过滤阴极真空电弧制备非晶金刚石红外保护膜

韩杰才, 朱嘉琦

(哈尔滨工业大学 复合材料与结构研究所, 哈尔滨 150080)

摘 要:

采用过滤阴极真空电弧技术, 通过施加不同衬底偏压制备了非晶金刚石薄膜。 利用纳米压痕仪和光谱椭偏仪测试薄膜的力学性能和光学性能, 利用KLA-Tencor台阶仪测试硅衬底在薄膜沉积前后的曲率半径, 并根据Stoney方程计算薄膜应力, 利用可见光拉曼光谱和电子能量损耗谱研究了薄膜的微结构。 实验表明: 当衬底负偏压为80V时, 薄膜的硬度、 弹性模量、 光学带隙和折射率均达到最大值, 随着偏压的升高或降低, 各参量分别降低; 此时, 薄膜的sp3杂化含量最高, 斜坡系数却最小; 在宽红外波段范围内, 薄膜的消光系数趋近于零, 即红外透明; 另外, 薄膜具有接近金刚石的高硬度和高模量, 并且其微结构以及光学和力学性能可调, 因此是一种优异的红外光学窗口增透保护薄膜材料。

关键词: 非晶金刚石; 过滤阴极真空电弧; 红外保护膜 中图分类号: O461.21

文献标识码: A

Amorphous diamond films deposited by filtered cathodic vacuum arc technology as infrared protective coatings

HAN Jie-cai, ZHU Jia-qi

(Center for Composite Materials, Harbin Institute of Technology, Harbin 150080, China)

Abstract: Amorphous diamond (a-D) films deposited by filtered cathodic vacuum arc (FCVA) technology with different substrate bias were investigated. The mechanical properties were characterized with nanoindenter and the stress was calculated using Stoney equation. The optical properties were analyzed by spectroscopic ellipsometry and the microstructure was investigated by visible Raman spectroscopy and electron energy loss spectroscopy. The maximal hardness and elastic modulus consorting with the highest stress are presented as the negative substrate bias is 80V. With the bias increases or decreases, hardness, elastic modulus and stress descend gradually. However, the high impinging energy benefits the adhesion between the films and the substrate. Additionally, the optical gap and the refractive index exhibits the same changing regularities, whereas the minimal extinction coefficient is obtained at negative bias of 80V. It is found that the negative bias of 80V is the sp3-rich deposition condition according to the EELS measurements and the Raman slope coefficient. The changing rules of the mechanical and optical properties can be explained in light of the growth mechanism and microstructure of the films. In short, a-D films deposited by the FCVA technology are good at the infrared protective coatings because the films are transparent in the wide infrared band and the microstructure and properties can be modulated.

Key words: amorphous diamond; filtered cathodic vacuum arc; protective coatings

非晶金刚石是指sp3含量超过50%以上无氢类金刚石碳[1, 2], 具有高硬度、 高模量、 宽带隙、 良好的化学惰性以及红外透明性等一系列优异性能, 已被广泛应用于红外光学窗口、 磁存贮器件、 生物医疗器件以及微机电器件的保护膜[2-5]。 非晶金刚石薄膜可以采用离子束辅助沉积、 质量筛选离子束沉积、 脉冲激光熔敷以及过滤阴极真空电弧沉积等工艺进行制备[3-8], 其中过滤阴极真空电弧技术是制备高质量光学用途非晶金刚石薄膜最合适的方法。 本文作者以非晶金刚石薄膜的红外光学应用为目标, 采用过滤阴极真空电弧技术进行沉积, 并研究了非晶金刚石薄膜的微结构及其光学和力学性能。

1 实验

采用过滤阴极真空电弧系统, 施加0~2000V的脉冲衬底负偏压, 制备一组相同膜厚的非晶金刚石薄膜样品, 实验方法及系统参见文献[9]。 沉积前, 将p(100)单晶硅片用丙酮超声清洗15min, 再用Kaufman氩离子枪刻蚀5min。 薄膜的光学参数和力学性能分别利用Woollam公司的可变角光谱椭偏仪和MTS公司的纳米压痕仪测试, 薄膜应力根据曲率半径技术计算而得, 其中曲率半径利用KLA-Tencor公司的表面轮廓仪测试。 薄膜的微结构利用Ranishaw公司波长为514nm的拉曼光谱仪和配备有Gatan-666电子能量损耗谱的Philips Tecnai F30透射电子显微镜进行表征。

2 结果及讨论

2.1 薄膜的力学性能

薄膜压应力利用Stoney方程

![]()

根据硅衬底沉积薄膜前后曲率半径的变化计算而得。 如图1所示, 当衬底负偏压为80V时, 最大压应力为6.34GPa, 随着偏压增大或减小, 应力都将下降, 但是, 在高偏压下, 应力保持在更低的水平。 与McKenzie等[4], Shi等[10], Fallon等[11]制备的非晶金刚石薄膜相比, 本实验制备的非晶金刚石薄膜应力更低。

图1 非晶金刚石薄膜压应力随衬底负偏压的变化关系

Fig.1 Compressive stress of a-D films with same film thickness as function of negative substrate bias

如图2所示, 薄膜的硬度和弹性模量在富sp3能量窗口(衬底负偏压为80V)最高, 在零偏压下最低。 因此, 通过调整离子入射能量实现的硬度和弹性模量的可调范围分别约近20和200GPa。 另外, 当入射离子能量超过富sp3能量窗口后, 硬度和弹性模量下降趋于平缓。 在入射离子能量越低时, 硬度和弹性模量越高, 临界划擦载荷就越高, 但是, 在高衬底偏压下, 尽管薄膜的硬度和弹性模量比-80V衬底偏压时低得多, 但是其临界刮擦载荷却最高。 这说明给沉积离子施加适当的高能级入射能量, 有利于在衬底与薄膜交界处形成具有薄膜成分的梯度注入层, 从而明显提高薄膜与衬底之间的结合性能。

图2 不同负偏压条件下沉积非晶金刚石薄膜的力学性能

Fig.2 Hardness, elastic modulus and critical scratching load of films deposited at different negative substrate bias

2.2 薄膜的光学性能

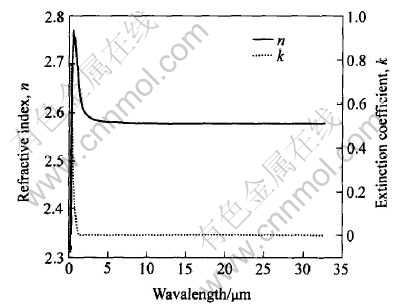

图3所示表明非晶金刚石薄膜的消光系数在整个红外波段几乎为零, 但是其折射率高于金刚石晶体或薄膜的折射率(CVD沉积Ⅰ型金刚石的折射率为2.42[12]), 也略高于其它非晶金刚石薄膜的折射率[13, 14]。 非晶金刚石薄膜的原子结构不是sp2和sp3两种杂化的简单混合, 当光在这样一种非晶网络中传播并与不同配位的碳原子相互作用时, 必然产生与金刚石呈四面体形状的面心立方结构所不同的极化现象, 其中镶嵌在σ键母体里断续的π键链或环产生了极为重要的作用, 也正因为sp2数量和分布的区别导致了不同实验方法制备非晶金刚石薄膜光学性能的差异。 另外, 与氢化非晶碳(a—C∶H)相比, 非晶金刚石薄膜的折射率也普遍较高, 但是通过改变制备工艺所能实现的调整范围则大大缩小。 氢原子对于稳定氢化非晶碳的四配位键和控制薄膜性能都起着至关重要的作用, 氢原子的含量也可在1%~60%较大范围内变化, 相应的折射率可从1.6到2.6宽幅度调整[15]。 氢的原子质量最低, 对光子的散射作用也最弱, 而且烃基先驱体离解后所产生原子基团的能量难于控制, 形成的膜层也比较疏松, 故氢化非晶碳的折射率普遍低于非晶金刚石薄膜的。

图3 非晶金刚石薄膜在紫外到远红外波段的折射率和消光系数

Fig.3 Refractive index and extinction coefficient of films in broad band from UV to far-IR

从图4可以很清楚地看出, 薄膜折射率和光学带隙都是随着衬底偏压的增加呈现先升高后下降的变化趋势, 并且当负偏压80V时达最高值; 但是消光系数却表现出完全相反的变化规律, 当负偏压为80V时达为最小值。 这正与Lossy等[16]的实验结果相反, 他们认为薄膜中sp3杂化比例越高就越接近金刚石晶体的性质, 既然金刚石的折射率是2.42, 那么随着沉积离子能量的升高, 薄膜的折射率就应该是先下降再升高的变化趋势。 这些差别的原因还有待进一步的研究。

图4 非晶金刚石薄膜的光学性能与衬底负偏压之间的关系

Fig.4 Relationship between optical properties of films and negative substrate bias

2.3 薄膜的微结构

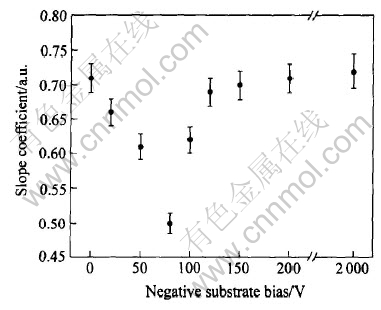

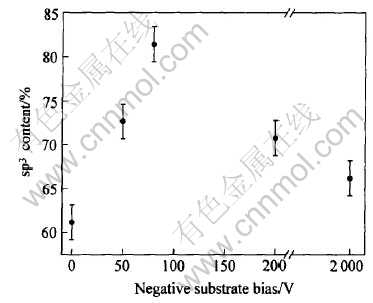

斜坡系数被定义为S=(I1300-I1100)/I1100, 其中I1300和I1100分别指拉曼偏移为1300cm-1和1100cm-1时的强度[17]。 如图5所示, 当衬底负偏压为80V时, 斜坡系数最小, 随着偏压增加或减少, 斜坡系数都将增大。 为了更准确地表征不同杂化的含量, 实验中利用电子能量损耗谱进行了测试。 图6清楚地显示了富sp3非晶金刚石薄膜的最佳沉积工艺为-80V衬底偏压。 根据非晶金刚石薄膜的浅注入生长机制, 为突破表面的束缚, 沉积离子需要适当的能量, 随着沉积离子的不断注入, 将在表面几个原子层以下产生极大的局部压应力, 创造了sp3杂化形成的条件, 但是过高的入射能量将转化为热并造成局部应力的松弛。 sp3杂化含量越高, 薄膜就越透明, sp3杂化最高时, 同时薄膜的光学带隙最高, 折射率最大, 消光系数也最小。 折射率最大是因为此时薄膜具有更高的原子密度。

图5 非晶金刚石薄膜Raman光谱的斜坡系数与衬底负偏压的关系

Fig.5 Relationship between slope coefficient and negative substrate bias of Raman spectra of a-D films

图6 非晶金刚石薄膜sp3含量与衬底负偏压的关系

Fig.6 Relationship between sp3 content and negative substrate bias of a-D films

3 结论

由过滤阴极真空电弧技术沉积的非晶金刚石薄膜在红外宽波段范围透明, 具有接近金刚石的高硬度和高模量, 并且其微结构以及光学和力学性能可调, 因此是一种优异的红外光学窗口增透保护薄膜材料。

REFERENCES

[1]Coll B F, Chhowalla M. Amorphous diamond film by enhanced arc deposition[J]. Surface and Coatings Technology, 1996, 79: 76-86.

[2]Robertson J. Diamond-like amorphous carbon[J]. Mater Sci Eng, 2002, R37: 129-281.

[3]Roth D, Rau B, Roth S, et al. Large area and three-dimensional deposition of diamond-like carbon films for industrial applications[J]. Surface and Coatings Technology, 1995, 74-75: 637-641.

[4]McKenzie D R, Muller D A, Kravtchinskaia E, et al. Synthesis, structure and applications of amorphous diamond[J]. Thin Solid Films, 1991, 206: 198-203.

[5]Veli-Matti T, Reijo L, Asko A. Protection of industrial sensors with Ta-C[J]. Vacuum, 2002, 67: 599-604.

[6]Zhu X D, Naramoto H, Xu Y, et al. Coarsening dynamics and surface instability during ion-beam-assisted growth of amorphous diamondlike carbon[J]. Physical Review B, 2002, 66: 165426-165430.

[7]Kulik J, Lempert G D, Grossman E, et al. sp3 content of mass-selected ion-beam-deposited carbon films determined by inelastic and elastic electron scattering[J]. Physical Review B, 1995, 52: 15812-15822.

[8]Sharma A K, Narayan R J, Narayan J, et al. Structural and tribological characteristics of diamond-like carbon films deposited by pulsed laser ablation[J]. Mater Sci Eng B, 2000, 77: 139-143.

[9]朱嘉琦, 王景贺, 孟松鹤, 等. 不同能级加速过滤电弧沉积四面体非晶碳膜的结构和性能研究[J]. 物理学报, 2004, 53: 1150-1156.

ZHU Jia-qi, WANG Jing-he, MENG Song-he, et al. The microstructure and properties of tetrahedral amorphous carbon films deposited by filtered arc accelerating at different energy grades[J]. Acta Physica Sinica, 2004, 53(4): 1150-1156.

[10]Shi Xu, Tay B K, Tan H S, et al. Properties of carbon ion deposited tetrahedral amorphous carbon films as a function of ion energy[J]. Journal of Applied Physics, 1996, 79: 7234-7240.

[11]Fallon P J, Veerasamy V S, Davis C A, et al. Properties of filtered-ion-beam-deposited diamondlike carbon as a function of ion energy[J]. Physical Review B, 1993, 48: 4777-4782.

[12]Tropf W J, Harris T J, Thomas M E. Electro-Optics Handbook(2nd ed)[M]. Columbus: McGraw-Hill Press, 2000. 11, 29.

[13]Lifshitz Y, Lempert G D, Grossman E, et al. Optical and photoemission studies of DLC films prepared with a systematic variation of the sp3: sp2 composition[J]. Diamond and Related Materials, 1997, 6: 687-693.

[14]Zhang X W, Cheung W Y, Ke N, et al. Optical properties of nitrogenated tetrahedral amorphous carbon films[J]. J Appl Phys, 2002, 92(3): 1242-1247.

[15]Smith F W. Optical constants of a hydrogenated amorphous carbon film[J]. J Appl Phys, 1984, 55(3): 764-771.

[16]Lossy R, Pappas D L, Roy R A, et al. Properties of amorphous diamond films prepared by a filtered cathodic arc[J]. J Appl Phys, 1995, 77(9): 4750-4756.

[17]Khriachtchev L Yu, Lappalainen R, Hakovirta M, et al. Raman diagnostics of amorphous diamond-like carbon films produced with a mass-separated ion beam[J]. Diamond Relat Mater, 1997, 6: 694-699.

基金项目: 国家“十五”预研资助项目(41312040401); 国家高技术研究发展计划资助项目(2002AA305507)

收稿日期: 2005-07-15; 修订日期: 2005-08-20

作者简介: 韩杰才(1966-), 男, 教授, 博士

通讯作者: 朱嘉琦, 副教授, 博士研究生; 电话: 0451-86417970; E-mail: zhujq@hit.edu.cn