粘结石墨基固体润滑涂层的微动摩擦磨损性能

冶银平,陈建敏,周惠娣

(中国科学院兰州化学物理研究所 固体润滑国家重点实验室,甘肃 兰州,730000)

摘 要:

摘 要:为了探讨粘结石墨基固体润滑涂层的微动摩擦磨损性能的作用机理,使用SRV微动摩擦磨损试验机对粘结石墨基固体润滑涂层在微动试验条件下的摩擦学性能以及抗承载能力进行研究,对其磨痕形貌和对偶转移膜进行分析。研究结果表明:粘结石墨基固体润滑涂层的磨损率随着试验载荷和摩擦速度的增大而减小;而摩擦因数随着试验载荷增大而减小,随摩擦速度增大而缓慢增大;在微动摩擦过程中,高载高速可以促进高质量转移膜在对偶表面形成,从而使得粘结石墨基固体润滑涂层具有良好的抗承载能力和优异的抗磨减摩性能。

关键词:

中图分类号:TH117.1 文献标识码:A 文章编号:1672-7207(2008)01-0103-05

Fretting friction and wear properties of bonded graphite solid lubricating coatings

YE Yin-ping, CHEN Jian-min, ZHOU Hui-di

(State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou 730000, China)

Abstract: In order to research into the mechanism of the fretting friction and wear properties of bonded graphite solid lubricating coatings, the tribological properties and load-carrying capacity of the coatings were investigated by SRV fretting friction-wear tester. The morphologies of the worn surface and the transfer films of bonded graphite solid lubricating coatings in opposite parts was studied. The results show that the wear rate of bonded graphite solid lubricating coating decreases with the increase of velocity and load, whereas the friction coefficient decreases with the increase of load, and increases slowly with the increase of velocity. The high load and velocity can promote the formation of the fine transfer films in opposite parts under fretting friction condition, so the bonded graphite solid lubricating coatings show high load-bearing capacity, fine antifriction and antiwear properties.

Key words: bonded solid lubricating coatings; fretting friction and wear; transfer films

粘结固体润滑涂层作为润滑和防护涂层在工程实际中已得到广泛应用[1-6]。研究结果表明, 常用的粘结MoS2基、石墨基及聚四氟乙烯(PTFE)基固体润滑涂层均具有良好的摩擦学性能[7-12]。石墨作为一种典型的固体润滑材料在高温安定性、化学稳定性、导热和导电等方面表现出良好的性能。与粘结MoS2基和聚四氟乙烯(PTFE)基固体润滑涂层相比,粘结石墨基固体润滑涂层在大气环境下具有良好的抗磨减摩性能和成本低廉的特点,应用广泛。徐进等[13-14]的研究结果表明:粘结固体润滑涂层的使用效果与实际的使用工况(包括接触形式、速度、载荷、温度及试验气氛等)密切相关,但实际使用工况千差万别,从而限制了粘结固体润滑涂层在工业领域的广泛应用。然而,有关粘结石墨基固体润滑涂层抗承载能力的系统研究报道却比较少。基于此,作者对粘结石墨基固体润滑涂层在微动试验条件下的摩擦磨损性能进行研究,考察大气环境条件下试验载荷和振动频率对涂层抗磨减摩性能的影响,并对其抗磨减摩机理进行探讨。

1 实 验

1.1 润滑涂层的制备

粘结石墨基固体润滑涂层的制备是先将石墨(粒径≤10 μm)、三氧化二锑(粒径≤10 μm)等固体组分进行研磨分散,然后,与酚醛环氧树脂、改性剂、混合溶剂等混合进行配料,再用类似于油漆的涂装工艺在摩擦件表面涂膜。涂膜前,试样经吹砂处理,将涂有该润滑涂层的试样在190 ℃保温1 h后随烘箱冷却即可使用。涂层表面粗糙度Ra=1.5~2.0 μm,涂层厚度为20~30 μm。

1.2 摩擦磨损试验

涂层的摩擦磨损试验在德国产的SRV微动摩擦磨损试验机上进行,上面试样是直径为9.8 mm的GGr15(洛氏硬度为58~61,粗糙度Ra=0.02 μm)钢球,下面试样为涂有该涂层的45号钢试样,接触形式是点接触。摩擦磨损试验条件如下:室温(15~25 ℃),大气环境(空气相对湿度为40%~50 %),试验振幅为1.0 mm,试验时间为30 min。试验后用三维轮廓仪测定磨损体积,并以磨损率表征。

2 结果与分析

2.1 载荷对涂层抗磨减摩性能的影响

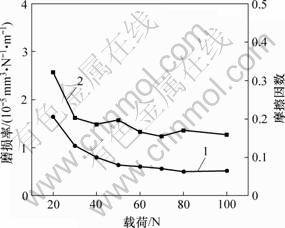

图1所示是振动频率为10 Hz时粘结石墨基固体润滑涂层的磨损率和摩擦因数随试验载荷的变化曲线。可以看出,载荷从20 N增加到30 N时,涂层的磨损率大幅度降低;当载荷大于30 N后,随试验载荷的增大,磨损率降低的幅度趋于缓慢,但总的趋势是随着试验载荷的增大而降低。同样,涂层的摩擦因数也是随着试验载荷的增大而逐渐降低,特别是当载荷大于50 N时,摩擦因数逐渐趋于稳定,其值小于0.1。上述试验结果表明,石墨基固体润滑涂层在高载荷试验条件下表现出良好的抗磨减摩性能,即粘结石墨基固体润滑涂层在微动试验条件下具有良好的抗承载能力和摩擦学性能。

1—摩擦因素;2—磨损率

图1 试验频率为10 Hz时试验载荷对石墨涂层的磨损率和摩擦因数的影响

Fig.1 Effects of load on wear rate and friction coefficient of graphite coating when frequency is 10 Hz

2.2 试验频率对涂层抗磨减摩性能的影响

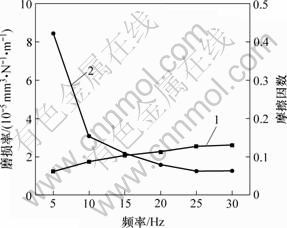

图2所示是载荷为50 N的试验条件下涂层的磨损率和摩擦因数随频率的变化曲线。可以看出,试验频率从5 Hz增加到10 Hz 时,涂层的磨损率大幅度 降低;当试验频率大于10 Hz时,随着试验频率增大,

1—摩擦因素;2—磨损率

图2 试验荷载为50 N时试验频率对石墨涂层的磨损率和摩擦因数的影响

Fig.2 Effects of frequency on wear rate and friction coefficient of graphite coating when load is 50 N

涂层的磨损率逐渐降低。振动频率的增大也就是摩擦速度的增大,即涂层的磨损率随摩擦速度的增大而降低。试验的振动频率对石墨基润滑涂层的摩擦因数也有影响,从图2可以看出,涂层的摩擦因数随着试验频率的增大而逐渐增大,但在试验频率为5~30 Hz时涂层摩擦因数均小于0.15,表现出良好的减摩性能。可见,粘结石墨基固体润滑涂层在微动试验条件下具有良好的抗速度能力和抗磨减摩性能。

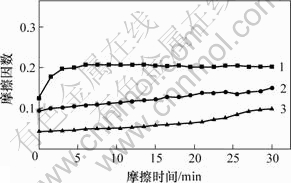

图3所示为载荷和频率不同时几种典型的涂层摩擦因数随试验时间的变化曲线。可以看出,在低速度低载荷试验条件下,摩擦因数在非常短的时间内快速上升并达到稳定,在之后的摩擦过程中,涂层的摩擦因数比较稳定,其值约为0.2;在高载高速和高载低速试验条件下摩擦因数均是随摩擦时间的延长而缓慢上升,而且试验载荷对石墨基固体润滑涂层减摩性能的影响远大于速度的影响。但总的来说,粘结石墨基固体润滑涂层在较宽的载荷和速度范围内表现出非常良好的减摩性能。

1—20 N, 10Hz; 2—50 N, 30 Hz; 3—100 N, 10 Hz

图3 在不同载荷和频率下石墨涂层的摩擦因数随摩擦时间的变化曲线

Fig.3 Relationship between friction coefficient of graphite coating and friction time under different loads and frequencies

2.3 摩擦磨损机理分析

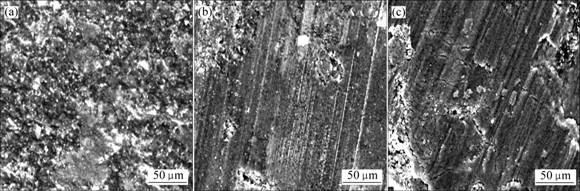

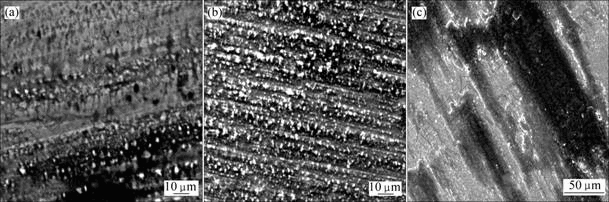

图4所示为载荷和频率不同时石墨涂层磨痕表面的形貌照片。可以看出,在低载荷和低频率的试验条件下涂层表面的摩擦非常轻(图4(a)),没有出现沿着滑动方向排列的划痕;当试验载荷增加到100 N时,涂层磨痕表面显示出沿着滑动方向排列的划痕(图4(b)),摩擦程度加重;在高载荷高频率的试验条件下,涂层磨痕表面除显示有沿着滑动方向排列的划痕外还出现了塑性流动,同时,磨痕表面出现微裂纹(图4(c))。表明在高载荷高频率的试验条件下,摩擦程度更加严重。

(a) 20 N, 10 Hz;(b) 100 N, 10 Hz;(b) 50 N, 30 Hz

图4 试验时间为10 min时粘结石墨涂层磨痕表面的SEM形貌照片

Fig.4 SEM morphologies of worn surface of graphite coatings when testing time is 10 min

从图5所示的相应对偶表面转移膜的形貌SEM照片可以看出,在载荷和频率不同时对偶GCr15钢球表面形成的转移膜的形貌特征明显不同: 在低载荷和低频率的试验条件下,对偶表面已形成均匀、致密的转移膜(图5(a)),摩擦痕迹非常轻;当载荷增加到100 N时,转移膜表面显示出与磨痕表面相同的沿着滑动方向排列的划痕(图5(b));在高载荷和高频率的试验条件下,对偶钢球表面形成的转移膜沿着滑动方向出现了塑性流动(图5(c)),同时形成的转移膜更加致密、光滑。

(a) 20 N, 10 Hz; (b) 100 N, 10 Hz; (c) 50 N, 30 Hz

图5 试验时间为10 min时粘结石墨涂层在对偶表面转移膜的SEM形貌照片

Fig.5 SEM morphologies of transfer films of graphite coatings in opposite parts when testing time is 10 min

石墨为层状结构,相邻层碳原子之间的结合力远小于同层内相邻碳原子间的结合力,使石墨层间具有较低的剪切力和低摩擦因数[15],同时,在摩擦过程中,石墨容易转移到对偶金属表面并形成转移膜,直接影响粘结固体润滑涂层的摩擦磨损性能[16-18],而且转移膜的特征与摩擦过程中试验条件(包括载荷、速度等)密切相关。在试验频率一定的微动试验条件下,随着试验载荷的增大,真实接触面积也随之增大,但是,真实接触面积的增大程度远低于试验压力的增加程度,所以,摩擦因数随试验载荷的增大而降低。 在试验载荷一定的微动试验条件下,随着试验频率的增大,摩擦面和转移膜表面变得更加致密﹑光滑,甚至出现了塑性流动(图4(c)和图5(c)),光滑的摩擦表面和塑性变形将导致摩擦副真实接触面积增大,因此,摩擦力也随之增大。在载荷一定的试验条件下,摩擦因数则随试验频率(摩擦速度)的增大而有所上升。上述试验中涂层磨痕表面形貌及转移膜的特征表明,在微动试验条件下,高载高速有利于生成致密、均匀的石墨转移膜,同时也增强了转移膜在对偶金属表面的结合力,使得粘结石墨基固体润滑涂层在高载高速试验条件下同钢对摩时表现出良好的抗承载能力和优异的抗磨减摩性能。

3 结 论

a. 在微动摩擦磨损试验条件下,粘结石墨基固体润滑涂层的磨损率随着试验载荷和摩擦速度的增大而减小;而摩擦因数随着试验载荷增大而减小、随摩擦速度增大而缓慢增大;粘结石墨基固体润滑涂层表现出良好的抗承载能力和优异的抗磨减摩性能。

b. 在微动试验条件下,高载高速有利于致密、均匀的石墨转移膜生成,同时也增强了转移膜在对偶金属表面的结合力。

参考文献:

[1] Charles J B. Solid film lubricants[J]. Metal Finishing, 2000, 98(1): 513-517.

[2] 陈建敏, 冶银平, 党鸿辛. 粘结固体润滑膜及其应用[J]. 摩擦学学报, 1994, 14(2): 180-189.

CHEN Jian-min, YE Yin-ping, DANG Hong-xin. Developing situation and application of bonded solid lubricant films[J]. Tribology, 1994, 14(2): 180-189.

[3] Hiraoka N. Wear life mechanism of journal bearings with bonded MoS2 film lubricants in air and vacuum[J]. Wear, 2001, 249(10/11): 1014-1020.

[4] Langlade C, Vannes B, Taillandier M, et al. Fretting behavior of low-friction coatings: contribution to industrial selection[J]. Tribology International, 2001, 34(1): 49-56.

[5] 肖 军, 周惠娣, 李铁虎, 等. 导弹发射装置滑轨表面MoS2干膜防护高温高速两相燃气流应用研究[J]. 摩擦学学报, 2003, 23(5): 435-440.

XIAO Jun, ZHOU Hui-di, LI Tie-hu, et al. Protection of ablative adhesion and erosion of slide track of missile launcher by high- temperature two-phase exhaust using MoS2-based bonded solid lubricant film[J]. Tribology, 2003, 23(5): 435-440.

[6] 郑友华, 李冀生, 王美玲. FM-510型粘结固体润滑涂层的摩擦性能[J]. 摩擦学学报, 1998, 18(4): 373-376.

ZHENG You-hua, LI Ji-sheng, WANG Mei-ling. Friction characteristic of FM-510 bonded solid film[J]. Tribology, 1998, 18(4): 373-376.

[7] Langlade C, Fayeulle S, Olier R. Characterization of graphite superficial thin films achieved during friction[J]. Applied Surface Science, 1993, 65/66: 83-89.

[8] SONG Hao-jie, ZHANG Zhao-zhu. Investigation of the tribological properties of polyfluowax/polyurethane composite coatings filled with several micro-particulates[J]. Materials Science and Engineering, 2006, 424(1/2): 340-346.

[9] Xu J, Zhou Z R, Zhang C H, et al. An investigation of fretting wear behaviors of bonded solid lubricant coatings[J]. Journal of Materials Processing Technology, 2007, 182(1/3): 146-151.

[10] Kubart T, Polcar T, Kopecky L, et al. Temperature dependence of tribological properties of MoS2 and MoSe2 coatings[J]. Surface and Coatings Technology, 2005, 193(1/3): 230-233.

[11] 徐 进, 朱旻昊, 周仲荣. 粘结石墨固体润滑涂层微动磨损性能研究[J]. 机械工程材料, 2004, 28(10): 7-10.

XU Jin, ZHU Min-hao, ZHOU Zhong-rong. Fretting wear behavior of bonded graphite solid lubrication coating[J]. Materials for Mechanical Engineering, 2004, 28(10): 7-10.

[12] 朱旻昊, 周惠娣, 陈建敏, 等. 二硫化钼粘结固体润滑涂层的径向和切向微动损伤的比较研究[J]. 摩擦学学报, 2002, 22(1): 14-18.

ZHU Min-hao, ZHOU Hui-di, CHEN Jian-min, et al. A comparative study on radial and tangential fretting damage of molybdenum disulf ide bonded solid lubrication coating[J]. Tribology, 2002, 22(1): 14-18.

[13] 徐 进, 朱旻昊, 刘捍卫, 等. 湿度、温度及润滑油对粘结MoS2固体润滑涂层微动磨损寿命的影响[J]. 机械工程材料, 2003, 27(9): 21-23.

XU Jin, ZHU Min-hao, LIU Han-wei, et al. Influence of relative humidity, temperature, oil lubrication on the fretting wear life of bonded solid lubricant coating[J]. Materials for Mechanical Engineering, 2003, 27(9): 21-23.

[14] Miyoshi K. Durability evaluation of selected solid lubricating films[J]. Wear, 2001, 251(9/10): 1061-1067.

[15] 顾则名. 利用分子轨道理论研究石墨的润滑机理[J]. 摩擦学学报, 1983, 3(1): 1-5.

GU Ze-ming. The lubrication mechanism of graphite studied by molecular orbital theory[J]. Tribology, 1983, 3(1): 1-5.

[16] 周惠娣, 岳美娥, 陈建敏, 等. 纳米LaF3微粒对聚酰亚胺粘结固体润滑涂层摩擦学性能及抗腐蚀性能的影响[J]. Tribology, 2004, 24(3): 225-229.

ZHOU Hu-di, YUE Mei-e, CHEN Jian-min, et al. Effect of nanometer lanthanum fluoride as filler on the tribological behavior and corrosion resistance of polyimide boned solid lubricating coating[J]. Tribology, 2004, 24(3): 225-229.

[17] Wilfried J B, Xu J F. Wear behaviour and failure mechanism of bonded solid lubricants[J]. Wear, 1991, 150(1/2): 231-246.

[18] Xu J, Zhu M H, Zhou Z R, et al. An investigation on fretting wear life of bonded MoS2 solid lubricant coatings in complex condition[J]. Wear, 2003, 255(1/6): 253-358.

收稿日期:2007-04-15;修回日期:2007-06-05

基金项目:国家创新群体基金资助项目(50421502)

作者简介:冶银平(1967-),男,甘肃陇南人,博士,研究员,从事材料摩擦磨损性能研究

通信作者:冶银平,男,研究员;电话:0931-4968150;E-mail: yeyinping585@sina.com