文章编号:1004-0609(2010)S1-s0822-04

Ti5Mo5V2Cr3Al合金热变形行为

尤振平1,王 博2,惠松骁1,叶文君1,于 洋1,刘 睿1

(1. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088;

2. 中国石油工程建设公司,北京 100120)

摘 要:

采用Gleeble-1500热模拟试验机对TB10合金进行高温压缩变形实验,分析该合金在变形温度为700~1 050 ℃,应变速率为0.1~50 s-1条件下的变形行为及流变应力的变化规律。结果表明,流变应力受变形温度和应变速率显著影响,流变应力随变形温度的升高和应变速率的降低而降低。采用双曲正弦模型确定该合金的变形激活能Q和应力指数n,建立了相应的热变形本构关系。

关键词:

中图分类号:TG146.23 文献标志码:A

Hot deformation behavior of Ti5Mo5V2Cr3Al alloy

YOU Zhen-ping1, WANG Bo2, HUI Song-xiao1, YE Wen-jun1, YU Yang1, LIU Rui1

(1. State Key Laboratory of Nonferrous Metals and Processes, General Research Institute for Nonferrous Metals,

Beijing 100088, China;

2. China Petroleum Engineering & Construction Corporation, Beijing 100120, China)

Abstract: The hot compression deformation behavior of TB10 alloy was investigated by Gleeble-1500 simulator at the strain rate range from 0.1 to 50 s-1 and the temperature range from 700 to 1 050 ℃. The laws of microstructure evolvement and the characteristic of flow stress were analyzed. The results indicate that the flow stress decreases with increasing temperature and decreasing strain rate. The constitutive relationship of TB10 alloy is obtained on the base of Arrhenius equations.

Key words: Ti5Mo5V2Cr3Al alloy; hot deformation; constitutive relationship

Ti5Mo5V2Cr3Al(TB10)是一种近β型钛合金。该合金中β稳定元素总含量在临界浓度附近,使得合金兼有α+β和亚稳定β型合金的性能特征,具有比强度高、断裂韧性好、淬透性高等一系列优点,可满足高结构效益、高可靠性结构件的使用要求,是理想的结构材料。国内对该合金的研究主要集中在组织与性能关系方面[1-4],对其热变形行为的研究较少。

在金属塑性成形中,本构方程作为描述材料变形时热力学参数之间的关系模型,是采用有限元数值模拟方法预测和优化生产工艺参数的重要前提。

本文作者利用Gleeble-1500热模拟试验机对TB10合金进行高温压缩变形试验,分析在高温变形过程中流变应力与变形温度、应变速率之间的关系,并以Arrhenics方程为模型,确定应力指数n、应变激活能Q等参数,建立TB10合金热变形条件下的本构方程。

1 实验

实验材料为真空自耗熔炼TB10合金铸锭,经过开坯、热锻加工成16 mm棒材,然后沿轴向机加工成直径10 mm、长度15 mm的热模拟试样。淬火金相法测得该炉次合金的相变点为(825±5) ℃。利用Gleeble-1500热模拟试验机对TB10合金进行了恒温压缩实验,试验方案如下:变形温度为700、750、800、850、900、950、1 000和1 050 ℃;应变速率为:0.1、 1、10和50 s-1;试样加热速率为1 ℃/s,保温时间为5 min,总变形量不少于50%。

2 结果与分析

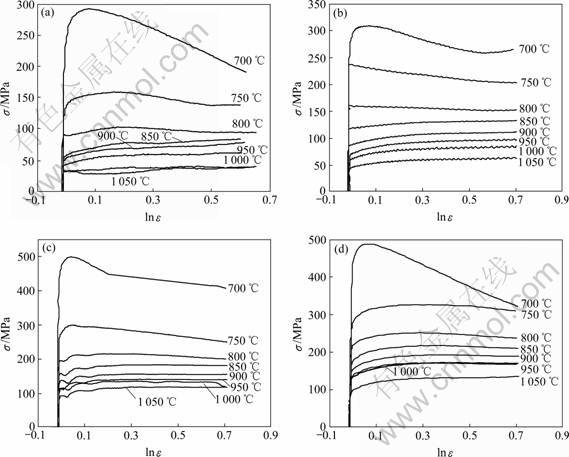

由高温压缩实验获得不同温度和不同应变速率下的真应力—真应变曲线如图1所示。从图1可以看出,流变应力随温度的升高和应变速率的降低而降低。

从曲线变化特征来看:在高温变形时,TB10合金容易发生动态回复和动态再结晶。变形初期,加工硬化产生,位错大量增殖和缠结,此时流变应力随应变的增长而迅速增大;但是随着应变量的不断增大,位错密度不断增高 ,回复和再结晶的驱动力不断增大,刃位错的攀移、异号位错对消,以及再结晶的发生造成的位错湮没和重组造成的软化作用不断增强,从而表现出流变应力随应变的增加的增长速率不断减少,即曲线斜率逐渐减小;达到峰值的时候,软化速率与加工硬化速率基本相等,随着进一步变形,动态回复造成软化作用和加工硬化作用趋于动态平衡[5-13]。

另一方面,当变形温度一定时,流变应力随着应变速率的增大而增大,在本次实验的温度范围内,应变速率为50 s-1的流变应力比应变速率为0.1 s-1的流变应力大150~200 MPa。这是因为应变速率变大后,单位时间内塑性变形量增加,合金中生成大量新位错,使得合金内部的畸变程度加剧,动态回复和结晶得不到及时和充分进行,从而导致流变应力随之增大。

从前面分析可知,TB10合金在热变形时流变应力的大小与应变量、应变速率、变形温度存在明显的相互影响关系,在金属热变形过程中,合金的热变形和

图1 TB10合金热压缩变形真应力—真应变曲线

Fig.1 True stress—strain curves of TB10 alloy hot-compressed at different temperatures and strain rates: (a) 0.1 s-1; (b) 1 s-1; (c) 10 s-1; (d) 50 s-1

高温蠕变过程非常相似,都存在一个热激活过程。Arrhenius双曲正弦形式本构方程是包括变形激活能Q和变形温度T来描述这种热变形行为[14-15]。

![]() (1)

(1)

又可以表达成:

![]() (2)

(2)

式中:σ为流变应力;R为摩尔气体常数;A、α和n 均为与材料状态相关的常数;Q为热变形激活能,反映材料热变形的难易程度,其大小取决与材料的组织状态,其值通常与激活焓?H相等;Z为Zener-Hollomon参数,其物理意义是温度补偿的应变速率因子。

对式(1)进行泰勒级数展开就可以发现在低应力条件下接近式(3),在高应力条件下接近式(4)。

![]() (3)

(3)

![]() (4)

(4)

式中:A1、A2、n1和β均为常数,且常数α、β、n1之间满足:

![]() (5)

(5)

利用式(3)~(5)的关系,可以确定式(1)中各个参数。将式(2)和(3)取对数并整理得

![]() (6)

(6)

![]() (7)

(7)

根据真应力—真应变曲线分别作![]() —

—![]() ,

,![]() —

—![]() 的关系曲线,采用最小二乘法进行线性回归,得到图2。低应力方程式(3)的常数n1取峰值应力较低,即温度为1 000 ℃和1 050 ℃两条直线的斜率的平均值,得到n1=5.60,高应力表达式(4)中的常数β取峰值应力较高,即温度为700 ℃和750 ℃两条直线的斜率的平均值,得β=0.031 457,从而求出α=0.005 617。

的关系曲线,采用最小二乘法进行线性回归,得到图2。低应力方程式(3)的常数n1取峰值应力较低,即温度为1 000 ℃和1 050 ℃两条直线的斜率的平均值,得到n1=5.60,高应力表达式(4)中的常数β取峰值应力较高,即温度为700 ℃和750 ℃两条直线的斜率的平均值,得β=0.031 457,从而求出α=0.005 617。

假定变形激活能Q和变形温度T无关时,对式(1)两边分别取对数有

![]() (8)

(8)

对温度T求偏积分并变形后有

![]() (9)

(9)

由前面算得的α值和真应力—真应变实验曲线绘 制出![]() —

—![]() 以及

以及![]() —1/T关 系如图3所示。代入式(8)和(9)中得到n=5.882 76,

—1/T关 系如图3所示。代入式(8)和(9)中得到n=5.882 76,

图2 流变应力—应变速率曲线

Fig.2 ![]() —

—![]() (a) and

(a) and ![]() —

—![]() (b) curves

(b) curves

图3 ![]() —

—![]() 和

和![]() —(1/T)曲线

—(1/T)曲线

Fig.3 ![]() —

—![]() (a) and

(a) and ![]() —(1/T)(b) curves

—(1/T)(b) curves

Q=179 826,A =1.21×1010。

将前面所求的激活能Q值代入式(2)有

![]() (10)

(10)

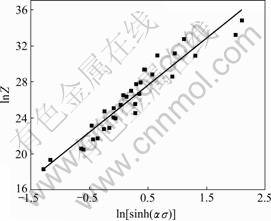

不同变形温度下合金热变形的变形速率代入式(2)计算,就可以得到对应的Z值,与对应的峰值应力得到lnZ—![]() 关系曲线如图4所示。采用一元线性回归分析得出两者线性关系为lnZ=25.044 9+ 5.226 36

关系曲线如图4所示。采用一元线性回归分析得出两者线性关系为lnZ=25.044 9+ 5.226 36![]() ,其相关系数高达0.919以上。

,其相关系数高达0.919以上。

图4 流变应力与Z参数关系

Fig.4 Relationship between ln Z and ![]()

3 结论

1) TB10合金属于正应变速率敏感材料,应变速率和变形温度对合金流变应力有显著影响,热变形流变应力随温度升高而降低,随变形速率增加而增大。

2) 依Arrhenius双曲正弦形式建立TB10合金高温变形本构方程为![]()

![]() 。

。

REFERENCES

[1] LIU Wei, ZHANG Zhu, HUI Song-xiao. Study on mar-contain properties of TB10 alloy[J]. Rare Metal Materials and Engineering, 2005, 34: 383-385.

[2] 张 翥, 惠松骁, 刘 伟. 高强高韧TB10钛合金棒材研究[J]. 稀有金属, 2006, 30(2): 221-224.

ZHANG Zhu, HUI Song-xiao, LIU Wei. High strength and high toughness TB10 titanium alloy bars[J]. Chinese Journal of Rare Metals, 2006, 30(2): 221-224.

[3] 程 奔, 叶文君, 惠松骁. TB10钛合金筒体反挤压成形的有限元模拟[J]. 锻压技术, 2009, 34(5): 162-166.

CHENG Ben, YE Wen-jun, HUI Song-xiao. FEM simulation of backward extrusion process of TB10 titanium alloy cylinder[J]. Forging & Stamping Technology, 2009, 34(5): 162-166.

[4] 魏衍广, 陶海明, 陈海珊. 固溶温度对TB10钛合金力学性能的影响[J]. 稀有金属, 2010, 34(1): 111-114.

WEI Yan-guang, TAO Hai-ming, CHEN Hai-san. Effect of solid solution temperature on mechanical property of TB10 titanium alloy[J]. Chinese Journal of Rare Metals, 2010, 34(1): 111-114.

[5] HUANG L J, GENG L, LI A B, CUI X P, LI H Z, WANG G S. Characteristics of hot compression behavior of Ti-6.5Al-3.5Mo- 1.5Zr-0.3Si alloy with an equiaxed microstructure[J]. Materials Science and Engineering A, 2009, 505: 136-143.

[6] ZENG Zhi-peng, ZHANG Yan-shu, JONSSON S. Deformation behaviour of commercially pure titanium during simple hot compression[J]. Materials and Design, 2009, 30: 3105-3111.

[7] XU S W, MATSUMOTO N, KAMADO S, HONMA T, KOJIMA Y. Dynamic microstructural changes in Mg-9Al-1Zn alloy during hot compression[J]. Scripta Materialia, 2009, 61: 249-252.

[8] JIN Neng-ping, ZHANG Hui, HAN Yi, WU Wen-xiang, CHEN Jiang-hua. Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature[J]. Materials Characterization, 2009, 60: 530-536.

[9] LIN Gao-yong, ZHENG Xiao-yan, YANG Wei, FENG Di, PENG Da-shu. Study on the hot deformation behavior of Al-Zn-Mg-Cu-Cr aluminum alloy during multi-stage hot compression[J]. Acta Metall Sin (Engl Lett), 2009, 22(2): 110-116.

[10] LI L X, PENG D S, LIU J A, LIU Z Q. An experiment study of the lubrication behavior of graphite in hot compression tests of Ti-6Al-4V alloy[J]. Journal of Materials Processing Technology, 2001, 112: 1-5.

[11] HUANG C, LAI K L, LEE C S. Deformation characteristics of Ti-24Al-14Nb-3V-0.5Mo alloy during hot compression[J]. Journal of Materials Processing Technology. 1998, 73: 119-124.

[12] WARCHOMICKA F, STOCKINGER M, DEGISCHER H P. Quantitative analysis of the microstructure of near β titanium alloy during compression tests[J]. Journal of Materials Processing Technology, 2006, 177: 473-477.

[13] LI Miao-quan, XIONG Ai-ming, HUANG Wei-chao, WANG Hai-rong, SU Shao-bo, SHEN Li-chuang. Microstructural evolution and modeling of the hot compression of a TC6 titanium alloy[J]. Materials Characterization, 2003, 49: 203-209.

[14] MAJTA J, BATOR A. Effects of dynamic grain boundary migration during the hot compression of high stacking fault energy metals[J]. Journal of Materials Processing Technology, 2002, 125/126: 77-83.

[15] HUANG Jin-song, HUANG Lan, LIU Bin, ZHANG Yong-hong, ZHANG Wei, HE Xiao-yu, LIU Yong. Simulation of hot compression of TieAl alloy[J]. Intermetallics, 2007, 15: 700-705.

通信作者:惠松骁;电话:010-82241162;E-mail: huisx@grinm.com