DOI: 10.11817/j.issn.1672-7207.2015.08.015

单弓形小圆孔折流板换热器壳程流体特性

杨程,刘宏昭,龚春园,李文丽

(西安理工大学 机械与精密仪器工程学院,陕西 西安,710048)

摘 要:

本原理和周期性充分发展模型理论对换热器壳程流体进行分析。提出一种单弓形小圆孔折流板管束支撑结构,即在传统的单弓形折流板上开孔,减小传热死区和换热管束的振动。利用CFD技术对这种单弓形小圆孔折流板换热器壳程流体的流动和传热性能进行数值模拟。分析结构和操作参数对单弓形小圆孔折流板换热器综合换热性能的影响,利用多元线性回归推导其壳程压降和对流换热系数的准数关系式。研究结果表明:单弓形小圆孔折流板换热器的壳程压降、对流换热系数和综合换热性能分别为传统单弓形折流板换热器的34.25%~50.86%,73.17%~95.29%和1.438 9~2.782 2倍。

关键词:

中图分类号:TK224.1+2 文献标志码:A 文章编号:1672-7207(2015)08-2863-08

Flow and heat transfer characteristics for shell side of single bow baffle plate with small holes heat exchanger

YANG Cheng, LIU Hongzhao, GONG Chunyuan, LI Wenli

(School of Mechanical and Precision Instrument Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: The shell-side fluid of heat exchanger was analyzed based on the basic principle of hydromechanics and theory of the periodically fully developed model. A supporting structure for single bow baffle with small holes was proposed, namely holes were made on the traditional single bow baffle to reduce the heat transfer dead zone and release the vibration of the heat exchange pipes. The heat exchangers with the single bow baffle with small holes and the single bow baffle respectively were simulated through CFD. The effect of the structure and operation on the comprehensive performance for the single bow baffle with small holes heat exchanger was analyzed. Both the correlative equations of the convective heat transfer coefficient and the pressure drop were deduced through the multiple linear regression. The results show that the pressure drop of the single bow baffle with small holes heat exchanger is only 34.25%-0.86% of that of the traditional single bow baffle heat exchanger, and the convective heat transfer coefficient of the former is 73.17%-95.29% of that of the latter. Therefore, the comprehensive performance of the former is 1.438 9-2.782 2 times of that of the latter.

Key words: periodical; heat exchanger; numerical simulation; convective heat transfer coefficient; pressure drop

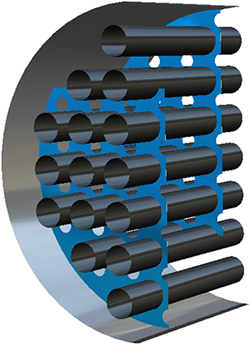

在管壳式换热器中,管束支撑结构直接影响着换热器壳程的流阻和传热性能。支撑结构不仅要能对换热管束进行有效的支撑,防止因流体的冲刷振动而导致机械损坏,还要对流体有扰动作用,以提高壳程的对流换热系数。在工艺方面还必须易加工制作,便于整个换热器的装配。因此,管壳式换热器的管束支撑结构设计一直是壳程流阻和传热研究的难点和热点。Lutcha等[1-3]提出了螺旋折流板换热器,并对其进行了系统的研究,研究表明,该换热器具有压降低、管束振动小、综合换热性能好等优点,但是制作和安装工艺非常复杂。董其伍等[4-5]对折流杆换热器的壳程建立了周期性单元流道模型,用FLUENT进行了流动和传热模拟,得出了流道内流体流动和传热的细观特征和折流栅间距的最佳取值范围。古新等[6]建立了折流杆换热器壳程周期性全截面计算模型,对壳程近壁局部区域的流场和温度进行了数值模拟,提出了换热器壳程内关键局部区域流体流动和传热状况的改善措施。Zhang等[7-8]对传统的螺旋折流板支撑结构进行了改造,对改造前后的流体流动和传热性能进行了实验和FLUENT模拟研究,并将所得结果进行了对比。Farhad等[9]采用了增强壁面函数法对不同螺旋角的螺旋折流板换热器进行FLUENT模拟并得出了其壳程压降和对流换热系数。古新等[10]提出了换热器壳程流体“斜向流”的新概念,开发出了一种斜向流换热器,并对其壳程流体的流动和传热特性进行了数值模拟,证明了这种换热器具有强化传热和降低流阻的性能。Lei等[11]对7种不同折流板倾斜角度的连续型螺旋折流板换热器进行了数值研究,得出连续型螺旋折流板的最佳倾斜角度大约为45°。王珂等[12]利用周期性模型对弓形、折流杆式和H型壳程支撑结构的换热器壳程内流体进行了分析,得出不同管束支撑结构的换热器壳程压降和对流换热系数不同的主要原因在于壳程内流体的横向流速度分量存在差别。You等[13-14]利用CFD对花隔板换热器壳程进行了数值模拟,得出了其流动和传热性能参数。Chen等[15]对一种周向重叠三分螺旋折流板换热器壳程进行了流动和传热性能研究,分析了这种换热器高效强化传热的主要机理。蒋夫花等[16]对壳程多通道管壳式换热器中并列分置管束长宽比锐减对其内部速度场和深度换热性能的影响进行了研究,提供了并列分置管束模型长宽比变化对冷热流体深度换热与壳程阻力影响程度的信息。曹小林等[17]利用FLUENT对一种新型结构形式的重力热管换热器内部的温度场和流场进行了模拟。本文作者提出一种单弓形小圆孔折流板管束支撑结构,即在传统的单弓形折流板上的换热管孔周围开小圆孔让壳程流体流过,使通过小圆孔的流体对滞流区的流体进行扰动,减小了传统的单弓形折流板换热器的传热死区,也使横向冲刷换热管的流体速度减小,减缓了管束的振动。采用FLUENT模拟对单弓形小圆孔折流板换热器的综合换热性能与传统单弓形折流板换热器的换热性能进行了对比。

1 几何模型建立与简化

1.1 结构参数

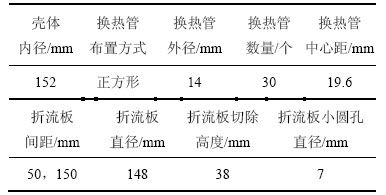

本文所研究的换热器具体结构参数如表1所示,单弓形小圆孔折流板如图1所示。

表1 换热器的结构参数

Table 1 Structure parameters of heat exchanger

图1 单弓形小圆孔折流板(单位:mm)

Fig. 1 Single bow baffle plate with small holes

1.2 模型简化

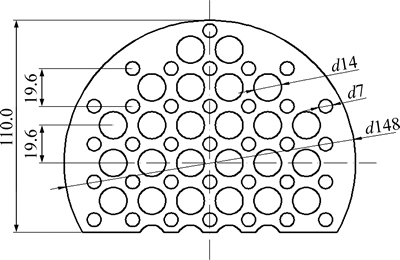

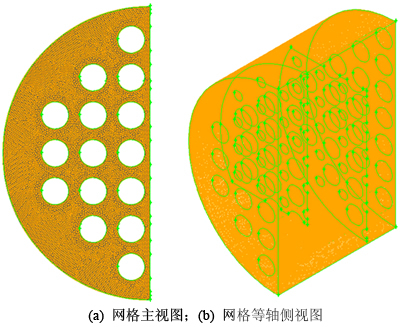

单弓形小圆孔折流板换热器壳程沿流体流动方向可分为进口段、周期性充分发展段和出口段,且换热器壳程大部分换热段处于周期性充分发展段,该区域的性能决定了换热器的整体性能[18]。根据单弓形小圆孔折流板换热器这一特点,本文采用周期性充分发展模型对单弓形折流板换热器和单弓形小圆孔折流板换热器壳程流体的流动和传热性能分别进行数值模拟,对比其传热强化机理。由于所研究换热器结构的对称性,建模时取对称的半个实体(如图2所示)。

图2 计算单元模型

Fig. 2 Model of compute unit

2 理论基础

壳程流体为水,为了建立水在管束间流动与传热的数学模型,须作以下假设:1) 流体的物性参数为常数;2) 流体为不可压缩的牛顿流体,物性为各向同性且为连续介质;3) 不考虑重力作用;4) 换热管壁面温度为常数。

2.1 控制方程

在笛卡儿坐标系中,用于计算换热器壳程流体流动和传热的控制方程[19]如下。

连续性方程:

(1)

(1)

动量方程:

(2)

(2)

能量方程:

(3)

(3)

湍流-动能方程:

(4)

(4)

其中:u,v和w分别为速度矢量v在x,y和z方向的分速度;μ为流体黏度,Pa·s;λ为流体的传热系数,W/(m·K);ρ为流体密度,kg/m3;p为压力;T为热力学温度,K;cp为流体的比定压热容,kJ/(kg·K);Su,Sv,Sw和Sh为源项;Γ为扩散系数;K为湍动能,J;G为由于平均速度梯度和浮力引起的湍动能的产生项;ε为耗散率;ΓK为湍动能的扩散系数。

2.2 周期性充分发展流动

周期性充分发展流动具有周期性的流动特性:

(5)

(5)

其中:r为位置矢量;L为考虑区域的周期性长度矢 量;n为周期数。

压力虽然不是周期性的,但是计算单元的压降Δp是周期性的:

(6)

(6)

对于常数壁面温度,当流体通过周期性区域时其温度接近壁面边界的温度,因此,温度可以用周期性来衡量。对于具有常数壁面温度的周期性流动,定义无因次温度和体积温度分别为:

(7)

(7)

(8)

(8)

其中:V为体积;A为入口周期性边界。

无因次温度 服从通过长度L的周期性条件为

服从通过长度L的周期性条件为

(9)

(9)

3 网格生成与数值计算

3.1 网格生成

利用UG建立计算单元(图2)的三维实体模型,对计算单元内部做布尔运算,即得到整个换热器的内部流域模型。利用GAMBIT对该模型进行网格划分,对3种网格间距(2.0 mm,1.0 mm,0.5 mm)分别进行计算,发现后2种网格的压降和换热系数相对误差均在2%左右,因此,考虑计算成本和精度,选择网格间距为1.0 mm进行非结构性网格划分(图3)。

3.2 数值计算与结果分析

3.2.1 求解器与边界条件设置

使用分离式求解器,稳态隐式求解。开启能量方程,选用RNG理论k-ε湍流模型,近壁节点采用壁面函数法处理[20-21]。模型的进、出口为周期性边界条件,壳体壁面和折流板采用不可渗透、无滑移绝热边界条件。设定换热管壁温度为333 K,将流体的入口温度设置为293 K,在周期性条件中设置壳程流量。压力和速度的耦合采用SIMPLE算法,动量和能量采用二次迎风格式离散。设定残差和迭代次数进行计算。所用计算机器为1台DELL工作站,配置有酷睿i5四核处理器和4 GB内存,计算1个工况需要24 h左右。对于数值方法的精度的评判标准见文献[7-9]。

图3 计算单元流域网格

Fig. 3 Grid of basin for compute unit

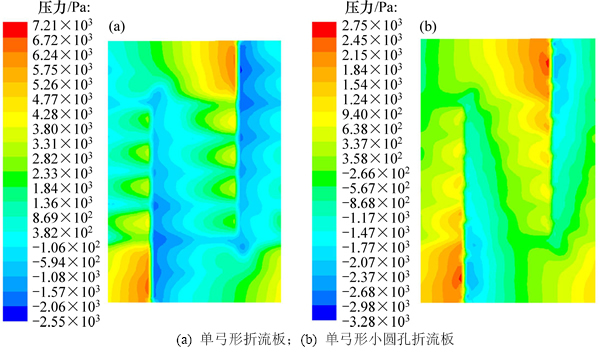

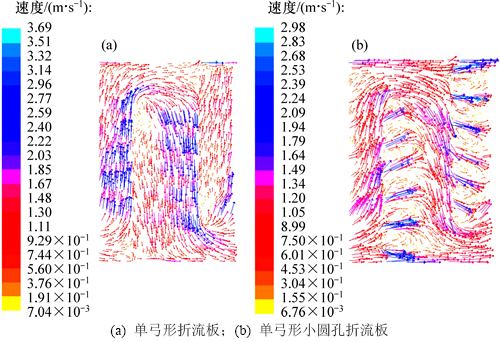

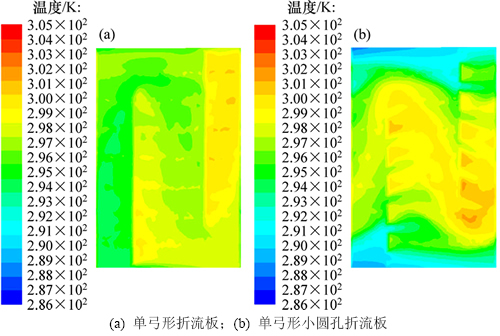

3.2.2 数值模拟结果

经过数值计算,得到了换热器壳程的压力、速度和温度分布(见图4~6)。以雷诺数Re=6 000、折流板间距Lb=50 mm为例进行说明。从图4可知:由于单弓形折流板换热器壳程的流动死区较大,因而沿流动方向的压力变化较大。而对于单弓形小圆孔折流板换热器,在半径方向压力分布较均匀,且沿流动方向的压力变化较单弓形折流板换热器的小,因而压降小。从图5可知:单弓形小圆孔折流板换热器与单弓形折流板换热器相比,基本上消除了滞流区,增大了传热区域,提高了传热效率。从图6可知:对于单弓形小圆孔折流板支撑结构,由于对流体的扰动较强,总体温度较高,因而换热较强。

图4 壳程流体的压力分布云图

Fig. 4 Pressure cloud picture of shell-side fluid

图5 壳程流体的速度矢量图

Fig. 5 Velocity vector picture of shell-side fluid

3.2.3 数据处理

数值计算在雷诺数Re为2 000~10 000内进行,每隔2 000取1个点来进行计算。压力梯度和加热功率可直接从FLUENT的计算结果中采集得到,单位长度的压降根据压力梯度和换热器长度计算得到,壳程对流换热系数h和努塞尔特数Nu分别根据式(10)和(11)计算得到:

(10)

(10)

(11)

(11)

其中:h为对流换热系数,W/(m2·K);Q为加热功率,W;S为换热面积,m2;ΔT为换热管温度和壳程流体平均温度差,K;de为壳程的当量直径,m;λ为水的导热系数,W/(m·K)。

3.2.4 模拟结果分析

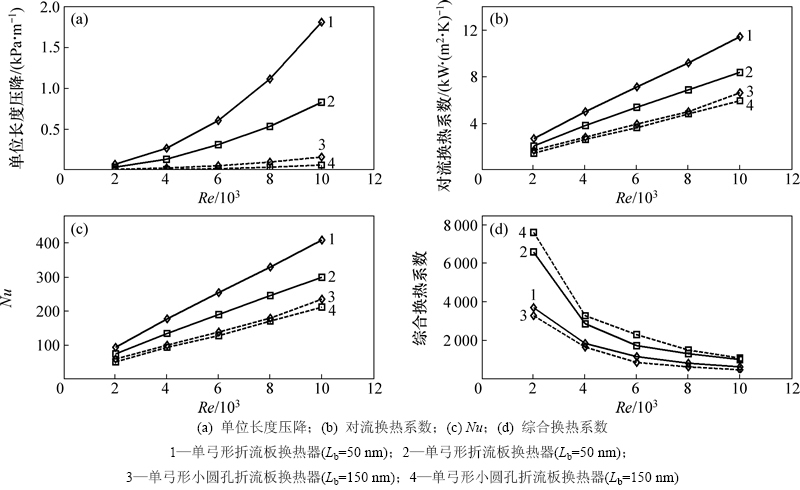

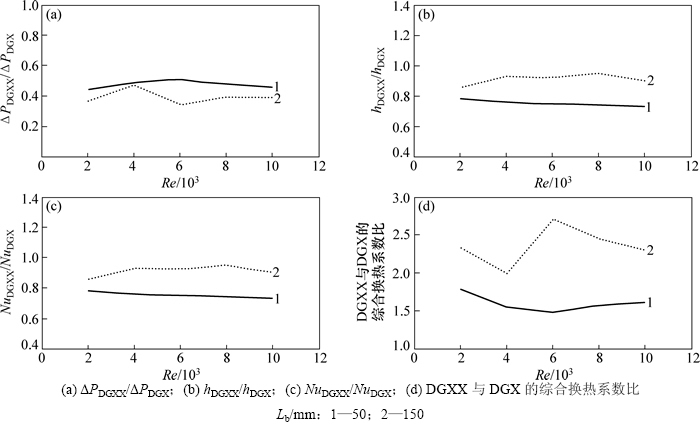

比较不同支撑结构下换热器壳程流体的流动和传热性能,并将每个模型进行比较,结果如图7所示。

图6 壳程流体的温度分布云图

Fig. 6 Temperature cloud picture of shell-side fluid

图7 换热器性能参数随雷诺数Re的变化曲线

Fig. 7 Curve of performance parameters for heat exchanger according to changing of Reynolds number

图8 换热器性能参数的相对关系随Re数的变化曲线

Fig. 8 Curve of relationship on performance parameters for heat exchanger according to changing of Reynolds number

由图7可以看出:单弓形折流板换热器和单弓形小圆孔折流板换热器的单位长度压降、对流换热系数h和努塞尔特数Nu都随雷诺数Re的增大而增大,前者的增幅大于后者的增幅;单弓形折流板换热器和单弓形小圆孔折流板的综合换热系数都随雷诺数Re的增大而减小。这都与文献[13-14]得出的实验数据趋势相同。从图7还可以看出:在折流板间距Lb相同时,单弓形小圆孔折流板的单位长度压降、对流换热系数h和努塞尔特数Nu均低于单弓形折流板换热器,而综合换热性能高于单弓形折流板换热器。

换热器性能参数的相对关系随Re数的变化曲线如图8所示,其中,DGXX代表单弓形小圆孔折流板换热器;DGX代表单弓形折流板换热器。在所研究的雷诺数范围内,单弓形小圆孔折流板换热器壳程流体的单位长度压降、对流换热系数h和Nu数分别为单弓形折流板换热器的34.25%~50.86%,73.17%~ 95.29%和73.17%~95.29%。当折流板间距Lb=50 mm时,单弓形小圆孔折流板换热器的综合换热系数为单弓形折流板换热器的1.473 8~1.783 5倍;当折流板间距Lb=150 mm时,单弓形小圆孔折流板换热器的综合换热系数为单弓形折流板换热器的1.983 8~2.439 5倍。这2种换热器的对流换热系数h相差不大,但是单弓形小圆孔折流板换热器壳程的单位长度压降仅为单弓形折流板换热器的34.25%~50.86%,因此前者的综合换热性能要优于后者的综合换热性能。

4 单弓形小圆孔折流板换热器壳程换热系数及流体压降准数关联式

经过分析,换热器壳程的对流换热系数h主要与换热器壳程的当量直径de、管壁平均温度下流体黏度μw、平均温度下的流体黏度μ、壳程流体的流速u、折流板间距Lb和小圆孔直径dx等参数有关。这些物理参数可用一般函数表达式表示:

(12)

(12)

即采用因次分析法,可得单弓形小圆孔折流板换热器壳程的换热系数的准数关系式为

(13)

(13)

式(13)也可表示为

(14)

(14)

由摩擦阻力的性质和有关研究可知:单弓形小圆孔折流板换热器壳程的压降Δp主要与换热器壳程的当量直径de、壳程流体的流速u、折流板间距Lb、流体密度ρ、平均温度下的流体黏度μ和小圆孔直径dx等参数有关。这些物理参数可用一般函数表达式表示:

(15)

(15)

单弓形小圆孔折流板换热器壳程压降的准数关系式为

(16)

(16)

式(16)也可表示为

(17)

(17)

根据文献[22],式(14)中的指数a2=1/3,a3=0.14,系数m和n以及指数a1,a4,a5,b1,b2和b3均由数值模拟结果而定。

利用最小二乘法原理,应用多元线性回归分析对数值模拟数据进行拟合,可得:

m=0.171 4,a1=0.782 1,a4=-0.334 6,a5=0.177 8,

n=147.31,b1=-4.164 2,b2=-0.984 6,b3=7.857 9。

当2 000<Re<10 000时,单弓形小圆孔折流板换热器壳程换热系数和压降的准数关系式为:

(18)

(18)

(19)

(19)

5 结论

1) 在不同折流板间距的情况下换热器壳程的单位长度压降、对流换热系数和努塞尔特数随雷诺数的增大而增大,并且单弓形小圆孔折流板换热器的增幅大于单弓形折流板换热器,综合换热系数随雷诺数的增大而减小。在所有的计算工况中,折流板间距为150 mm时,单弓形小圆孔折流板换热器的综合换热性能最好。

2) 在本文所研究的结构参数和雷诺数范围内,单弓形小圆孔折流板换热器的壳程单位长度压降和对流换热系数分别为同尺寸的单弓形折流板换热器的34.25%~50.86和73.17%~95.29%,综合换热参数为单弓形折流板换热器的1.438 9~2.782 2倍,明显提高了换热器的综合换热性能。

3) 推导了单弓形小圆孔折流板换热器壳程换热系数和压降的准数关系式,通过已知的换热器结构参数和壳程流体的物理参数就可以计算出换热器的壳程压降和换热系数,为其工程设计和推广应用提供了参考依据。

参考文献:

[1] Lutcha J, Nemcansky J. Performance improvement of tubular heat exchangers by helical baffles[J]. Chemical Engineering Research & Design, 1990, 68(3): 263-270.

[2] Stehlik P, Nemcansky J, Kral D. Comparison of correction factors for shell-and-tube heat exchangers with segmental or helical baffles[J]. Heat Transfer Engineering, 1994, 15(1): 55-65.

[3] Kral D, Stelik P, Van Der Ploeg H J, et al. Helical baffles in shell-and-tube heat exchangers, part one: Experimental verification[J]. Heat Transfer Engineering, 1996, 17(1): 93-101.

[4] 董其伍, 刘敏珊, 赵晓冬. 杆栅支撑纵流壳程换热器壳侧流体流动与传热的数值模拟[J]. 化工学报, 2006, 57(5): 1073-1078.

DONG Qiwu, LIU Minshan, ZHAO Xiaodong. Numerical simulation and research of fluid flow and heat transfer in the shellside of rod baffle heat exchanger with longitudinal flow of shellside fluid[J]. Journal of Chemical Industry and Engineering, 2006, 57(5): 1073-1078.

[5] 王永庆. 纵流壳程换热器不同支承结构壳程特性研究与分析[D]. 郑州: 郑州大学化学与能源学院, 2005: 12-20.

WANG Yongqing. Characteristic research and analysis of shellside with different support structures in heat exchangers with longitudinal flow of shell side fluid[D]. Zhengzhou: Zhengzhou University. School of Chemical Engineering and Energy, 2005: 12-20.

[6] 古新, 董其伍, 王珂. 纵流壳程换热器壳程近壁区流场和温度场数值研究[J]. 工程热物理学报, 2009, 30(4): 683-686.

GU Xin, DONG Qiwu, WANG Ke. Numerical research on flow field and temperature field of shell side near-wall region of longitudinal shell-and-tube heat exchanger[J]. Journal of Engineering Thermophysics, 2009, 30(4): 683-686.

[7] ZHANG Jianfei, HE Yaling, TAO Wenquan. 3D numerical simulation on shell-and-tube heat exchangers with middle-overlapped helical baffles and continuous baffles. Part I: Numerical model and results of whole heat exchanger with middle-overlapped helical baffles[J]. International Journal of Heat and Mass Transfer, 2009, 52(23/24): 5371-5380.

[8] ZHANG Jianfei, HE Yaling, TAO Wenquan. 3D numerical simulation on shell-and-tube heat exchangers with middle-overlapped helical baffles and continuous baffles. Part II: Simulation results of periodic model and comparison between continuous and noncontinuous helical baffles[J]. International Journal of Heat and Mass Transfer, 2009, 52(23/24): 5381-5389.

[9] Farhad N T, Sirous Z M, Kazem R, et al. Baffle space impact on the performance of helical baffle shell and tube heat exchangers[J]. Applied Thermal Engineering, 2012, 44: 143-149.

[10] 古新, 王珂, 董其伍. 基于导向型折流栅的换热器壳程强化传热数值模拟[J]. 工程热物理学报, 2010, 31(6): 1041-1044.

GU Xin, WANG Ke, DONG Qiwu. Numerical simulation on heat transfer enhancement in shell-and-tube heat exchanger with guide shutter baffles[J]. Journal of Engineering Thermophysics, 2010, 31(6): 1041-1044.

[11] LEI Yonggang, HE Yaling, LI Rui, et al. Effects of baffle inclination angle on flow and heat transfer of a heat exchanger with helical baffles[J]. Chemical Engineering and Processing: Process Intensification, 2008, 47(12): 2336-2345.

[12] 王珂, 王永庆, 董晓琳, 等. 新型管壳式换热器三维流场分析[J]. 工程热物理学报, 2011, 32(12): 2114-2116.

WANG Ke, WANG Yongqing, DONG Xiaolin, et al. Analysis of fluid flow field in shell sides of shell-and-tube heat exchanger[J]. Journal of Engineering Thermophysics, 2011, 32(12): 2114-2116.

[13] YOU Yonghua, FAN Aiwu, HUANG Suyi, et al. Numerical modeling and experimental validation of heat transfer and flow resistance on the shell side of a shell-and-tube heat exchanger with flower baffles[J]. International Journal of Heat and Mass Transfer, 2012, 55(25/26): 7561-7569.

[14] YOU Yonghua, FAN Aiwu, LAI Xuejiang, et al. Experimental and numerical investigations of shell-side thermo-hydraulic performances for shell-and-tube heat exchanger with trefoil-hole baffles[J]. Applied Thermal Engineering, 2013, 50(1): 950-956.

[15] CHEN Yaping, SHENG Yanjun, DONG Cong, et al. Numerical simulation on flow field in circumferential overlap trisection helical baffle heat exchanger[J]. Applied Thermal Engineering, 2013, 50(1): 1035-1043.

[16] 蒋夫花, 邓先和. 壳程多通道管壳式换热器中并列分置管束长宽比与深度换热[J]. 中南大学学报(自然科学版), 2011, 42(11): 3564-3571.

JIANG Fuhua, DENG Xianhe. Ratio of length to width and deep heat transfer in multi-parallel-channel shell-and-tube heat exchangers[J]. Journal of Central South University (Science and Technology), 2011, 42(11): 3564-3571.

[17] 曹小林, 曹双俊, 马卫武, 等. 新型重力热管换热器传热特性的数值模拟[J]. 中南大学学报(自然科学版), 2013, 44(4): 1689-1694.

CAO Xiaolin, CAO Shuangjun, MA Weiwu, et al. Numerical simulation on steady-state heat transfer characteristic of a novel gravity-assisted heat pipe heat exchanger[J]. Journal of Central South University (Science and Technology), 2013, 44(4): 1689-1694.

[18] DONG Qiwu, LIU Minshan, ZHAO Xiaodong. Research on the characteristic of shellside support structures of heat exchanger with longitudinal flow of shellside fluid[J]. IASME Trans, 2005, 8(2): 1491-1498.

[19] YANG Xia, ZHANG Jie, YU Jiuyang, et al. Numerical simulation on flow and heat transfer at shell-side of flat-tube heat exchangers[J]. Wuhan University Journal of Natural Sciences, 2010, 15(5): 427-432.

[20] Yakhot V. Renormalization group analysis of turbulence I: Basic theory[J]. Journal of Scientific Computing, 1986, 57(14): 1722-1724.

[21] 陶文铨. 数值传热学[M]. 2版. 西安: 西安交通大学出版社, 2001: 20-45.

TAO Wenquan. Numerical heat transfer[M]. 2nd ed. Xi’an: Xi’an Jiaotong University Press, 2001: 20-45.

[22] 古新. 管壳式换热器数值模拟与斜向流换热器研究[D]. 郑州: 郑州大学化学与能源学院, 2006: 15-30.

GU Xin. Numerical simulation of shell-and-tube heat exchanger and research on sideling-flow heat exchanger[D]. Zhengzhou: Zhengzhou University. School of Chemical Engineering and Energy, 2006: 15-30.

(编辑 赵俊)

收稿日期:2014-09-10;修回日期:2014-11-18

基金项目(Foundation item):陕西省13115重大科技专项(2009ZDKG-33)(Project (2009ZDKG-33) supported by the Shaanxi Provincial 13115 Major Science and Technology Program)

通信作者:刘宏昭,教授,博士生导师,从事机电系统建模及仿真研究;E-mail:liu-hongzhao@163.com

摘要:基于流体力学基本原理和周期性充分发展模型理论对换热器壳程流体进行分析。提出一种单弓形小圆孔折流板管束支撑结构,即在传统的单弓形折流板上开孔,减小传热死区和换热管束的振动。利用CFD技术对这种单弓形小圆孔折流板换热器壳程流体的流动和传热性能进行数值模拟。分析结构和操作参数对单弓形小圆孔折流板换热器综合换热性能的影响,利用多元线性回归推导其壳程压降和对流换热系数的准数关系式。研究结果表明:单弓形小圆孔折流板换热器的壳程压降、对流换热系数和综合换热性能分别为传统单弓形折流板换热器的34.25%~50.86%,73.17%~95.29%和1.438 9~2.782 2倍。

[4] 董其伍, 刘敏珊, 赵晓冬. 杆栅支撑纵流壳程换热器壳侧流体流动与传热的数值模拟[J]. 化工学报, 2006, 57(5): 1073-1078.

[5] 王永庆. 纵流壳程换热器不同支承结构壳程特性研究与分析[D]. 郑州: 郑州大学化学与能源学院, 2005: 12-20.

[6] 古新, 董其伍, 王珂. 纵流壳程换热器壳程近壁区流场和温度场数值研究[J]. 工程热物理学报, 2009, 30(4): 683-686.

[10] 古新, 王珂, 董其伍. 基于导向型折流栅的换热器壳程强化传热数值模拟[J]. 工程热物理学报, 2010, 31(6): 1041-1044.

[12] 王珂, 王永庆, 董晓琳, 等. 新型管壳式换热器三维流场分析[J]. 工程热物理学报, 2011, 32(12): 2114-2116.

[16] 蒋夫花, 邓先和. 壳程多通道管壳式换热器中并列分置管束长宽比与深度换热[J]. 中南大学学报(自然科学版), 2011, 42(11): 3564-3571.

[17] 曹小林, 曹双俊, 马卫武, 等. 新型重力热管换热器传热特性的数值模拟[J]. 中南大学学报(自然科学版), 2013, 44(4): 1689-1694.

[21] 陶文铨. 数值传热学[M]. 2版. 西安: 西安交通大学出版社, 2001: 20-45.

[22] 古新. 管壳式换热器数值模拟与斜向流换热器研究[D]. 郑州: 郑州大学化学与能源学院, 2006: 15-30.