实验。盘试样为淬火45钢,销试样为不同含量纳米Al2O3的复合镀层(镀态,400 ℃热处理)。淬火45钢的硬度为614.8HV0.2。淬火45钢和复合镀层对摩面的表面粗糙度为0.2~0.4 μm,载荷为30 N,转动速度为100 r/min,线速度为0.115 m/s,运行时间为15 min。采用JSM-6380LV型扫描电镜(SEM)观察复合镀层的磨损表面形貌。

在真空炉内进行耐铝液侵蚀性能实验。为了进行对比分析,采用热轧45钢、Ni-P合金镀层和Ni-P/20 g/L纳米Al2O3复合镀层为基体,尺寸为45 mm×45 mm×5 mm;铝材为工业纯铝,尺寸为12 mm×12 mm。试验时将铝试样放置于基体表面中心。实验参数如下:真空度2.6×10-3 Pa,加热温度675 ℃,保温4 min;随炉冷却。用游标卡尺测量铝液在基板表面的铺展直径,沿铺展直径方向切开、磨平后测定铝液在基板表面的润湿角。采用JSM-6380LV型扫描电镜(SEM)观察铝/基体接触界面的结合状态。

2 结果与讨论

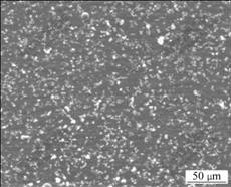

图1所示为镀液中悬浮的纳米Al2O3质量浓度为20 g/L时Ni-P/纳米Al2O3复合镀层镀态时的SEM像。图2所示为复合镀层镀态以及400 ℃热处理后复合镀层的XRD谱。由图1和2可以看出,Ni-P/纳米Al2O3复合镀层镀态时呈非晶态结构,是一种介稳定的过饱和Ni-P合金,纳米Al2O3颗粒镶嵌在Ni-P合金镀层内,而Fe的衍射峰是由Q235基体产生的。经400 ℃热处理后复合镀层内析出了大量弥散的Ni3P颗粒和少量Ni12P5颗粒。

图1 Ni-P/20 g/L纳米Al2O3复合镀层的SEM像

Fig.1 SEM image of Ni-P/20 g/L nano-Al2O3 composite coating

图2 Ni-P/20 g/L纳米Al2O3复合镀层镀态及400 ℃热处理后的XRD谱

Fig.2 XRD patterns of Ni-P/20 g/L nano-Al2O3 composite coatings as-deposited (a) and heat treated at 400 ℃ (b)

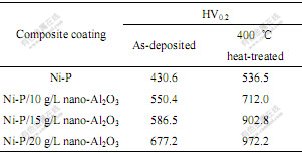

表1所列是镀液中悬浮的纳米Al2O3质量浓度为0~20 g/L的Ni-P/纳米Al2O3复合镀层镀态时和400 ℃热处理后的显微硬度。经热处理,由于镀层内析出大量细小的Ni3P粒子,对镀层起到弥散强化,因而热处理后镀层的硬度显著提高。

表1 Ni-P/纳米Al2O3复合镀层的显微硬度

Table 1 Microhardness of Ni-P/nano-Al2O3 composite coatings

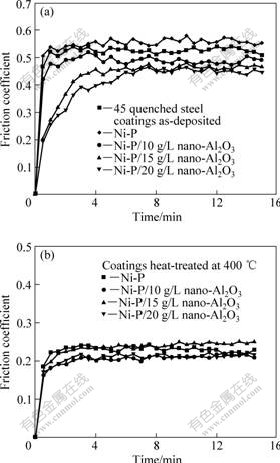

图3所示为不同纳米Al2O3质量浓度的Ni-P/纳米Al2O3复合镀层在摩擦过程中摩擦因数随时间的变化曲线。Ni-P/纳米Al2O3复合镀层(镀态)与淬火45钢对摩时的摩擦因数为0.45~0.55,摩擦因数相对较高,与对摩偶件均为淬火45钢的摩擦因数相近。400 ℃热 处理后Ni-P/纳米Al2O3复合镀层与淬火45钢对摩时摩擦因数较低,为0.20~0.24。但复合镀层中纳米Al2O3的质量浓度对2组对摩材料的摩擦因数影响比较小,摩擦因数主要取决于Ni-P/纳米Al2O3复合镀层的组织结构。

图3 复合镀层摩擦因数的变化曲线

Fig.3 Changes of friction coefficients with time in pin-on-disc tests for composite coatings as-deposited (a) and heat-treated at 400 ℃ (b)

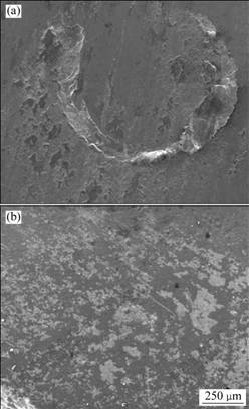

图4所示为Ni-P/20 g/L纳米Al2O3复合镀层材料的磨损表面形貌。从图4可以看出:镀态条件下,复合镀层与淬火45钢对摩的磨损表面出现严重的块状剥落,其磨损形式主要为疲劳磨损;经400 ℃热处理后复合镀层与淬火45钢对摩的磨损表面较光滑,出现轻微粘着和少量浅的磨蚀坑。这是因为镀态状态时复合镀层是一种过饱和Ni-P固溶体;其次,在电沉积过程中阴极同时发生析氢反应,氢气吸附在沉积镀层表面,一部分残留在复合镀层内,形成氢脆。因此,复合镀层呈镀态时内部存在较大的内应力,在对摩过程中法向应力和摩擦力的交互作用下容易诱发微裂纹,并不断扩展和剥离,在摩擦表面产生许多疲劳剥落坑,导致摩擦表面粗糙度增大,从而摩擦因数较大。

图4 Ni-P/20 g/L纳米Al2O3复合镀层的磨损表面的SEM像

Fig.4 SEM images of worn surfaces of Ni-P/20 g/L nano-Al2O3 composite coatings as-deposited (a) and heat treated at 400 ℃ (b)

复合镀层经400 ℃热处理后,残存在镀层内的氢气在热激活作用下从镀层表面逸出,氢脆消失,同时镀层内析出大量细小的Ni3P粒子,Ni-P固溶体过饱和程度减轻,镀层内部应力降低,因而在Ni3P粒子弥散强化作用下复合镀层硬度显著提高的同时韧性得到极大提高,从而改善了复合镀层的疲劳性能。其次,复合镀层材料在热处理过程中镀层内合金元素(主要为Ni)与基体Fe发生热扩散,镀层/基体的界面结合强度提高,也改善了复合镀层的疲劳性能。因此,热处理后的复合镀层与淬火45钢对摩后,没有发生塑性变形和疲劳剥落。在磨损过程中,Ni基体首先被磨损,使作为耐磨增强相的Ni3P和纳米Al2O3粒子逐渐凸显出来,并承载了对摩偶件的压力。由于Ni3P(四方晶胞)粒子和纳米Al2O3与Fe、Ni原子的相容性差,在摩擦过程中接触点间的粘着力小, 因而粘着现象较轻。当粒子与基体的结合力不足以抵抗摩擦力时,第二相粒子脱落,在摩擦表面产生磨蚀坑,但由于粒子尺寸较小,起到类似于抛光作用,使得磨损表面较光滑,因而摩擦因数较小。

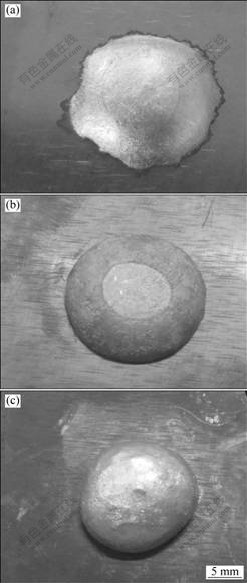

图5所示为铝液在45钢、Ni-P合金镀层和Ni-P/20 g/L纳米Al2O3复合镀层表面的铺展情况。对铝液在3种材料表面的铺展直径进行测量,分别为22.8、20.62和17.2 mm,润湿角分别为52?、91?和109?。从铺展直径和润湿角的测量结果可以看出,铝液在45钢表面的接触角较小,铺展性最好,且明显地观察到铝液沿45钢材料表面润湿;铝液与Ni-P/20 g/L纳米Al2O3复合镀层的湿润性较差。

图5 铝液在45钢、Ni-P合金镀层和Ni-P/20 g/L 纳米Al2O3复合镀层表面的铺展情况

Fig.5 Aluminum spreading states on surface of 45 steel (a), Ni-P alloy coating (b) and Ni-P/20 g/L nano-Al2O3 composite coating (c)

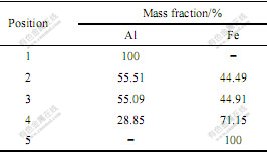

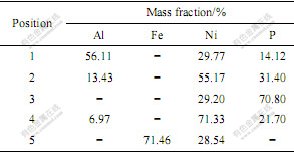

图6所示为沿铺展直径方向切开的铝与基体的界面结合状态。由图6可知:铝液在较短时间内在45钢基体中产生了较厚的扩散层,界面产生了良好的冶金结合;铝液与复合镀层的接触界面清晰可见,但镀层与基体Fe产生了一定厚度的扩散层,说明镀层和Fe基体结合较好。表2和3所列分别为铝/45钢界面和铝/复合镀层结合界面的能谱线分析结果。可以看出,Al在45钢基体中的浓度由表至里呈梯度分布。由Fe-Al 相图可知,675 ℃时Al在α-Fe中的固溶度为23%,说明Fe和Al具有良好的相容性。扩散层靠铝侧Al的浓度大于23%,将形成FeAl2或FeAl相,扩散层靠铁侧主要是Fe-Al固溶体相。而Al在Ni中的最大溶解度不到0.4%,几乎不溶于P,图6(b)中位置2、4处Al的存在是由于镀层中存在Al2O3物质的缘故。铝液在Ni-P/20 g/L 纳米Al2O3复合镀层表面只发生界面反应,产生较薄的金属化合物Al3Ni或AlP层,不利于铝液在复合镀层上的铺展。因此,Ni-P/20 g/L纳米Al2O3复合镀层表现出良好的耐铝液侵蚀性能。

图6 铝/45钢和铝/Ni-P/20 g/L纳米 Al2O3复合镀层的界面结构

Fig.6 Interface structures between aluminum and 45 steel (a) and between aluminum and Ni-P/20 g/L nano-Al2O3 composite coating (b)

表2 图6中对应位置的铝/45钢界面区域的化学成分

Table 2 Chemical compositions in interface region between aluminum and 45 steel shown in Fig.6

表3 铝/Ni-P/20 g/L纳米Al2O3复合镀层界面区域的化学成分

Table 3 Chemical compositions in interface region between aluminum and Ni-P/20 g/L nano-Al2O3 composite coating shown in Fig.6

3 结论

1) Ni-P/纳米Al2O3复合镀层(镀态)与淬火45钢对摩时的摩擦因数为0.45~0.55,磨损为疲劳剥落;经400 ℃热处理后的Ni-P/纳米Al2O3复合镀层与淬火45钢对摩时,摩擦因数为0.2~0.24,具有明显的减摩效果,其磨损机理为轻微粘着和磨蚀。

2) 铝液在Ni-P/20 g/L纳米Al2O3复合镀层表面的润湿角为109?,润湿性差,表明Ni-P/20 g/L纳米Al2O3复合镀层具有良好的耐铝液侵蚀性能。

REFERENCES[1] ABDEL S H, SHOEIB M A, HADY H, ABDEL SALAM O F. Corrosion behavior of electroless Ni-P alloy coatings containing tungsten or nano-scattered alumina composite in 3.5% NaCl solution[J]. Surface and Coatings Technology, 2007, 202: 162-171.

[2] NABEEN K, SHRESTHA, MASABUMI M, TETSUO S. Composite plating of Ni/SiC using azo- cationic surfactants and wear resistance of coatings[J]. Wear, 2003, 254: 555-564.

[3] 张 恒, 沈献民. Ni-P/SiC耐磨性化学复合镀工艺参数优化[J]. 郑州大学学报, 2004, 36(3): 54-58.

ZHANG Heng, SHEN Xian-min. Optimization of technology parameter of Ni-P/SiC wear resistance composite electroless plating[J]. Journal of Zhengzhou University, 2004, 36(3): 54-58.

[4] 罗建东, 阮 锋, 刘慧平. (Ni-P)-SiC复合电刷镀[J]. 电镀与精饰, 2007, 29(1): 19-21.

LUO Jian-dong, RUAN Feng, LIU Hui-ping. (Ni-P)-SiC composite brush plating[J]. Plating and Finishing, 2007, 29(1): 19-21.

[5] 刘铁虎. Ni-P-Cr2O3化学复合镀层耐磨性的研究[J]. 润滑与密封, 2002(6): 45-46.

LIU Tie-hu. Study on wear resistance of Ni-P-Cr2O3 composite electroless plating[J]. Lubrication Engineering, 2002(6): 45-46.

[6] 张 欢, 郭忠诚, 蒋琪英, 胡文远, 唐敬友, 樊北旭. 稀土- Ni-W-P-SiC脉冲复合镀层的耐蚀性研究[J]. 材料热处理学报, 2007, 28(3): 116-120.

ZHANG Huan, GUO Zhong-cheng, JIANG Qi-ying, HU Wen-yuan, TANG Jing-you, FAN Bei-xu. Study on corrosion resistance of RE-Ni-W-P-SiC composite coating prepared by pulsing current plating[J]. Transaction of Material and Heat Treatment, 2007, 28(3): 116-120.

[7] POMPEI E, MAGAGNIN L, LECIS N, CAVALLOTTI P L. Electrodeposition of nickel-BN composite coatings[J]. Electrochimica Acta, 2009, 54: 2571-2574.

[8] LEON O A, STAIA M H, HINTERMANN H E. Deposition of Ni-P-BN(h) composite autocatalytic coatings[J]. Surface and Coatings Technology, 1998, 108/109: 461- 465.

[9] LEON O A, STAIA M H, HINTERMANN H E. Wear mechanism of Ni-P-BN(h) composite autocatalytic coatings[J]. Surface and Coatings Technology, 2005, 200: 1825-1829.

[10] 黄仲佳, 熊党生. Ni-PS-MoS2复合镀层的制备及摩擦磨损性能[J]. 郑州大学学报, 2008, 29(4): 42-46.

HUANG Zhong-jia, XIOANG Dang-sheng. Preparation and friction and wear performance of Ni-PS-MoS2 composite coating[J]. Journal of Zhengzhou University, 2008, 29(4): 42-46.

[11] 张秋道, 张丽娟, 宋来洲, 许光辉. 化学复合镀Ni-P-PTFE镀层性能的研究[J]. 哈尔滨工业大学学报, 1999, 31(1): 127-129.

ZHANG Qiu-dao, ZHANG Li-juan, SONG Lai-zhou, XU Guang-hui. Study of Ni-P-PTFE electroless[J]. Journal of Harbin Institute of Technology, 1999, 31(1): 127-129.

[12] ZHAO Hai-jun, LIU Lei, HU Wen-bin, SHEN Bin. Friction and wear behavior of Ni-graphite composites prepared by electroforming[J]. Materials & Design, 2007, 28: 1374-1378.

[13] BADARULZAMAN N A, PURWADARIA S, MOHAMAD A A, AHMAD Z A. The production of nickel-alumina composite coating via electroplating[J]. Ionics, 2009, 5: 603-607.

[14] 张卫国, 穆高林, 姚素薇. Ni-P/纳米Al2O3复合镀层的制备及其耐磨性能[J]. 有色金属, 2008, 60(2): 25-28.

ZHANG Wei-guo, MU Gao-lin, YAO Su-wei. Synthesis and wear resistance of electroless Ni-P/nano-Al2O3 composite coatings[J]. Nonferrous Metals, 2008, 60(2): 25-28.

[15] 姚素薇, 穆高林, 张卫国. 化学镀Ni-P/纳米Al2O3复合镀层结构及性能研究[J]. 材料保护, 2007, 40(10): 26-28.

YAO Su-wei, MU Gao-lin, ZHANG Wei-guo. Properties of electroless Ni-P/nano-Al2O3 composite coatings[J]. Journal of Materials Protection, 2007, 40(10): 26-28.

[16] 周 琦, 邵忠宝, 贺春林, 邵忠财, 才庆魁, 高维娜. 表面活性剂对镍-磷-纳米氧化铝复合镀的影响[J]. 中国腐蚀与防护学报, 2007, 27(1): 27-30.

ZHOU Qi, SHAO Zhong-bao, HE Chun-lin, SHAO Zhong-cai, CAI Qing-kui, GAO Wei-na. Effect of surfactants on electroless deposition Ni-P-nano-Al2O3 composite coating[J]. Journal of Chinese Society for Corrosion and Protection, 2007, 27(1): 27-30.

[17] 高加强, 刘 磊, 沈 彬, 朱建华, 胡文彬, 丁文江. 纳米氧化铝粒子对化学镀镍-磷合金晶化行为的影响[J]. 中国有色金属学报, 2004, 14(1): 64-68.

GAO Jia-qiang, LIU Lei, SHEN Bin, ZHU Jian-hua, HU Wen-bin, DING Wen-jiang. Crystallization behavior of nano-Al2O3 composite coatings prepared by electroless plating[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 64-68.

_____________________________

基金项目:国家自然科学基金资助项目(50764004);江西省教育厅科技资助项目(赣教技字[2007]202号)

收稿日期:2010-02-03;修订日期:2010-05-04

通信作者:彭成章,副教授,博士;电话:0731-58290624;E-mail:pcz2002@sohu.com

(编辑 龙怀中)