文章编号:1004-0609(2011)03-0636-06

ZnO-B2O3对CaCu3Ti4O12陶瓷结构和介电性能的影响

张 程, 曾桂林, 郑兴华, 汤德平, 肖 娟

(福州大学 材料学院,福州 350108)

摘 要:

采用传统固相反应法,将ZnO-B2O3(ZB)与1 100 ℃预烧的CaCu3Ti4O12(CCTO)粉末混合烧结成陶瓷。探讨ZB对CCTO陶瓷显微结构和介电性能的影响,并进一步分析CCTO陶瓷的巨介电机理。结果表明:当添加少量ZB(w≤2%,质量分数)时,形成体心立方BCC类钙钛矿结构的CCTO单相;当w>2%时,生成Zn2TiO4杂相;当ZB的添加量为0.5%和10%时,CCTO陶瓷的介电常数明显增大,介电损耗也较高;而当ZB的添加量为1.0%~5.0%时,介电常数的变化很小,同时具有较低的损耗和良好的温度稳定性。其中,w=2%时CCTO基陶瓷具有优异的介电性能(100 kHz),即相对介电常数εr=336,介电损耗tan δ=0.018,介电常数温度系数τε=-1.5×10-5 ℃-1。ZB掺杂CCTO基陶瓷的阻抗谱表明:CCTO陶瓷由半导体化晶界和相对绝缘的晶粒构成,因此,其具有巨介电常数。

关键词:

CaCu3Ti4O12陶瓷;ZnO;B2O3;巨介电常数;温度系数;

中图分类号:TM28 文献标志码:A

Effects of ZnO-B2O3 on structure and dielectric properties of CaCu3Ti4O12 ceramics

ZHANG Cheng, ZENG Gui-lin, ZHENG Xing-hua, TANG De-ping, XIAO Juan

(College of Materials Science and Engineering, Fuzhou University, Fuzhou 350108, China)

Abstract: ZnO-B2O3 (ZB) doped CaCu3Ti4O12 (CCTO) ceramics were prepared by solid-state reaction, from the mixture of ZB and CCTO powder calcined at 1 100 ℃. The effects of ZB on the microstructure and dielectric properties of CCTO ceramics were investigated. And the dielectric mechanism with giant dielectric constant was also analyzed. The results show that CCTO ceramics with a small amount of ZB additive (w≤2%, mass fraction) is of single CCTO phase with BCC perovskite structure. Zn2TiO4 phase is detected when w is above 2%. For the CCTO ceramics with w=0.5% and 10%, the dielectric constant is enhanced obviously, while the dielectric loss is higher than that of CCTO. On the other hand, for the CCTO ceramics with 1%-5% ZB additions, the dielectric constant is nearly independent of ZB content and frequency. And they exhibit low dielectric loss and good thermal stability. Especially, CCTO ceramics with 2% ZB exhibit the excellent dielectric properties: relative dielectric constant εr=336,dielectric loss tan δ=0.018,temperature coefficient of dielectric constant τε=-1.5×10-5 ℃-1. The impedance spectra of the ZB-doped CCTO ceramics indicate that CCTO ceramics consist of semiconducting grain boundaries and insulating grains, which results in the giant dielectric constant of CCTO ceramics.

Key words: CaCu3Ti4O12 ceramics; ZnO; B2O3; giant dielectric constant; temperature coefficient

具有高介电常数、低介电损耗和近零温度系数的介质陶瓷在电容器、谐振器、滤波器及双工器等电子元器件方面具有广泛的应用。正因为如此,CaCu3Ti4O12陶瓷由于具有巨介电常数(ε≈104~105)及良好的频率和温度稳定性[1-5],使其在该领域具有潜在的应用价值。目前,对CCTO巨介电机理的研究表明,CCTO材料的巨介电响应是非本征的。SINCLAIR等[6]利用交流阻抗谱以及通过借鉴(Ba, Sr)TiO3的高介电原理,推测绝缘性晶界包裹半导性晶粒形成的异质结构的内部阻挡层电容(IBLC)是导致CCTO具有巨介电性的原因。随后,FANG等[7]通过实验发现,CCTO的巨介电性是晶界、畴及筹界形成的异质结构所致,且晶界析出的Cu离子可增大其电阻率。但NI等[8]则认为,晶界析出的Cu离子促成了半导性的晶粒边界。PRAKASH和VARMA[9]通过改变烧结温度及保温时间控制Cu相在晶界和晶粒表面的析出,发现缺Cu时阻抗谱中只出现一个半圆弧,而富Cu时存在两个明显的半圆弧。近期,FU等[10]运用原子力显微镜检测CCTO晶界和晶粒的电学性质。研究结果表明:晶界为半导性,而晶粒内部同时具有半导和绝缘的区域。迄今为止,关于CCTO内部阻挡层电容的形成,尤其是晶粒和晶界的电学性质仍没有统一的说法。另一方面,由于CCTO的异质结构和半导性,使其漏导大,损耗高,从而阻碍了它在电子元器件领域的应用。

ZnO-B2O3氧化物的软化点低,常作为低温烧结助剂[11-14]。目前,关于玻璃相添加剂对CCTO陶瓷的影响研究较少。因此,本文作者选择高温预烧的CCTO粉料,通过添加这种绝缘性的烧结助剂,在较低温度下制备CCTO基陶瓷,改变其电学性质;研究其显微结构和介电性能的变化,进一步探讨CCTO陶瓷的巨介电机理。

1 实验

采用传统的固相合成工艺,以分析纯CaCO3、CuO和TiO2粉末为原料合成CCTO。按化学计量比配料,以蒸馏水为介质球磨8 h,烘干过筛后于1 100 ℃预烧3 h,获得CCTO粉料。以质量比为1:2的ZnO和H3BO3为添加剂,将预烧后的CCTO粉料与一定质量分数的ZnO-B2O3(0.5%、1%、2%、5%、10%)混合球磨8 h,烘干过筛后添加约5% 聚乙烯(PVA)粘结剂造粒,于100 MPa下压制成直径为10 mm、厚度为(2~4) mm的圆片,再于1 000 ℃烧结保温3 h。

根据Archimedes定理,采用排水法测定烧结样品的密度。用X射线衍射仪(荷兰飞利浦X pert Pro MPD,Cu Kα,λ=0.154 06 nm,由Co靶转换)分析样品物相组成。样品表面经抛光后,在一定温度下进行热腐蚀,用场发射扫描电子显微镜 (S-4800)观察其显微结构。清洗试样并涂上银浆,于550 ℃保温1 h镀上银电极,用精密LCR仪(Agilent 4284A)测试电容、介电损耗及阻抗。

2 结果与讨论

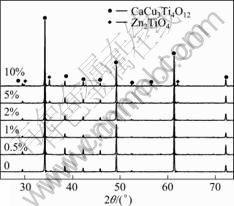

图1所示为ZB-CCTO陶瓷的XRD谱。从图1可知:当w≤2%时,形成了体心立方(BCC)类钙钛矿结构的CCTO单相;当w>2%时, 出现第二相Zn2TiO4,且随ZB添加量的增大而增大。据报道,ZB在650 ℃将出现液相[15-16]。CCTO粉料与液相共熔,可能先生成ZnTiO3,而当烧结温度高于950 ℃时,ZnTiO3分解成Zn2TiO4相[16-18]。

图1 ZB-CCTO陶瓷的XRD谱

Fig.1 XRD patterns of ZB-CCTO ceramics

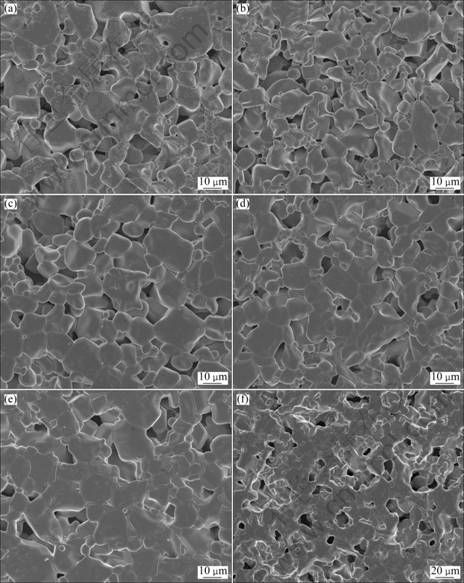

图2所示为ZB-CCTO陶瓷的显微结构。由图2可知:当添加少量ZB时,由于在烧结过程中晶粒间液相形成的毛细孔力作用较弱,颗粒重排速度较慢,导致气孔较多;随着添加量的增加,液相含量逐渐增高,有利于颗粒间的重排,因此气孔减少;但当液相过多时,液相在高温下的挥发反而使得气孔增多[19]。另外,当w≤1%,晶粒间晶界明显,且部分颗粒或晶界间有少量液态状固体存在;随着添加剂含量的增高,液态状固体变得更加显著;当w>5%时,颗粒明显地被完全包裹在液相中。

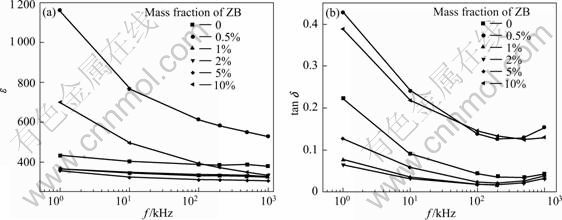

图3所示为ZB-CCTO陶瓷的介电性能与频率(f )的关系。由图3可知:当频率f>1 kHz,ZB-CCTO陶瓷的介电常数ε急剧下降;随着频率的增大,ε趋于稳定。此外,当ZB的添加量为0.5%时,ε高于600,而频率为1 kHz时可达到1 200。随着添加量的增大,ε呈减小的趋势,在整个频率范围内ε维持在300~380。

图2 不同ZB含量ZB-CCTO陶瓷的SEM像

Fig.2 SEM images of ZB-CCTO ceramics with different mass fractions of ZB: (a) 0%; (b) 0.5%; (c) 1%; (d) 2%; (e) 5%; (f) 10%

图3 ZB-CCTO陶瓷介电常数和介电损耗随频率的变化

Fig.3 Variation of dielectric constant (a) and dielectric loss (b) of ZB-CCTO ceramics with frequency

当w=10%,ε有所回复,1 kHz时约为700。而介电损耗tan δ随频率升高先减小;当f >200 kHz时, 介电tan δ随频率增加而增大;当1%≤w≤5%时,tan δ随ZB添加量的增加先减小后增大;当f为100~200 kHz时,tan δ约为0.025;而当w=0%、0.5%和10%时tan δ较大。通常,玻璃相的介电常数为6~15[20],当其存在于陶瓷中时,根据多相陶瓷介电常数的经验公式:

![]() (1)

(1)

式中:φ1和φ2分别为1和2相占材料的体积分数;εr1和εr2分别为1和2相的相对介电常数。因此,玻璃相可以降低陶瓷的介电常数。但本实验发现,ZB对CCTO陶瓷介电性能的影响并不完全符合式(1),其原因有待进一步探讨。

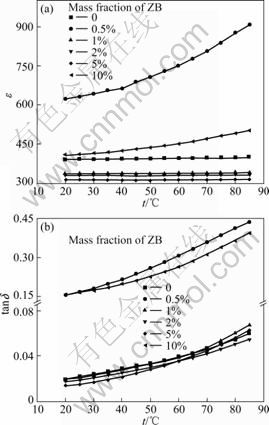

图4所示为ZB-CCTO陶瓷的介电性能随温度的变化。当w=0.5%和10%时, 试样的ε和tan δ随着温度的升高而增大,热稳定性变差;当1%≤w≤5%时,CCTO基陶瓷的介电性能随温度的变化比较平缓,热

图4 100 kHz时ZB-CCTO陶瓷介电常数和介电损耗随温度的变化

Fig.4 Variation of dielectric constant (a) and dielectric loss (b) with temperature for ZB-CCTO ceramics with different mass fractions of ZB at 100 kHz

稳定性较好。根据介电常数温度系数公式:

![]() (2)

(2)

式中:εt是温度为t时的介电常数;εt0是初始温度为t0时的介电常数。在100 kHz时,CCTO陶瓷的τε= 2.82×10-4℃-1,而当w分别为0.5%、1%和2%时,τε分别为7.09×10-3、2.16×10-4和1.54×10-5℃-1;当w分别为5%和10%,τε分别为8.05×10-5和3.617×10-3℃-1。在CCTO基陶瓷的显微结构图中,纯CCTO陶瓷与添加少量ZB的陶瓷中含有较多的气孔。添加量的增大促进了陶瓷试样的致密化。 但当添加量过多时,由于液相的挥发,又使气孔数量增多。而气孔的存在使陶瓷材料热膨胀系数α的增大,材料的温度稳定性降低。此外,添加ZB后CCTO陶瓷中出现Zn2TiO4相,且其数量随添加量的增大而增多。CCTO是具有正温度系数的介质材料,而Zn2TiO4具有负温度系数[17],因此,第二相的析出对CCTO的谐振温度系数可以起到一定的中和作用。

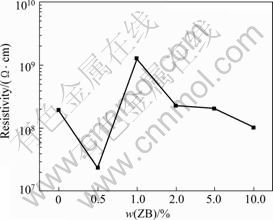

图5所示为室温时ZB-CCTO陶瓷的直流电阻率。当w≤0.5%时, 电阻率急剧减小;而当w=1%时,其电阻率达到109Ω·cm;之后,随着添加量的增多,电阻率逐渐减小;当w=10%,其直流电阻率又小于纯CCTO的。CCTO陶瓷是具有半导性的材料,因此,其介电性能的变化主要是由于电学性质的改变而造成的。添加少量ZB可以促进CCTO陶瓷的烧结,使晶粒接触紧密,从而有利于电子在晶粒间的迁移,导致电阻率的减小和漏导的增大,因此,ZB-CCTO的tan δ增大。同时,由于电子的迁移变化,温度升高时动能增大,所以,介电性能随温度的变化较大,类似于高温烧结的CCTO[9]。当适量添加ZB时(1%≤w≤5%),液相的增多阻隔了晶粒间的接触,使电阻率增大及tan δ减小;另一方面,由于电子所受束缚变大,因此,温度稳定性良好。但随着ZB的增多,大量的液相促进了晶粒的长大和重排,有利于部分晶粒间的接触,电阻率逐渐减小,因此,tan δ又有所增大且热稳定性变差。

交流阻抗谱是反映材料显微结构电学性能的有效方法。图6所示为120 ℃下ZB-CCTO陶瓷的交流阻抗谱。 ZB-CCTO陶瓷均出现了两个Cole-Cole半圆弧,说明试样中仍存在电学性质相异的IBLC,故使ε达到102以上。当1%≤w≤5%时,高频下的半圆弧逐渐增大。这与液相对颗粒的包裹有关,包裹面积增大,使电阻率增大,减弱了IBLC的作用,因此,ε减小;当w=0.5% 和10%时,其高频下的电阻率减小,而ε和tan δ增大。前人的研究结果表明:高频下的半圆弧

图5 室温时ZB-CCTO陶瓷的直流电阻率随ZB含量的 变化

Fig.5 Variation of DC resistivity of ZB-CCTO ceramics with mass fraction of ZB at room temperature

图6 120 ℃时ZB-CCTO的阻抗谱

Fig.6 Complex impedances of ZB-CCTO with different mass fraction of ZB at 120 ℃ (a) and expanding curves measured at high frequency (b)

对应半导性的晶粒,低频下的半圆弧对应绝缘的晶 界[6-7, 9]。而本实验研究发现,液相包裹颗粒后,改变了其高频下的电阻率,且这种电学性能的变化能明显影响其介电性能。因此, CCTO的巨介电性是由具有半导性的晶界和相对绝缘性的晶粒所组成的IBLC所致。另外,通过改变CCTO陶瓷的异质结构,增大其电阻率,能有效降低试样的tan δ,这与Ni等[8]的研究结果相一致。

3 结论

1) 采用固相法制备了不同ZB含量的ZB-CCTO陶瓷。当ZB含量w≥2%时,ZB-CCTO陶瓷中出现Zn2TiO4第二相,且Zn2TiO4的数量随着ZB添加量的增大而增大;当ZB掺杂量为1%≤w≤5%时, CCTO基陶瓷的ε和tan δ随频率和温度的变化平缓。

2) 添加适量ZB能实现对CCTO晶粒的包裹,增大CCTO基陶瓷的电阻率,减小漏导,从而降低损耗。

3) CCTO的巨介电性是由半导晶界和相对绝缘的晶粒构成的IBLC所致。当ZB的添加量w=2%时,CCTO基陶瓷具有良好的介电性能(100 kHz):εr=336,tan δ=0.018,τε=-1.5×10-5 ℃-1。

REFERENCES

[1] SUBRAMANIAN M A, LI D, DUAN N, REISNER B A, SLEIGHT A W. High dielectric constant in ACu3Ti4O12 and ACu3Ti3FeO12 phases[J]. J Solid State Chem, 2000, 151: 323-325.

[2] HOMES C C, VOGE T, SHAPIRO S M, WAKIMOTO S, RAMIREZ A P. Optical response of high-dielectric-constant perovskite-related oxide[J]. Science, 2001, 121: 625-629.

[3] WANG C M, KAO K S, LIN S Y, CHEN Y C, WENG S C. Processing and properties of CaCu3Ti4O12 ceramics[J]. J Phys Chem Solids, 2008, 69: 608-610.

[4] KROHNS S, LUNKENHEIMER P, EBBINGHAUS S G, LOID A. Broadband dielectric spectroscopy on single-crystalline and ceramic CaCu3Ti4O12[J]. Appl Phys Lett, 2007, 91: 022910.

[5] 倪维庆, 俞建长, 郑兴华, 梁炳亮. 烧成工艺对CaCu3Ti4O12陶瓷介电性能的影响[J].电子元件与材料, 2006, 25(10): 26-29.

NI Wei-qing, YU Jian-chang, ZHENG Xing-hua, LIANG Bing-liang. Effect of sintering process on dielectric properties of CaCu3Ti4O12 ceramics[J].Electronic Components and Materials, 2006, 25(10): 26-29.

[6] SINCLAIR D C, ADAMS T B, MORRISON F D, WEST A R. CaCu3Ti4O12: One-step internal barrier layer capacitor[J]. Appl Phys Lett, 2002, 80(12): 2153-2155.

[7] FANG T T, MEI L T, HO H F. Effects of Cu stoichiometry on the microstructures, barrier-layer structures, electrical conduction, dielectric responses, and stability of CaCu3Ti4O12[J]. Acta Mater, 2006, 54: 2867-2875.

[8] NI L, CHEN X M, LIU X Q, HOU R Z. Microstructure-dependent giant dielectric response in CaCu3Ti4O12 ceramics[J]. Solid State Commun, 2006, 139: 45-50.

[9] PRAKASH B S, VARMA K B R. The influence of the segregation of Cu-rich phase on the microstructural and impedance characteristics of CaCu3Ti4O12 ceramics[J]. J Mater Sci, 2007, 42: 7467-7477.

[10] FU D S, HIROKI H T, TMOMYASU T, MITSURU I, KOSHIHARA S Y. Origin of giant dielectric response in nonferroelectric CaCu3Ti4O12: Inhomogeneous conduction nature probed by atomic force microscopy[J]. Chem Mater, 2008, 20(5): 1694-1698.

[11] MASSEE D J, PUCEL R A, READEY D W. New low-loss, high-kappa, temperature-compensating dielectric for microwave applications[J]. Proc IEEE, 1971, 59: 1628-1629.

[12] 李胜春, 陈 培. ZnO-B2O3-P2O5低熔点玻璃的性能和结构[J]. 电子元件与材料, 2007, 26(6): 34-36.

LI Sheng-chun, CHEN Pei. Properties and structure of the ZnO-B2O3-P2O5 low-melt point glass[J]. Electronic Components and Materials, 2007, 26(6): 34-36.

[13] 熊 钢, 周东祥, 李忠明, 吴四清, 刘江华. ZnO-B2O3-Na2O玻璃对Ca[(Li1/3Nb2/3)0.8Sn0.2]O3-δ陶瓷微波介电性能的影响[J]. 陶瓷学报, 2009, 30(1): 10-13.

XIONG Gang, ZHOU Dong-xiang, LI Zhong-ming, WU Si-qing, LIU Jiang-hua. Effect of ZnO-B2O3-Na2O glass on microwave dielectric properties of Ca[(Li1/3Nb2/3)0.8Sn0.2]O3-δ ceramics[J]. Journal of Ceramics, 2009, 30(1): 10-13.

[14] KIM D W, LEE D G. Low-temperature firing and microwave dielectric properties of BaTi4O9 with Zn-B-O glass system[J]. Mater Res Bull, 2001, 36: 585-595.

[15] KASUMOVA R N, BANANYARLY S I. System ZnO·B2O3-CuO·B2O3[J]. Inorg Mater, 2005, 41(3): 279–280.

[16] DULIN F H, RASE D E. Phase equilibria in the system ZnO-TiO2[J]. J Am Ceram Soc, 1960, 43(3): 125-131.

[17] HSIEH M L, CHEN L S, WANG S M, SUN C H, WENG M H, HOUNG M P, FU S L. Low-temperature sintering of microwave dielectrics (Zn, Mg)TiO3[J]. Jpn J Appl Phys, 2005, 44(7): 5045-5048.

[18] LEE Y C, LEE W H. Effects of glass addition on microwave dielectric properties of Zn0.95Mg0.05TiO3 + 0.25TiO2 ceramics[J]. Jpn J Appl Phys, 2005, 44(4): 1838-1843.

[19] 高旭芳, 丘 泰. Bi掺杂对Ba6-3xLa8+2x(Ti0.95Zr0.05)18O54(x=2/3)陶瓷的烧结性能和介电性能的影响[J]. 中国有色金属学报, 2010, 20(3): 529-533.

GAO Xu-fang, QIU Tai. Effects of Bi doping on sintering and dielectric characteristics of Ba6-3xLa8+2x(Ti0.95Zr0.05)18O54(x=2/3) ceramics[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 529-533.

[20] TOSHIMI F, CHIHIRO S, MASAHIKD O. Preparation of Ba(Mg1/3Ta2/3)O3 ceramics as microwave dielectrics through alkoxide-hydroxide route[J]. J Mater Res, 1992, 7(7): 1883-1887.

基金项目:福建省高等学校新世纪优秀人才支持计划资助项目(XSJRC2007-16); 福建省发改委项目(827014)

收稿日期:2010-05-30;修订日期:2010-09-18

通信作者:郑兴华,副教授,博士;电话:0591-22866531; E-mail: brook76@163.com