Trans. Nonferrous Met. Soc. China 23(2013) 14-22

Effect of ruthenium on γ′ precipitation behavior and evolution in single crystal superalloys

Li-rong LIU1, Tao JIN2, Jin-lai LIU2, Xiao-feng SUN2, Zhuang-qi HU2

1. School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110870, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

Received 19 October 2011; accepted 30 March 2012

Abstract:

The effect of Ru on γ′ precipitation behavior and evolution in single crystal superalloys with different Ru contents were investigated by scanning electron microscopy with energy dispersive spectroscopy, 3D atomic probing, differential scanning calorimetry. The results show that the solvus of the γ′ phase decreases gradually with increasing Ru content in the alloys by casting or by the same solution and aging treatments, the alloy with a larger Ru content yields a smaller γ′ phase. The addition of Ru increases the growth rate and coarsening rate of the γ′ phase. Ru mainly distributes in the γ phase, which causes more Re and Mo partition into the γ′ phase, increasing the absolute value of mismatch and the rafting rate of the γ′ phase.

Key words:

single crystal superalloy; ruthenium; gamma prime; precipitation; growth rate; coarsening rate; mismatch;

1 Introduction

The excellent high-temperature performance of the Ni-based single superalloys is mostly due to the strengthening precipitates, thus, the control of the amount, size, morphology and distribution of phases to improve the strength and plasticity of alloys by heat treatment and tailoring alloy compositions is critical [1-3]. Generally, the volume fraction of the γ′ phase is 60%-70% in a single crystal superalloy. The outstanding high-temperature mechanical properties of alloys benefit from the addition of a number of refractory alloying elements. Therefore, γ′ precipitation behavior and evolution obtained by adding alloying elements are important for improving the temperature capability of alloys.

Many researchers have studied the effect of Ru on the microstructure of single crystal superalloys; however, there are some controversial points. For example, MA et al [4] found that 3% Ru content has no effect on the suppression of the topological closed packed (TCP) phase of single crystal superalloys with high contents of refractory alloying elements. It was pointed out that Ru could suppress the precipitation of the TCP phase [5,6]. Some researchers [7-9] indicated that the partition behavior of alloying element is not affected by the addition of Ru. CARROLL et al [10] maintained that Ru causes matrix-forming element partitioning in the γ′ phase. Reports on the evolution of the γ′ phase in Ru-containing single crystal superalloys are infrequent. Therefore, in the present work, the effects of Ru on γ′ the precipitation behaviors and evolution in single crystal superalloys are investigated in detail.

2 Experimental

The experimental single crystal superalloys used in the current investigation included three alloys containing different Ru contents (0, 1.5%, and 3% in mass fraction). The nominal compositions of tested alloys are listed in Table 1. The three alloys were designated as 0Ru alloy, 1.5Ru alloy, and 3Ru alloy, respectively. Single crystal bars with dimensions of d16 mm×160 mm were produced in the <001> direction by the screw selection method, with a mould drawing rate of 6 mm/min in a directional solidification vacuum induction furnace. Differential scanning calorimetry (DSC) was performed on the samples to determine the transformation temperatures in the as-cast and heat-treated samples. To investigate the effect of heat treatment on the γ′ phase evolution of the three alloys, different solution and aging treatments were proceeded. A 3-D atom probe (3DAP) was used to determine the alloying element partitioning between the γ and γ′ phases in the heat-treated samples. In order to lower the alloy element segregation, the 3DAP samples were solution heat-treated for a long time shown in Table 2 and then aged at 1120 °C for 4 h and 899 °C for 20 h. Three samples were analyzed for each alloy. To study the γ′ phase coarsening behavior at high temperatures, the specimens were exposed to a temperature of 1100 °C for 200 h. The γ′ phase morphologies of the as-cast, heat-treated, and long-term exposed samples were analyzed by scanning electron microscopy (SEM). The mean sizes of the γ′ particles were measured by quantitative metallography, and at least 500 γ′ particles were measured under each condition. The average sizes of the samples (denoted by “a”) were utilized. For cuboidal and global γ′ particles, “a” was designated as the edge length or the diameter.

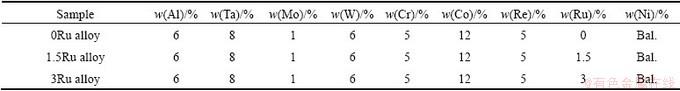

Table 1 Nominal compositions of tested alloys

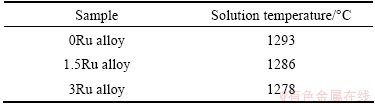

Table 2 Solution treatment conditions of three alloys with different contents of ruthenium

3 Results and discussion

3.1 Morphology of γ′phase in as-cast alloys

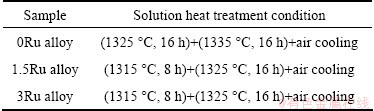

Under the same solidification condition, the three alloys with different Ru contents solidify as dendrite structures, which consist of dendrite core, dendrite arm, and interdendritic region. Some γ/γ′ eutectics are observed in the interdendritic region of the three alloys. Figure 1 shows the γ′ phases in the dendrite cores and interdendritic regions in three alloys in the as-cast state. In all three alloys, the size of the γ′ phase in the dendrite core is smaller than that in the interdendritic region. The size of the γ′ phase decreases slightly with increasing Ru content.

During the directional solidification under steady-state condition, the mushy zone is comprised of the single phase γ dendrites and the liquid phase. The alloying elements addition in the Ni-based superalloys tends to partitioning preferentially into either the γ phase or the γ′ phase; thus, the limited solubility of γ′-forming elements exists within the single phase dendrites during the solidification, and elements such as Ta and Al are enriched in the liquid phase. The other alloying element addition, Re, W, Cr, Co, Mo, or Ru, is soluble in the γ phase and tends to partition preferentially into γ dendrites during the solidification. After the termination of solidification, the solid continues to cool. While cooling from the solidus temperature, the supersaturation of the γ phase with Al and Ta could occur as the solubility limits are exceeded. Thus, the γ′ phase rich in Al and Ta would precipitate from the supersaturated γ phase.

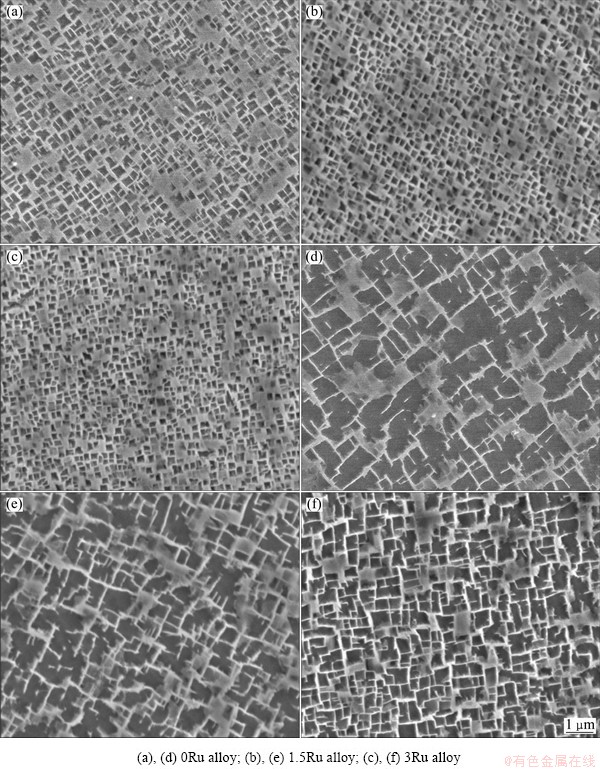

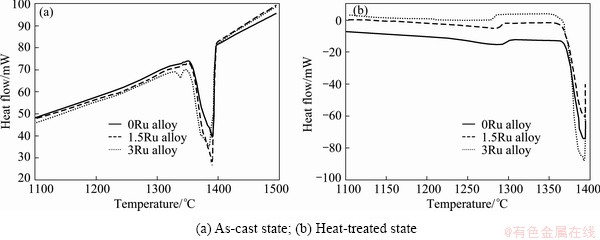

Figure 2(a) shows the DSC heating curves of the three alloys in the as-cast state with different Ru contents. Three endothermic peaks in the heating curves of each alloy are observed. The first gentle peak near 1250 °C corresponds to the endothermic peak of the γ′ phase solution. In single crystal superalloys, the γ /γ′ eutectic is the last region to solidify, so the incipient melting is defined as the melting temperature of the γ /γ′ eutectic, which corresponds to the second peak in the heating curves. The main peak shows the exothermic peak for the melting of the γ phase.

Due to the segregation of the alloying elements in the dendrite structure, the compositions of the γ′ phase in the dendrite core and interdendritic region are not identical, and the precipitation or solution of the γ′ phase occurs over a large temperature range. Moreover, the γ′ phase precipitation from the γ matrix belongs to coherent precipitation, therefore, the transformation process needs less absorption of heat. Consequently, the slope of the endothermic peak of the γ′ phase is gentle and almost unobservable in Fig. 2(a). To study the effect of Ru on the solution temperature of the γ′ phase, fully heat-treated samples were analyzed by DSC, as shown in Fig. 2(b). The DSC curves show two endothermic peaks: one is for the solution of the γ′ phase, and its peak value is listed in Table 3; the other is for the melting of the γ phase. From the position of the peaks, the solution temperature of the γ′ phase decreases with increasing Ru content.

The earlier the γ′ phase precipitates, the lower the γ′ solubility limit is. From the above results, we can deduce that Ru increases the solubility limits of Al and Ta in the γ phase. In the 0Ru alloy, the γ′ phase precipitates earliest, whereas the γ′ phase in the 3Ru alloy precipitates latest. Because the γ′phase in the Ru-containing single crystal superalloys precipitates later, compared with the 0Ru alloy. The γ′ particles in alloys with Ru cannot grow sufficiently during quick cooling. As a result, the γ′ particles in the 3Ru alloy are smaller than those in the 0Ru alloy, as shown in Fig. 1.

Fig. 1 SEM images showing γ′ morphology in dentrite cores (a, b, c) and in interdentritic regions (d, e, f) of as-cast single crystal superalloys with different Ru contents

Fig. 2 DSC heating curves of three alloys with different Ru contents

Table 3 Solution temperatures of γ′ phase for three alloys with different contents of ruthenium

3.2 Microstructure after solution treatment

According to the DSC curves in Fig. 2(a), the solution heating treatment condition of three alloys were scheduled as shown in Table 3. After the high temperature solution treatment, the γ /γ′ eutectic and coarse γ′ in the interdendritic region were dissolved.

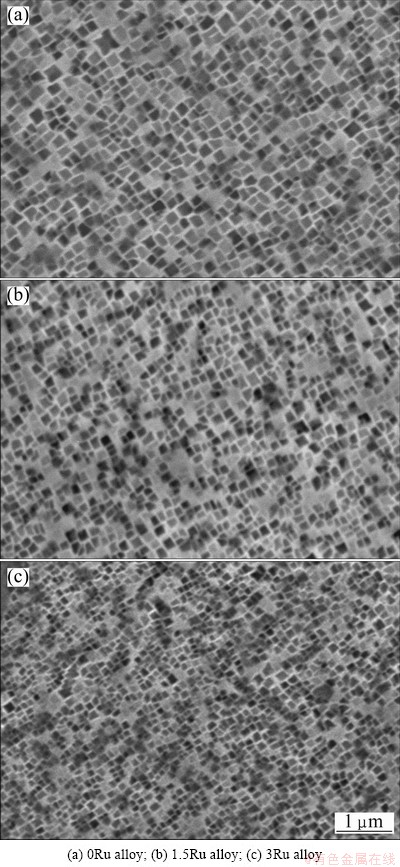

Figure 3 shows the morphology of the γ′ phase in the three alloys with different Ru contents after the solution treatment. All the γ′ phases of the three alloys are cubic in shape. With increasing Ru content, the size of the γ′ phase decreases from 200 nm in the 0Ru alloy to 120 nm in the 3Ru alloy. The γ′ phase precipitates from a supersaturated solution as it cools from the solution treatment. As mentioned in Section 3.1, Ru decreases the solubility of the γ′ phase, therefore when cooled from the solid solution temperature, the γ′ phase in the 0Ru alloy precipitates from the γ matrix earlier than the others, and the size of the γ′ particles in the 3Ru alloy is smaller compared with the 0Ru alloy.

3.3 γ′ phase morphology after aging treatment

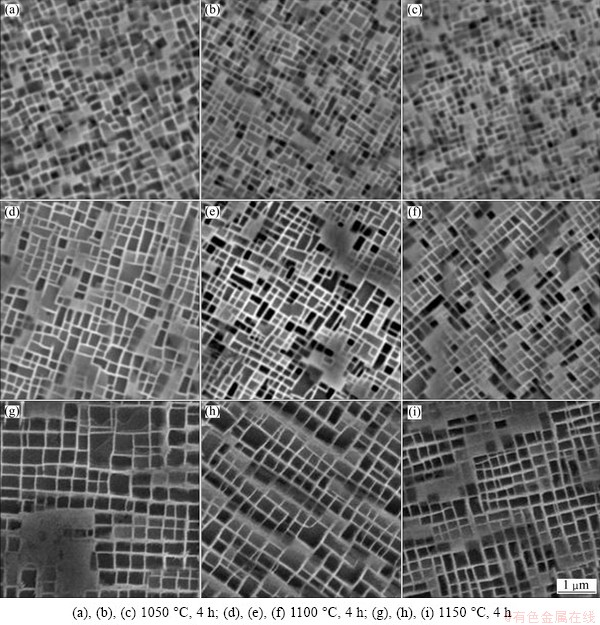

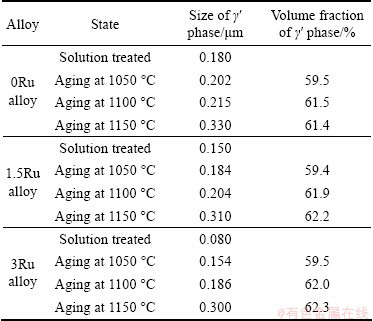

Figure 4 shows the morphology of the γ′ phase in the three alloys after aging for 4 h at different temperatures. The morphology of the γ′ particles in the three alloys under different temperatures all appears cubic in shape. By quantitative metallographic analysis, the volume fraction and the size of γ′ phase under different conditions were counted and listed in Table 4. From the data in Table 4, we can conclude that under the condition of 1050 °C for 4 h, the volume fraction of γ′ phase did not reach equilibrium. In the process, the growth of γ′ phase is mainly transformation process. If there is any residual supersaturation left in the γ phase, the γ′ will grow rapidly until the γ′ equilibrium volume fraction is attained. Once the equilibrium volume fraction of γ′ is reached, then coarsening occurs to minimize the interfacial energies. During aging above 1100 °C, the volume fraction of γ′ phase has no obvious change, which is close to the equilibrium volume of γ′ phase. Therefore, during the aging treatment above 1100 °C, γ′ phase mainly undergoes the growth and coarsening. In this process, it is difficult to distinguish the growth from coarsening of the γ′ phase. For each alloy, the γ′ size increases with increasing aging temperature, and decreases with increasing Ru content. Table 4 shows that at the same temperature, the 3Ru alloy has the smallest γ′ particles.

Fig. 3 SEM images showing morphology of γ′ phase of three alloys with different Ru contents after solution treatment

From the above results, the size of the γ′ phase decreases with increasing Ru content by not only solution treatment, but also by aging treatment. Ru appears to suppress the growth of γ′ particles. Other studies [11] provided the same conclusion. However, when statistics and analysis on the γ′ phase size under different conditions are conducted, Ru is found to be unable to suppress the growth of the γ′ phase; on the contrary, Ru increases the growth rate of the γ′ phase. This conclusion can be confirmed by the results in the following section.

Fig. 4 SEM images showing morphology of γ′ phase in 0Ru alloy (a, d, g), 1.5Ru alloy (b, e, h) and 3Ru alloy (c, f, i) with different Ru contents after aging heat treatment at different temperatures

Table 4 Size and volume fraction of γ′ particles after aging heat treatment for 4 h at different temperatures

In LSW [12] theory, if the growth of the γ′ precipitates is diffusion-controlled, formula (1) will be valid.

(1)

(1)

where  is the initial particle radius;

is the initial particle radius;  is the instantaneous particle radius; k is the growth rate; t is the growth time. Research on the growth of the γ′ phase [13,14] shows that the growth of a single γ′ phase is controlled by diffusion. Evidently,

is the instantaneous particle radius; k is the growth rate; t is the growth time. Research on the growth of the γ′ phase [13,14] shows that the growth of a single γ′ phase is controlled by diffusion. Evidently,  =

= /2 and

/2 and  = a0/2, where

= a0/2, where  represents the mean length of the side of a cubic γ′ particle after aging for different time, and

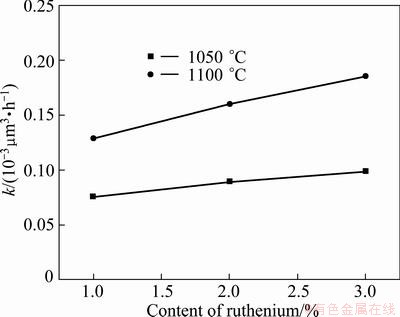

represents the mean length of the side of a cubic γ′ particle after aging for different time, and  is the mean length of the side of the cubic γ′ after solution treatment. By Eq.(1), the k value is calculated and marked in Fig. 5. With increasing Ru content, the growth rate of all the γ′ phases increases, and a larger Ru content corresponds to a higher growth rate.

is the mean length of the side of the cubic γ′ after solution treatment. By Eq.(1), the k value is calculated and marked in Fig. 5. With increasing Ru content, the growth rate of all the γ′ phases increases, and a larger Ru content corresponds to a higher growth rate.

Fig. 5 Relationship between growth rate of γ′ particles and Ru content

3.4 Coarsening of γ′ phase during long-term thermal exposure

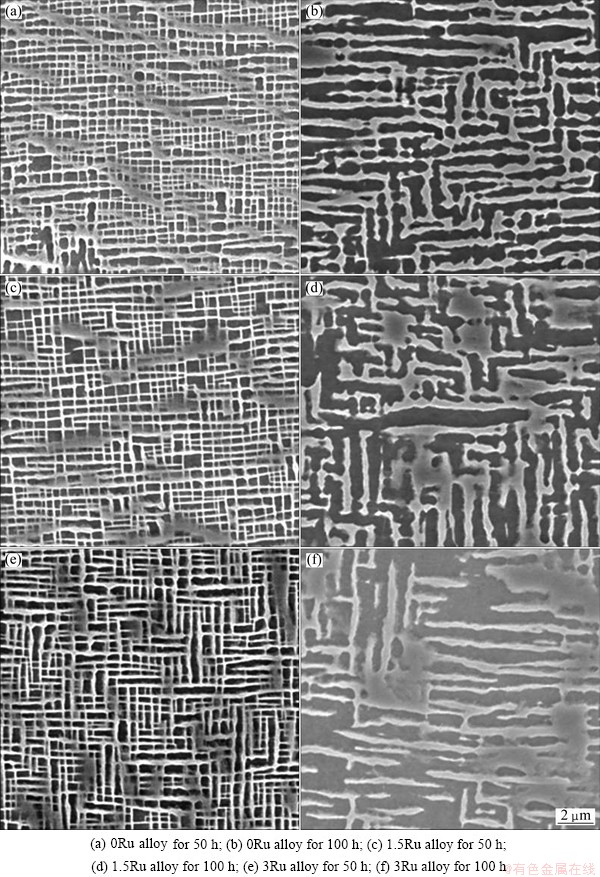

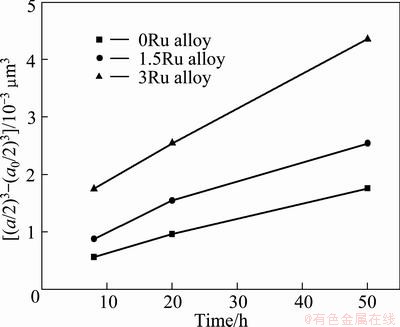

The coarsening of γ′ phase occurs during the long-term thermal exposure in three alloys with different Ru contents, as shown in Fig. 6. In 50 h, the γ′ phase particles remain cubic in shape. After 100 h, γ′ phase particles begin to link and rafts form, which is different from the single γ′ particle. The sizes of the γ′ phase after long-term aging at different time were measured, and the plots of (a/2)3–(a0/2)3 versus t are constructed.

Fig. 6 SEM images showing morphology of γ′ phases after long-term thermal exposure for different time at 1100 °C

Fig. 7 Relationship between coarsening rate of γ′ particles and Ru content

Figure 7 shows the excellent linear fitting of the γ′ growth rates of the 0Ru, 1.5Ru, and 3Ru alloys at 1100 °C. The linear slope is related to the diffusion coefficient. Figure 7 indicates that the slopes vary with the Ru content, and that a higher Ru content corresponds to a larger slope and more rapid γ′ coarsening. The only difference in the three alloys is their Ru content. Thus, it may be concluded that the addition of Ru accelerates the coarsening of the γ′ phase.

Figure 6 shows that after 50 h long-term thermal exposure, the γ′ phases of the three alloys retain their cubic shape. After 100 h, some γ′ particles of the 0Ru alloy transform into links and rafts, while the γ′ particles of the 3Ru alloy form rafts. Thus, the addition of Ru increases the tendency of the alloys to raft.

3.5 Partition of alloying elements in γ and γ′ phases

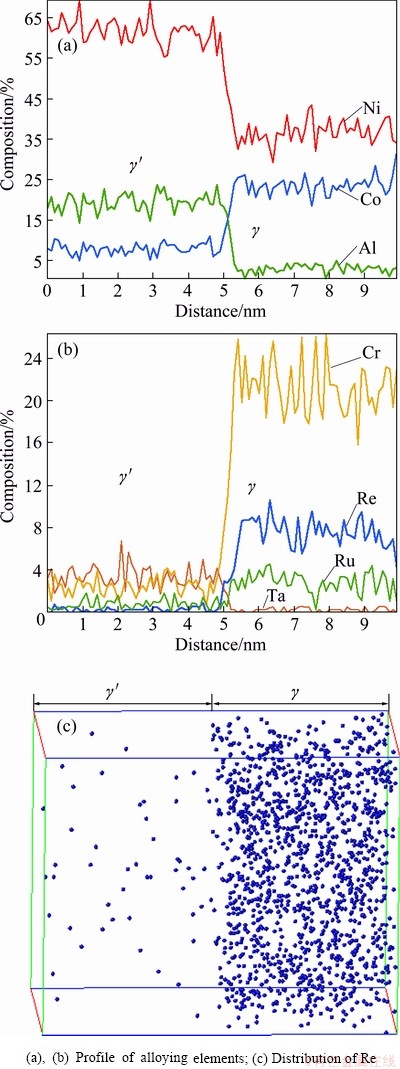

To analyze the effect of Ru on the composition of the γ′ phase, 3DAP was used to measure the compositions of the γ and γ′ phases. The 3DAP results show that the distribution behaviors of the alloying elements in the γ and γ′ phases are similar in the three alloys with different Ru contents, that is, the elements Re, W, Mo, Cr, Co, and Ru tend to enrich in the γ phase, and the elements Ta, Al, and Ni tend to partition in the γ′ phase, as shown in Fig. 8.

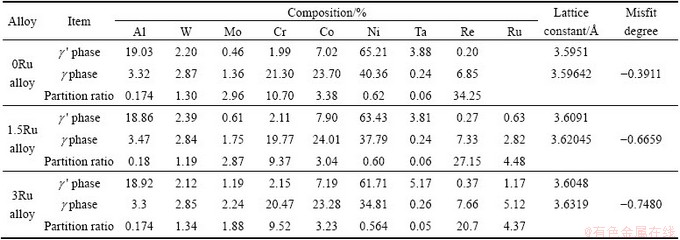

In these elements, Re has the strongest segregation tendency in the γ phase. The elements Cr, Mo, Co, and W have smaller segregation tendency, and Ru has the smallest segregation tendency in the γ phase. Ta and Al show stronger partition tendency to γ′ than Ni. The partition ratios in the γ and γ′ phases are calculated by Eq. (2). The atom mole fraction of each element in the alloys, as well as their partition ratios, are listed in Table 5.

ki=xiy'/xiy (2)

where ki is the partition coefficient of element I; xiy is the concentration of element i in the γ phase; and xiy' is the concentration of element i in the γ′ phase. The addition of Ru does not change the distribution character of the elements, but it changes their partition coefficients. From the above analysis, it may be concluded that the addition of Ru could cause more γ matrix-forming elements, such as Re, W, and Mo, to enter the γ′ phase, which is consistent with the reverse partitioning first reported by O’HARA et al [11]. However, our results show no obvious changes in the partitioning tendencies of the γ′ phase-forming elements Al and Ta.

Fig. 8 Distribution of alloying elements in γ and γ′ phases for 1.5Ru alloy measured by 3DAP

It was pointed out that the low diffusion coefficient of Re could inhibit the growth of the γ′ phase [15]. Re is a γ matrix-forming element whose concentration in the γ′ phase is very low. Therefore, the higher the concentration of Re in the γ matrix is, the stronger the inhibition to γ′ phase growth is. While the tested alloys contain the same mass fraction of Re, as mentioned above, Ru causes more Re to enter the γ′ phase. That is, with increasing Ru content, the concentration of Re in the γ matrix decreases. The low coefficient of Re and its low partition ratio in the γ phase are the main reasons for the increase in the growth rate of the γ′ phase in Ru-containing single crystal superalloys with increasing Ru content.

Table 5 Influence of Ru addition on distribution behavior of elements in three alloys

Using the phase composition obtained by 3DAP, the lattice constants of the γ′ and γ phases are estimated by the following equations [3]:

aγ=3.524+0.0196CCo+0.110CCr+0.478CMo+0.444CW+ 0.441CRe+0.3125CRu+0.179CAl+0.422CTi+0.7CTa+ 0.7CNb

aγ ′=3.57-0.004C′Cr+0.208C′Mo+0.194C′W+0.262C′Re+0.1335C′Ru+0.258C′Ti+0.5C′Ta+0.46C′Nb

The calculated lattice constants of the γ′ (aγ ') and γ (aγ) phases of the three alloys, as well as their mismatch (δ), are calculated by Eq. (3) and listed in Table 5.

δ=2(aγ ′ – aγ ′)/(aγ ′+aγ ′) (3)

The lattice constants of the γ and γ′ phases increase with increasing Ru addition, but the increase in amplitude of the γ matrix is larger than that of the γ′ phase. As a result, the absolute value of the misfits is enlarged. Therefore, Ru could enhance the tendency of alloys to raft.

4 Conclusions

1) The sizes of the γ′ phase in alloys in the as-cast state, including the dendrite core and interdendritic region, decrease with increasing Ru content.

2) Ru decreases the solution temperature of the γ′ phase. After solid solution treatment, the alloy with larger Ru content yields a smaller γ′ phase.

3) During the aging treatment at different temperatures, all the γ′ particles retain a cubic shape. For each alloy, the size of the γ′ particles increases with increasing temperature; at the same aging temperature, the size of the γ′ particles decreases with increasing Ru content.

4) Ru mainly distributes in the γ phase. It promotes the distribution of more matrix-forming elements, such as Re and Mo, into the γ′ phase.

5) During the aging treatment, the addition of Ru accelerates the growth and coarsening of the γ′ phase.

References

[1] HOBBS R A, ZHANG L, RAE C M F, TIN S. TCP suppression in a ruthenium bearing single crystal nickel-based superalloy [J]. JOM, 2008, 60: 37-42.

[2] CARROLL L J, FENG Q, MANSFIELD J F. High refractory, low misfit Ru-containing single-crystal superalloys [J]. Metalurgical and Materials Transactions A, 2006, 37: 2927-2938.

[3] CARON P. High γ′ solvus new generation nickel-based superalloys for single crystal turbine blade applications [C]// Superalloys 2000. Warrendale, PA: TMS, 2000: 737-746.

[4] MA W Y, LI S S, HAN Y F. Effect of Ru on microstructure of a single crystal nickel-base superalloy [J]. Materials Science Forum, 2007, 546-549: 1195-2000.

[5] CUI C Y, GU Y F, PING D H, HARADA H, OSAWA M, SATO A. Effects of Ru additions on the microstructure and phase stability of Ni-base superalloy UDIMET 720Li [J]. Metall Mater Trans A, 2006, 37: 355-360.

[6] WANG W B, FENG Q, CARROLL L J, WANG Y L, CHEN γ L, POLLOCK T M. Influence of Ru and Cr on the heat-treated microstructure of Ni-based superalloys [J]. Materials Science Forum, 2007, 546-549: 1207-1210.

[7] YOKOKAWA T, OSAWA, M, NISHIDA K, KOIZUMI Y, KOBAYASHI T, HARADA H. Effect of Ru addition to partitioning behavior of alloying elements into γ and γ′ phases of Ni-base superalloys [J]. Journal of the Japan Institute of Metals, 2004, 68: 138-141.

[8] VOLEK A, PYCZAK F, SINGER R F. Partitioning of Re between γ′ and γ phase in nickel-base superalloys [J]. Scripta Materialia, 2005, 52: 141-145.

[9] TIN S, YEH A C, OFORI A P, REED R C, BABU S S, MILLER M, KTIN S, YEH A C, OFORI A P. Atomic partitioning of ruthenium in Ni-based superalloys [C]// Superalloys 2004. New York: TMS, 2004: 735-741.

[10] CARROLL L J, FENG Q, MANSFIELD J F, POLLOCK T M. Elemental partitioning in Ru-containing nickel-base single crystal superalloys [J]. Materials Science and Engineering A, 2007, 457: 292-299.

[11] O’HARA K, WALSTON W S, ROSS E W. Nickel base superalloy and article: International Patent application 5.482.789 [P]. 1996-01-09.

[12] VANDERMOLEN E H , OBLAK J M, KRIEGE O H. Control of γ′ particle size and volume fraction in the high temperature superalloy Udimet 700 [J]. Metall Trans, 1971, 2: 1627-1633.

[13] WANG W Z, JIN T, LIU J L, SUN, X F, GUAN H R, HU Z Q. Role of Re and Co on microstructures and γ′ coarsening in single crystal superalloys [J]. Materials Science and Engineering A, 2008, 479: 148-156.

[14] LIU L R, JIN T, ZHAO N R, SUN, X F, GUAN H R, HU Z Q. Microstructural evolution of a single crystal nickel-base superalloy during thermal exposure [J]. Materials Letters, 2003, 57: 4540-4546.

[15] ROWLAND L J, FENG Q, POLLOCK T M. Microstructural stability and creep of Ru-containing nickel-base superalloys [C]// GREEN K A, POLLOCK T M, HARADA H. Superalloys 2004. New York: TMS, 2004: 697-706.

Ru对单晶高温合金中γ′相析出行为和演化的影响

刘丽荣1, 金 涛2, 刘金来2, 孙晓峰2, 胡壮麒2

1. 沈阳工业大学 材料科学与工程学院,沈阳 110870;

2. 中国科学院金属研究所,沈阳 110016

摘 要:采用扫描电镜、3D原子探针、示差热分析等方法研究了合金元素Ru对单晶高温合金中γ′相的析出和演化过程的影响。研究结果表明:γ′的溶解温度随着Ru含量的增加而逐渐降低。铸态下以及固溶处理和时效处理后,γ′相尺寸都随着Ru含量的增加而减小。Ru的加入加快了γ′相的长大和粗化速率,Ru主要分布在γ′基体中。Ru的加入使更多的Mo和Re等元素向γ′相分配,导致错配度的绝对值增大,同时加快γ′相的形筏速率。

关键词:单晶高温合金;钌;γ′相;析出;长大速率;粗化速率;错配度

(Edited by Hua YANG)

Foundation item: Project (U1037601) supported by the National Natural Science Foundation of China

Corresponding author: Li-rong LIU; Tel: +86-24-25691530; Fax: +86-24-25496768; E-mail: lrliu866@sohu.com

DOI: 10.1016/S1003-6326(13)62423-1

Abstract: The effect of Ru on γ′ precipitation behavior and evolution in single crystal superalloys with different Ru contents were investigated by scanning electron microscopy with energy dispersive spectroscopy, 3D atomic probing, differential scanning calorimetry. The results show that the solvus of the γ′ phase decreases gradually with increasing Ru content in the alloys by casting or by the same solution and aging treatments, the alloy with a larger Ru content yields a smaller γ′ phase. The addition of Ru increases the growth rate and coarsening rate of the γ′ phase. Ru mainly distributes in the γ phase, which causes more Re and Mo partition into the γ′ phase, increasing the absolute value of mismatch and the rafting rate of the γ′ phase.