ARTICLE

J. Cent. South Univ. (2019) 26: 1563-1572

DOI: https://doi.org/10.1007/s11771-019-4112-9

Ultrafine and fine particle emission in turning titanium metal matrix composite (Ti-MMC)

Seyed Ali NIKNAM1, Masoud SABERI1, Jules KOUAM2, Ramin HASHEMI1,Victor SONGMENE2, Marek BALAZINSKI3

1. School of Mechanical Engineering, Iran University of Science and Technology, Hengam St., Resalat Square, Fehran 13114-16846, Iran;

2. Department of Mechanical Engineering, Ecole de Technologie Superieure (ETS), Montreal,QC, H3C 1K3, Canada;

3. Department of Mechanical Engineering, Polytechnique Montreal, Montreal, QC, H3T 1J4, Canada

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract:

Titanium metal matrix composite (Ti-MMC) has excellent features and capabilities which can be considered a potential candidate to replace commercial titanium and superalloys within an extensive range of products and industrial sectors. Regardless of the superior features in Ti-MMC, however, referring to several factors including high unit cost and existence of rigid and abrasive ceramic particles in the generated matrices of the work part, the Ti-MMC is grouped as extremely difficult to cut with a poor level of machinability. Furthermore, adequate process parameters for machining Ti-MMCs under several lubrication methods are rarely studied. Therefore, adequate knowledge of this regard is strongly demanded. Among machinability attributes, ultrafine particles (UFPs) and fine particles (FPs) have been selected as the main machinability attributes and the factors leading to minimized emission have been studied. According to experimental observations, despite the type of coating used, the use of higher levels of flow rate led to less UFPs, while no significant effects were observed on UFPs. Under similar cutting conditions, higher levels of FPs were recorded under the use of uncoated inserts. Moreover, cutting speed had no significant influence on UFPs; nevertheless, it significantly affects the FPs despite the type of insert used.

Key words:

metal matrix composites (MMCs); particle emission; dust emission; turning, lubrication mode;

Cite this article as:

Seyed Ali NIKNAM, Masoud SABERI, Jules KOUAM, Ramin HASHEMI, Victor SONGMENE, Marek BALAZINSKI. Ultrafine and fine particle emission in turning titanium metal matrix composite (Ti-MMC) [J]. Journal of Central South University, 2019, 26(6): 1563-1572.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-019-4112-91 Introduction

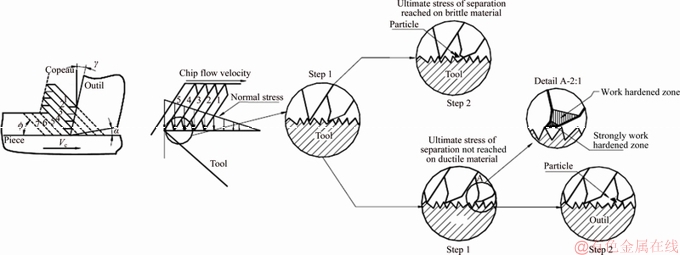

The machinability attributes including surface roughness, cutting forces, tool wear and UFPs and FPs are of prime importance in high precision studies of Ti-MMC [1, 2]. The machining of Ti-MMC is in general associated with several problems and hindering factors including low edge and surface qualities, as well as short tool life. However, most of the works reported in the literature are referred to dry machining of Ti-MMC and except few works; limited information is available on influences of machining factors and lubrication methods on machinability attributes of Ti-MMC. In particular, dust generation within both micro and nano scales was not studied in any lubricated mode. This lack of knowledge will be intended to remedy partially in this work. The creation of FPs within the cutting process is mainly affected by plastic deformation, frictions as well as the mode of chip formation. The micrometric and nanometric size particles are generated when rubbing is taking place between the chip micro- segments. Likewise, the generation of particles can be related to friction effects at the rake face between chip and tool. The best source of information about the particle emission can be achieved from analysis of the chips. According to Figure 1, the formation of particles continues over two main phases, dependent on the workpiece material. Phase 1 appears when the material is divided to separate parts, while phase 2 happens when the chip slides on the tool’s rake face.

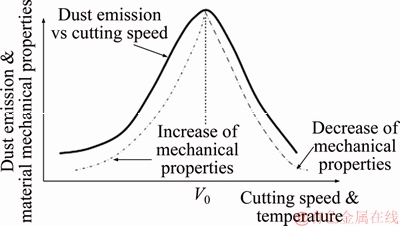

Other significant elements are brittleness and ductility of materials and the generated temperature in the cutting zone (Figure 2), which is in direct correlation with material properties (e.g. mechanical properties), cutting parameters, in particular cutting speed as well as the cutting tools attributes (geometry and material). The size and composition of the dust are the main governing factors on the level of toxicity in metallic dust. Particles with sizes between 2.5–10 μm stay in the trachea and bronchioles, and those with higher size and scales (10 μm) generally stay within the thorax and nose. These last particles are less hazardous and are generally removed from the human body. The UFP refers to the particle size range of 0.1 μm and the FP is referred to those particles with aerodynamic diameter of 2.5 μm or smaller.

Empirical and analytical modeling of particle emission have been conducted in literature and the governing factors on the fine and UFPs under various lubrication modes and family of materials have been presented comprehensively [3–10]. However, according to review of literature, no work was found in this regards when machining Ti-MMC. Irrespective of numerous investigations on the high precision cutting of titanium alloys and many other widely used superalloys [11–23], inadequate information is available on machining Ti-MMCs using conventional and non-conventional methods [24–32]. In other words, no comprehensive information is available on machinability of Ti-MMCs. Furthermore, factors governing FPs and UFPs during machining Ti-MMC were not investigated in the literature. This can be considered an exceptional topic with limited information available. The main reasons for limited information can be related to difficulties of dust emission control and supervision as well as limited studies on adequate levels of cutting parameters used in machining of Ti-MMC.

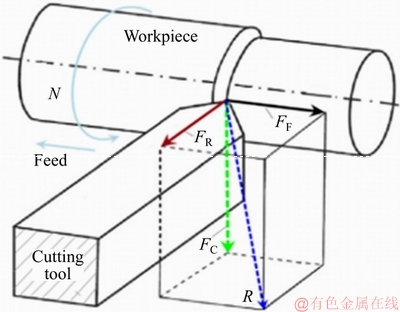

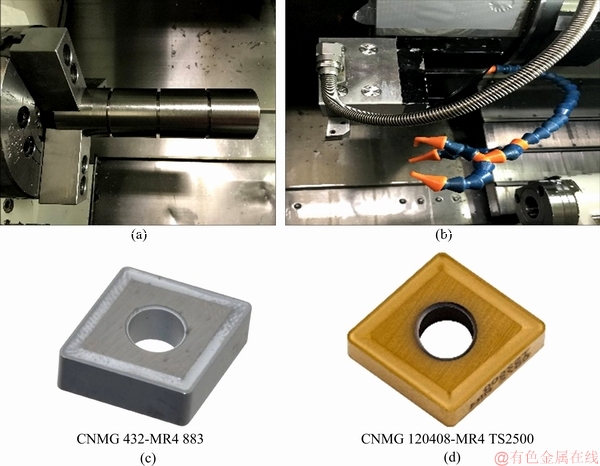

Furthermore, except limited works reported [24–27], turning Ti-MMC when using various kinds of carbide inserts is rarely studied. Therefore, this work intends to present the influence of machining parameters and the modes of lubrication (dry and semi-dry) on FPs and UFPs during turning Ti-MMC using commercial coated and uncoated carbide inserts (see Figure 3). Furthermore, an overview of cutting forces in time and frequency domain is also presented in this work.

2 Experimental plan

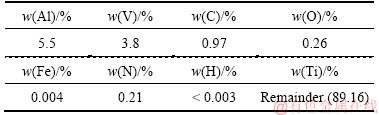

The cylindrical block of Ti-6Al-4V with the elemental compositions presented in Table 1 was arranged in 53.62 mm in diameter and 210 mm in length (Figure 4). The work part consisted of 10%–12% volume fraction of TiC particles with uneven shapes and 10–20 μm size.The elemental compositions were determined by optical emission spectroscopy (OES) and, inductively coupled plasma (ICP) method. The CNC Mazak Nexus 100-II M was used in experimental works. The cutting parameters used in all cutting conditions were the constant length of 65 mm, feed rate 0.15 mm/r and depth of 1 mm. Additionally five levels of cutting speeds (20, 30, 40, 50, 60 m/min) as well as dry and semi-dry conditions under various flow rates (100–300 mL/min) were used in all entire cutting tests. The Oemeta Novamet 100 was used as the lubricant.

Figure 1 Schematic overview of two mechanisms of dust emission [3]

Figure 2 Profile of dust emission through variation in cutting speed and mechanical behavior [3]

Figure 3 Overview of turning cutting forces [33]

Table 1 Elemental composition of Ti-MMC

The particles were monitored by SMPS for UFP in 3–300 nm and APS for FP in the range of 5–20m. Both UFP and FP can be expressed in terms of PNC, specific surface concentration and mass concentration. The turning table dynamometer was used to record the directional cutting forces using sampling frequency of 12 kHz. The turning cutting forces can be expressed as radial force (FR), feed force (FF) and cutting force (FC).

3 Results and discussion

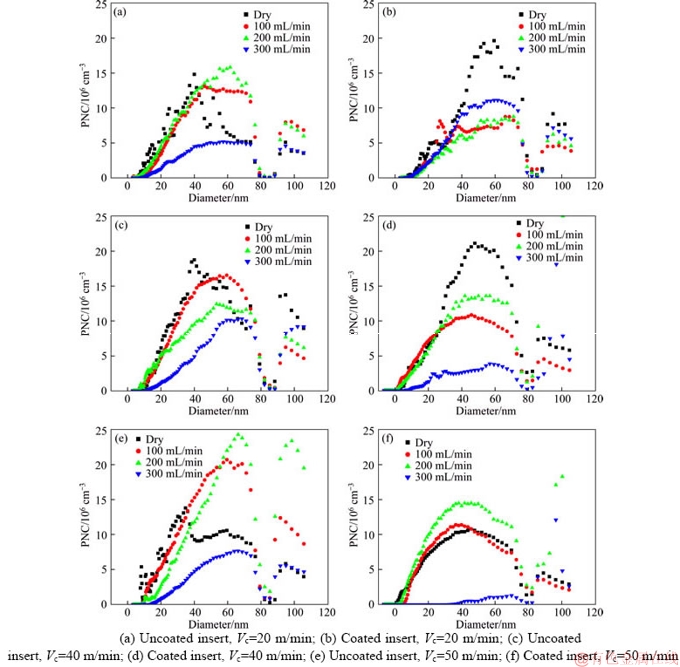

It is very well understood that the machining operations are associated with dust generation and in turn, the presence of dust generation in cutting operations may lead to health and environmental concerns in wide scopes. Although it is believed that wet (flood) machining may tend to decrease the generated dust in machining area, the concentration and size of particles widely related to the flow rates and cutting parameters used. Figure 5 presents the PNC of UFP during turning of Ti-MMCs using coated and uncoated inserts at cutting speeds 20, 40 and 50 mm/min under dry and semi-dry lubrication modes. As shown in Figure 5(a), regardless of cutting speed used, less UFP was monitored at higher levels of flow rate. Likewise, as compared to readings made at flow rates 100 and 200 mL/min, less particles were monitored under dry mode. Based on Figure 3, in the case of using uncoated insert and coated insert, less UFPs were monitored at higher levels of flow rate. The substantial interaction effects among lubrication modes, tool coating and cutting speed can be clearly shown from experimental results. Based on Figure 5, the general observation reveals that the lubrication reduces the particle emission in turning operation. It is also observed that at high levels of flow rate, the use of coated insert led to less UFPs as compared to coated insert. This phenomenon could be related to lack of coating in tool as well as more strength of coated tool which is more suitable for rough cutting conditions. It is also observed that the use of the coated tool at high cutting speed and high flow rate reduces the PNC of UFPs. The PNC of UFPs increases and reaches the maximum at around 60 nm diameter and decreases. Referring to Figure 5, despite the type of insert used, cutting speed has no major effect on UFPs.

Figure 4 Ti-MMC work part (a), lubrication and cutting force acquisition setup (b), uncoated carbide insert (c) and coated carbide insert (d)

Figure 5 UFP at various conditions:

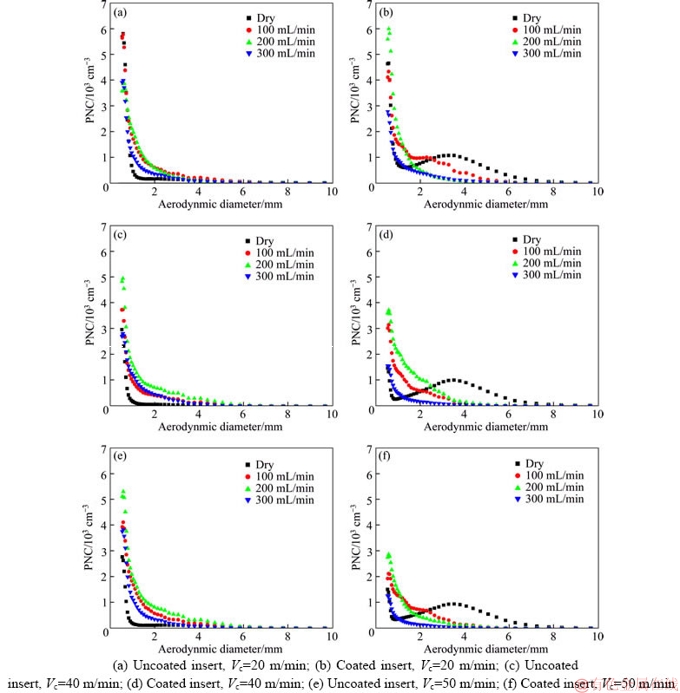

Figure 6 presents the PNC of FPs during turning of Ti-MMC using coated and uncoated inserts at cutting speeds 20, 40 and 50 mm/min under dry and semi-dry lubrication modes. The use of lubrication in Figure 6 led to the highest FPs according to the aerodynamic diameter in turning operations using uncoated insert which is different from the case of UFP in Figure 5. It is also observed that the use of coated insert at high levels of flow rate led to more FPs as compared to dry condition. Using the coated insert at low aerodynamic diameter (less than 1.5 m) at higher levels of flow rate led to more FPs as compared to readings under dry condition. After 1.5 m aerodynamic diameter, PNC of FPs in dry condition is higher than the readings made under semi-dry conditions. The FPs under dry condition were increased up to 3.5 m and then decreased with the aerodynamic diameter. According to Figure 6, despite the type of insert used, cutting speed has a significant impact on recorded values of UFPs.

Figure 6 FP at various conditions:

3.1 Cutting force assessment in time domain

According to Figure 3, the FC is the primary cutting force element. It should be underlined that during turning of hard to cut materials (i.e. Ti-MMC), the FF may exceed the FC when cutting time increases. This phenomenon may refer to several reasons, including rapid tool wear, nothing as well as vibrational instability of the systems which may tend to change the depth of cut, cutting force and dimensional accuracy. It is known that the interactions between the work part and the tool faces as well as generated temperature in machining operations are the main critical factors to wear mechanism [34–36]. However, comprehensive studies about tool wear morphology and material characterization in machining Ti-MMC under different lubrication mode are beyond the scope of this work. However, since the cutting forces were recorded in this work, the time and frequency analyses on cutting forces were conducted in order to assess the vibration modes during cutting operations.

To better elaborate the effects of cutting forces, the resultant force (FRes) was also calculated using Eq. (1) in order to take into account the effects of FF.

(1)

(1)

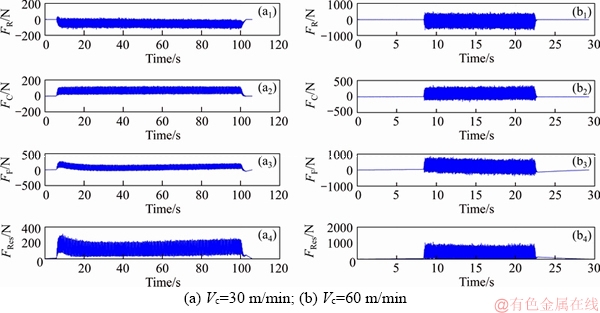

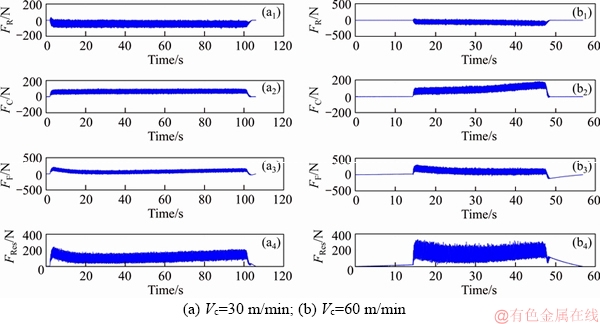

The overview of FRes under various lubrication mode and the flow rate is presented in Figures 7 and 8. It is shown that under dry mode and high cutting speed, the cutting force elements, including FC and FRes tend to increase sharply when cutting time increases. This phenomenon may refer to effects of cutting temperature on the tool wear mode. Moreover, although higher cutting forces were resulted under high flow rate, dislike dry mode, no negligible fluctuation was observed on the cutting forces. The higher resulting values of cutting forces under lubricated mode may refer to several noise factors such as non-adequate arrangement and situation of injecting nozzles which in fact may generate a thin film of lubricant along cutting direction. The generated film is thought to act against the cutting tool movement in cutting direction. Consequently higher resulting values of cutting forces were observed at high cutting speed, although under similar cutting conditions lower flank and rake wear were resulted as compared to dry mode. The precise and accurate adjustment and calibration of the nozzle are of prime importance in perspective works.

3.2 Cutting force assessment in frequency domain

The main concept of Fourier analysis is to convert a signal from its original domain (often time or space) to frequency domain. The FFT has a wide range of applications in many aspects, manufacturing sectors and application. As engineering point of view, it is always encouraged to analyze the signal in frequency domain instead of time domain. To convert a continuous time domain signal to the frequency domain, Eq. (2) is applied.

(2)

(2)

where j=0, …, N-1 is complex number.

Figure 7 Cutting forces when flow rate is 300 mL/h:

Figure 8 Cutting forces in dry mode:

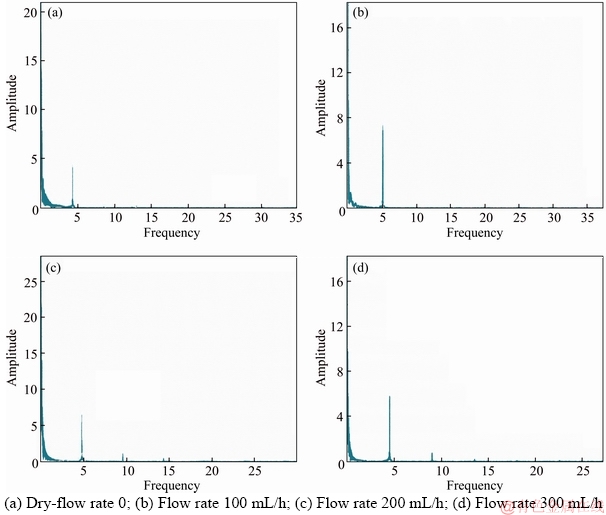

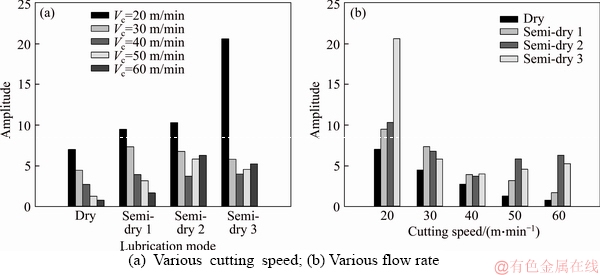

The time domain cutting force signals were converted to the frequency domain using FFT. The FFT diagram of recorded cutting forces under various flow rates (0–300 mL/h) at cutting speed 30 m/min is presented in Figure 9. It can be shown that amplitude of the peaks changes according to flow rates used. In fact increased amplitude is the signature of the changes in the mode of chip formation morphology and cutting operation. Consequently, the fluctuated cutting forces can be observed, although constant levels of cutting parameters were used. A similar analysis was conducted on the higher levels of cutting force. Consequently, the amplitude and frequency domain diagram of the work parts under different cutting speed and flow rate are presented in Figure 10.

As can be seen in Figure 10, at cutting speed 20 m/min, the lowest peak amplitude was observed at dry mode. Surprisingly, the highest amplitude was observed at cutting speed 20 m/min at semi-dry 3 (flow rate 300 mL/h). It can be shown that at low levels of cutting speed, the use of fluid has no significant effects on the cutting performance.One reason to describe this phenomenon is a non- adequate selection of cutting process parameters. Secondly, due to the specific microstructure of the work part, the injected fluid may tend to initiate thermo-mechanical stress on the work part during cutting operation when the work part is in engagement with the cutting tool. This phenomenon may increase the edge hardening of the work part and as a result, higher resulting values of cutting forces are expected. In addition, Ti-MMC is inhomogeneous materials, reinforced with TiC elements, which are principally abrasive. Despite the lubrication method and flow rates used, as a result of interaction between the work part and the TiC elements, higher resulting values of cutting forces are expected. This phenomenon is intensified at higher levels of cutting speed (50 and 60 m/min), while relatively similar peak amplitudes were observed under various flow rates at cutting speeds 30 and 40 m/min. In order to draw a better operational window in terms of the effects of flow rates and cutting speeds on the cutting forces attribute at time and frequency domain, comprehensive works on MQL and MQCL machining of Ti-MMCs are demanded.

4 Conclusions

In general, it was observed that except minor cases, the use of higher flow rate led to less UFPs as compared to readings of dry machining. In fact, despite the cutting speed at uncoated insert, less UFPs were detected under higher flow rate. Also, except the low level of cutting speed, the lowest value of PNC was observed when using coated tool at the highest levels of flow rate and speed.On the basis of experimental results, the effects of flow rate and coating on UFPs can be precisely determined.Despite the type of insert used, the use of dry cutting has a major influence on FPs.

Figure 9 FFT diagram of recorded cutting forces under various flow rates:

Figure 10 Frequency domain diagram of work part under different cutting conditions:

Under similar cutting conditions, higher levels of PNC of FPs were recorded under the use uncoated inserts. Moreover, according to experimental results, the cutting speed had no substantial impact on the PNC of UFPs, but, the cutting speed significantly affects the FPs despite the type of insert used.

The FFT diagram of recorded cutting forces under various flow rates (0–300 mL/h) exhibited that amplitude of the peaks changes according to flow rates used. In fact increased amplitude is the signature of the changes in the mode of chip formation morphology and cutting operation.

Fluctuated cutting forces were observed under dry conditions. Higher cutting forces resulted when cutting time increases. This is the primary indication of tool wear at the cutting operations.

It was observed that at low levels of cutting speed, the use of fluid has no significant effects on the cutting performance. The non-adequate selection of cutting process parameters, nonprecise injection mode and direction as well as thermo-mechanical stress on the work part as a result of rapid cooling down during cutting operations are the main reasons of increased cutting forces.

It is worth to note that results were entirely restricted to specific cutting conditions, but, the experimental results under the cutting conditions presented may enable us to present an operation window of dust emission control when machining Ti-MMC under various cutting conditions. The present studies need to expand in wider scopes, employing a various range of cutting parameters and experimental conditions.

Acknowledgments

The financial support received from Fonds Québécois de la Recherche sur la Nature et les Technologies (FQRNT) is appreciated.

References

[1] KHETTABI R, SONGMENE V, MASOUNAVE J. Effect of tool lead angle and chip formation mode on dust emission in dry cutting [J]. Journal of Materials Processing Technology, 2007, 194(1–3): 100–109.

[2] KREMER A, EL MANSORI M. Influence of nanostructured CVD diamond coatings on dust emission and machinability of SiC particle-reinforced metal matrix composite [J]. Surface and Coatings Technology, 2009, 24(6): 1051–1055.

[3] KHETTABI R, SONGMENE V, ZAGHBANI I, MASOUNAVE J. Modeling of particle emission during dry orthogonal cutting [J]. Journal of Materials Engineering and Performance, 2010, 19(6): 776–789.

[4] HOU T H, SU C H, LIU W L. Parameters optimization of a nano-particle wet milling process using the Taguchi method, response surface method and genetic algorithm [J]. Powder Technology, 2007, 173(3): 153–162.

[5] KHETTABI R, SONGMENE V. Particle emission during orthogonal and oblique cutting [J]. International Journal of Advances Machining and Forming Operations, 2009, 1(1): 1–9.

[6] ZAGHBANI I, SONGMENE V, KHETTABI R. Fine and ultrafine particle characterization and modeling in high-speed milling of 6061-T6 aluminum alloy [J]. Journal of Materials Engineering and Performance, 2009, 18(1): 38–48.

[7] KOOUAM J, SONGMENE V, DJEBARA A, KHETTABI R. Effect of friction testing of metals on particle emission [J]. Journal of Materials Engineering and Performance, 2012, 21(6): 965–972.

[8] KAMGUEM R, DJEBARA A, SONGMENE V. Investigation on surface finish and metallic particle emission during machining of aluminum alloys using response surface methodology and desirability functions [J]. The International Journal of Advanced Manufacturing Technology, 2013, 69(5–8): 1283–1298.

[9] KHETTABI R, FATMI L, MASOUNAVE J, SONGMENE V. On the micro and nanoparticle emission during machining of titanium and aluminum alloys [J]. CIRP Journal of Manufacturing Science and Technology, 2013, 6(3): 175–180.

[10] NIKNAM S A, KOUAM J, SONGMENE V. Experimental investigation on part quality and metallic particle emission when milling 6061-T6 aluminium alloy [J]. International Journal of Machining and Machinability of Materials, 2016, 18(1, 2): 120–137.

[11] NIKNAM S A, KHETTABI R, SONGMENE V. Machinability and machining of titanium alloys: A review [M]//Machining of Titanium Alloys. Berlin, Heidelberg: Springer, 2014: 1–30.

[12] ZHANG X, SHIVPURI R, SRIVASTAVA A. A new microstructure-sensitive flow stress model for the high-speed machining of titanium alloy Ti–6Al–4V [J]. Journal of Manufacturing Science and Engineering, 2017, 139(5): 051006. DOI: 10.1115/1.4035037.

[13] LIU D, WANG F, LIU R Y. Experimental study on the serrated chip while machining titanium alloy [M]// DEStech Transactions on Engineering and Technology Research. 2017: 525–530.

[14] JACKSON M J, NOVAKOV T, WHITFIELD M, ROBINSON G, HANDY R, SEIN H, AHMED W. VFCVD diamond-coated cutting tools for micro-machining titanium alloy Ti6Al4V [J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(5–8): 2881–2918.

[15] NATH C, KAPOOR S G, SRIVASTAVA A K, IVERSON J. Study of droplet spray behavior of an atomization-based cutting fluid spray system for machining titanium alloys [J]. Journal of Manufacturing Science and Engineering, 2014, 136(2): 021004.

[16] SHAMS O, PRAMANIK A, CHANDRATILLEKE T. Thermal-assisted machining of titanium alloys [M]. Advanced Manufacturing Technologies. Springer, 2017: 49–76.

[17] LIU D, LIU R Y, WANG F. Simulation of cutting temperature distribution while machining titanium alloy TC4 [M]// DEStech Transactions on Engineering and Technology Research, 2017.

[18] CHENG Q, REN W D, LIU Z F, CHEN D J, GU P H. Load-induced error identification of hydrostatic turntable and its influence on machining accuracy [J]. Journal of Central South University, 2016, 23(10): 2558–2569.

[19] GUO C B, WEI D B, DI S C. Improving energy utilization efficiency of electrical discharge milling in titanium alloys machining [J]. Journal of Central South University, 2016, 23(10): 2550–2557.

[20] ZHANG Y J, DONG G J, ZHOU M. Simulation and experiment analysis on thermal deformation of tool system in single-point diamond turning of aluminum alloy [J]. Journal of Central South University, 2016, 23(9): 2223–2229.

[21] CUI W, TANG J Y. New method for calculating face gear tooth surface involving worm wheel installation errors [J]. Journal of Central South University, 2017, 24(8): 1767–1778.

[22] CHEN H, CHEN K H, XU Y C, PAN C X, YI J Y, ZHU C J. Microstructure, mechanical properties, and milling performance of arc-PVD AlTiN-Cu and AlTiN/AlTiN-Cu coatings [J]. Journal of Central South University, 2018, 25(3): 506–515.

[23] WANG Q B, MA H B, KONG X G, ZHANG Y M. A distributed dynamic mesh model of a helical gear pair with tooth profile errors [J]. Journal of Central South University, 2018, 25(2): 287–303.

[24] ARAMESH M, ATTIA H M, KISHAWY H A, BALAZINSKI M. Observation of a unique wear morphology of CBN inserts during machining of titanium metal matrix composites (Ti-MMCs); leading to new insights into their machinability [J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(1–4): 519–530.

[25] KAMALI ZADEH S. Initial tool wear mechanisms in turning of titanium metal matrix composites [D]. Montreal, Canada:  cole Polytechnique de Montréal, 2016.

cole Polytechnique de Montréal, 2016.

[26] BEJJANI R, BALAZINSKI M, ATTIA H, PLAMONDON P,  SP

SP RANCE G L. Chip formation and microstructure evolution in the adiabatic shear band when machining titanium metal matrix composites [J]. International Journal of Machine Tools and Manufacture, 2016, 109: 137–146.

RANCE G L. Chip formation and microstructure evolution in the adiabatic shear band when machining titanium metal matrix composites [J]. International Journal of Machine Tools and Manufacture, 2016, 109: 137–146.

[27] ARAMESH M. Machinability of titanium metal matrix composites (Ti-MMCs) [D]. Montreal, Canada:  cole Polytechnique de Montréal, 2015.

cole Polytechnique de Montréal, 2015.

[28] ASGARI A. Cutting conditions optimisation of titanium metal matrix composites in turning and face milling [D]. Montreal:  cole Polytechnique de Montréal, 2015.

cole Polytechnique de Montréal, 2015.

[29] BEJJANI R. Machinability and modeling of cutting mechanism for titanium metal matrix composites [D].  cole Polytechnique de Montréal, 2012.

cole Polytechnique de Montréal, 2012.

[30] BEJJANI R, SHI B, ATTIA H, KISHAWY H. Machinability and chip formation of titanium metal matrix composites [J]. International Journal of Advance Manufacturing System, 2011, 13(1): 75–90.

[31] BEJJANI R, SHI B, ATTIA H, BALAZINSKI M. Laser assisted turning of titanium metal matrix composite [J]. CIRP Annals-Manufacturing Technology, 2011, 60(1): 61–64.

[32] NIKNAM S A, KOUAM J, SONGMENE V, BALAZINSKI M. Dry and semi-dry turning of titanium metal matrix composites (Ti-MMCs) [J]. Procedia CIRP, 2016, 77: 62–65.

[33] DUONG X, MAYER J, BALAZINSKI M. Initial tool wear behavior during machining of titanium metal matrix composite (TiMMCs) [J]. International Journal of Refractory Metals and Hard Materials, 2016, 60: 169–176.

[34] KWON P. Predictive models for flank wear on coated inserts [J]. ASME J Tribol, 2000, 122(1): 340–347.

[35] ISLAM C, LAZOGLU I, ALTINTAS Y. A three-dimensional transient thermal model for machining [J]. Journal of Manufacturing Science and Engineering, 2016, 138(2): 021003.

[36] KUMAR S, SINGH R, BATISH A, SINGH T. Modeling the tool wear rate in powder mixed electro-discharge machining of titanium alloys using dimensional analysis of cryogenically treated electrodes and workpiece [J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2017, 231(2): 271–282.

(Edited by YANG Hua)

中文导读

旋切钛基复合材料(Ti-MMC)的超细微粒粉尘排放

摘要:钛基复合材料(Ti-MMC)具有优异的特性和相容性,有望取代已广泛应用的商用钛和高温合金。尽管Ti-MMC具有优越的性能,但因生产成本高、工件基体的刚性和存在的磨料陶瓷颗粒等因素,被归类为加工性能差的极难切削材料。采用润滑方法加工Ti-MMCs的工艺参数很少被研究。考虑到可切削性能,选择了超细粒(UFPs)和细颗粒(FPs),研究了影响粉尘排放的因素。根据实验观察,无论使用哪种类型涂层,较高的流量水平会导致较少的超细粉,但没有观察到对细颗粒的显著影响。在类似的切削条件下,使用无涂层刀片时会排放较高水平的细颗粒。此外,切削速度对超细粉没有显著影响,但对细的颗粒有显著的影响,且与插入类型无关。

关键词:金属基复合材料(MMCS);颗粒排放;粉尘排放;旋切;润滑模式

Received date: 2018-11-04; Accepted date: 2019-01-17

Corresponding author: Seyed Ali NIKNAM, PhD, Assisant Professor; Tel: +98-2177240203; E-mail: saniknam@iust.ac.ir; ORCID: 0000-0001-9901-9032

Abstract: Titanium metal matrix composite (Ti-MMC) has excellent features and capabilities which can be considered a potential candidate to replace commercial titanium and superalloys within an extensive range of products and industrial sectors. Regardless of the superior features in Ti-MMC, however, referring to several factors including high unit cost and existence of rigid and abrasive ceramic particles in the generated matrices of the work part, the Ti-MMC is grouped as extremely difficult to cut with a poor level of machinability. Furthermore, adequate process parameters for machining Ti-MMCs under several lubrication methods are rarely studied. Therefore, adequate knowledge of this regard is strongly demanded. Among machinability attributes, ultrafine particles (UFPs) and fine particles (FPs) have been selected as the main machinability attributes and the factors leading to minimized emission have been studied. According to experimental observations, despite the type of coating used, the use of higher levels of flow rate led to less UFPs, while no significant effects were observed on UFPs. Under similar cutting conditions, higher levels of FPs were recorded under the use of uncoated inserts. Moreover, cutting speed had no significant influence on UFPs; nevertheless, it significantly affects the FPs despite the type of insert used.