文章编号:1004-0609(2015)-09-2366-06

2197铝锂合金形变热处理中T1相的析出行为

毛柏平1,闫晓东2,沈 健2

(1. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088;

2. 北京有色金属研究总院 有色金属加工中心,北京 100088)

摘 要:

对2197铝锂合金进行形变热处理,采用HREM高分辨电镜观察合金欠时效和峰时效两个阶段的显微组织,研究T1相析出长大行为及其界面特征。结果表明:形变热处理2197合金在欠时效阶段主要存在δ′、θ′和T1相,T1相尺寸约为40 nm;峰时效阶段合金中δ′和θ′数量减少,主要析出相为T1相,其尺寸为50~150 nm,T1相可通过δ′相的溶解而长大。在欠时效和峰时效两阶段,T1相末端与基体共格,其他区域与基体非共格。T1相为六方晶系,与基体存在惯析关系:(0001)T1//(111)A1、[1010]T1//[110]A1,惯析面为{111}A1。

关键词:

中图分类号: TG166.3 文献标志码:A

Precipitation behavior of T1 phase during thermo-mechanical treatment of 2197 Al-Li alloy

MAO Bai-ping1, YAN Xiao-dong2, SHEN Jian2

(1. State Key Laboratory of Nonferrous Metals and Processes,

General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Nonferrous Metals Processing Division, General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: 2197 Al-Li alloy was thermo-mechanically treated, and the precipitation and growth of the T1 phase and the phase interface characteristics were studied. The microstructures of thermo-mechanical treated 2197 Al-Li alloy for under-aged and peak-aged states were observed by high resolution electron microscopy (HREM). The results show that during thermo-mechanical treatment, δ′, θ′ and T1 phases are the main phases of under-aged 2197 alloy, the size of T1 phase is about 40 nm. δ′ and θ′ phases number reduce at peak-aged state, while the main phase of peak-aged 2197 alloy is T1 phase with the size of 50-150 nm. The T1 phase grows up by the dissolving of δ′ phase. The end of T1 phase of peak-aged 2197 alloy is coherent with the matrix while the rest is non-coherent during under-aged and peak-aged states. Habit relationships between T1 phase which is hexagonal crystal system and the matrix is as follow: (0001)T1//(111)A1 and [1010]T1//[110] A1, and the habit plane is {111}A1.

Key words: 2197 Al-Li alloy; thermo-mechanical treatment; T1 phase; precipitation behavior

铝锂合金具有低密度、高比强度和比刚度以及良好的耐腐蚀性和卓越的超塑成型性能等特点,用其取代常规铝合金,可使构件质量减轻10%~15%,刚度提高10%~20%,因此被认为是21世纪航空航天工业领域中最理想的轻质高强结构材料[1-6]。2197合金为第三代铝锂合金,该合金已成功取代2124合金用于F-16战斗机的后隔框,满足了8000 h使用寿命的要求,而且合金质量减轻5%,断裂韧性则提高7%[7]。且2197合金由于具有较高的强度和较低的各向异性受到普遍关注,该合金属于Al-Cu-Li-Mg-Mn系合金,常采用固溶+预变形时效工艺改善合金的强度,提高其塑韧性[8]。已有研究表明,对固溶后的铝合金进行预拉伸可引入位错,进而影响合金中的强化相的析出行为,时效初期,主要析出相为δ′(Al3Li)、θ′(Al2Cu)和T1(Al2CuLi)相,峰时效时,主要析出相为T1相,T1相及其尺寸与分布不仅决定铝锂合金的强度,而且还会影响铝锂合金的各向异性[3, 9-13]。KUMAR等[14]和TOSTEN等[15]研究认为,时效初期的θ′相和T1相之间相互争夺Cu原子,δ′相与T1相之间相互竞争Li原子;而在峰时效阶段,T1相以消耗δ′相和θ′相而分别获得Li原子和Cu原子。高文理等[16]采用Kissinger法求得了T1相的析出激活能为75.9 kJ/mol。目前,关于2197合金形变热处理的T1相的高分辨研究较少,对其形核和长大过程、与基体的界面关系等缺少直接观察。因此,本文作者以2197合金为研究对象,采用HREM分析研究形变热处理过程中T1相析出行为和长生长方式,分析T1相与合金基体的位相关系,对优化提高现有铝锂合金性能和研究开发新型铝锂合金具有重要的理论指导意义。

1 实验

试验样品取自工业热轧板材,化学成分为(质量分数,%):Cu 2.88、Li 1.50、Mg 0.24、Mn 0.35、Zr 0.09、Fe 0.05、Si 0.04、Zn<0.006、余量为Al。合金板材经520 ℃、1 h固溶处理,水淬至室温。随后对其进行形变热处理,预拉伸变形量为2%~3%,时效温度为170 ℃,时效时间分别为8、12和20 h,其中8和12 h对应欠时效阶段,20 h对应峰时效阶段。前期研究表明[17],将不同热处理状态的合金板材试样制备成透射电镜试样,采用JEOL-2010型高分辨透射分析电镜观察不同热处理状态的2197合金显微组织。

2 结果与分析

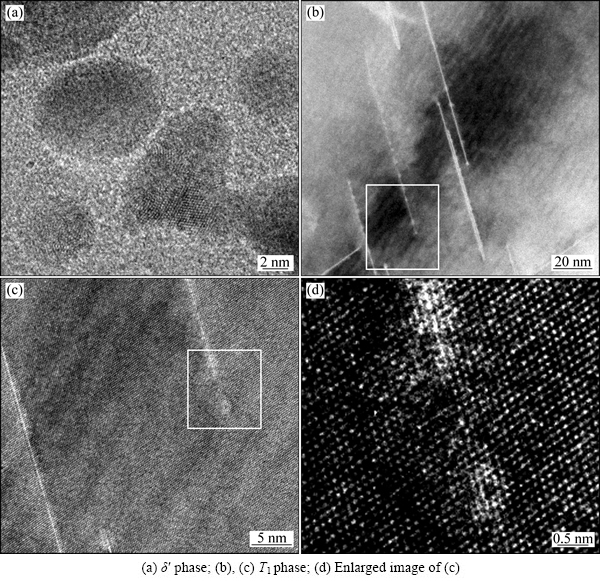

图1所示为2197合金板材时效初期(时效时间为8 h)的高分辨观察显微组织。由图1(a)可以发现,合金中存在尺寸在5 nm左右的圆形衬度相,已有研究表 明[3, 12-13],该相为球状的δ′相。由图1(b)可以观察到合金中还存在尺寸为40 nm左右的针状析出相,该相为时效初期形成的T1相,该相宽度较窄,多为1个面间距(见图1(c))。还可以发现,在T1相局部存在亮点,对其进行放大观察,发现该相存在局部断续现象,显示部分区域正在形核长大过程中,对其进行处理,发现亮点区域为类球形的晶格紊乱区(见图1(d))。经分析认为此区域应为δ′相,由此可看出,T1相的一个正长大的相边界层沿着α/T1共格面扩展,并且穿过了和这个共格面相连接的δ′相,即T1相正通过δ′相的溶解而长大。

图1 时效时间为8 h时2197合金的高分辨TEM像

Fig. 1 High resolution TEM images of 2197 alloy aged for 8 h

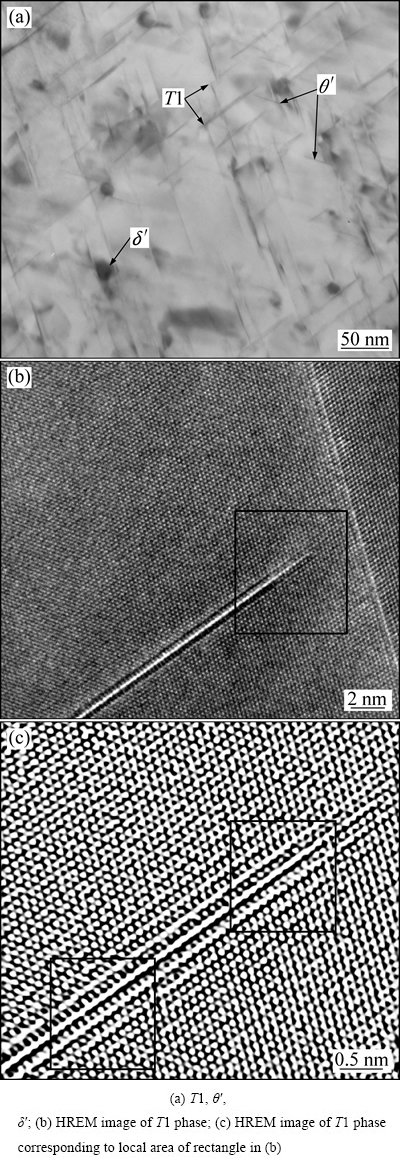

图2所示为合金经170 ℃时效12 h(欠时效)的显微组织(由[110]Al晶带轴入射观察)。由图2(a)可以看出,合金中除存在尺寸约15 nm的大量δ′相外,还存在大量尺寸约70 nm左右的针状T1相以及少量的θ′相。研究表明[18],在[110]Al入射方向,T1相与θ′相呈125.3°关系,而T1相与T1相之间呈109.4°关系。图2(b)所示为T1相的高分辨相,图2(c)所示为图2(b)中方框部位的放大图像。由图2(c)可以看出,2197合金在欠时效阶段T1相的宽度较小,仅有2个原子面间距。由图2(c)中右上方的红色方框所示可以看出,该析出相的末端与合金基体共格;由图2(c)中左下方的红色方框可以看出,T1相在其他部位与基体非共格。

图2 时效时间为12 h时2197合金的显微组织

Fig. 2 Microstructures of 2197 alloy aged for 12 h

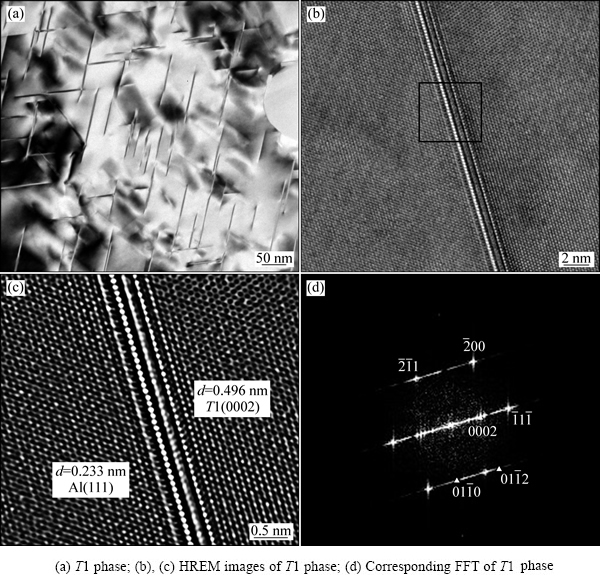

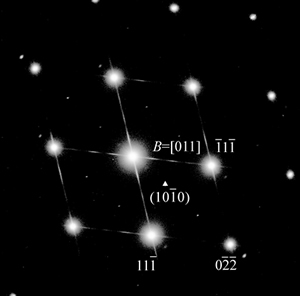

图3所示为由Al基体沿[110]晶带轴入射观察的峰时效状态(时效时间为20 h)的2197合金HREM像。由图3(a)可以看出,合金中存在大量的尺寸为50~150 nm的针状T1相,相对于时效初期,峰时效时T1析出相的尺寸和密度均明显增大。图3(b)所示为该析出相的高分辨相,图3(c)所示为图3(b)中局部区域的放大。由图3(c)可以发现,峰时效时2197合金的T1相宽度比时效初期时明显增大,图3(c)中可观察到5个原子面间距,该析出相在其末端与基体共格,但在其他区域则非共格。图3(d)所示为经Digital Micrograph(DM)软件处理图3(c)区域获得的衍射斑点,通过对衍射斑点标定可知图中所示Al基体(111)面面间距为0.233 nm,该相(0002)的面间距为0.496 nm,与资料中T1相的数据吻合。图3(d)中“△”所示为T1相的衍射斑点,由于该衍射斑点对应的晶带轴为[1010],通过与基体衍射斑点位置观察可以证实(0001)T1//(111)A1,[1010]T1//[110]A1,且T1相与基体间存在惯析关系,易在(111)面析出。图4所示为T1相与基体的衍射斑点,对基体和T1相的衍射斑点进行标定,再次印证T1相与基体间的位相关系。

3 讨论

研究表明[3, 9-12],2197合金是属于Al-Cu-Li-Mg-Mn系合金,对于Cu含量为2%~5%(质量分数)的Al-Cu-Li系合金, 当m(Cu)/m(Li)质量比小于2时,其主要析出过程大致如下:α过饱和固溶体→G.P.区+ δ′→T1+δ′+θ′→T1。δ′相是一种亚稳的LI2型(Cu3Au)有序相,与α基体错配度非常小,表面能也很小,且在A1-Li合金中,Li与空位的结合能很高,使Li原子在淬火期间就捕获大量空位。基于以上原因,δ′相在过饱和固溶体中析出驱动力大,因此,在时效初期就有大量球形的δ′粒子析出。而由于预变形引入大量位错,T1相较早的形核析出,随着时效时间的延长,T1相逐渐长大,消耗了大量的溶质原子,从而抑制θ′相析出,或消耗部分已析出的θ′相,因此,在图3(a)中未明显观察到θ′相。通过高分辨电镜观察发现,时效初期,2197合金中存在较多的δ′相,消耗了Li原子,因而,欠时效状态时T1相的析出量较少,且尺寸较小(见图1)。随着时效时间延长,T1相开始析出并长大。时效12 h时(见图2(a)),析出主要为15 nm的δ′相,还存在大量尺寸约70 nm左右的针状T1相以及少量的θ′相。峰值时效态时,主要析出相为50~150 nm的T1相(见图3)。这表明在从欠时效至峰时效过程中,T1相、δ′相和(θ′相)之间发生了一系列反应:在欠时效条件下,δ′相、θ′相和T1相分别析出,在峰时效、过时效条件下,则以消耗δ′和θ′而生长,导致δ′相和θ′数量锐减。已有研究表明[13], [19],T1相消耗δ′相生长,存在两种方式,δ′相与T1相紧密相切,Li从δ′相中扩散至板状T1相的相边界层,或者T1相的相边界层沿着α/T1共格面扩展长大并且穿过了和这个共格面相连接的δ′相。通过对时效初期析出相的HREM实验观察,直接观察到T1相通过溶解而长大,T1相与δ′相紧密相切(见图1(b)和(c))。δ′相的溶解比较缓慢,导致针状的T1相的粗化速率也很小,因而δ′相和T1相的相互反应进行过程比较长[6, 11],相应的2197合金形变热处理后达到峰时效状态的时间也较长。

图3 时效时间为20 h时2197合金的显微组织

Fig. 3 Microstructures of 2197 alloy aged for 20 h

图4 T1相与基体的衍射斑点(沿[011]入射)

Fig. 4 Diffraction spots of T1 phase and matrix (taken along [011])

关于2197合金形变热处理峰时效时的主要强化相T1,研究表明[9, 13]:T1相为六方晶系,晶格常数为a≈0.4965 nm,c≈0.9345 nm。T1相与基体存在如下惯析关系:(0001)T1//(111)A1、[1010]T1//[110]A1、惯析面为{111}A1,实验中的观察也印证了这一点。T1相为密排六方结构(HCP),T1相要想在面心立方(FCC)结构的Al基体中析出,基体中的层错是T1相形核的最佳场所,与δ′及θ′等其他强化相相比,T1相的强化效应更大[13, [20]。

4 结论

1) 形变热处理2197合金欠时效阶段主要存在δ′、θ′相和T1相,峰时效时主要析出相为尺寸为50~150 nm的T1相。

2) 试验观察到T1相可通过δ′相的溶解而长大,δ′相与T1相紧密相切,Li从δ′相中扩散至板状T1相的相边界层而使T1相长大。

3) 通过HREM观察与分析,发现T1相末端与基体共格,其他区域与基体非共格,验证了T1相为密排六方结构,晶格常数为a≈0.4965 nm,c≈0.9345 nm。T1相与基体存在如下惯析关系:(0001)T1//(111)A1、[1010]T1//[110]A1,惯析面为{111}A1。

REFERENCES

[1] RIOJA J R. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications[J]. Materials Science and Engineering A, 1998, 257(1): 100-107.

[2] MUKHOPADHYAY A K. High strength aluminum alloys for structural application[J]. Metals Materials and Processes, 2007, 119(1): 1-26.

[3] 郑子樵, 李劲风, 陈志国, 李红英, 李世晨, 谭澄宇. 铝锂合金的合金化与微观组织演化[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

ZHENG Zi-qiao, LI Jin-feng, CHEN Zhi-guo, LI Hong-ying, LI Shi-chen, TAN Cheng-yu. Alloying and microstructural evolution of Al-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2337-2351.

[4] 程 彬, 郑子樵, 范春平, 钟继发, 韩 烨, 孙景峰. 时效制度对新型 Al-Cu-Li 合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(4): 926-933.

CHENG Bin, ZHENG Zi-qiao, FAN Chun-ping, ZHONG Ji-fa, HAN Ye, SUN Jing-feng. Effect of aging treatments on microstructures and properties of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 926-933.

[5] GIUMMARRA C, THOMAS B, RIOJA R J. New aluminum lithium alloys for aerospace applications[C]//Proceedings of the Light Metals Technology Conference. Ottawa, 2007: 24-26.

[6] GUILLAUMIN V. Aluminum lithium alloys in airbus air frames[J]. Aerospace Eng, 2005, 5: 8-13.

[7] 黄兰萍, 郑子樵, 黄永平. 2197铝-锂合金的组织和性能[J]. 中国有色金属学报, 2004, 14(12): 2066-2071.

HUANG Lan-ping, ZHENG Zi-qiao, HUANG Yong-ping. Microstructure and properties of 2197 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2066-2071.

[8] 魏修宇, 郑子樵, 潘峥嵘, 陈圆圆, 李世晨, 陈秋妮. 预变形对2197 铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

WEI Xiu-yu, ZHENG Zi-qiao, PAN Zheng-rong, CHEN Yuan-yuan, LI Shi-chen, CHEN Qiu-ni. The role of plastic deformation on microstructure and mechanical properties of 2197 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1996-1999.

[9] 黄兰萍, 郑子樵, 黄永平. 2197铝-锂合金的组织和性能[J]. 中国有色金属学报, 2004, 14(12): 2066-2071.

HUANG Lan-ping, ZHENG Zi-qiao, HUANG Yong-ping. Microstructure and properties of 2197 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2066-2071.

[10] BAIRWA M L, DATE P P. Effect of heat treatment on the tensile properties of Al-Li alloys[J]. Journal of Materials Processing Technology, 2004, 12(153/154): 603-607.

[11] KUMAR K S, BROWN S A, PICKENS J R. Microstructural evolution during aging of an Al-Cu-Li-Ag-Mg-Zr alloy[J]. Acta Materialia, 1996, 44(5): 1899-1915.

[12] GABLE B M, ZHU A W, CSONTOS A A, STARKE E A Jr. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al-Li-Cu-X alloy[J]. Journal of Light Metals, 2001(1): 1-14.

[13] YOSHIMURA R, TOYOHIKO J K, ABE E, HIRAGA K. Transmission electron microscopy study of the evolution of precipitates in aged Al-Li-Cu alloys: the θ′ and T1 phases[J]. Acta Materialia, 2003, 51(14): 4251-4266.

[14] KUMAR K S, BROWN S A, PICKENS J R. Structure and properties during of an ultra-high strength Al-Cu-Li-Ag-Mg ally[J]. Scripta Metalluriga et Materialia,1990, 24(5): 79-84.

[15] TOSEN M H, VASUDEVAN A K, HOWELL P R. Structure and deformation behavior of T1 precipitate plates in an Al-2Li-1Cu alloy[J]. Metallurgical and Materials Transactions A, 1988, 19(12): 2911-2920.

[16] 高文理, 闫 豪, 冯朝辉, 陆 政. 时效制度对2A97铝锂合金组织和力学性能的影响[J]. 中国有金属学报, 2014, 24(5): 1026-1211.

GAO Wen-li, YAN Hao, FENG Zhao-hui, LU Zheng. Effect of aging treatment on microstructure and mechanical properties of 2A97 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1026-1211.

[17] 毛柏平, 李俊鹏, 沈 健. 形变热处理对2197铝锂合金组织和性能的影响[J]. 重庆大学学报, 2010, 33(11): 66-69.

MAO Bai-ping, LI Jun-peng, SHEN Jian. Effect of thermo-mechanical heat treatment of 2197 Al-Li alloy[J]. Journal of Chongqing University, 2010, 33(11): 66-69.

[18] ZHANG S F, ZENG W D, YANG W H, SHI C L, WANG H J. Ageing response of a Al-Cu-Li 2198 alloy[J]. Materials and Design, 2014, 63: 368-374.

[19] KATSIKIS S, NOBLE B, HARRIS S J. Microstructural stability during low temperature exposure of alloys within the Al-Li-Cu-Mg system[J]. Materials Science and Engineering A, 2008, 485(1/2): 613-620.

[20] GUPTA R K, NAYAN N, NAGASIREESHA G, SHARMA S C. Development and characterization of Al-Li alloys[J]. Materials Science and Engineering A, 2006, 420(1/2): 228-234.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2013CB514208)

收稿日期:2014-01-06;修订日期:2015-05-21

通信作者:毛柏平,高级工程师,博士;电话:18901089698;E-mail:maobaiping@grinm.com

摘 要:对2197铝锂合金进行形变热处理,采用HREM高分辨电镜观察合金欠时效和峰时效两个阶段的显微组织,研究T1相析出长大行为及其界面特征。结果表明:形变热处理2197合金在欠时效阶段主要存在δ′、θ′和T1相,T1相尺寸约为40 nm;峰时效阶段合金中δ′和θ′数量减少,主要析出相为T1相,其尺寸为50~150 nm,T1相可通过δ′相的溶解而长大。在欠时效和峰时效两阶段,T1相末端与基体共格,其他区域与基体非共格。T1相为六方晶系,与基体存在惯析关系:(0001)T1//(111)A1、[1010]T1//[110]A1,惯析面为{111}A1。

[3] 郑子樵, 李劲风, 陈志国, 李红英, 李世晨, 谭澄宇. 铝锂合金的合金化与微观组织演化[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

[4] 程 彬, 郑子樵, 范春平, 钟继发, 韩 烨, 孙景峰. 时效制度对新型 Al-Cu-Li 合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(4): 926-933.

[6] GUILLAUMIN V. Aluminum lithium alloys in airbus air frames[J]. Aerospace Eng, 2005, 5: 8-13.

[7] 黄兰萍, 郑子樵, 黄永平. 2197铝-锂合金的组织和性能[J]. 中国有色金属学报, 2004, 14(12): 2066-2071.

[8] 魏修宇, 郑子樵, 潘峥嵘, 陈圆圆, 李世晨, 陈秋妮. 预变形对2197 铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

[9] 黄兰萍, 郑子樵, 黄永平. 2197铝-锂合金的组织和性能[J]. 中国有色金属学报, 2004, 14(12): 2066-2071.

[16] 高文理, 闫 豪, 冯朝辉, 陆 政. 时效制度对2A97铝锂合金组织和力学性能的影响[J]. 中国有金属学报, 2014, 24(5): 1026-1211.

[17] 毛柏平, 李俊鹏, 沈 健. 形变热处理对2197铝锂合金组织和性能的影响[J]. 重庆大学学报, 2010, 33(11): 66-69.