Effects of rheoforming on microstructures and mechanical properties of 7075 wrought aluminum alloy

GUO Hong-min(郭洪民)1, YANG Xiang-jie(杨湘杰)1, WANG Jia-xuan(王家宣)2,HU Bin(胡 斌)1, ZHU Guang-lei(朱光磊)1

1. School of Materials Science and Engineering, Nanchang University, Nanchang 330031, China;

2. School of Materials Science and Engineering, Nanchang Aerospace University, Nanchang 330063, China

Received 24 March 2009; accepted 10 June 2009

Abstract:

It is economically advantageous to cast wrought aluminum alloys directly into near-net-shape components. The objective of the present work is to take advantage of the rheoforming with 7075 alloy to improve the competitiveness of this emerging technology in the manufacture of wrought aluminum alloy. High quality semi-solid slurry was produced, in which primary α(Al) presents in diameter of 62 μm and shape factor of 0.78 and features no eutectics entrapped. Higher forming pressure results in small grain size, improved shape factor and higher density. Especially, rheoforming can effectively reduce the occurrence of hot tearing. The average yield strength and elongation of the rheoformed samples in the T6 condition are 483 MPa and 8%, respectively.

Key words:

7075 Al alloy; rheoforming; semi-solid processing;

1 Introduction

Wrought aluminum alloys have wide applications in aerospace and automobile industries due to their superior properties compared to casting aluminum alloys[1]. It is economically advantageous to cast wrought aluminum alloys directly into near-net-shape components, which can offer more considerable cost saving than methods that introduce plastic deformation, such as forging, extrusion or rolling. The biggest problems in casting these alloys are their high tendency to form hot tearing and their bad fluidity in conventional casting processes[2].

One of the promising technologies capable of producing near-net-shape casting of wrought aluminum alloys is the semi-solid metal (SSM) processing[3]. SSM processing offers several potential advantages, such as producing high integrity components capable of full heat treatment to maximize properties, minimizing macrosegregation and solidification shrinkage, and reducing the forming temperature to extend the die life[4-5]. The focus of current investigations on wrought aluminum alloys is mainly given to thixoforming (one of the most popular SSM processes)[6-8], in which pre-processed non-dendritic alloys are reheated to the semi-solid region prior to the component shaping[9-10]. High manufacturing cost, arising from pre-processed non-dendritic billet, billet reheating, as well as the difficulty of scrape recycling, are the biggest disadvantages of this approach[5]. Moreover, wrought alloys are relatively difficult to thixoform because of a higher sensitivity of the liquid fraction to temperature fluctuation[3]. Thus, thixoforming of wrought aluminum alloy has not been available in industrial application. In recent years, another SSM process, rheoforming, has become popular, in which a molten alloy is transformed into semi-solid slurry and followed directly by component shaping[11]. Currently, rheoforming is mainly applied to produce components of casting aluminum alloys A356 and A357. One of the major challenges is to develop rheoforming for higher performance alloys such as 7000 series, to produce higher crucial components.

The present work is undertaken to investigate the rheoforming of 7075 alloy, which has the potential for semi-solid processing[3]. Microstructure features of semi-solid and rheoformed materials, mechanical properties of rheoformed material in T6 condition are examined.

2 Experimental procedures

The material used was a commercial wrought 7075 aluminum alloy (5.9% Zn, 2.2% Mg, 1.7% Cu, 0.35% Fe, 0.1% Si, Al balance, mass fraction) supplied in the form of directional cast (DC) rods of 69 mm in diameter. The liquidus and solidus temperature of the alloy are 635 ℃ and 477 ℃respectively, determined by differential scanning calorimetry.

The semi-solid slurry was produced by low superheat pouring with shear field (LSPSF) which mainly consists of a rotating barrel, a slurry holder and a temperature control unit. The details of the LSPSF system can be found in Ref.[12]. 7075 alloy was melted using an electric resistance furnace at 750 ℃, then, it was cooled to pouring temperature (PT) and poured into the rotating barrel. The rotation speed (RS) of barrel was set at 30-120 r/min, the inclined degree of barrel was set at 30?, the rotating barrel was operated at a temperature of 200 ℃ and the temperature of slurry holder was kept at (620±1) ℃. The melt flowing through out of the barrel was collected in the slurry holder, and was cooled quiescently with an average cooling rate of 0.48 ℃/s. Samples sectioned from the semi-solid slurry were quenched in water and their microstructures were analyzed in order to optimize slurry-making practice. Rheoforming was carried out with a libratory press which relied on the vertical downwards acting cylinder to provide the forming load. When the temperature of the semi-solid slurry reached 628 ℃ in the slurry holder, it was released into the cavity of the lower die. After a delay time of 3-4 s, the upper die (plunger) was moved downwards and the load was applied to the slurry for 25 s, further solidification occurred in the die cavity at high pressure. The whole die assembly used for the casting was preheated to 250 ℃ using a small electric furnace. A series of rectangle plates (with length of 120 mm, width of 75 mm, and depth of 18 mm) were formed, using pressures varying from 30 to 120 MPa to optimize a relatively suitable forming pressure. Under the optimum pressure, cup-shaped parts were formed using rheoforming, and counterparts were also produced by conventional forming the molten alloy at 720 ℃.

The tensile samples were machined from rheoformed plate with and without T6 heat treatment, with a gage length of 25 mm and a rectangular cross section of 6 mm×3 mm. The heat treated samples were solution treated at 485 ℃ for 6 h, followed by quenching and then aged at 125 ℃ for 12 h. The metallographic samples were sectioned from the semi-solid slurry quenched in water. The rheoformed parts were prepared using the standard practice, etched with Keller’s reagent, and were examined using an optical microscope. The primary α(Al) was characterized quantitatively to measure its diameter and shape factor[12].

3 Results and discussion

3.1 Preparation of 7075 alloy semi-solid slurry

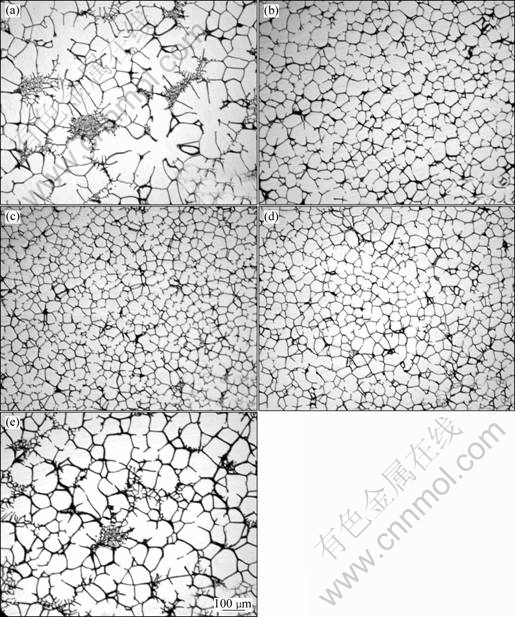

The desired starting feedstock for rheoforming is partially solidified slurry in which the solid is present as fine and nearly perfect globular particles. Fig.1 and Table 1 summarize the evolution of microstructures obtained by LSPSF process. The pouring temperature appears to have important influence on microstructure of slurry. When performing the process at relatively low pouring temperatures, fine and globular primary α(Al) are formed as shown in Figs.1(b) and (c). At higher pouring temperature, however, primary α(Al) presents coarse dendrite (Fig.1(a)). Figs.1(c)-(e) show the effect of rotation speed of barrel under a pouring temperature of 660 ℃. It is evident that increase in the rotation speed from 30 r/min up to 90 r/min leads to decrease in the size of primary α(Al) and improvement of shape factor. With further increase in the rotation speed from 90 r/min to 120 r/min, the effect of rotation speed is not significant any more. In view of the above, it is concluded that LSPSF can produce superior semi-solid slurry of 7075 alloy when the melt is poured at 660-680 ℃ and meanwhile mixed at a rotation speed of 90-120 r/min. Primary α(Al) presented can be obtained in semi-solid slurry with a diameter of 62 μm, shape factor of 0.78 and featured zero-entrapped eutectic. Such microstructure features are distinctly different from those of reheated slug in thixoforming[6-10].

Fig.1 Microstructures of semi-solid slurry cast under different preparation conditions: (a) 690 ℃, 90 r/min; (b) 680 ℃, 90 r/min; (c) 660 ℃, 90 r/min; (d) 660 ℃, 120 r/min; (e) 660 ℃, 30 r/min

Table 1 Characteristics of semi-solid slurry and exit temperatures

In LSPSF process, solidification of metals takes place in the rotating barrel under the influence of gravity force, centrifugal force and friction force[12]. The rotation speed is zero when molten metal is introduced into the rotating barrel, and then it tends to increase by means of friction and centrifugal forces. However, the inertia and gravity forces restrain this tendency, resulting in a relative motion between the melt and the barrel wall. In addition, the gravity force pushes and accelerates the melt to flow along the axial direction of the inclined barrel, resulting in another relative motion. Driven by these relative motions, the region near the solid-liquid interface suffers a violent turbulent flow and shear stress. The rotation of barrel can result in large and ever-renewing surface area between the melt and the barrel wall, which provides localized rapid heat extraction. During this process, copious nucleation takes place on or near the barrel wall. The violent convection caused by the relative motions leads to the detachment of formed crystals from the barrel wall or the breaking of dendrites adjacent to the barrel wall, which are formed in the thermal undercooled region[4, 13]. These primary α(Al) are distributed in the melt during flowing and they descend into the slurry holder. By increasing the rotation speed, more localized chill, convection and substrate surface for nucleation are obtained, resulting in higher grain refinement as shown in Figs.1(c) and (d). Pouring temperature determines the physical heat carried in the poured melt, and rotation speed affects the level of localized chill. When the pouring temperature is too high, or the rotation speed is lower, the exit temperature of melt (the temperature of melt at the exit of rotating barrel) is above its liquidus, as shown in Table 1. In this case, the melt may not start to solidify, or fewer crystals will be produced and only a small percentage of them may survive, resulting in a low grain refinement and coarse primary α(Al), as shown in Figs.1(a) and (e). However, under appropriate combination of the two factors mentioned above, the melt at the exit of barrel has already been thermal undercooled, the survival of the segregated crystals and broken fragments is enhanced, resulting in higher grain refinement.

3.2 Forming of 7075 alloy semi-solid slurry

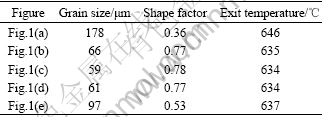

Metallography was conducted to examine the influence of the forming pressure on the cast microstructure. Fig.2 shows the optical micrographs of the rheoformed plate parts and the quantitative metallographic results are illustrated in Table 2. Increasing the forming pressure from 30 MPa to 90 MPa reduces the grain size of primary α(Al) from 67 to 46 μm and improves the shape factor from 0.76 to 0.81. The thermal resistance at the melt-mould interface varies inversely with the pressure at the interface[14]. The pressure applied through the punch promotes an intimate contact of the melt with the mould wall, and this largely increases the cooling rate in the bulk owing to the enhancement of the heat transfer coefficient[14-15]. Such a high cooling rate under pressure results in the refinement of primary α(Al) because of a shorter time for grain growth. The flow of the liquid phase under forming pressure leads to the collision and abrasion between grains, which could improve the rounding of primary α(Al).

Fig.2 Microstructures of plate part rheoformed under different applied pressure: (a) 30 MPa; (b) 60 MPa; (c) 90 Mpa

Table 2 Microstructure characteristics and density of rheoformed plate part showing critical pressure

The density measured by Archimedes’ principle is tabulated in Table 2. With increasing the forming pressure, the density increases markedly between 30 and 60 MPa and increases gradually thereafter from 60 to 120 MPa. All rheoformed specimens formed by a pressure above 90 MPa are relatively dense. The rheoformed parts under forming pressure of 90 MPa were heat treated to T6 condition. The yield strength of the samples without heat treatment is about 290-310 MPa. After heat treatment, the average yield strength and elongation are 483 MPa and 8%, respectively. Mechanical properties offered by the present rheoforming are better than thixoforming using cooling plate to produce non-dendritic slug[3], similar to thixoforming using recrystallisation and partial remelting (RAP) produce non-dendritic slug[3, 6], but lower than standard forged 7075 (yield strength 505 MPa, elongation 11%). However, rheoforming of 7075 alloy directly from molten alloy offers considerable cost saving and is thus much more attractive in industrial applications. Further work on die design, process optimization and heat treatments should be done to further improve the mechanical properties of rheoformed parts.

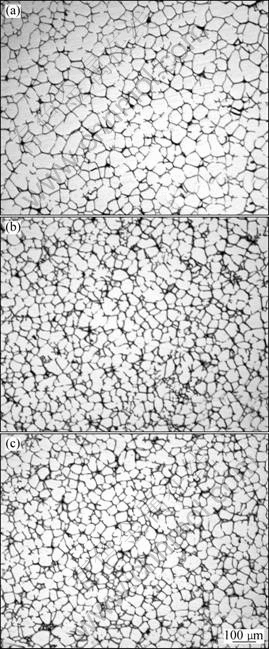

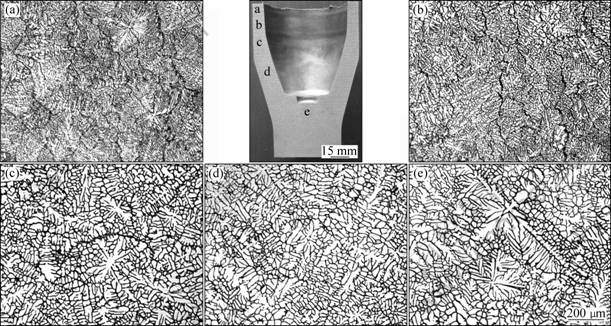

Cup-shaped component production trials have been conducted to further confirm the rheoforming process for wrought alloy component production. The microstructure features across the mid-section of the parts formed from full molten alloy and semi-solid slurry are shown in Figs.3 and 4, respectively. The microstructures of these two parts exhibit different features. The former exhibits a heterogeneous structure with fine dendrites at the upper ring (as shown in Figs.3(a) and (b)) and coarse one at bottom section. In contrast, most of the primary α(Al) in the rheoformed part are present as fine globular particles. Some liquid segregation is noted towards the upper ring of the part with an accompanying enrichment of the primary α(Al) at the bottom section. This is also a typical phenomenon present in most thixoforming[6-7] and is linked with the squeezing out of the liquid phase under forming pressure. Also obvious in Figs.3 and 4 is the difference in the occurrence of hot tearing between the two parts. Hot cracks of hundreds of micrometers are noticed in most conventional cast parts, and most of hot tearing is most frequently observed between branched dendrites at upper ring of the part (Fig.3). The part rheoformed from semi-solid slurry, on the other hand, reveals a relatively homogeneous structure with no evidence of hot tearing. It is generally accepted that hot tears occur in the later stage of solidification, when the contraction strains pull the solid dentrites apart and the empty inter dentritic area can not be filled by the liquid due to restricted flow between dendrites[2]. Rheoforming minimizes hot tearing tendencies of 7075 alloy by changing the morphology of the primary α(Al) from a dendritic morphology to a predominantly globular shape. This change in the morphology of the primary α(Al) phase results in an increase in the micro-channels which are available for feeding the casting with liquid during the later stage of solidification. In addition, rheoforming uses a much lower forming temperature than conventional casting processes due to its semi-solid processing nature. This results in much less solidification shrinkage, which further contributes to the reduced tendency to hot tearing.

Fig.3 Microstructures taken from different positions on mid-section of cup-shaped part formed from full liquid at 720 ℃

Fig.4 Microstructures taken from different positions on mid-section of cup-shaped part formed from semi-solid slurry at 628 ℃

4 Conclusions

1) LSPSF process can produce high quality semi-solid slurry of 7075 wrought alloy. Under proper conditions, the primary α(Al) presents in diameter of 62 μm and shape factor of 0.78, and features no eutectics entrapped.

2) It is shown that rheoforming process can reduce the occurrence of hot tearing, decrease the grain size and increase the density of 7075 alloy.

3) With further processing the rheoformed parts to T6 condition, improved mechanical properties can be attained close to the level of wrought targets. The rheoforming process directly from molten alloy offers considerable cost saving and is thus much more attractive for manufacturing of 7075 alloy and other similar wrought alloys.

References

[1] LIM S G, YUNG Y S, KIM S S. Characteristics of rapidly solidified Al 7075-xwt.%Mn alloys [J]. Scripta Materialia, 2000, 43(12): 1077-1081.

[2] ESKIN D G, KATGERMAN. Mechanical properties in the semi-solid state and hot tearing of aluminum alloys [J]. Progress in Materials Science, 2004, 49 (5): 629-711.

[3] ATKINSON H V, KAPRANOS P, KIRKWOOD D H. Alloy development for thixoforming [C]//CHIARMETTA G L, ROSSO M. Proceedings of the Sixth International Conference on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 443-450.

[4] FLEMINGS M C. Behavior of metal alloys in the semi-solid state [J]. Metallurgical Transactions A, 1991, 22(4): 957-981.

[5] FAN Z. Semisolid metal processing [J]. International Materials Reviews, 2002, 47 (2): 1-37.

[6] CHAYONG S, ATKINSON H V, KAPRANOS P. Thixoforming 7075 aluminium alloys [J]. Materials Science and Engineering A, 2005, 390(1/2): 3-12.

[7] LIU D, ATKINSON H V, KAPRANOS P. Microstructure evolution and tensile mechanical properties of thixoformed high performance aluminum alloys [J]. Materials Science and Engineering A, 2003, 361(1/2): 213-224.

[8] KANG C G, SEO P K, JEON Y P. Thixo diecasting process for fabrication of thin-type component with wrought aluminum alloys and its formability limitation [J]. Journal of Materials Processing Technology, 2005, 160(1): 59-69.

[9] DONG J, CUI J Z, LE Q C. Liquidus semi-continuous casting, reheating and thixoforming of a wrought aluminum alloy 7075 [J]. Materials Science and Engineering A, 2003, 345(1/2): 234-242.

[10] BIROL Y. Thixoforging experiments with 6082 extrusion feedstock [J]. Journal of Alloys and Compounds, 2008, 455(1/2) 178-185.

[11] KAPRANOS P. Semi-solid metal processing—A process looking for a market [J]. Solid State Phenomena, 2008(141/143): 1-8.

[12] GUO H M, YANG X J. Efficient refinement of spherical grain by LSPSF rheocasting process [J]. Materials Science and Technology, 2008, 24(1): 55-63.

[13] OHNO A. Solidification—The separation theory and its practical applications [M]. Berlin: Springer-Verlag Press, 1987.

[14] HASHEMI H R, ASHOORI H, DAVAMI P. Microstructure and tensile properties of squeeze cast Al-Zn-Mg-Cu alloy[J]. Materials Science and Technology, 2001, 17 (6): 639-644.

[15] LUO S J, CHEN B G, QI P X. Liquid forging and squeeze casting [M]. Beijing: Chemical Industry Press, 2006. (in Chinese).

Foundation item: Projects(50804023, 50474007) supported by the National Natural Science Foundation of China; Project(GJJ08006) supported by the Jiangxi Provincial Education Department, China

Corresponding author: GUO Hong-min; Tel/Fax: +86-791-3969611; E-mail: guohongmin@ncu.edu.cn

DOI: 10.1016/S1003-6326(09)60146-1