Phase structure of ZK60-1Er magnesium alloy compressed at 450 ?C

WANG Zhong-jun(王忠军)1, YANG Qing-xiang(杨庆祥)2, QIAO Jun(乔 军)1

1. School of Materials Science and Metallurgy, University of Science and Technology Liaoning,Anshan 114051, China;

2. School of Materials Science and Engineering, Yanshan University, Qinhuangdao 066004, China

Received 23 September 2009; accepted 30 January 2010

Abstract:

The phase structure of ZK60-1Er magnesium alloy thermally compressed at the temperature of 450 ?C and the strain rate of 1×10-4 s-1 was determined by transmission electron microscopy (TEM) and high-resolution electron microscopy (HREM). The results show that this magnesium alloy contains many new W phases (Mg3Zn3Er2, FCC structure) in the matrix. Those new W phases have two morphologies, either irregularly rectangular or rod morphology. Lattice constants of the two new W phases are slightly higher than those of W Phase (Mg3Zn3Y2) containing rare earth element of yttrium.

Key words:

ZK60; Er; W phase; magnesium alloy; phase structure;

1 Introduction

ZK60 is a kind of conventional wrought magnesium alloy, in which the mainly alloying element is zinc (Zn) [1-3]. Magnesium-zinc based alloy has excellent hardening response in the magnesium-based alloy system [4-5]. Unfortunately, the application of ZK60 alloy is extremely limited by its bad casting characteristics[6-7]. Recently, improvement of this performance can be introduced by the addition of the rare earth (RE) element of erbium (Er) which can shorten the solidification distance of metal liquid[8-9]. In the meanwhile, many small rare earth phases containing W phase, I phase and Z phase in Mg-Zn-Y and Mg-Zn-Y-Zr alloys deformed at elevated temperatures (250-420 ℃) were reported to improve the mechanical properties of these alloys, especially at high temperature[10-15]. However, few studies on phase structure of the Mg-Zn-Er-Zr system alloy have been carried out. In this work, our main objective is to analyze and determine the phase structure of ZK60-1Er magnesium alloy thermally compressed at high temperature of 450 ?C and very slow strain rate of 1×10-4 s-1.

2 Experimental

Chemical composition (mass fraction, %) of ZK60-1Er alloy used in the present study was as follows: Zn 5.82, Zr 0.51, Er 1.10, Cu 0.03, Ni 0.005, Si 0.01, Fe 0.01, Be 0.001 and Mg balance. The alloy was melted in a mild steel crucible. The ingot was homogenized at 673 K for 18 h. The cylindrical specimen for hot compression was machined to be 8 mm in diameter and 15 mm in length. Before the hot compression test, the specimen was heated to the test temperature for 5 min. Hot compression test was carried out on a Gleeble 1500D hot simulation machine. Compression test was conducted at the temperature of 450 ?C and the strain rate of 1×10-4 s-1. After hot compression, the specimen was water quenched. The TEM specimens, disks with 3 mm in diameter, were punched from the foils mechanically machined and taken from hot compressed specimen for subsequent jet electro-polishing. Thin foil specimens for TEM and HREM were polished in a 15% (volume fraction) nitric acid and 85% methyl alcohol solution at -30 ?C under a voltage of 20 V. After polishing, the black opaque layer on the surface of the specimen was removed by dipping for 1-2 s in 20% nitric acid and 80% ethanol solution. TEM and HREM observation and analysis were made with a TecNai F30 microscope operated at a voltage of 200 kV and 400 kV, respectively, with a double-tilt stage.

3 Results and discussion

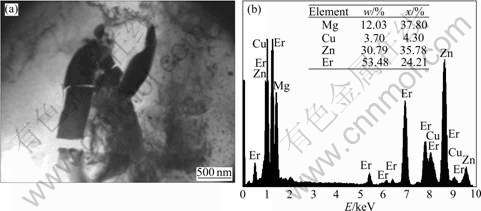

Fig.1(a) shows that there exists irregularly rectangular phases along grain boundaries in the alloy matrix. The molar ratio of Mg, Zn and Er element of the phase is approximately equal to 3:3:2 according to the analytical result of energy dispersive spectrum (EDS, Fig.1(b)), and the chemical formula of this phase should be expressed as Mg3Zn3Er2.

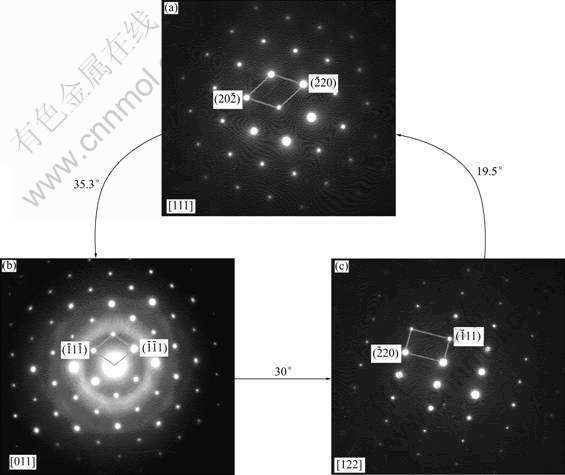

Fig.2 shows a series of selected area diffraction (SAD) patterns of the Mg3Zn3Er2 phase through large-angle tilting of the TEM stage. The crystal structure

Fig.1 TEM image (a) and its EDS result (b) of irregularly rectangular phase

Fig.2 Three SAD patterns of irregularly rectangular phase: (a) [111] axis zone; (b) [011] axis zone; (c) [112] axis zone

of this phase was determined by indexation of crystal plane, calculation and self-consistency analysis to be face-centered cubic (FCC) structure. The calculated value of the crystal lattice constant is equal to 0.706 nm.

From the above experimental results, we can see that both the chemical formula and the crystal structure of the irregularly rectangular phase (Mg3Zn3Er2) are similar to those of the W phase (Mg3Zn3Y2) of the Mg-Zn-Y ternary alloys. In the meanwhile, the calculated lattice constant (0.706 nm) of Mg3Zn3Er2 phase is slightly larger than, but approximately equal to 0.685 nm of Mg3Zn3Y2 (W phase)[12]. So, we can denominate the Mg3Zn3Er2 phase as new W phase, temporarily.

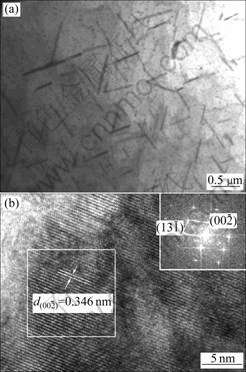

It was also found that there are a lot of or many rod-liked phases in the matrix of this hot compressed alloy (Fig.3(a)). This kind of rod-like phase is another morphology of the new W phase, whose chemical formula can likewise be expressed as Mg3Zn3Er2 by EDS and HREM analytical result.

Fig.3 TEM image (a) and HREM image, inverse Fourier transform and interplanar spacing of crystal plane ![]() of rod-like new W phase (b)

of rod-like new W phase (b)

Fig.3(b) shows the HREM image, inverse Fourier transform result and its plane indexation of reciprocal lattice of the new W phase. We can obtain the values of some different interplanar spacings from Fig.3(b). For example, the value of the interplanar spacing of the low index number plane of ![]() can be measured, which is equal to 0.346 nm. Consequently, the value (0.692 nm) of the lattice constant of the rod-like new W phase can be calculated by cubic crystal system equation:

can be measured, which is equal to 0.346 nm. Consequently, the value (0.692 nm) of the lattice constant of the rod-like new W phase can be calculated by cubic crystal system equation:

a=![]()

which is also slightly higher than that (0.685 nm) of the W phase (Mg3Zn3Y2)[9], possibly resulting from the higher atomic radius of Er than that of Y.

4 Conclusions

1) The phase structure of ZK60-1Er magnesium alloy thermally compressed at the temperature of 450 ?C and strain rate of 1×10-4 s-1 contains many new W phases (Mg3Zn3Er2, FCC structure) besides the alloy matrix.

2) New W phases have two morphologies, irregular rectangle and rod-like morphology.

3) The value of the lattice constants of the irregular rectangle and rod-liked new W phase are 0.706 nm and 0.692 nm, respectively, larger than that of the W phase (Mg3Zn3Y2) containing rare element of Y, 0.685 nm.

References

[1] ZHAO Zu-de, CHEN Qiang, WANG Yan-bin, SHU Da-yu. Effect of predeformation on semi-solid microstructure of ZK60+RE magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 535-539.

[2] LUO Shou-jing, SHAN Wei-wei. Steady state rheological behavior of semi-solid ZK60-RE magnesium alloy during compression [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(5): 974-980.

[3] LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theoretical principle & application of Mg-based light metal alloys [M]. Beijing: China Machine Press, 2002: 30-70. (in Chinese)

[4] MA Yan-long, ZUO Lu-lin, TANG Ai-tao, ZHANG Jing, PAN Fu-sheng. Analysis of microstructure of as-cast ZK60 magnesium alloy [J]. Journal of Chongqing University: Natural Science, 2004, 27(8): 53-56. (in Chinese)

[5] YU Kun, LI Wen-xian, WANG Ri-chu. Effects of heat treatment on microstructures and mechanical properties of ZK60 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 188-190.

[6] WEI L Y, DUNLOP G L, WESTERNGON H. The intergranular microstructure of cast Mg-Zn and Mg-Zn-rare earth alloys [J]. Metall & Mater Trans A, 1995, 26: 1947-1948.

[7] LUO A P, PEKGULERVUZ M O. Cast magnesium alloys for elevated temperature applications [J]. J Mater Sci, 1994, 24: 5259-5261.

[8] WANG Zhong-jun, ZHANG Cai-bei, CUI Jian-zhong, LE Qi-chi, SHAO Xiao-hong, SUN Yue. Effect of erbium and neodymium on microstructure and mechanical properties of ZK60 magnesium alloy [J]. Journal of the Chinese Rare Earth Society, 2006, 24(6): 710-712. (in Chinese)

[9] WANG Qu-dong, LI Da-quan, LIU Qaing. Effects of Er on microstructure and mechanical properties of Mg-Zn-Er-Zr magnesium alloys [J]. Materials Science Forum, 2007, 546/549: 105-108.

[10] SINGH A, TSAIAI A P. On the cubic W phase and its relationship to the icosahedral phase in Mg-Zn-Y alloys [J]. Scripta Materialia, 2003, 49(2): 143-148.

[11] SINGH A, WATANABE M, KATO A. Crystallographic orientations and interfaces of icosahedral quasicrystalline phase growing on cubic W phase in Mg-Zn-Y alloys [J]. Mater Sci Eng A, 2005, 397(1/2): 22-24.

[12] LUO Zi-peng. Microstructures of rare earth magnesium alloys in the Mg-Zn-Zr-RE system [D]. Beijing: Institute of Beijing Aerospace Materials, 1993: 9-100. (in Chinese)

[13] BAO D H, KIM S H, KIM D H. Deformation behavior of Mg-Zn-Y alloys reinforced by icosahedral quasicrystalline particles [J]. Acta Materialia, 2002, 50: 2343-2346.

[14] LUO Zi-peng, ZHANG Si-qin. Comment on the so-called Z-phase in magnesium alloys containing zinc and rare-earth elements [J]. Journal of Material Science Letters, 1993, 12: 1490-1493.

[15] ZENG Xiao-qin, ZHANG Ya, CHEN Lu, DING Wen-jiang, WANG Yin-xin, ZHU Yan-pin. Precipitation behavior and mechanical properties of a Mg-Zn-Y-Zr alloy processed by thermo-mechanical treatment [J]. Journal of Alloys and Compounds, 2005,395: 213-219.

Foundation item: Project(2008329) supported by Liaoning Provincial Education Ministry, China; Project supported by the Key Laboratory of Material Processing & Control of Liaoning Province, China

Corresponding author: WANG Zhong-jun; Tel: +86-412-5929535; Fax: +86-412-5929525; E-mail: zhongjunwang@126.com