- Abstract:

- 1 Introduction▲

- 2 Experimental▲

- 3 Test results and discus...▲

- 4 Conclusions▲

- References

- Figure

- Fig.1 Relationship between dynamic modulus and frequency for asphalt mixture at different temperatures

- Fig.2 Relationship between phase angle and frequency for asphalt mixture at different temperatures

- Fig.3 Effects of fibers on |E*| and δ of asphalt mixture

- Fig.4 Creep test curves for asphalt mixtures containing fibers

J. Cent. South Univ. Technol. (2008) 15(s1): 333-336

DOI: 10.1007/s11771-008-375-2

![]()

Rheological properties of asphalt mixtures containing various fibers

YE Qun-shan(叶群山)1, WU Shao-peng(吴少鹏)2, CHEN Zheng(陈 筝)2, LIU Zhi-fei(刘至飞)2

(1. Communication and Transportation Engineering, Changsha University of Science and Technology, Changsha 410076, China;

2. Key Laboratory of Silicate Materials Science and Engineering of Ministry of Education, Wuhan University of Technology, Wuhan 430070, China)

Abstract:

Rheological characteristics of fiber-modified asphalt mixture were investigated. Cellulous fiber, polyester fiber and mineral fiber were used as additives for asphalt mixture, and the dosages were 0.3%, 0.3%, 0.4%, respectively. Dynamic modulus test using superpave simple performance tester (SPT) was adopted to study the dynamic modulus and phase angle for the control mixture and fiber-modified ones at various temperatures and frequencies. Test results show that the rheological properties can be improved significantly by the addition of various fibers. The dynamic modulus increases with the increase of frequency, and the phase angle decreases with the increase of frequency. When various fibers are used, the dynamic modulus increases and phase angle decreases at each frequency. This indicates that the stiffness and the elastic portion of fiber-modified asphalt mixtures can be enhanced when various fibers are used, which results in the change of viscoelastic properties of mixtures. The creep test results show that the total strain and the permanent strain of asphalt mixtures during load-unload cycle can be significantly reduced, which results in the improvement of resistance to permanent deformation for asphalt mixtures containing various fiber additives. The Burgers model can be employed effectively to illustrate the rheological properties of fiber modified asphalt mixtures.

Key words:

asphalt mixture; fiber modified; rheological property; dynamic modulus; rheological model;

1 Introduction

Bitumen rheology can widely be represented by two main viscoelastic parameters: complex modulus and phase angle. These parameters change with temperature and loading time. Complex modulus represents stiffness, whilst phase angle is normally used to demonstrate the viscoelastic response of bituminous materials[1]. Higher values of phase angle indicate a tendency towards more viscous behaviour, whilst lower values indicate more elastic response. It is widely accepted that there is a trade-off between the low and high temperature performance of bituminous materials, and that bitumen rheology can provide preliminary indications of the resulting bituminous mixture performance. For unmodified bitumens, elastic behaviour (low phase angle) is generally associated with high stiffness and increased brittleness, while the viscous response reflects high ductility and low stiffness[2].

Fibers are playing an increasingly important role in the asphalt industry and are one of the most technically advanced bitumen modifiers currently available[3-4]. To achieve the goal of improving bitumen properties, a selected fiber should create a secondary network or new balance system within bitumens by overlap joint. The formation of such functional modified bitumen system is based on the fine dispersion of fibers in bitumen. The degree of modification depends on the fiber characteristics, fiber concentration and nature of the original bitumen[5-7].

In this research, various fiber modified asphalt mixtures were prepared with the optimum fiber concentration. Dynamic modulus test and creep test were conducted to investigate the rheological properties of asphalt mixtures containing fiber modifiers. The effects of fibers on the rheological characteristics and permanent deformation of asphalt mixture were analyzed, and Burgers model was adopted to depict the rheological property of fiber modified asphalt mixtures.

2 Experimental

2.1 Raw materials

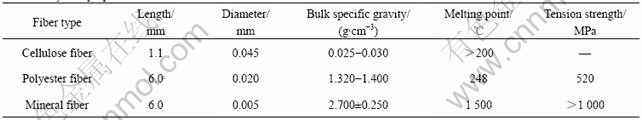

Asphalt was heavy-duty AH-70 produced by Koch Asphalt Co. Ltd (Hubei Province, China), with a penetration of 68 (0.1 mm at 25 ℃, 100 g, 5 s), ductility of 26.7 cm (at 5 ℃) and softening point 48.5 ℃. Cellulose fiber and polyester fiber used in this research were provided by Tianhui Fiber Co Ltd. (Hubei Province,China), and mineral fiber provided by Fiber and Co Ltd. (Beijing, China). Physical properties of these fibers are shown in Table 1. The dosages of cellulose fiber, polyester fiber and mineral fiber are 0.3%, 0.3%, 0.4%, respectively.

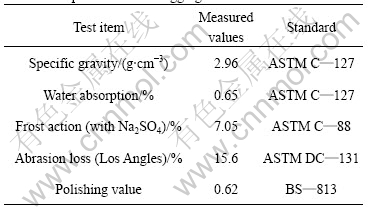

Asphalt mixtures were obtained with a 12.5 mm superpave gradation. Basalt was used as coarse aggregates in the mixtures preparation, and physical properties of such aggregates are shown in Table 2. Limestone was used as fine aggregates and mineral filler.

2.2 Specimen preparation

Standard superpave mix procedures were employed to prepare specimens for dynamic modulus test and indirect tension fatigue test after the mixtures were short-term oven aged at 135 ℃ for 4 h, and then such specimens were sawed and polished to the required specimen gauge. Fibers were added into the container firstly to mix with the preheated aggregate for 30 s, and then mixed with asphalt and mineral filler for 90 s, respectively. The diameter and height of specimens for dynamic modulus test were 100 mm and 150 mm, respectively, and for creep test were 100 mm and 100 mm, respectively. The optimum binder content for mixtures without fiber is 4.8%, for mixtures with cellulous fiber, polyester fiber and mineral fiber are 5.1%, 5.0% and 4.9%, respectively.

2.3 Test procedure

The dynamic modulus test was conducted by Universal Testing Machine (UTM-25, produced by IPC, Australia) in accordance with AASHTO TP 62-03. Test specimens were placed in the environmental chamber and allowed to equilibrate to the specified testing temperature ±0.5 ℃. A continuous uniaxial sinusoidal (haversine) compressive stress at a specified test frequency is applied to the unconfined cylindrical test specimen. The dynamic modulus test was conducted with a uniaxial haversine load inducing approximately 100 microstrain in the specimen. The test was conducted on each specimen at -10, 4.4, 21.1, 37.8 and 54.4 ℃, using frequencies of 25, 20, 10, 5, 2, 1, 0.5, 0.2 and 0.1 Hz.

A static creep test with a loading and recovery period was conducted on the asphalt mixture by UTM. The loading period, recovery period, compression stress and test temperature for the creep test were chosen as 3 600 s, 4 500 s, 0.1 MPa and 40 ℃, respectively. Before the test was done, a strain sweep test to determine the linear viscoelastic range were conducted.

3 Test results and discussion

3.1 Frequency and temperature dependency of |E*| and δ

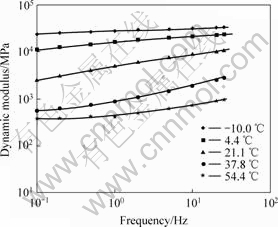

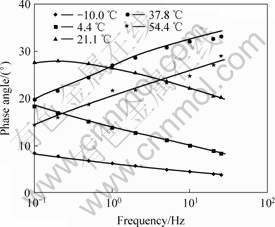

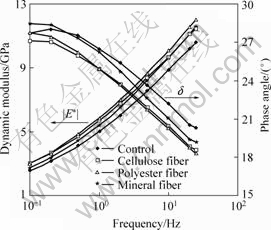

Dynamic modulus and phase angle are two critical parameters to investigate the rheological characteristics of asphalt mixtures containing various fibers with apparent frequency and temperature dependency. |E*| and δ curves for polyester fiber modified asphalt mixtures are shown in Figs.1-2.

The dynamic modulus decreases with the increase of temperature and the decrease of loading frequency. Phase angle increases with the increase of temperature and the decrease of loading frequency from -10 ℃ to 21.1 ℃, but the phase angle take an opposite trend during higher temperature range from 37.8 ℃ to 54.4℃. The reason may be that the asphalt mastic is softened at high temperature and low frequency, and the viscoelastic property of asphalt mixture is dependent on the aggregate skeleton. High elastic property of aggregate will result in the reduction of phase angle of asphalt mixture.

3.2 Effects of fibers on |E*| and δ

The effects of fibers on the dynamic modulus (|E*|) and phase angle (δ) of asphalt mixtures depend on the fiber types, frequency and temperature. |E*| and δ of asphalt mixtures containing various fibers at 21.1 ℃ is shown in Fig.3. It reveals that |E*| of asphalt mixtures increases by the addition of fiber modifiers. As to the phase angle, δ of fiber modified asphalt mixtures all decreases. The test results prove that the viscoelastic properties of asphalt mixtures can be changed by the fiber modifiers. Such fiber modifiers can enhance the stiffness and the elastic property of asphalt mixtures, which results in the reduction of permanent deformation and fatigue damage for fiber modified asphalt mixtures during their serving lifespan.

Table 1 Physical properties of various fibers

Table 2 Properties of basalt aggregate

Fig.1 Relationship between dynamic modulus and frequency for asphalt mixture at different temperatures

Fig.2 Relationship between phase angle and frequency for asphalt mixture at different temperatures

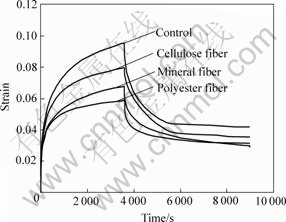

3.3 Creep deformation

Creep test curves of asphalt mixtures containing various fibers are shown in Fig.4. It can be observed that the response of strain for all asphalt mixtures have the same trend. After the initial elastic response when the loading is conducted, the creep portion of the response curve eventually becomes linear, giving a constant slope. After the release of the applied stress, the elastic deformation recovers followed by time dependent recoverable elastic deformation. The residual strain, which exists after complete elastic recovery, is the non- recoverable permanent deformation.

Fig.3 Effects of fibers on |E*| and δ of asphalt mixture

Fig.4 Creep test curves for asphalt mixtures containing fibers

It can also be seen from Fig.4 that the development of creep strain curves for fiber modified asphalt mixture is changed to some extend. On one hand, the total strain of asphalt mixture can be reduced greatly by the addition of various fibers. On the other hand, the elastic strain and the recoverable elastic strain increases, which results in the reduction of permanent strain of asphalt mixture.

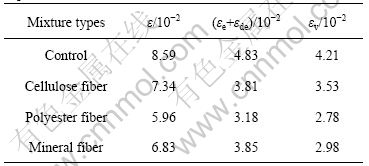

The composition of creep deformation of fiber modified asphalt mixtures is illustrated in Table 3, in which ![]() ,

, ![]() and

and ![]() refer to the total strain, elastic and delayed elastic strain, permanent strain, respectively. The resistance to permanent deformation of asphalt mixture can be improved significantly by fiber modifiers. The total strain of polyester fiber modified asphalt mixture is only 69.4% of the control mixture, and the permanent strain is reduced about 34.0%.

refer to the total strain, elastic and delayed elastic strain, permanent strain, respectively. The resistance to permanent deformation of asphalt mixture can be improved significantly by fiber modifiers. The total strain of polyester fiber modified asphalt mixture is only 69.4% of the control mixture, and the permanent strain is reduced about 34.0%.

Table 3 Composition of creep deformation of fiber modified asphalt mixtures

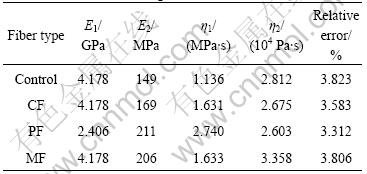

3.4 Burgers model

Burgers model is usually adopted to investigate the viscoelastic properties of asphalt mixture. The creep equation is as follow:

![]() (1)

(1)

where σ0 and ε are the stress and strain of creep test, respectively; E1, E2, η1 and η2 are the coefficients of elastic spring and dash-pot, respectively. The data of creep tests can be used to define the coefficients of models for all asphalt mixtures containing fibers by the least square fitting method in a Microsoft Excel? spreadsheet. The constants simulated are shown in Table 4. E2 and η1 of asphalt mixtures increases significantly by the addition of various fibers, which results in the improvement of resistance to permanent deformation for asphalt mixtures[8].

Table 4 Parameters for Burgers mode

4 Conclusions

1) Dynamic modulus of fiber modified asphalt mixtures decreases with the increase of temperature and reduction of loading frequency. The phase angles increases with the increase of temperature and reduction of loading frequency at lower temperature, but presents a opposite development at higher temperature.

2) Dynamic modulus of asphalt mixtures can be increased by the addition of fiber modifiers, and phase angle is reduced for fiber modified asphalt mixture.

3) The total creep strain and permanent strain are reduced for fiber modified asphalt mixtures.

4) Burgers model can be adopted to depict the viscoelastic property of asphalt mixtures containing fibers, the resistance to permanent deformation can be enhanced for fiber modified asphalt mixtures.

References

[1] TEUGELS W. The black diagram, only a rheological data presentation?[C]//2nd Euroasphalt & Eurobitumem Congress. Barcelona, 2000: 52-58.

[2] VINOGRADOV G V, MALKIN A YA. Rheology of polymers[M]. Moscow: Mir Publication, 1980.

[3] SERFASS J P, SAMANOUS J. Fiber-modified asphalt concrete characteristics, application and behavior[J]. Journal of the Association of Asphalt Paving Technologists, 1996, 65(1): 193-230.

[4] PUTMAN B J, AMIRKHANIAN S N. Utilization of Waste fibers in stone matrix asphalt mixtures[J]. Resources, Conservation and Recycling, 2004, 42(3): 265-274.

[5] BUENO, et al. Engineering properties of fiber reinforced cold asphalt mixes[J]. Journal of Environmental Engineering, 2003, 10: 952-955.

[6] SERKAN T. The effect of polypropylene fibers on asphalt performance[J]. Building and Environment, 2008, 43(6): 1065-1071.

[7] WU S P, YE Q S, LI N. Effects of fibers on the dynamic properties of asphalt mixtures[J]. Journal of Wuhan University of Technology- Mater Sci Ed, 2007, 22(4): 733-736.

[8] SZYDLO A, MACKIEWICZ P. Asphalt mixes deformation sensitivity to change in rheological parameters[J]. Journal of Materials in Civil Engineering, 2005, 17(2): 1-9.

Foundation item: Projects (NCET-05-0656) supported by Education Ministry for the New Century Excellent Talents, China

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: YE Qun-shan, Doctor; Tel: +86-27-87162595; E-mail: yeqs@whut.edu.cn

- Rheological properties of asphalt mixtures containing various fibers