DOI: 10.11817/j.ysxb.1004.0609.2021-35999

Al-Cu系耐热铝合金的研究进展

付俊伟,崔 凯,王江春

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:

Al-Cu合金因其具有低密度、良好的强度和成型工艺性等优点,广泛应用于汽车、船舶、航空航天和建筑等领域。随着现代工业的不断发展,对铝合金强韧化、高温性能等方面提出更高的要求。通过添加合金元素,在铝合金中析出稳定的耐高温强化相,通过控制凝固过程、固溶和时效等热处理措施增强弥散强化作用,从而使基体得到稳定,使晶界得到强化。此外,考虑到大规模生产的成本,降低耐热铝合金的制备成本是十分必要的。本文以 Al-Cu 系耐热铝合金为中心,从微量元素的作用和热处理工艺两方面综述该系铝合金的研究进展,并提出了 Al-Cu 系耐热铝合金的发展方向。

关键词:

文章编号:1004-0609(2021)-07-1827-15 中图分类号:TG142 文献标志码:A

引文格式:付俊伟,崔 凯,王江春. Al-Cu系耐热铝合金的研究进展[J]. 中国有色金属学报, 2021, 31(7): 1827-1841. DOI: 10.11817/j.ysxb.1004.0609.2021-35999

FU Jun-wei, CUI Kai, WANG Jiang-chun. Recent development in Al-Cu series heat-resistant aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(7): 1827-1841. DOI: 10.11817/j.ysxb.1004.0609.2021-35999

铝基合金因比强度高、良好的强度和加工性能,被广泛用作汽车行业的结构材料。汽车用铝的发展经历了三个阶段:第一阶段主要是车门车盖;第二阶段主要是底盘、发动机和轮毂等部件;第三阶段是车身整体框架,例如特斯拉的全铝车身。理论上可以通过替换车身材料材质使汽车减重35%,使汽车工业更好地朝着高效能、低能耗、低排放方面发展[1]。轻量化技术已成为提高汽车企业核心竞争力的有效措施,而铝基合金的发展在其中扮演着越来越关键的作用。

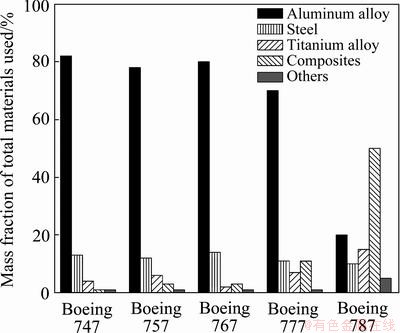

80多年来,铝基合金在航空航天中应用广泛[2]。铝的密度是钢的三分之一,可以促进飞机机身的轻量化(见图1),铝基合金(例如7075-T6)的屈服强度最高可达520 MPa[3]。采用此类铝基合金可以改善发动机的力学性能,从而提高燃油效率,增加有效载荷并增加飞行距离,直接降低飞机的运营成本。在飞行过程中,机翼由于机动或湍流而产生的动态载荷会发生弯曲。在滑行、起飞和着陆期间,起落架、前缘板条和后缘襟翼还会承受额外的载荷。因此,机翼的上表面在飞行过程中处于压缩状态,在滑行过程中处于张紧状态,而下表面则处于相反的状态。这就要求机翼材料既要具有高抗拉强度又要具有高抗压强度[4]。由于机身暴露于高机舱压力和剪切载荷的条件下,因此要求材料同时具有高拉伸强度和剪切强度。目前已开发的铝基合金可以满足这些要求,例如,2024合金具有中等屈服强度(324 MPa)、良好的断裂韧性(37 MPa·m1/2)和高伸长率(21%),因此已广泛用作机身材料。

随着发动机制造技术的发展,企业对发动机壳体和活塞等铸造铝合金部件的高温强度、耐热疲劳能力等性能提出了更高的要求。柴油发动机或高性能发动机的局部工作温度接近300 ℃[5],因此,现有铸造耐热铝合金用于制造发动机时,其高温强度、耐热疲劳能力需要进一步改良提升才能满足其服役条件的要求。

图1 波音系列飞机中使用的全部材料[2, 4]

Fig. 1 All materials used in Boeing series aircraft[2, 4]

本文以 Al-Cu 系耐热铝合金为中心,从微量元素的作用和热处理工艺两方面综述了该系铝合金的研究进展,并提出了 Al-Cu 系高强耐热铸造铝合金的发展方向。

1 Al-Cu二元合金

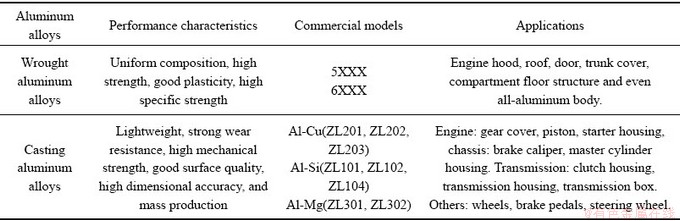

Al-Cu耐热铝合金研发历史悠久,已在工业制造领域,尤其是航天领域得到广泛应用(见表1)。Al-Cu合金中Cu的作用是固溶强化,固溶时效处理之后通过析出强化进一步提高了合金强度。Al-Cu系耐热铝合金的不足是抗热性能和耐蚀性能不佳,其线膨胀系数大于Al-Si等合金的线膨胀系数[6]。在凝固过程中,Al2Cu相和α相之间会产生较大的电位差,容易产生电化学腐蚀现象,使合金的耐蚀性变差。因此,Al-Cu系耐热铝合金大多用于制造发动机中体积较小、形状较为简单的零件,合金的最高使用温度为300~350 ℃[7],使用温度范围高于Al-Si合金。

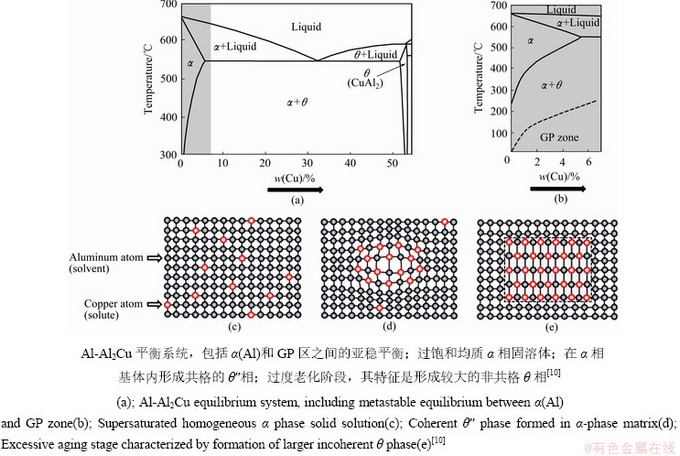

从图2展示的Al-Cu合金相图可以看出,Cu在共晶温度(548 ℃)时溶解度最大,约为5.6%(质量分数)。随着温度的下降,Cu的溶解度也急剧下降,在常温下的溶解度为0.05%[8]。因此可以通过利用Cu的溶解度在不同温度下的变化,对Al-Cu 合金进行固溶和时效处理,从而获得θ等析出强化相,从而阻止位错的滑移。同时Cu固溶在合金基体上,发生晶格畸变,产生固溶强化作用[9-10]。为了提高Al-Cu 合金抗拉强度等性能,通常采取时效强化和细化α相的晶粒度。

开发Al-Cu耐高温铝合金的原理是利用沉淀析出的体心正方(BCT)θ和θ′相来强化基体,提高其高温性能[11]。MOSTAFA等[12]研究了Al-1%Cu合金在不同应力和变形温度下的蠕变特性。发现亚稳相Al2Cu相超过200 ℃后会快速粗化,导致高温力学性能的下降,这种合金一般在250 ℃以下使用。铝合金的力学性能、抗腐蚀性能等在很大程度上都取决于其组织及相的特征,尤其是各析出相的类型、尺寸及分布状态等。BAHL等[13]研究了铸造Al-Cu系合金中Cu含量在6.0%~9.0%之间的变化对伸长率的影响。随着Cu含量的增加,时效后的Al-Cu系合金的伸长率单调降低。超出最大固溶极限的铝中过量的Cu以金属间颗粒的形式在晶界析出,这些颗粒的尺寸和体积分数随Cu含量的增加而增大。由于金属间颗粒在拉伸载荷下会产生破裂,并在此过程中充当裂纹的起始位置,因此随着Cu含量的增加,这些金属间颗粒尺寸和体积分数的增大会促进裂纹萌生。结合Al-Cu系铝合金的材料品种和相关分析认为,Al-Cu系合金中的Cu含量最好在5.6%以下[14]。

表1 铝合金的分类及应用情况

Table 1 Classification and application of aluminum alloys

图2 Al-Cu相图的概图

Fig.2 Overview of Al-Cu phase diagram

对于铸造Al-Cu合金而言,合金还需要具有较好的流动性。因此,选择合适的元素,并通过凝固和热处理工艺控制析出相的特征是获得铝合金优良性能的关键[15]。目前,变形耐热Al-Cu合金研究进展较为迅速,人们正在尝试把变形耐热Al-Cu合金的耐热机理推广至铸造耐热Al-Cu合金,以此来提高其高温性能。

2 Al-Cu系三元合金

2.1 Al-Cu-Mg

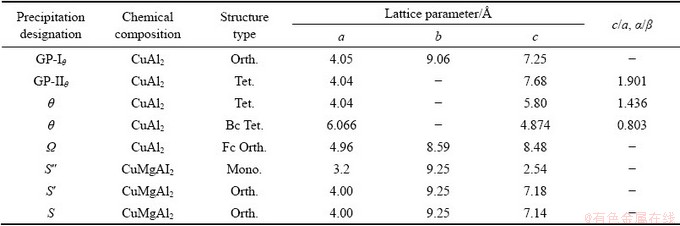

Al-Cu-Mg合金由于其高强度,良好的耐热性和加工性能而被广泛用于航空航天领域[16],其高强度主要归因于热处理过程中大量纳米级时效沉淀的形成[17]。通过微合金化和预应变可以改变时效析出物的尺寸和分布,从而改善Al-Cu-Mg铝合金的综合性能。根据文献[18-20]报道的结果,Al-Cu-Mg的析出顺序与合金中w(Cu)/w(Mg)有关,可分为三类:1) w(Cu)/w(Mg)≤4:SSS→GPB区→S″→S′→ S(Al2CuMg);2) w(Cu)/w(Mg)≥8:SSS→GP区→ θ″→θ′→θ(Al2Cu);3) 4≤w(Cu)/w(Mg)≤8:SSS→ GPB区→S′→ S-Al2CuMg。

w(Cu)/w(Mg)小的Al-Cu-Mg合金需要经过多次热处理形成Ω-Al2Cu相,w(Cu)/w(Mg)较高的Al-Cu-Mg合金只需要传统的时效热处理即可形成Ω相(见表2)。w(Cu)/w(Mg)对Ω相形成的影响可以解释如下:Al基体(0.144 nm)中的Cu原子(0.128 nm)将导致正畸变区域,而Mg原子(0.162 nm)将导致负畸变区域。当w(Cu)/w(Mg)较小时,Cu和Mg原子将形成Cu-Mg共聚簇,以中和变形区域,该变形区域随后变成S和S″相。当w(Cu)/w(Mg)较大时,Mg原子的存在可以减轻由Cu原子引起的负畸变。然后,Cu原子的偏析将发生在Al 基体中最靠近堆积平面{111}处,GP区随后演变为Ω相。此外,Ag的添加会大大加快这个步骤。Ω相会对Al-Cu-Mg合金的时效过程产生相当大的影响,其在基体{111}面大量均匀弥散分布,且呈极薄六角形的板条状,并与基体共格,不仅具有很好的时效强化效果,还能显著增强合金的强度和高温力学性能[20-23]。

Al-Cu-Mg合金中Cu元素的含量一般为2%~ 8%,主要的强化相是θ-Al2Cu析出相(见表3)。随着Cu含量的增加,在(200 MPa, 240 ℃)高温蠕变状态下,Cu含量为5.82%的合金的蠕变断裂时间为63.43 h,远大于Cu含量分别为5.23%和5.56%的其他两种合金,蠕变断口为韧性断裂。原因是Cu促进了Ω相的时效析出,Cu含量为5.82%的合金微观组织中Ω相密度最大,具有最好的高温热稳定性。Al-Cu-Mg合金中Mg含量从0.4%~1.2%逐步提高时,抗拉强度和屈服强度先上升后下降,塑性则先下降后上升[24]。此外,随着Mg含量增加,沿{111}面分布的GP区的密度也随之增加,可以显著提高Al-Cu 合金自然时效后的抗拉强度和屈服强度,但伸长率下降较大。含1.2%Mg的Al-Cu合金与含0.4%Mg的Al-Cu合金相比,前者自然时效后的抗拉强度和屈服强度约高出前者15%,伸长率下降约20%[25]。

表2 Al-Cu-Mg合金中Ω相的w(Cu)/w(Mg) [22]

Table 2 Mass fraction ratio of Cu/Mg in Ω phase for Al-Cu-Mg alloys[22]

热处理技术对Al-Cu-Mg系合金的力学性能具有积极影响。目前,铸造铝铜合金热处理主要包括均匀化处理、固溶和时效热处理三个过程。马文静等[26]对Al-Cu-Mg合金进行固溶淬火(495 ℃, 1 h)和人工时效(190 ℃, 10 h),使Al-Cu-Mg合金的残余应力消减率达到92.7%,屈服强度为463.6 MPa,抗拉强度为502.5 MPa,伸长率为12.7%。微观组织的分析结果表明:在进行新型热处理的合金中S′相比用传统热处理的更为细小、分布更均匀,由S′相析出的共格应力场与淬火残余应力场叠加使合金残余应力大幅度降低,提高了合金的综合性能。BORROS等[27]对Al-3Cu-0.5Mg在495 ℃下固溶处理3 h,然后在200 ℃下分别时效0.5 h、1 h和3 h。发现时效时间为0.5 h和1 h时,合金具有较低的腐蚀速率,在富Al基体的中心区域不发生腐蚀;时效时间为3 h时,合金的耐蚀性和显微硬度均显着降低。GU等[28]通过光学显微镜、透射电子显微镜、拉伸试验和耐冲击试验,研究了T9I6热处理工艺(包括固溶处理、淬火、预时效、冷加工、时效)对2519A铝合金组织,力学性能和耐冲击性的影响。经过T9I6处理后,2519A铝合金的屈服强度,拉伸强度和伸长率分别达到501 MPa,540 MPa和14%。在T9I6过程中,在时效过程中,GP区的沉淀更细密,从而使得后续相的析出也变得更为密集、细小。

2.2 Al-Cu-Mn

Al-Cu-Mn合金强度高、质量轻,因此广泛用于汽车和飞机行业。在工业上应用的Al-Cu-Mn合金中,Mn含量一般在1.6%以下,合金具有较高的强度、良好的塑性和工艺加工性能。Mn含量深刻影响着合金的力学性能,合金的强度和硬度随 Mn含量的增加而增高,但韧性随 Mn含量的增加而降低。当Mn含量高于1.6%时,铸造合金中就会形成粗大的Al6Mn析出相,导致合金的力学性能变差,变形时易开裂,塑性极低[29-30]。在合金中α(Al)和Al6Mn的电势受Mn的影响不大,因此合金中基体固溶体与化合物相的电位差很小,使得合金具有良好的耐腐蚀性能[31-32]。固溶强化和加工硬化是Al-Cu-Mn合金的主要强化方式,但是较小的固溶度制约了固溶强化作用,因此研究人员使用快速凝固或烧结的方法获得过饱和Mn含量的Al固溶体来提高性能,通过淬火将Mn的固溶度提高到15%。在高Mn含量的合金中,Al6Mn具有弥散强化效应,经过冷轧变形后会发生加工硬化,从而提高了合金的硬度。合金经过挤压、剪切变形、轧制等方法加工后,粗大的晶粒得以破碎、细化,从而得到块状铝合金细晶材料,抗拉强度等性能也能得到提高。Mn也可以提高Al-Cu-Mn合金的固溶体热稳定性,强化晶粒间界,降低固溶体的分解倾向。

表3 Al-Cu系合金析出相成分及晶体结构[21]

Table 3 Composition and crystal structure of some precipitated phases in Al-Cu series alloys[21]

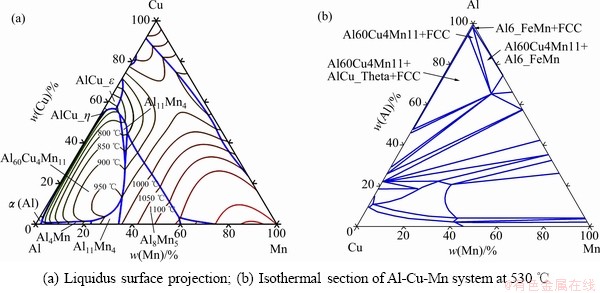

实际使用的Al-Cu-Mn合金主要在富Al区,Al-Cu-Mn三元合金的平衡相图如图3所示,合金系包含了一些稳定相(Al6Mn、Al12Mn、Al4Mn、Al8Mn5和Al11Mn4)和亚稳相[33-34]。Al6Mn相是合金系中与液相平衡的最富铝的金属间化合物相,它具有确定的化学计量比,完全没有固溶度[35]。Al6Mn金属间化合物相为正交结构,其晶格常数分别是a=0.75551,b=0.64994,c=0.88724 nm,空间群为Cmcm。KANG等[36]研究了定向凝固的Al-3Mn合金中Al6Mn初生金属间化合物在1 μm/s低生长速率下的形态和生长机理,发现单个初生Al6Mn晶体的3D形态是空心、扭曲的多面体,表面大多为凹面,并且表现出具有强各向异性的多面生长模式。Al6Mn初生晶体的最终形状取决于晶体结构和外部生长条件决定的固有生长特性。Al6Mn金属间化合物的晶体结构决定了其规则的八面体形状,该形状由8个{110}面界定。由于定向凝固中溶质和热量的限制传输,八面体变形并且其表面呈凹形,且Al6Mn晶体的不连续生长和成核导致最终的堆叠结构。

图3 Pandat软件计算的Al-Cu-Mn三元相图

Fig. 3 Al-Cu-Mn ternary phase diagrams calculated with Pandat software

LITTLE等[37]在1947年首次发现Al12Mn相,并命名为“G相”,之后SCHAEFER等[38]论证Al12Mn相是一种稳定相,在504~521 ℃之间通过包晶反应形成。KREINER等[39]和BENDERSKY[40]通过研究λ-Al4Mn和μ-Al4.12Mn的电子衍射花样,证实了这两个相与准晶I相的密切相关性,λ-Al4Mn和μ-Al4.12Mn都具有较大的单胞和复杂的六方结构,成分与准晶I相的成分相似度高。λ-Al4Mn的稳定性弱于μ-Al4.12Mn,λ-Al4Mn超过693 ℃转为非稳定相,而μ-Al4.12Mn超过919 ℃才转为非稳定相。Al3Mn、Al11Mn4和Al10Mn3相与十边形准晶D相最密切相关[41]。Al3Mn相的晶格常数为a=1.483、b=1.243、c=1.251nm,晶体结构为正交结构,空间群为Pnma[42-43]。TAYLOR等[44]对Al3Mn和Al10Mn3相进行了研究,发现Al3Mn相成分接近且具有三斜结构的相,称之为δ相,同时发现Al10Mn3相结构类似于Al5Co2,Mn原子的外围是由最近邻的10个Al原子和2个Mn原子构成的扭曲的二十面体。在Al-Mn系合金中,存在十边形准晶相(D相)和二十面体准晶相(I相)两种亚稳准晶相[45]。当Al-Mn系合金Mn含量较高时,可以通过旋淬来获取D相。D相具有一个十次对称轴,而且沿十次轴具有一维平移周期性。I相有五次对称的长程取向序,但没有平移恒定性。I相一般通过固态反应或者在熔体中淬火引起一级相变与α(Al)分离而形成,在加热过程中I相可以转变为稳定的 Al6Mn相。

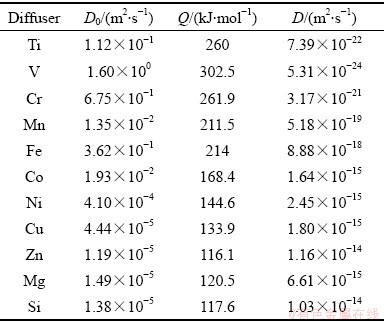

杜勇等[46]通过 Arrhenius方程给出了铝合金中常添加的Ti、V、Cr等元素在Al中的扩散系数,如表4所列。

表4 合金元素在Al中的扩散系数[46]

Table 4 Diffusion coefficients of alloying elements in Al at 400 ℃[46]

由表4可以看出,400 ℃时Mn元素在Al中的扩散系数较小。因此,可在Al-Cu合金中添加Mn以析出Al6Mn相来强化AI基体。与Al2Cu和Mg2Si相比,Al6Mn相的粗化速率要低很多。例如240 ℃时Al2Cu相的粗化动力学常数为690 nm3/s,而500 ℃时Al6Mn相的粗化动力学常数为0.00234 nm3/s[47]。JONATHAN等[48]使用APT和STEM对Al-Cu-Mn- Zr合金进行了详细研究,发现了协同添加对界面结构的影响。单独添加Zr和Mn只能将合金热稳定性提高到200 ℃和300 ℃,复合添加后Al-Cu-Mn合金可以承受高达350 ℃的长时间高温工作环境。APT和STEM结果表明,Mn添加物稳定θ′的时间足以使扩散较慢的Zr原子偏析为相干的θ′界面,最终形成θ′/L12-Al3(Zrx,Ti1-x)共沉淀结构。Mn与其他元素的结合以及它们在偏析物中的偏析在稳定负责合金硬度的亚稳θ′析出物中起着重要作用。

CHEN等[49]报道了在Al-5Cu-1Mn合金固溶处理过程中大量弥散的TMn和AlCu3Mn2颗粒的析出行为。在300 ℃时的拉伸试验表明,高温强度的增加是由于固溶过程(T6)中分散相的析出,这与TMn和AlCu3Mn2颗粒的数量增加和尺寸减小相关。而在时效阶段(170 ℃时效4 h)的析出行为大大提高了室温下的拉伸强度。在均质化过程或固溶处理过程中形成的小分散颗粒增强效果,以及在时效处理过程中形成的细小沉淀物的固化效果均可以实现基质的增强。WANG等[50]以含Mn的2024和2124合金为基础,探究相应的热处理能否使Al-Cu系合金析出Ω相。研究发现,经过固溶处理和不同时效温度,发现Ω相可以在含锰弥散相上均匀形核,且Ω相偏向在Al20Cu2Mn3相上形核。说明了Mn对Ω相析出有一定的辅助作用,从而促进形核,增加了形核质点。

此外,Al-Cu-Mn合金在凝固过程中容易产生铸件缺陷,例如偏析、收缩、孔隙,尤其是热撕裂,这会严重影响力学性能[51]。所有这些因素都要求通过适当的合金设计策略来改善Al-Cu-Mn合金的耐热性能。当前关于Mn的加入对Al-Cu系高强铝合金影响的研究多集中在如何提高合金的强度、塑性、韧度、耐热、耐腐蚀性能以及焊接性能等方面,全面提高该系铝合金的综合性能仍将是今后一个时期国内外学者重点关注的焦点。

2.3 其他Al-Cu三元合金

Al-Cu-Li合金因其出色的拉伸强度、延展性和刚度,应用前景广阔[52-53]。这些特性主要取决于相应的沉淀结构和Cu/Li质量比[54]。例如,Cu/Li质量比较低的Al-Cu-Li合金弹性模量较好,这归因于基体中较高的Li浓度以及晶粒内的主要析出物δ′-Al3Li相[55-56]。Cu/Li质量比较高的Al-Cu-Li合金晶粒内会析出T1-Al2CuLi和θ′-Al2Cu相。这些相对Al-Cu-Li合金的力学性能和腐蚀行为产生一定的影响[57]。LI等[58]研究了Al-Cu-Li合金经时效处理的屈服强度和工作硬化行为,发现Al-Cu-Li合金经155 ℃时效24 h后,屈服强度高达500 MPa。LIU等[59]从微观结构的角度研究了变形加工后Al-Cu-Li合金的腐蚀行为并探索了时效后合金的晶粒取向和晶界析出物。发现合金在170 ℃时效72 h过程中,合金的腐蚀敏感性仍保持相对较低的值,约100~180 μm。这表明使用非常规方式,例如添加元素或进行热处理,可以破坏晶界相的均匀性,以此提高耐腐蚀性。

Al-Cu-Si合金比常规Al-Si合金的强度要高,比Al-Cu合金的耐腐蚀性要好[60-61]。轻金属合金强度的提高可以大大减少运输部门的能源消耗。共晶Al-Cu-Si体系可显著提高铝合金的力学性能。共晶合金在较小的温度范围内凝固,与纯组分的熔点相比,它们的熔点低,并且由于其光滑的凝固前沿而具有出色的流动性[62],通过减小共晶间距,改善了力学性能。PARK等[63]开发了具有不同成分和铸造方法的Al-Cu-Si合金,从而形成了高度精细的共晶组织。Al-27Cu-6Si三元合金通过102~103 K/s的不同冷却速率铸造,形成超细共晶结构。所形成的微观结构由二元(α(Al)+Al2Cu)共晶和纳米晶三元(α(Al)+Al2Cu+Si)共晶基体组成。通过压缩试验测定了合金的力学性能:屈服强度为0.8 GPa,极限断裂强度为1.1 GPa,塑性应变为11%。

GAO等[64]将Al-Cu-Sc合金时效温度从250 ℃升高到350 ℃,研究了Cu和Sc的沉淀序列及其在不同温度范围内的相互作用。在250 ℃附近,发现Sc在靠近θ′-Al2Cu析出物的局部区域内聚集,在远离基体的区域Sc的聚集速率很慢。在350 ℃附近,基体中的Al3Sc析出伴随着θ′-Al2Cu附近Sc聚集的消失。发现通过利用这种析出特征,可以人为地调整Al-Cu-Sc系统中θ′-Al2Cu和Al3Sc的双重析出物,以优化析出物的分散性,提高时效硬化响应,并改善抗蠕变性。LI等[65]研究了Sc对Al-5Cu合金组织和成核机理的影响,发现添加0.8%的Sc可以有效地将α(Al)晶粒从粗枝晶转变为细等轴晶,晶粒平均尺寸减小至29.8 μm,改善了合金的力学性能。已知在铝中微量添加的Er会形成稳定的Al3Er(L12)纳米颗粒,从而改善室温和高温下的强度[66-67]。PAN等[68]以Al-3Cu作为基础合金,研究了不同Er含量的微合金化效果,将均匀化方案优化为(450 ℃, 3 h)+(490 ℃, 20 h)。添加0.24%的Er使Al-Cu合金的抗拉强度提高了25 MPa。尽管Er的添加使得Al-Cu合金的微观组织得到改善,但微量添加Er的效果仍有很大的提升空间。这是因为合金凝固时Er大多在晶界偏析,生成粗共晶Al8Cu4Er相,具有很好的稳定性,并且在Al-Cu合金中进行均匀化后不能充分溶解到基体中,从而导致Al3Er强化相较少[69]。研究人员为了改善这一缺陷,尝试着将Er和Zr适量混合添加,从而增加Al3Er强化相的析出。

3 Al-Cu系多元合金

在Al-Cu系合金发展的同时,Al-Zn系合金也在蓬勃发展。研究人员发现,Al-Zn系合金的强韧性比Al-Cu系合金更高,便将Zn元素加入到Al-Cu-Mg合金中,经过时效处理后,合金强度得到明显提高,原因是合金中存在弥散分布的MgZn2相[70]。Cu在Al中的固溶度为5.6%,远低于Zn的31.6%。Al-Cu-Mg-Zn合金除了形成强化相MgZn2和Al2Mg3Zn3之外,在随后的固溶和时效处理时,合金还会析出新的强化相Al2CuMg和Al2Cu相,使合金的强度再次提高[71]。

只将Zn加入Al-Cu-Mg合金制成的铝合金材料,例如X70S和X71S型铝合金,虽然强度得到提高,但是生产时易开裂,所以并未在生产上得到大规模应用。直至研究人员将Mn、Cr等元素与Zn一起加入到Al-Cu-Mg合金中,才在一定程度上减轻了合金的开裂敏感性[72]。为了提高Al-Cu-Mg-Zn合金的强韧性和应力腐蚀敏感性,研究人员不断尝试,找到了Cu、Mg和Zn元素的最佳配比。当Mg、Cu、Zn总含量小于5%时,合金综合性能好,应力腐蚀抗力较大;当Mg、Cu、Zn总含量为6%~8%时,合金强度得到提高;当Mg、Cu、Zn总含量大于9%时,强度维持较高水平,应力腐蚀抗力增加,但是抗疲劳性能开始下降[73]。此外,通过减少合金中Fe、Si等杂质元素含量,使合金的强韧性得到进一步提高,这些合金被广泛运用于飞机机翼等部位结构材料[74]。

在Al-Cu-Li合金中添加微合金元素也是一种提高强度和耐蚀性等性能的有效方法。LIU等[75]研究了添加Mg和Zn的Al-Cu-Li合金的组织演变,Mg被认为促进了θ′或θ″相的形成,而Zn对此类相的形成没有明显影响。同时,还证实了合金中Mg和Zn的结合加速了δ′-Al3Li相成核析出并抑制了δ′相的生长。HIROSAWA等[76-77]研究了Al-Cu-Li合金中各种微合金元素的原子行为对合金中析出的微观结构的影响。Mg的加入促进了Mg/ Li/空位络合物的生成,从而促进了δ′相的成核。研究人员也从电化学的角度对添加了微合金元素的Al-Cu-Li合金的耐腐蚀性进行了研究。

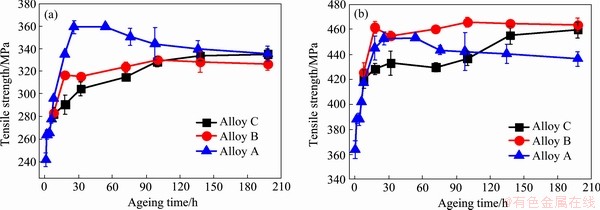

图4 合金A(Al-Cu-2.5Li-0.7Zn-0.3Mn-0.1Zr)、B(Al-Cu-2.4Li-0.4Mg-0.3Mn-0.1Zr)和C(Al-Cu-2.4Li-0.7Zn-0.4Mg-0.3Mn-0.1Zr)时效后的屈服强度和拉伸强度[74]

Fig. 4 Yield strengths and tensile strengths of alloys A(Al-Cu-2.5Li-0.7Zn-0.3Mn-0.1Zr), B(Al-Cu-2.4Li-0.4Mg-0.3Mn-0.1Zr) and C(Al-Cu-2.4Li-0.7Zn-0.4Mg-0.3Mn-0.1Zr) after aging[74]

LI等[78]研究了在不同时效条件下添加Zn的Al-Cu-Li合金的耐蚀性,发现添加少量的Zn降低了较低Cu/Li比值合金(Al-2.7Cu-1.7Li-0.3Mg)的IGC深度,耐蚀性得到了改善,但力学性能不受添加锌的影响。SEMENOV等[79]研究了添加Mg和热处理工艺对Al-Cu-Li基合金腐蚀性能的影响,发现Mg浓度(质量分数)低于0.4%可以改善腐蚀和力学性能,但是Mg浓度高于1%则降低了合金的抗腐蚀性。时效后铝合金的腐蚀行为归因于析出物的类型以及时效阶段的析出物分布[80-81],随着时效时间的延长,腐蚀类型从晶间腐蚀(IGC)变为点蚀,并且IGC耐腐蚀性与晶界处析出物的连续性有关。

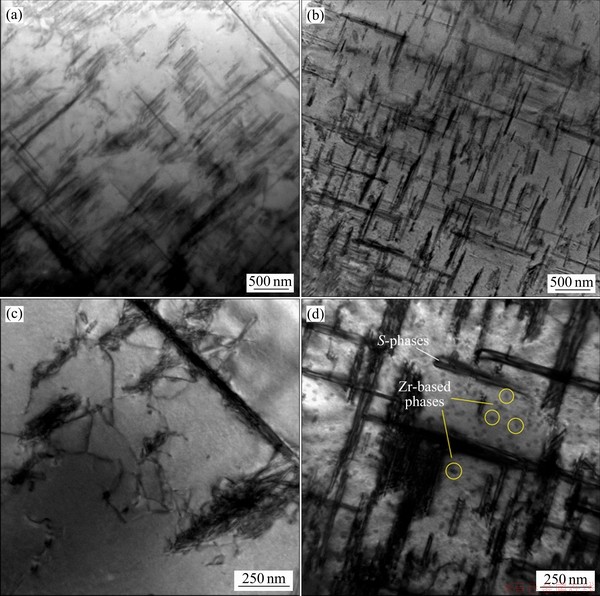

近些年来,人们对Zr元素在铝合金中的作用进行了系统的探究。研究人员在广泛应用于飞机结构部件的2014和2024铝合金基础上,通过添加Zr并降低杂质(Fe和Si)来开发优化出Al-Cu-Mg-Zr合金[82]。Zr的添加使铝合金中形成细小的球形Al3Zr颗粒,如图5所示,这些颗粒在热加工过程中起抑制再结晶和保持未再结晶组织的重要作用[83]。同时,Al-Cu-Mg-Zr合金的力学性能和抗应力腐蚀开裂性在很大程度上取决于热变形和随后的热处理过程中的显微组织发展状态[84]。POURKIA等[85]研究了Zr含量对2618合金的过时效和拉伸行为的影响。Zr含量从0.1%逐渐提高到0.25%,然后进行T6热处理,即525 ℃下保温8 h,在50 ℃水中淬火以及在200 ℃人工时效20 h。实验结果表明,0.25%的Zr不会引起2618合金发生宏观上的结构变化,而在纳米级上可以观察到Zr基体沉淀的存在。在室温和250 ℃及其他热处理参数相同的条件下,与基础合金相比,过时效富集Zr的合金显示出更高的屈服强度和极限抗拉强度,其屈服强度和极限抗拉强度均比基础合金高出10%。瞿猛等[86]研究了添加Zr对合金耐腐蚀性能影响,添加0.15% Zr 的合金的强度和伸长率得到显著提高,耐腐蚀性能也得到不同程度的改善。其中抗应力腐蚀和晶间腐蚀性能提升最为明显,应力腐蚀指数由4.6%降至1.5%,晶间腐蚀等级由3级降至1级。这是因为添加 Zr 抑制了合金的再结晶,大角度晶界分数的降低提升了合金的耐腐蚀性能。

图5 低倍率和高倍率下2618合金和2618+Zr合金的TEM像[83]

Fig. 5 TEM images of 2618 alloy at low(a) and high(c) magnifications, and 2618+Zr alloy at low(b) and high(d) magnifications[83]

SHYAM等[87]将Mn和Zr微合金化,使Al-Cu合金中的亚稳θ′相的最高稳定温度为350 ℃。Al-Cu-Mn-Zr合金由于Mn和Zr在稳定亚稳θ′相中的作用,形成了更大的θ′-Al2Cu析出物,从而使合金得到强化。Al-Cu-Mn-Zr合金中的Mn和Zr偏析到基体θ′界面,有助于降低热力学驱动力并减慢析出物粗化过程。LIAO等[88]通过300 ℃的拉伸试验获得了在T4和T6回火中铸造的Al-5Cu-1Mn-xNi合金的高温强度。分别讨论并仔细观察了均匀化、固溶和时效处理过程中形成的三种耐热相对高温强化的贡献。发现在固溶和时效处理期间形成的耐热相比均匀化期间形成的耐热相对高温强度增强的贡献更大。Al-Cu-Mn-Ni合金时效处理过程中形成的θ″相可作为高温下的耐热强化相。有力地证实了一种新的观点:通过固溶处理过程中形成的小分散颗粒和时效处理过程中形成的细小沉淀来增强基质应引起更多关注。

导致Al-Cu合金耐热性能和抗蠕变性能下降的原因主要是亚稳相在高温时会发生粗化,因此通常会采用合金化方法使析出相的尺寸减小,数量增加,例如加入Sc、Zr等元素。LI等[89]设计了一系列Al-Mg-Si-Sc-Zr合金,以此来开发选择性激光熔融(SLM)增材制造的高强度铝合金,通过进一步微调合金成分,设计了一种新的合金Al-8.0Mg-1.3Si- 0.5Mn-0.5Sc-0.3Zr。这种新合金显著改善了合金的微观结构,该微观结构由亚微米晶胞和位于该晶胞中的相干Al3(Sc,Zr)纳米粒子和晶间Al-Mg2Si共晶组成。样品的拉伸强度和伸长率分别高达497 MPa和11%。时效处理后,拉伸强度达到550 MPa,而延展性最高达到17%。但在实际生产中,考虑到成本问题,中外学者希望添加一定的稀土元素或过渡族金属元素来替代Sc,生成纳米析出相,以此来钉扎位错和晶界,并有效抑制主要热稳定相(如Ω相和θ-Al2Cu相等)的生长速率。YAO等[90]研究了1.0% La对 Al-Cu合金的影响,发现Al11La3会限制位错运动,合金的抗蠕变性能提高了至少3倍。此外,其他稀土元素的加入也会产生类似的效果,例如Pr。实验结果表明,稀土元素 Pr 的加入使析出相的尺寸减小,数量增加,Al11Pr3在晶界和枝晶边缘析出, 抑制了蠕变时的晶界迁移及位错的运动,降低了合金的蠕变速率。

此外,一些加工工艺也会增强合金的力学性能。孟凡生等[91]通过直接挤压铸造制备了具有不同Zr添加量的Al-5.0Cu-0.4Mn合金。通过试验研究了Zr对铸态和T6热处理合金的组织和力学性能的影响。挤压压力通常改善了力学性能,尤其是伸长率。在100 MPa的挤压压力下,热处理合金的最佳伸长率为19.3%。DENG等[92]研究了焊后冷轧(PWCR)和退火处理对搅拌摩擦焊接Al-Cu接头的组织和力学性能的影响。结果发现PWCR有效地抑制了焊缝接头中Al-Cu界面处的拉伸断裂。焊后冷轧和退火处理优化了Al-Cu界面处金属间化合物层的分布,降低了Al-Cu接头的性能梯度,提高了Al-Cu异种接头的力学性能。异种Al-Cu对接接头的强度从79 MPa显着增加至384 MPa,伸长率从1.0%增加到17.5%。GUO等[93]研究了热轧变形对晶粒细化、Al2Cu颗粒破碎和力学性能的影响。通过设计从10%到40%不等的热轧变形程度,研究晶粒结构的演变、Al2Cu颗粒的特性和三维力学性能以及相应的机理,发现热轧变形程度的增加可以促进动态重结晶,并产生更多的亚晶粒;Al2Cu颗粒更分散并且破碎和溶解得更彻底;主要断裂模式从晶间断裂转变为穿晶断裂,伸长率显著增加,热轧变形达到30%的样品表现出最佳的总体伸长率。实验结果为改进大型2219 合金的制造工艺提供了基础。

4 结语

目前,Al-Cu系耐热铝合金研究活动包括:改善力学性能,降低制造、维护和维修成本,防止腐蚀以及在整个使用寿命中能够可靠运行。在铝合金的优良力学性能的基础上,保持汽车飞机零件的结构完整性,还需特别注意微动疲劳,减轻因疲劳引起的损害。除了轻量化和改善材料的结构性能外,通过开发制造技术来降低成本也是关键问题。因此,通过引入高速加工、新颖的装配技术可以降低生产成本和零件数量。例如,与Al-Cu-Mg/Mn合金不同,Al-Cu-Li合金的熔焊性可能为机身制造带来新的发展。

一方面,随着能源资源紧缺以及环境保护的必要,另一方面,汽车业的快速发展对高性能材料的迫切需求,Al-Cu系耐热铝合金得到更广泛的关注和研究。为了实现Al-Cu系耐热铝合金更好地发展,应集中力量对以下几个方面进行研究和开发:

1) 对Al-Cu系耐热铝合金机理深入研究,总结出合金中耐热相的数量、大小、分布等受添加元素的影响规律,紧跟发展前沿,加大对新型合金的研究,例如Al-Cu-Li合金,从而丰富耐热铝合金的种类。

2) 对Al-Cu系耐热铝合金的制备和加工工艺进行创新优化,例如通过添加增强相来获得良好性能的耐热铝合金。使生产成本降低的同时,同步提高耐热铝合金的规模制备能力。

3) 深入研究废铝再生回收技术,将其和变质处理、快速凝固等技术结合,满足大规模生产的需要,降低制造成本获得规模效益。

REFERENCES

[1] MILLER W S, ZHUANG L, BOTTEMA J, et al. Recent development in aluminium alloys for the automotive industry[J]. Materials Science and Engineering A, 2000, 280(1): 37-49.

[2] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[3] RIOJA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical and Materials Transactions A, 2012, 43(9): 3325-3337.

[4] WARREN A S. Developments and challenges for aluminum—A boeing perspective[J]. Materials Science Forum, 2004, 28: 24-31.

[5] HIRSCH J, AL-SAMMAN T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications[J]. Acta Materialia, 2013, 61(3): 818-843.

[6] MAKINENI S K, SUGATHAN S, MEHER S, et al. Enhancing elevated temperature strength of copper containing aluminium alloys by forming L12-Al3Zr precipitates and nucleating θ″ precipitates on them[J]. Scientific Reports, 2017, 7(1): 111-124.

[7] SHENG M, TAO Z, JIA P, et al. Effects of Y and Y combined with Al-5Ti-1B on the microstructure and mechanical properties of hypoeutectic Al-Si alloy[J]. JOM, 2015, 67: 330-335.

[8] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南工业大学出版社, 2000.

WANG Zhu-tang, TIAN Rong-zhang. Aluminium alloy and its processing manual[M]. Changsha: Central South University Press, 2000.

[9] PIRHAYATI P, AVAL H J. Effect of post-heat treatment on friction surfaced Al-Cu-Mg alloy coating containing Ag[J]. Surface and Coatings Technology, 2020, 397: 125984.

[10] ASHKENAZI D. How aluminum changed the world: A metallurgical revolution through technological and cultural perspectives[J]. Technological Forecasting and Social Change, 2019, 143: 101-113.

[11] 张新明, 邓运来, 张勇. 高强铝合金的发展及其材料的制备加工技术[J]. 金属学报, 2015, 51(3): 257-271.

ZHANG Xin-ming, DENG Yun-lai, ZHANG Yong. Development of high-strength aluminum alloy and its material preparation and processing technology[J]. Acta Metallurgica Sinica, 2015, 51(3): 257-271.

[12] MOSTAFA M M, EL-SAYED M M, EI-SAYED H A, et al. Steady state creep during transformation in Al-1wt.% Cu alloy[J]. Materials Science and Engineering A, 2009, 518(1/2): 97-99.

[13] BAHL S, HU X, HOAR E, et al. Effect of copper content on the tensile elongation of Al-Cu-Mn-Zr alloys: Experiments and finite element simulations[J]. Materials Science and Engineering A, 2020, 772: 138801.

[14] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[15] STARKE E A JR, STALEY J T. Application of modern aluminum alloys to aircraft[J]. Progress in Aerospace Sciences, 1996, 32(2/3): 131-172.

[16] 刘克明, 陆德平, 杨 滨. 快速凝固耐热铝合金的现状与进展[J]. 材料导报, 2008, 22(2): 57-60.

LIU Ke-ming, LU De-ping, YANG Bin. Current status and progress of rapidly solidified heat-resistant aluminum alloys[J]. Materials Review, 2008, 22(2): 57-60.

[17] RAVIPRASAD K, HUTCHINSON C R, SAKURAI T, et al. Precipitation processes in an Al-2.5Cu-1.5Mg(wt.%) alloy microalloyed with Ag and Si[J]. Acta Materialia, 2003, 51(17): 5037-5050.

[18] WANG S B, CHEN J H, YIN M J, et al. Double-atomic- wall-based dynamic precipitates of the early-stage S-phase in Al-Cu-Mg alloys[J]. Acta Materialia, 2012, 60(19): 6573-6580.

[19] WANG S Q, SCHNEIDER M, YE H Q, et al. First-principles study of the formation of Guinier-Preston zones in Al-Cu alloys[J]. Scripta Materialia, 2004, 51(7): 665-669.

[20] LIU J Z, YANG S S, WANG S B, et al. The influence of Cu/Mg atomic ratios on precipitation scenarios and mechanical properties of Al-Cu-Mg alloys[J]. Journal of Alloys and Compounds, 2014, 613: 139-142.

[21] 刘志义, 李云涛, 刘延斌, 等. Al-Cu-Mg-Ag合金析出相的研究进展[J]. 中国有色金属学报, 2007, 17(12): 1905-1915.

LIU Zhi-yi, LI Yun-tao, LIU Yan-bin, et al. Research progress of Al-Cu-Mg-Ag alloy precipitated phases[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1905-1915.

[22] LI S, ZHANG J, YANG J, et al. Influence of Mg contents on aging precipitation behavior of Al-3.5Cu-xMg alloy[J]. Acta Metallurgica Sinica-English Letters, 2014, 27(1): 107-114.

[23] 隋育栋, 王渠东. 铸造耐热铝合金在发动机上的应用研究与发展[J]. 材料导报, 2015, 29(3): 14-19.

SUI Yu-dong, WANG Qu-dong. Application research and development of casting heat resistant aluminum alloy in engine[J]. Materials Review, 2015, 29(3): 14-19.

[24] 夏雅阁, 王杰芳, 张国鹏, 等. Cu含量对Al-Cu-Mg-Ag合金蠕变行为和微观组织的影响[J]. 特种铸造及有色合金, 2019, 39(8):914-918.

XIA Ya-ge, WANG Jie-fang, ZHANG Guo-peng. Effect of Cu content on creep behavior and microstructure of Al-Cu-Mg-Ag alloy[J]. Special Casting and Nonferrous Alloys, 2019, 39(8): 914-918.

[25] 周振平, 李荣德, 马建超. 热速处理对Al-Fe合金组织与性能的影响[J]. 中国有色金属学报, 2004, 14(8): 1420-1425.

ZHOU Zhen-ping, LI Rong-de, MA Jian-chao. Effect of thermal rate treatment on as-cast microstructure and mechanical property of Al-Fe alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1420-1425.

[26] 马文静, 陈志国, 李鸿娟, 等. 新型热处理调控Al-Cu-Mg合金残余应力的工艺和机理[J]. 材料研究学报, 2019, 33(6): 435-442.

MA Wen-jing, CHEN Zhi-guo, LI Hong-juan, et al. Process and mechanism of new heat treatment regulating residual stress in Al-Cu-Mg alloy[J]. Chinese Journal of Materials Research, 2019, 33(6): 435-442.

[27] BARROS A, CRUZ C, SILVA A P, et al. Length scale of solidification microstructure tailoring corrosion resistance and microhardness in T6 heat treatment of an Al-Cu-Mg alloy[J]. Corrosion Engineering Science and Technology, 2020, 55(6): 471-479.

[28] GU Gang, YE Ling-ying, JIANG Hai-chun, et al. Effects of T916 thermo-mechanical process on microstructure, mechanical properties and ballistic resistance of 2519A aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2295-2300.

[29] LU Y, WANG J, LI X, et al. Effect of pre-deformation on the microstructures and properties of 2219 aluminum alloy during aging treatment[J]. Journal of Alloys and Compounds, 2017, 699: 1140-1145.

[30] PRABHU T R. Effects of ageing time on the mechanical and conductivity properties for various round bar diameters of AA 2219 Al alloy[J]. International Journal of Engineering Science, 2017, 20, 133-142.

[31] 李雪峰, 张 辉, 蒋福林. 新型Al-Mn合金均匀化处理过程中组织和性能演变[J]. 中国有色金属学报, 2014, 24(2): 380-386.

LI Xue-feng, ZHANG Hui, JIANG Fu-lin. Evolution of microstructure and properties of new Al-Mn alloy during homogenization treatment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 380-386.

[32] 黄晓锋, 冯 凯, 谢 锐. Mg及Mn元素对Al-Si合金显微组织和力学性能的影响[J].中国有色金属学报, 2012, 22(8): 2196-2204.

HUANG Xiao-feng, FENG Kai, XIE Rui. Effects of Mg and Mn on the microstructure and mechanical properties of Al-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2196-2204.

[33] MCALISTER A J, MURRAY J L. The (Al-Mn) aluminum- manganese system[J]. Journal of Phase Equilibria, 1987, 8(5): 438-447.

[34] JANSSON A. A thermodynamic evaluation of the Al-Mn system[J]. Metallurgical Transactions A, 1992, 23(11): 2953-2962.

[35] KONTIO A, COPPENS P. New study of the structure of MnAl6[J]. Acta Crystallographica Section B, 1981, 37(2): 433-435.

[36] KANG H J, LI X Z, SU Y Q, et al. 3-D morphology and growth mechanism of primary Al6Mn intermetallic compound in directionally solidified Al-3at.% Mn alloy[J]. Intermetallics, 2012, 23: 32-38.

[37] LITTLE K, RAYNOR G V, HUME-ROTHERY W. A new aluminum-rich phase in the alloys of aluminum and manganese[J]. Japan Institute of Metal, 1947, 73: 83-90.

[38] SCHAEFER R J, BIANCANIELLO F S, CAHN J W. Formation and stability range of the G phase in the AlMn system[J]. Scripta Metallurgica, 1986, 20(10): 1439-1444.

[39] KREINER G, FRANZEN H F. The crystal structure of λ-Al4Mn[J]. Journal of Alloys and Compounds, 1997, 261(1/2): 83-104.

[40] BENDERSKY L A. Structural relationship between crystalline and quasicrystalline phases in Al-Mn system[J]. Materials Science Forum, 1987, 22/24: 151-162.

[41] LAISSARDIERE G, MANH D N, MAYOU D. Electronic structure of complex hume-rothery phases and quasicrystals in transition metal aluminides[J]. Progress in Materials Science, 2005, 50(6): 679-788.

[42] TAYLOR M A. The space group of MnAl3[J]. Acta Crystallographica, 1961, 14(1): 84.

[43] HIRAGA K, KANEKO M, MATSUO Y, et al. The structure of Al3Mn: Close relationship to decagonal quasicrystais[J]. Philosophical Magazine Part B, 1993, 67(2): 193-205.

[44] TAYLOR M A. Intermetallig Phases in the aluminium manganese binary system[J]. Acta Metallurgica, 1960, 8(4): 256-262.

[45] BENDERSKY L. Quasicrystal with one-dimensional translational symmetry and a tenfold rotation axis[J]. Physical Review Letters, 1985, 55(14): 1461-1463.

[46] DU Y, CHANG Y A, HUANG B, et al. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation[J]. Materials Science and Engineering A, 2003, 363(1/2): 140-151.

[47] RYLANDS L M, WILKES D M J, RAINFORTH W M, et al. Coarsening of precipitates and dispersoids in aluminium alloy matrices: A consolidation of the available experimental data[J]. Journal of Materials Science, 1994, 29(7): 1895-1900.

[48] POPLAWSKY J D, MILLIGAN B K, ALLARD L F, et al. The synergistic role of Mn and Zr/Ti in producing θ′/L12 co-precipitates in Al-Cu alloys[J]. Acta Materialia, 2020, 194: 577-586.

[49] CHEN J L, LIAO H C, WU Y, et al. Contributions to high temperature strengthening from three types of heat-resistant phases formed during solidification, solution treatment and ageing treatment of Al-Cu-Mn-Ni alloys respectively[J]. Materials Science and Engineering A, 2020, 772: 138819.

[50] WANG L M, FLOWER H M, LINDLEY T C. Precipitation of the ω phase in 2024 and 2124 aluminium alloys[J]. Scripta Materialia, 1999, 41(4): 391-396.

[51] 龚 习, 王恒强, 付敏敏. 航空航天用Al-Cu-Mn系高强铝合金的研究进展[J]. 热加工工艺, 2015, 44(22): 6-10.

GONG Xi, WANG Heng-qiang, FU Min-min. Research progress of Al-Cu-Mn series high-strength aluminum alloys for aerospace use[J]. Hot Working Technology, 2015, 44(22): 6-10.

[52] IMMARIGEON J P, HOLT R T, KOUL A K, et al. Lightweight materials for aircraft applications[J]. Materials Characterization, 1995, 35(1): 41-67.

[53] RIOJA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical and Materials Transactions A, 2012, 43(9): 3325-3337.

[54] DECREUS B, DESCHAMPS A, GEUSER F D, et al. The influence of Cu/Li ratio on precipitation in Al-Cu-Li-x alloys[J]. Acta Materialia, 2013, 61(6): 2207-2218.

[55] BECCARIA A M, TRAVERSO P. Effect of heat treatments on 8090 AlLi alloy pitting susceptibility in sea water[J]. Materials and Corrosion, 1996, 47(5): 261-267.

[56] HUANG J L, LI J F, LIU D Y, et al. Correlation of intergranular corrosion behaviour with microstructure in Al-Cu-Li alloy[J]. Corrosion Science, 2018, 139: 215-226.

[57] GUMBMANN E, DE GEUSER F, SIGLI C, et al. Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al-Cu-Li alloy[J]. Acta Materialia, 2017, 133: 172-185.

[58] LI Yong, SHI Zhu-sheng, LIN Jian-guo. Experimental investigation and modelling of yield strength and work hardening behaviour of artificially aged Al-Cu-Li alloy[J]. Materials and Design, 2019, 183: 108121.

[59] LIU Dan-yang, SANG Feng-jian, LI Jin-feng, et al. The role of grain structure characteristics on the localised corrosion feature in the 1445 Al-Cu-Li alloy[J]. Materials Characterization, 2019, 158: 109981.

[60] PAN X M, LIN C, BRODY H D, et al. An assessment of thermodynamic data for the liquid phase in the Al-rich corner of the Al-Cu-Si system and its application to the solidification of a 319 alloy[J]. Journal of Phase Equilibria and Diffusion, 2005, 26(3): 225-233.

[61] PONWEISER N, RICHTER K W. New investigation of phase equilibria in the system Al-Cu-Si[J]. Journal of Alloys and Compounds, 2012, 512(1): 252-263.

[62] KARMA A, SARKISSIAN A. Morphological instabilities of lamellar eutectics[J]. Metallurgical and Materials Transactions A, 1996, 27(3): 635-656.

[63] PARK J M, KIM K B, KIM D H, et al. Multi-phase Al-based ultrafine composite with multi-scale microstructure[J]. Intermetallics, 2010, 18(10): 1829-1833.

[64] GAO Y H, KUANG J, ZHANG J Y, et al. Tailoring precipitation strategy to optimize microstructural evolution, aging hardening and creep resistance in an Al-Cu-Sc alloy by isochronal aging[J]. Materials Science and Engineering A, 2020, 795: 139943.

[65] LI Qing-lin, ZHANG Yu-shi, LAN Ye-feng, et al. The effect of Sc addition on the novel nano-AlCu phase in as-cast Al-5%Cu alloy[J]. Journal of Alloys and Compounds, 2020, 831: 154739.

[66] WEN S P, GAO K Y, LI Y, et al. Synergetic effect of Er and Zr on the precipitation hardening of Al-Er-Zr alloy[J]. Scripta Materialia, 2011, 65(7): 592-595.

[67] DALEN M E V, KARNESKY R A, CABOTAJE J R, et al. Erbium and ytterbium solubilities and diffusivities in aluminum as determined by nanoscale characterization of precipitates[J]. Acta Materialia, 2009, 57(14): 4081-4089.

[68] PAN Shi-wei, CHEN Xiao-hua, ZHOU Xiang-lin, et al. Micro-alloying effect of Er and Zr on microstructural evolution and yield strength of Al-3Cu(wt.%) binary alloys[J]. Materials Science and Engineering A, 2020, 790: 139391.

[69] CHEN Xu, LIU Zhi-yi, BAI Song, et al. Alloying behavior of erbium in an Al-Cu-Mg alloy[J]. Journal of Alloys and Compounds, 2010, 505(1): 201-205.

[70] SANDER W. Influence of compound MgZn2 on the availability of aluminum alloys[J]. Journal of Inorganic and General Chemistry, 1926, 154(1): 144-151.

[71] SUN Yong-gen, DU Zhi-ming, et al. Effect of Zn/Mg/Cu additions on hot cracking tendency and performances of Al-Cu-Mg-Zn alloys for liquid forging[J]. Journal of Wuhan University of Technology (Materials Science), 2020, 35(1): 176-182.

[72] 罗先甫, 郑子樵, 钟继发, 等. Mg、Ag、Zn多元微合金化对新型Al-Cu-Li合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

LUO Xian-fu, ZHENG Zi-qiao, ZHONG Ji-fa, et al. The effect of Mg, Ag, Zn multi-element microalloying on the aging behavior of new Al-Cu-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1833-1842.

[73] 刘金干, 李念奎, 凌 高, 等. 铝合金材料与热处理技术[M]. 北京: 冶金工业出版社, 2012: 315-354.

LIU Jin-gan, LI Nian-kui, LING Gao, et al. Aluminum alloy materials and heat treatment technology[M]. Beijing: Metallurgical Industry Press, 2012: 315-354.

[74] LUKASAK D A, HART R M. Aluminum alloy development efforts for compression dominated structure of aircraft[J]. Light Metal Age, 1991, 49(9/10): 11-15.

[75] LIU Dan-yang, MA Yun-long, LI Jin-feng, et al. Precipitate microstructures, mechanical properties and corrosion resistance of Al-1.0wt% Cu-2.5wt.% Li alloys with different micro-alloyed elements addition[J]. Materials Characterization, 2020, 167: 110528.

[76] YOKOTA J I, HIROSAWA S, SATO T. Computer simulation of the effects of trace-additional Cu and Mg elements on the δ′ phase precipitation in an Al-Li alloy[J]. Journal of Japan Institute of Light Metals, 1999, 49(2): 51-56.

[77] HIROSAWA S, SATO T, KAMIO A. Effects of Mg addition on the kinetics of low-temperature precipitation in Al-Li-Cu-Ag-Zr alloys[J]. Materials Science and Engineering A, 1998, 242(1/2): 195-201.

[78] LI J F, BIRBILIS N, LIU D Y, et al. Intergranular corrosion of Zn-free and Zn-microalloyed Al-xCu-yLi alloys[J]. Corrosion Science, 2016, 105: 44-57.

[79] SEMENOV A M. Effect of Mg additions and thermal treatment on corrosion properties of Al-Li-Cu-Base alloys[J]. Protection of Metals, 2001, 37(2): 126-131.

[80] LI H, ZHAO P P, WANG Z X, et al. The intergranular corrosion susceptibility of a heavily overaged Al-Mg-Si-Cu alloy[J]. Corrosion Science, 2016, 107: 113-122.

[81] LIU Q, ZHU R H, LIU D Y, et al. Correlation between artificial aging and intergranular corrosion sensitivity of a new Al-Cu-Li alloy sheet[J]. Materials and Corrosion, 2017, 68(1): 65-76.

[82] TOSCHI S, BALDUCCI E, CESCHINI L, et al. Effect of Zr addition on overaging and tensile behavior of 2618 aluminum alloy[J]. Metals, 2019, 9(2): 130.

[83] SJOLANDER E, SEIFEDDINE S. The heat treatment of Al-Si-Cu-Mg casting alloys[J]. Journal of Materials Processing Technology, 2010, 210(10): 1249-1259.

[84] BO G W, JIANG F L, DONG Z Y, et al. Revealing the influence of pre-precipitation microstructure on hot workability in an Al-Cu-Mg-Zr alloy[J]. Materials Science and Engineering A, 2019, 755(7): 147-157.

[85] POURKIA N, EMAMY M, FARHANGI H, et al. The effect of Ti and Zr elements and cooling rate on the microstructure and tensile properties of a new developed super high-strength aluminum alloy[J]. Materials Science and Engineering A, 2010, 527(20): 5318-5325.

[86] 瞿 猛, 唐建国, 叶凌英, 等. 过时效与添加Zr对Al-Zn-Mg合金耐腐蚀性能影响的对比[J]. 材料导报, 2020, 34(1): 02083-02087.

QU Meng, TANG Jian-guo, YE Ling-ying, et al. Comparison of the effects of overaging and adding Zr on the corrosion resistance of Al-Zn-Mg alloys[J]. Materials Reports 2020, 34(1): 02083-02087.

[87] SHYAM A, ROY S, SHIN D, et al. Elevated temperature microstructural stability in cast AlCuMnZr alloys through solute segregation[J]. Materials Science and Engineering A, 2019, 765: 138279.

[88] CHEN J L, LIAO H C, WU Y N, et al. Contributions to high temperature strengthening from three types of heat-resistant phases formed during solidification, solution treatment and ageing treatment of Al-Cu-Mn-Ni alloys respectively[J]. Materials Science and Engineering A, 2020, 772: 138819.

[89] LI R, WANG M, LI Z, et al. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: crack- inhibiting and multiple strengthening mechanisms[J]. Acta Materialia, 2020, 193: 83-98.

[90] YAO D M, XIA Y M, QIU F. Effects of La addition on the elevated temperature properties of the casting Al-Cu alloy[J]. Materials Science and Engineering A, 2011, 528(3): 1463-1466.

[91] MENG Fan-sheng, ZHANG Wei-wen, HU Yuan, et al. Effect of zirconium on microstructures and mechanical properties of squeeze cast Al-5.0Cu-0.4Mn-0.1Ti-0.1RE alloy[J]. Journal of Central South University, 2017, 24(10): 2231-2237.

[92] DENG Q, FU R, JING L, et al. Influence of cold-rolling and annealing treatments on microstructure and mechanical properties of friction stir-welded Al-Cu joints[J]. Science and Technology of Welding and Joining, 2016, 21(8): 614-623.

[93] GUO W, YI Y, HUANG S, et al. Effects of warm rolling deformation on the microstructure and ductility of large 2219 Al-Cu alloy rings[J]. Metals and Materials International, 2020, 26: 56-68.

Recent development in Al-Cu series heat-resistant aluminum alloys

FU Jun-wei, CUI Kai, WANG Jiang-chun

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 23009, China)

Abstract: Al-Cu alloy is widely used in automobile, shipbuilding, construction, aerospace and other fields because of its low density, good strength and forming process. With the continuous development of new technologies, higher requirements were put forward for aluminum alloys’ toughness and high-temperature performance. By adding alloying elements, a stable high temperature resistant strengthening phase is precipitated in the aluminum alloy, and the dispersion strengthening effect is enhanced by controlling the solidification process and heat treatment measures, so that the matrix is stabilized and the grain boundary is strengthened. In addition, considering the cost of large-scale production, it is necessary to reduce the production cost of heat-resistant aluminum alloys. This article focuses on the Al-Cu series heat-resistant aluminum alloys, discusses the research progress of this series of aluminum alloys from the effects of trace elements and heat treatment processes, and proposes the development direction of Al-Cu series heat-resistant aluminum alloys.

Key words: heat-resistant aluminum alloys; Al-Cu alloys; heat treatment; alloy elements

Foundation item: Project(51571081) supported by the National Natural Science Foundation of China

Received date: 2020-08-06; Accepted date: 2020-11-24

Corresponding author: FU Jun-wei; Tel: +86-13966754090; E-mail: hitfujw@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51571081)

收稿日期:2020-08-06;修订日期:2020-11-24

通信作者:付俊伟,副教授,博士;电话:13966754090;E-mail:hitfujw@163.com

摘 要:Al-Cu合金因其具有低密度、良好的强度和成型工艺性等优点,广泛应用于汽车、船舶、航空航天和建筑等领域。随着现代工业的不断发展,对铝合金强韧化、高温性能等方面提出更高的要求。通过添加合金元素,在铝合金中析出稳定的耐高温强化相,通过控制凝固过程、固溶和时效等热处理措施增强弥散强化作用,从而使基体得到稳定,使晶界得到强化。此外,考虑到大规模生产的成本,降低耐热铝合金的制备成本是十分必要的。本文以 Al-Cu 系耐热铝合金为中心,从微量元素的作用和热处理工艺两方面综述该系铝合金的研究进展,并提出了 Al-Cu 系耐热铝合金的发展方向。

[8] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南工业大学出版社, 2000.

[11] 张新明, 邓运来, 张勇. 高强铝合金的发展及其材料的制备加工技术[J]. 金属学报, 2015, 51(3): 257-271.

[16] 刘克明, 陆德平, 杨 滨. 快速凝固耐热铝合金的现状与进展[J]. 材料导报, 2008, 22(2): 57-60.

[21] 刘志义, 李云涛, 刘延斌, 等. Al-Cu-Mg-Ag合金析出相的研究进展[J]. 中国有色金属学报, 2007, 17(12): 1905-1915.

[23] 隋育栋, 王渠东. 铸造耐热铝合金在发动机上的应用研究与发展[J]. 材料导报, 2015, 29(3): 14-19.

[24] 夏雅阁, 王杰芳, 张国鹏, 等. Cu含量对Al-Cu-Mg-Ag合金蠕变行为和微观组织的影响[J]. 特种铸造及有色合金, 2019, 39(8):914-918.

[25] 周振平, 李荣德, 马建超. 热速处理对Al-Fe合金组织与性能的影响[J]. 中国有色金属学报, 2004, 14(8): 1420-1425.

[26] 马文静, 陈志国, 李鸿娟, 等. 新型热处理调控Al-Cu-Mg合金残余应力的工艺和机理[J]. 材料研究学报, 2019, 33(6): 435-442.

[31] 李雪峰, 张 辉, 蒋福林. 新型Al-Mn合金均匀化处理过程中组织和性能演变[J]. 中国有色金属学报, 2014, 24(2): 380-386.

[32] 黄晓锋, 冯 凯, 谢 锐. Mg及Mn元素对Al-Si合金显微组织和力学性能的影响[J].中国有色金属学报, 2012, 22(8): 2196-2204.

[42] TAYLOR M A. The space group of MnAl3[J]. Acta Crystallographica, 1961, 14(1): 84.

[51] 龚 习, 王恒强, 付敏敏. 航空航天用Al-Cu-Mn系高强铝合金的研究进展[J]. 热加工工艺, 2015, 44(22): 6-10.

[72] 罗先甫, 郑子樵, 钟继发, 等. Mg、Ag、Zn多元微合金化对新型Al-Cu-Li合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

[73] 刘金干, 李念奎, 凌 高, 等. 铝合金材料与热处理技术[M]. 北京: 冶金工业出版社, 2012: 315-354.

[86] 瞿 猛, 唐建国, 叶凌英, 等. 过时效与添加Zr对Al-Zn-Mg合金耐腐蚀性能影响的对比[J]. 材料导报, 2020, 34(1): 02083-02087.