文章编号:1004-0609(2007)09-1404-06

基于裂纹柔度法的铝合金预拉伸板内部残余应力测试

唐志涛,刘战强,艾 兴,万 熠

(山东大学 机械工程学院,济南 250061)

摘 要:

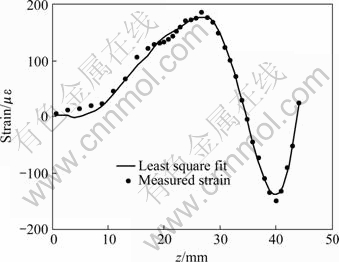

采用裂纹柔度法测试残余应力时,柔度函数的计算和插值函数阶数的合理选择对计算结果的精确性有着较大影响。采用有限元法计算得到测试试样的裂纹柔度函数;考虑应力计算不确定度两个主要的来源:应变测量数据的随机误差以及模型误差,基于应力总不确定度的最小化目标,确定最优的插值函数阶数,进而计算得到铝合金预拉伸板7050-T7451内部残余应力的分布规律。结果表明:采用9阶勒让德多项式能较好地拟合此铝合金板材内部残余应力的分布,不确定度的均方根值为2.797 MPa,预拉伸板内部残余应力呈明显的外压内拉的“M型曲线”分布规律。

关键词:

中图分类号:TB 11; TG 146.2 文献标识码:A

Measuring residual stresses depth profile in pre-stretched aluminum alloy plate using crack compliance method

TANG Zhi-tao, LIU Zhan-qiang, AI Xing, WAN Yi

(School of Mechanical Engineering, Shandong University, Ji’nan 250061, China)

Abstract: In the evaluation of the residual stresses by the crack compliance method, the calculation of compliance functions and the choice of the order of interpolation function are important to calculation results. The compliance functions were calculated by using finite element method. An optimal expansion order was obtained based on minimizing the total stress uncertainty which was evaluated by considering the two main sources in the calculation of stress uncertainty: the random errors in strain data and model error. Then the residual stress depth profiles in pre-stretched aluminum alloy plate 7050-T7451 were determined. The results reveal that Legendre polynomials that the fit order is 9 can evaluate accurately through-thickness residual stresses of thick plate, and the root-mean-square average over uncertainty is only 2.797 MPa. It is also shown that the residual stresses distribution in pre-stretched aluminum alloy plate can be revealed by “M type curves”, that is, the exteriors are residual compressive stress and the interiors are residual tensile stress.

Key words: series expansion; residual stresses; crack compliance method; pre-stretched aluminum alloy plate; uncertainty

航空整体结构件通常采用高强度变形铝合金厚板直接铣削加工而成,在加工过程中,由于毛坯初始残余应力的释放与重分布而引起的加工变形问题,已成为我国航空整体结构件制造中的关键技术难点之一。为分析与预测残余应力引起的加工变形,必须首先测量铝合金厚板内部残余应力的分布情况[1]。裂纹柔度法作为一种残余应力测试的新技术,与逐层钻孔法、X射线衍射法及剥层法相比,具有很好的灵敏性和精确度,且费用较低,特别适合测量各种热(冷)轧厚板的内部残余应力分布[2]。

裂纹柔度法由Vaidyanathan和Finnie在1971年首次提出[3],最初采用光弹性涂层法测量裂纹不同深度处的应力强度因子来计算残余应力,但光弹性试验较为繁琐复杂。到了1985年,Cheng和Finnie[4?8]采用应变片测量应变或者位移,代替用光弹性技术测量应力强度因子,使试验与计算过程大大简捷。Prime[9]最早将裂纹柔度法用于铝合金厚板中残余应力的测试。之后,王秋成[2]、王树宏[1]、张旦闻[9]等人分别采用该方法对7075铝合金板中的残余应力进行了检测。然而,在这些人的研究中,没有对插值函数阶数的选择及柔度函数的详细计算过程进行探讨,它们对计算结果的精确性有着较大的影响。本文作者采用有限元法计算得到了测试试样的裂纹柔度函数,考虑了应力不确定度两个主要的来源,基于应力总不确定度的最小化目标确定了最优的插值函数阶数,进而计算得到了45 mm厚铝合金预拉伸板7050-T7451内部残余应力的分布规律。

1 测量原理及基本理论

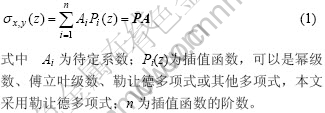

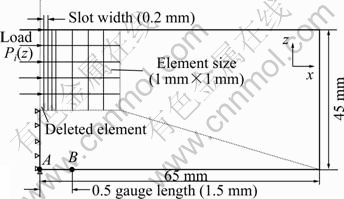

裂纹柔度法的测量原理是在被测物体的表面引入一条深度逐渐增加的裂纹来释放残余应力,通过测量对应不同裂纹深度的指定点处的应变值来计算残余应力。铝合金预拉伸板的长度和宽度远远大于其厚度,板的轧制变形、淬火、拉伸、时效等条件均对称于板中面[11],因此假定残余应力σx,y(z)沿板的长度、宽度方向均匀分布,仅沿厚度方向(z向)变化,其分布为深度坐标z的函数,如图1所示,可表示为一个级数展开[9]:

为了确定上述级数扩展中的待定系数Ai,首先要计算图1所示应变片位置上的应变随裂纹深度aj变化的响应值Cij,Cij被称为柔度函数。根据叠加原理,该应变也可表示为一个级数展开:

![]()

图1 裂纹柔度法测试原理图

Fig.1 Schematic diagram of crack compliance method

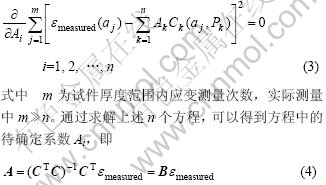

为了减小计算误差,根据柔度函数计算得到的应变值与实验得到的应变数据,采用最小二乘法拟合,有

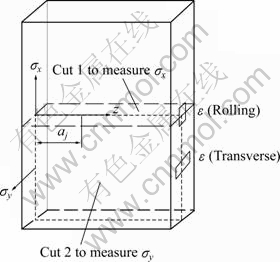

2 实验

测试试样选用美国ALCOA公司生产的高强度变形铝合金板7050-T7451,T7451表示材料的状态,即热轧后进行固溶处理,然后在规定的时间内沿轧制方向进行1.5%~3%拉伸塑性变形,再进行时效处理。从规格为915 mm×265 mm×45 mm的板材截取尺寸为92 mm×130 mm×45 mm的试样3块,分别用于测量铝合金板沿轧制方向和横向残余应力沿板厚的分布。

试样裂纹的引入可采用锯割和铣削等加工方法获得 [12]。本实验采用电火花线切割的方法,设备使用苏州金马生产的DK7725型数控线切割机床,电极丝为d 0.15 mm的钼丝,切割后的裂缝宽度约为0.2 mm。应变片选用BHF120-3AA高精密级箔式环氧酚醛类电阻应变片,敏感栅的尺寸为3 mm×2 mm,切割位置和应变片粘贴位置如图1所示。为防止工作乳液对应变片的破坏,在应变片表面涂上一层704硅橡胶防护。采用半桥接线法进行组桥,以实现温度的补偿。沿板厚方向切割深度![]() 每增加1 mm,用SDY2101型动态应变仪进行读数,待应变仪的读数稳定在一定范围内,记录读数对其求平均值,算得的应变值如图2所示。

每增加1 mm,用SDY2101型动态应变仪进行读数,待应变仪的读数稳定在一定范围内,记录读数对其求平均值,算得的应变值如图2所示。

图2 实验测得的应变值

Fig.2 Measured strains by WEDM test

3 裂纹柔度函数计算

裂纹柔度函数矩阵Cij可以用断裂力学解析法、体力法以及有限元法或其它数值方法进行求解[12]。本文采用ABAQUS6.5 有限元软件来分析计算。步骤如下。

第一步,如图3所示,根据试样的对称性,仅需以线切割的裂缝为对称轴将半个试样网格化,采用八节点平面应变单元CPE8,工件左边网格间距恰为裂缝宽度,值为0.2 mm,其余的网格间距为1 mm。工件左边x方向位移自由度受到约束,端点A的x方向与z方向的位移自由度均受到约束。材料的弹性模量为71.7 GPa,泊松比为0.33。

图3 有限元网格划分及边界条件施加示意图

Fig.3 Diagram of mesh generation and application of boundary conditions

第二步,采用Compad Visual Fortran6.0编写用户子程序DLOAD,将2~12阶勒让德多项式Pi(z)分别作为初始应力载荷沿板的厚度方向加载。

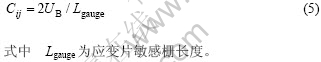

第三步,在模型上通过对裂缝处单元的去除来模拟裂纹的逐步扩展,同时输出应变片所在位置的节点A、B位移值,其应变值根据式(5)计算,即可得到2~12阶裂纹柔度函数,如图4(a)和图4(b)所示,其中,图4(a)为偶数阶裂纹柔度函数,图4(b)为奇数阶裂纹柔度函数。

图4 测试试样的裂纹柔度函数(沿轧制方向)

Fig.4 Crack compliance functions of test sample (in rolling direction)

4 不确定度评定

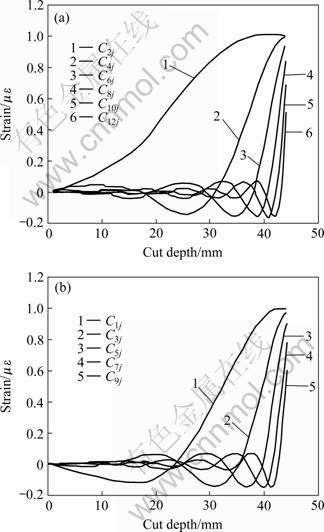

采用裂纹柔度法进行残余应力计算时,应力计算的不确定度有2个主要的来源[13]。一个是来自应变测量数据的随机误差。图5所示为插值函数选用9阶勒让德多项式时,采用最小二乘法得到的应变随层深的分布曲线与实验测得的应变值的拟合情况,两者的偏差是应力计算不确定的来源之一。另一个为模型误差,当选择的级数扩展不能很好地拟合板中实际应力分布情况而引起的误差称为模型误差。插值函数选定后,插值函数阶数的选择是该误差的主要来源。基于应力总不确定度的最小化目标,可以确定最佳的插值函数收敛阶数。

图5 由柔度函数计算得到的应变与实测值的拟合曲线

Fig.5 Measured and predicted strain curve by least square fit (in rolling direction)

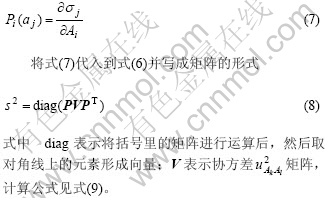

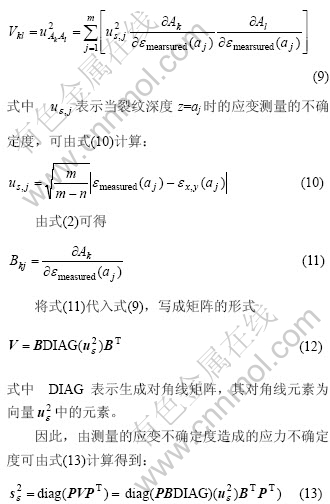

对于采用级数扩展表达的应力形式,现有文献的解析计算公式大都忽略了拟合系数间协方差项,从而导致当扩展阶数增加时,计算结果越来越不精确。本文在不确定度的传递公式中增加了协方差项,其应力不确定度传递的一般公式为

考虑测量的应变不确定度,系数Ai的协方差矩阵为

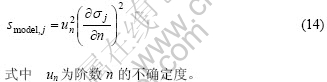

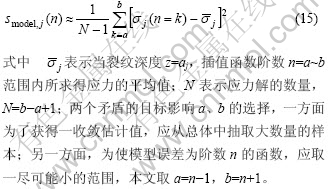

在计算模型误差引起的应力不确定度时,插值函数的阶数n是其内在不确定性的主要因素。因此,由阶数n的不确定度造成的应力不确定度sm,j的计算公式为[15]

由于它不是实验测得的量,很难估计其不确定度。在这里将其近似等于应力计算的标准偏差,如式(15)所示:

所以,残余应力计算总不确定度 stotal,j为

![]()

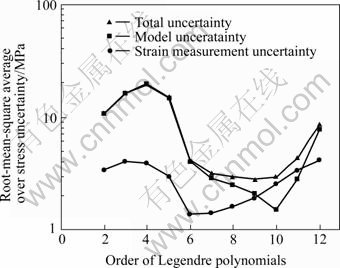

在Matlab7.1中根据式(13)、(15)、(16)进行编程计算,得到不同阶数的每一层深aj三种应力计算不确定度,对其求均方根,得到不同阶数的应力计算的不确定度的均方根值,如图6所示。从中可以看出,当勒让德多项式的阶数取9时,对应的应力计算的总不确定度的值最小,约为2.797 MPa,表明9阶勒让德多项式是拟合此板应力分布一种理想的插值函数。

图6 不同阶数三种应力不确定度的均方根值

Fig.6 Root-mean-square average over stress uncertainty for different expansion orders

5 测试结果

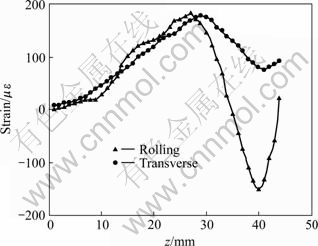

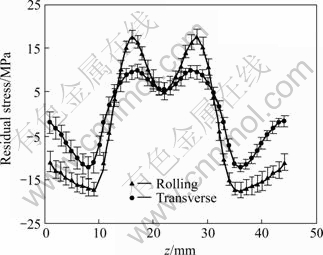

采用9阶勒让德多项式作为插值函数,在Matlab7.1 中对上述残余应力计算公式进行编程求解,得到45 mm厚铝合金预拉伸板7050-T7451内部残余应力分布及总不确定度,如图7所示。

图7 45 mm厚铝合金预拉伸板7050T7451内部残余应力的分布

Fig.7 Residual stress depth profiles in pre-stretched aluminum alloy plate 7050T7451

1) 无论是轧制方向还是横向,残余应力沿厚度方向的分布曲线规律相似,呈明显的外压内拉的“M型曲线”分布规律。残余应力沿板的中面对称分布,且在板的中面出现局部的残余拉应力的最小值。横向的残余应力平均值约为轧制方向的70%左右。

2) 无论是轧制方向还是横向,残余压应力的最大值不在板的表面,而在距板的表面约1/5板厚处,轧制方向的残余压应力的最大值约为?17.2 MPa,横向的最大值约为?12.3 MPa。同样,残余拉应力的最大值不在板的中面,而在距板的中面约1/8板厚处,轧制方向的最大值约为17.6 MPa,横向的最大值约为9.7 MPa。

3) 虽然铝合金预拉伸板内部的应力值较低,但裂纹柔度法能较好地拟合此铝合金预拉伸板内部残余应力的分布规律。当扩展阶数为9时,不确定度的均方根植约为2.797 MPa。

[1] 王树宏, 马康民, 马 骏. 预拉伸铝合金板7075T7351内部残余应力分布测试[J]. 空军工程大学学报, 2004, 5(3): 19?21.

WANG Shu-hong, MA Kang-min, MA Jun. Method of measuring the residual stress distribution in pre-stretched aluminum alloy plate 7075T7351[J]. Journal of Air Force Engineering University(Natural Science Edition), 2004, 5(3): 19?21.

[2] 王秋成, 柯映林, 章巧芳. 7075铝合金板材残余应力深度梯度的评估[J]. 航空学报, 2003, 24(4): 336?338.

WANG Qiu-cheng, KE Ying-lin, ZHANG Qiao-fang. Evaluation of residual stress depth profiling in 7075 aluminum alloy plates [J]. Acta Aeronautica et Astronautica Sinica, 2003, 24(4): 336?338.

[3] Vaidyanathan S, Finnie I. Determination of residual stresses from stress intensity factor measurements[J]. Journal of Basic Engineering, 1971, 93: 242?246.

[4] Cheng W, Finnie I. A method for measurement of axisymmetric residual stresses in circumferentially weld thin-walled cylinders[J]. Journal of Engineering Materials and Technology, 1985, 107: 181?185.

[5] Cheng W, Finnie I. Measurement of residual hoop stress in cylinders using the compliance method[J]. Journal of Engineering Materials and Technology, 1986, 108: 87?92.

[6] Cheng W, Finnie I. The crack compliance method for residual stresses measurement[J]. Welding in the World, 1990, 28: 103?110.

[7] Cheng W, Finnie I. Measurement of residual stress distributions near the toe of an attachment welded on a plate using the crack compliance method[J]. Engineering Fracture Mechanics, 1993, 46: 79?91.

[8] Cheng W, Finnie I. The single slice method for measurement of axisymmetirc residual stresses in solid rods or hollow cylinders in the region of plane strain [J]. Journal of Engineering Materials and Technology, 1998, 120: 170?176.

[9] Prime M B, Hill M R. Residual stress, stress relief, and inhomogeneity in aluminum plate[J]. Scripta Materialia, 2002, 46(1): 77?82.

[10] 张旦闻, 刘宏昭, 刘 平. 裂纹柔度法在7075铝合金板残余应力检测中的应用[J]. 材料热处理学报, 2006, 27(2): 127?131.

ZHANG Dan-wen, LIU Hong-zhao, LIU Ping. Evaluation of residual stresses in 7075 aluminum alloy plate using crack compliance method [J]. Transactions of Materials and Heat Treatment, 2006, 27(2): 127?131.

[11] 董辉跃, 柯映林. 7075铝合金厚板预拉伸模拟分析及其在淬火残余应力消除中的应用[J]. 中国有色金属学报, 2004, 14(4): 639?645.

DONG Hui-yue, KE Ying-lin. Pre-stretching process and its application in reducing residual stress of quenched 7075 aluminum alloy thick plates[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 639?645.

[12] Prime M B. Residual stress measurement by successive extension of a slot: the crack compliance method [J]. Applied Mechanics Review, 1999, 52(2): 75?96.

[13] Prime M B, Hill M R. Uncertainty analysis, model error, and order selection for series-expanded, residual stress inverse solutions[J]. Journal of Engineering Materials and Technology, 2006, 128(2): 175?185.

[14] Prime M B, Gnaupel-Herold T, Baumann J, Lederich R J, Bowden D M, Sebring R J. Residual stress measurement in a thick dissimilar aluminum alloy friction stir weld[J]. Acta Materialia, 2006, 54(15): 4013?4021.

[15] Schajer G S, Prime M B. Use of inverse solutions for residual stress measurements[J]. Journal of Engineering Materials and Technology, 2006, 128(3): 375?382.

基金项目:国家自然科学基金重点资助项目(50435020)

收稿日期:2007-01-10;修订日期:2007-07-13

通讯作者:唐志涛;电话:0531-88392045;E-mail: tztcentury@163.com

(编辑 袁赛前)