应用电感耦合等离子体质谱研究硅灰中的重金属元素

李坦平1,谢华林2,聂西度1,梁逸曾3,唐有根3

(1. 湖南工学院 材料与化学工程学院,湖南 衡阳,421002;

2. 长江师范学院 化学化工学院,重庆 涪陵,408100;

3. 中南大学 化学化工学院,湖南 长沙,410083)

摘 要:

/反应池电感耦合等离子体质谱(ORS-ICP-MS)法测定硅灰中Cr,Ni,As,Cd,Sb和Pb等重金属元素的分析方法。样品经硝酸+氢氟酸密闭微波溶解后,采用ORS-ICP-MS法测定上述6种重金属元素。应用ORS技术消除高盐基体对待测元素产生的多原子离子质谱干扰,研究不同碰撞气流速对待测元素预估检测限(EDL)的影响,采用基体匹配并以Rh为内标元素校正质谱分析中基体效应并补偿了信号漂移。在选定的条件下,样品的加标回收率为92.0%~106.0%,相对标准偏差(RSD)均小于3.4%,各待测元素的检出限为12.8~31.5 ng/L。

关键词:

电感耦合等离子体质谱;八极杆碰撞/反应池;硅灰;重金属元素;

中图分类号:O657.63 文献标志码:A 文章编号:1672-7207(2014)10-3358-05

Application of inductively coupled plasma mass spectrometry to determine heavy elements in silica fume

LI Tanping1, XIE Hualin2, NIE Xidu1, LIANG Yizeng3, TANG Yougen3

(1. College of Material and Chemical Engineering, Hunan Institute of Technology, Hengyang 421002, China;

2. College of Chemistry and Chemical Engineering, Yangtze Normal University, Fuling 408100, China;

3. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: A method for simultaneous and quantitative determination of Cr, Ni, As, Cd, Sb and Pb in silica fume by octopole reaction system inductively coupled plasma mass spectrometry (ORS-ICP-MS) was established. The sample was digested by HNO3+HF with microwave digestion followed by dilution with ultrapure water and then the above six heavy metal elements in the solution were analyzed directly by ICP-MS. Using ORS, the polyatomic interferences caused by the high salty matrixes were eliminated. The effect of the He collision gas flow rate on the estimated detection limits of Cr, Ni, As and Cd was investigated. The matrix effect was minimized through matrix matching, and Rh was used as internal standard element. Under the optimal condition, the recovery of standard addition is 92.0%-106.0%, and the relative standard deviation (RSD) is less than 3.4%. The detection limits is 12.8-31.5 ng/L.

Key words: Inductively coupled plasma mass spectrometry; octopole reaction system; silica fume; heavy metal elements

硅灰是冶炼硅铁和金属硅过程中在炉内产生的大量挥发性SiO2和Si气体与空气迅速氧化冷凝沉淀而成的一类超细粉体材料,具有较高的火山灰活性。作为一种辅助性胶凝材料,能填充于水泥颗粒的空隙之间,显著提高混凝土的抗渗性和耐久性,广泛应用于核电、水利、桥梁、隧道、地铁中的高强度和高性能混凝土。由于来源和工艺的不同,硅灰中各元素组成存在较大差异,其中重金属元素含量的高低直接关系到产品的质量和等级,对混凝土的性能及安全也有着重要的影响作用。因此,准确测定硅灰中重金属元素的含量具有重要的意义。高硅样品中微量元素的分析已有大量文献报道,分析方法主要有中子活化学法(NAA)[1]、X线荧光(XRF)法[2]、原子吸收(AAS)法[3]、电感耦合等离子体发射光谱(ICP-OES)法[4-5]和电感耦合等离子体质谱(ICP-MS)法[6-9]。样品的消解方法主要有高温挥硅法和微波消解法,高温挥硅法能有效除去基体硅存在所产生的干扰,但在挥硅过程中易造成待测样品中易挥发元素的损失;微波消解法则可以有效避免待测元素的挥发损失,但大量基体元素的残留所产生的严重干扰直接影响分析结果的准确性。本文作者应用带八极杆碰撞/反应池的电感耦合等离子体质谱(ORS-ICP-MS)法研究硅灰中的Cr,Ni,As,Cd,Sb和Pb等6种重金属元素,考察碰撞/反应模式、碰撞/反应气流速以及高盐基体对分析结果的影响,建立硅灰中重金属元素的质谱分析方法。

1 实验

1.1 仪器与工作条件

仪器有:美国安安捷伦公司Agilent 7500c电感耦合等离子体质谱仪,采用调谐液优化后仪器工作功率为1 450 W,等离子气流量为14.5 L/min,载气流速为0.86 L/min,He流量为4.5 mL/min,样品提升量为0.4 mL/min,采样深度为8.2 mm,重复采样3次,同位素选择52Cr,60Ni,75As,111Cd,123Sb和208Pb;美国Millipore公司Milli-Q超纯水机;美国培安公司CEM MARS X微波消解系统。

1.2 标准溶液与试剂

标准溶液有:高纯二氧化硅,购自国家标准物质研究中心,配制成1 000 μg/mL Si标准溶液;Cr,Ni,As,Cd,Sb和Pb单元素标准溶液,1 000 μg/mL,购自国家标准物质研究中心;混合标准溶液,由Cr,Ni,As,Cd,Sb和Pb单元素标准溶液稀释而成;内标溶液,1.0 μg/mL,由1 000 μg/mL Rh单元素溶液稀释而成。

试剂有:超纯水,电阻率≥18.2 MΩ·cm;电子级高纯硝酸;电子级高纯氢氟酸;电子级高纯硼酸。

1.3 实验方法

准确称取0.100 0 g硅灰样品于PTFE消解罐内,先加入少量超纯水润湿,然后加入2 mL硝酸和1 mL氢氟酸,缓慢加入10 mL超纯水,放置10~15 min(预分解反应基本结束)后放入消解炉内消解。微波消解程序为:功率600 W,斜坡升温5 min,压力5 516 kPa,温控200 ℃持续15 min。消解完成冷却后,加入1 mL质量分数为10% H3BO3溶液中和残留的氢氟酸,用超纯水转移至100 mL容量瓶中定容,同时做试剂空白。

2 结果与讨论

2.1 仪器信号的稳定性

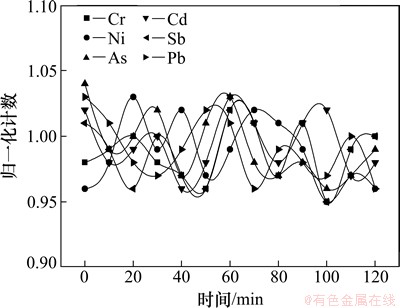

样品溶液中含盐浓度很高,长时间进样基体颗粒会在质谱锥口沉积,引起采样锥和截取锥的孔径变小,产生分析元素信号漂移。为确定样品分析过程中仪器信号的稳定性,实验首先研究了待测元素120 min的稳定情况,每10 min测定1次,结果表明所有待测元素均没有出现信号明显漂移现象,稳定性良好,相对标准偏差(RSD)的均小于5%。6种待测元素在样品溶液中120 min稳定性情况见图1。

图1 样品溶液中待测元素120 min的稳定性

Fig. 1 Stability of analyses in sample solution at 120 min

2.2 碰撞/反应模式的选择

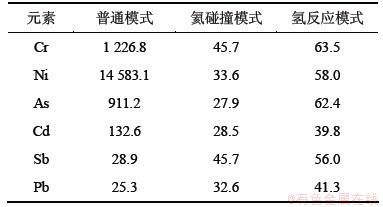

硅灰中的主要组成元素为Si,Ca,Al,Fe,Mg和Na,在质谱分析中易与等离子气以及溶液空气中的N,H和O结合形成多原子离子干扰待测元素的测定。其质谱干扰主要表现为:40Ar12C,19F16O21H,35Cl16O1H,36Ar16O,38Ar14N和26Mg++对52Cr;28Si16O2,27Al16O2H,23Na36ArH,23Na37Cl,44Ca16O和59Co1H对60Ni;40Ar35Cl,36Ar39K,36Ar38Ar1H,59Co16O和43Ca16O2对75As;95Mo16O,71Ga40Ar和79Br32S对111Cd,91Zr16O2对123Sb;192Os16O对208Pb的干扰。实验采用ORS技术进行校正,分别考察了在普通(Normal)、氦碰撞(He)和氢反应(H2) 3种模式下各待测元素的背景等效浓度(BEC)变化情况,结果见表1。待测元素Cr,Ni,As和Cd选择氦碰撞模式分析,而Sb和Pb选择普通模式进行测定。

表1 不同模式下各待测元素的背景等效浓度(BEC)

Table 1 Comparison of background equivalent concentration in different modes ng/L

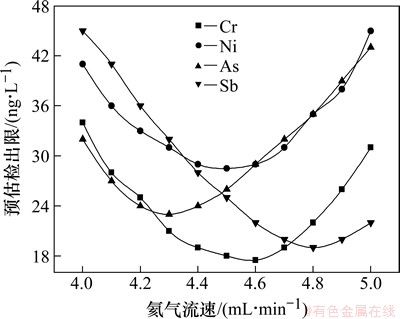

2.3 He气流速的优化

在ORS中影响其操作状态的因素较多,其中最关键的操作条件为ORS气体流速。分别配制300 ng/mL Cr,200 ng/mL Ni,200 ng/mL As和100 ng/mL Cd标准溶液为分析物溶液,以1 000 mg/L硅标准溶液为模拟基质溶液,考察He气流速对待测元素Cr,Ni,As和Cd预估检测限(DeDL)的影响,DeDL计算公式如下[10]:

式中:B为背景信号;N为净信号。

图2所示为改变He气流速对待测元素Cr,Ni,As和Cd预估检测限的影响。当He气流速分别为4.6,4.5,4.3和4.8 mL/min时,Cr,Ni,As和Cd具有最低的预估检测限,实验综合选择He气流速为4.5 mL/min。

图2 氦碰撞气流速的变化对Cr,Ni,As和Cd预估检出限的影响

Fig. 2 Effect of He collision gas flow rate on estimated detection limits of Cr, Ni, As and Cd

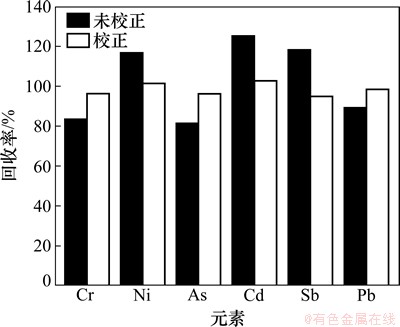

2.4 基体效应

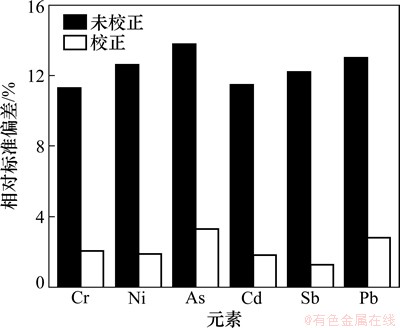

为避免待测元素的损失,在样品处理过程没有蒸发驱赶硅和氢氟酸,因此,在样品溶液中基体元素Si的含量很高,在质谱分析中会产生严重的基体效应。基体效应的校正最直接有效的方法是基体匹配法和内标法[11-15],实验选择高纯二氧化硅为匹配基质,并结合在线加入1.0 μg/mL的Rh内标元素进行校正。配制各待测元素浓度为50.0 μg/L的混合标准溶液对样品溶液进行加标回收,重复测定样品溶液6次,比较了校正前后各待测元素加标回收率和相对标准偏差(RSD)的变化情况,结果表明校正后各待测元素的加标回收率均分布在95%~102.7%范围内,分析结果的准确性得到了改善,如图3所示。图4所示为样品溶液中各待测元素的精密度。由图4可见:校正后各待测元素的精密度也得到了显著提高,相对标准偏差(RSD)在1.3%~3.3%范围内。

图3 样品溶液中各待测元素的加标回收率

Fig. 3 Recoveries of multi-element standard from sample solutions

图4 样品溶液中各待测元素的精密度

Fig. 4 Precision of multi-element standard from sample solutions

表2 标准曲线相关参数及检出限

Table 2 Parameters of standard curve and detection limits

表3 样品分析结果对比

Table 3 Comparison for sample analysis results μg/g

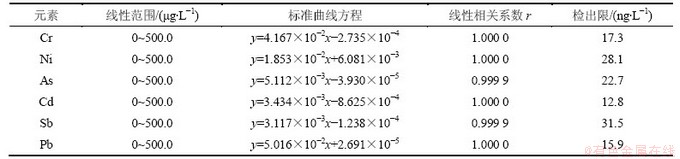

2.5 标准曲线及检出限

实验采用5%HNO3介质将混合标准溶液逐级稀释为10.0,20.0,50.0,100.0,200.0和500.0 μg/L的混合标准溶液系列,并以高纯二氧化硅为匹配基体,加入Rh内标溶液,建立标准曲线,如表2所示。由表2可见:各待测元素在0~500.0 μg/L内线性关系良好,线性相关系数均不低于0.999 9。在优化的实验条件下,用试剂空白溶液上机重复测定11次,计算标准偏差,其测量结果标准偏差3倍所计算的浓度即为检出限,待测元素的检出限见表2。

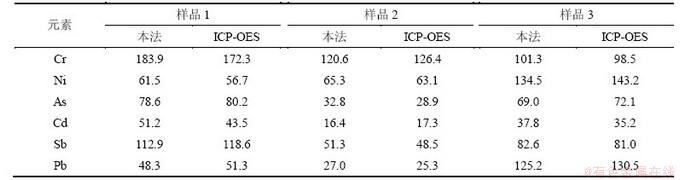

2.6 样品分析

按本文所建立的方法分别测定来自3个不同厂家的硅灰样品(样品1,2和3),测定结果与ICP-OES法测定结果相比对,结果见表3,超细硅灰颗粒具有很强的吸附能力,样品中重金属元素的富集浓度较高,对环境存在潜在危害。

3 结论

1) 建立了ORS-ICP-MS法测定硅灰中重金属元素的分析方法,通过比较了不同测定模式对待测元素BEC的影响情况,在选取的碰撞模式下考察了不同He气流速对元素预估检测限的影响,优化了质谱工作条件。

2) 采用基体匹配法并结合内标法校正了质谱分析过程中由于高盐浓度所产生的基体效应和信号漂移,各待测元素的加标回收率为92.0%~106.0%,相对标准偏差(RSD)均小于3.4%,各待测元素的检出限为12.8~31.5 ng/L,方法具有良好的准确度和精密度。

3) 超细硅灰颗粒具有很强的吸附能力,样品中重金属元素的富集浓度较高,对环境存在潜在危害。

参考文献:

[1] Wiehl N, Herpers U, Weber E. Study on the solid solubility of transition metals in high-purity silicon by instrumental neutron activation analysis and anticompton-spectrometry[J]. Journal of Radioanalytical and Nuclear Chemistry, 1982, 72(1/2): 69-78.

[2] Johnston M D, Barati M. Distribution of impurity elements in slag-silicon equilibria for oxidative refining of metallurgical silicon for solar cell applications[J]. Solar Energy Materials and Solar Cells, 2010, 94(12): 2085-2090.

[3] Minami H, Yada M, Yoshida T, et al. Simultaneous direct determination of aluminum, calcium and iron in silicon carbide and silicon nitride powders by slurry-sampling graphite furnace AAS[J]. Analytical Sciences, 2004, 20(3): 455-459.

[4] Wang Z, Qiu D, Ni Z, et al. Direct determination of impurities in high purity silicon carbide by inductively coupled plasma optical emission spectrometry using slurry nebulization technique[J]. Analytica Chimica Acta, 2006, 557(2): 288-294.

[5] Matschat R, Haβler J, Traub H, et al. Multielement trace determination in SiC powders: assessment of interlaboratory comparisons aimed at the validation and standardization of analytical procedures with direct solid sampling based on ETV ICP OES and DC arc OES[J]. Analytical and Bioanalytical Chemistry, 2005, 383(7/8): 1060-1074.

[6] Petrelli M, Perugini D, Poli G, et al. Graphite electrode lithium tetraborate fusion for trace element determination in bulk geological samples by laser ablation ICP-MS[J]. Microchimica Acta, 2007, 158(34): 275-282.

[7] 张金娥, 刘英, 臧慕文, 等. GDMS法和ICP-MS法测定太阳能级多晶硅中杂质元素含量[J].分析试验室, 2013, 32(9): 59-62.

ZANG Jine, LIU Ying, ZANG Muwen, et al. Determination of impure elements in solar grade polysilicon by GD-MS and ICP-MS[J].Chinese Journal of Analysis Laboratory, 2013, 32(9): 59-62.

[8] Sabatino M D, Dons A L, Hinrichs J, et al. Determination of relative sensitivity factors for trace element analysis of solar cell silicon by fast-flow glow discharge mass spectrometry[J]. Spectrochimica Acta Part B: Atomic Spectroscopy, 2011, 66(2): 144-148.

[9] 刘洁, 钱荣, 斯琴毕力格, 等. 直流辉光放电质谱法测定多晶硅中关键杂质元素的相对灵敏度因子[J]. 分析化学, 2012, 40(1): 66-71.

LIU Jie, QIAN Rong, SIQIN Bilige, et al. Determination of relative sensitivity factors of impurities in poly-silicon by direct current glow discharge mass spectrometry[J]. Chinese Journal of Analytical Chemistry, 2012, 40(1): 66-71.

[10] Tanner S D, Baranov V I, Bandura D R. Reaction cells and collision cells for ICP-MS: A tutorial review[J]. Spectrochimica Acta Part B: Atomic Spectroscopy, 2002, 57 (9): 1361-1452.

[11] NIE Xidu, LIANG Yizeng, TANG Yougen, et al. Determination of trace elements in high purity nickel by high resolution inductively coupled plasma mass spectrometry[J]. Journal of Central South University of Technology, 2012, 19(9): 2416-2420.

[12] Meermann B, Fabricius A L, Duester L, et al. Fraction-related quantification of silver nanoparticles via on-line species-unspecific post-channel isotope dilution in combination with asymmetric flow-field-flow fractionation (AF4)/sector field ICP-mass spectrometry (ICP-SF-MS)[J]. Journal of Analytical Atomic Spectrometry, 2014, 29(2): 287-296.

[13] Zhu Y, Hiokia A, Chib K. Quantitative analysis of the elements in powder samples by LA-ICP-MS with PMMA powder as the binder and Cs as the internal standard[J]. Journal of Analytical Atomic Spectrometry, 2013, 28(2): 301-306.

[14] 魏建军, 郎春燕, 林龙飞, 等. 真空蒸馏分离-电感耦合等离子体质谱法测定高纯碲中9种杂质元素[J]. 分析化学, 2013, 41(9): 1454-1457.

WEI Jianjun, LANG Chunyan, LIN Longfei, et al. Vacuum distillation separation/enrichment and determination of nine impurities in high Purity tellurium by ICP-MS[J]. Chinese Journal of Analytical Chemistry, 2013, 41(9): 1454-1457.

[15] Waentig L, Techritz S, Jakubowski N, et al. A multi-parametric microarray for protein profiling: simultaneous analysis of 8 different cytochromes via differentially element tagged antibodies and laser ablation ICP-MS[J]. Analyst, 2013, 138(21): 6309-6315.

(编辑 杨幼平)

收稿日期:2013-10-08;修回日期:2014-02-20

基金项目(Foundation item):国家自然科学基金资助项目(21075138);湖南省高校产业化培育资助项目(10CY002,13CY019);湖南省自然科学基金资助项目(14JJ5032);重庆市涪陵区科学技术研究项目(FLKJ,2014ABA2018);湖南省重点学科建设资助项目(湘教发[2011]76号)(Project(21075138) supported by National Natural Science Foundation of China; Projects (10CY002, 13CY019) supported by University of Hunan Province Industrialization Cultivation of Funded Projects; Project(14JJ5032) supported by Natural Science Foundation of Hunan Province of China; Project(FLKJ, 2014ABA2018) supported by Science and Technology Project of Fuling District in Chongqing; Project([2011]76) supported by Construct Program of the Key Discipline in Hunan Province)

通信作者:谢华林(1970-),男,湖南长沙人,博士,教授,从事质谱分析利用研究;电话:13807344508;E-mail:hualinxie@vip.163.com

摘要:建立八极杆碰撞/反应池电感耦合等离子体质谱(ORS-ICP-MS)法测定硅灰中Cr,Ni,As,Cd,Sb和Pb等重金属元素的分析方法。样品经硝酸+氢氟酸密闭微波溶解后,采用ORS-ICP-MS法测定上述6种重金属元素。应用ORS技术消除高盐基体对待测元素产生的多原子离子质谱干扰,研究不同碰撞气流速对待测元素预估检测限(EDL)的影响,采用基体匹配并以Rh为内标元素校正质谱分析中基体效应并补偿了信号漂移。在选定的条件下,样品的加标回收率为92.0%~106.0%,相对标准偏差(RSD)均小于3.4%,各待测元素的检出限为12.8~31.5 ng/L。