文章编号:1004-0609(2010)S1-s0224-05

热轧钛基复合材料的微观组织和力学性能

郭相龙,李九霄,王立强,覃继宁,吕维洁,张 荻

(上海交通大学 金属基复合材料国家重点实验室,上海 200240)

摘 要:

利用Ti和LaB6之间的化学反应,采用真空自耗电弧炉3次重熔制得TiB和La2O3增强的钛基复合材料,测得其相变点为1 045 ℃,然后经高温(1 100~1 050 ℃)锻造成板坯。在1 010 ℃对材料进行热轧,然后空冷,利用光学显微镜和扫描电镜研究变形量分别为40%、60%、80%、90%和95%时复合材料的显微组织和拉伸试样断口形貌。结果表明:当变形量到达到80%时,材料的强度一直上升,伸长率下降;变形量继续增大后,强度有所下降,伸长率提高。

关键词:

中图分类号:TG339 文献标志码:A

Microstructure and mechanical properties of hot-rolled titanium matrix composite

GUO Xiang-long, LI Jiu-xiao, WANG Li-qiang, QIN Ji-ning, L? Wei-jie, ZHANG Di

(State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: Utilizing the reaction between Ti and LaB6, titanium matrix composite (TMC) plate reinforced with TiB and La2O3 was prepared by casting trice and hot-forging, its transformation temperature measured was 1 045 ℃. The TMC was rolled at 1 010 ℃, then air-cooled. The microstructure and fracture surfaces were studied by OM and SEM at deformation amount of 40%, 60%, 80%, 90% and 95%. The results show that when the deformation amount reaches 80%, the strength of the composite material keeps on increasing, whereas the elongation decreases. However, if the deformation amount increases more, the strength of the material decreases slightly, and the elongation increases.

Key words: titanium matrix composite; hot-rolling; deformation amount; microstructure; room-temperature mechanical properties

非连续增强的钛基复合材料具有较好的高温力学性能及抗蠕变性能,已得到广泛研究[1-3]。采用原位自生的方法可以获得非连续增强的钛基复合材料,并且在采用原位自生方法获得的材料中,增强体和基体之间的界面干净无污染[4-9]。然而,加入增强体后,复合材料的变形能力变差,这增加了复合材料的制造成本,并且加大了复合材料的应用难度[10-12]。热加工既可以解决材料的成型问题、节约材料,又可以改变材料的原始铸态组织,提高材料的性能。目前,对材料热加工的研究集中于加工温度对对材料组织及各种性能的影响[13-15],但是,变形率对材料性能的影响的研究却很少,由于变形率对材料的组织和力学性能的影响显著,所以本文作者针对这一问题进行了研究。

1 实验

复合材料的熔炼在真空自耗电弧炉中进行,为了保证化学成分的均匀性,制备过程中采用3次熔炼。材料具体制备方法如下:首先按比例称取海绵钛(一级)、LaB6化合物、合金元素以及各种中间合金,将其混合均匀;接着利用压机将混合均匀的原料压制成电极棒;然后将电极放入真空自耗电弧炉中进行一次熔炼,获得一次锭;再用同样的方法熔炼3次,获得三次锭。

通过控制添加剂LaB6的含量来控制复合材料中增强体的体积分数。假设12Ti+2LaB6+3[O]→12TiB+ La2O3的化学反应进行完全,且忽略B、La在Ti基体中较低的固溶度,可根据各相的密度估算出增强体TiB和La2O3的名义体积分数分别为1.82%和0.58%。其中,基体合金的化学成分与高温钛合金IMI834的相同。由于B、La在Ti基体中的固溶度均极低,材料中增强体的体积分数与实际体积分数比较接近。采用光学金相法测定了耐热钛基复合材料的α+β→β相变点为1 045 ℃。将三次锭在1 100~1 050 ℃锻造成板坯,然后在1 010 ℃进行变形量分别为40%、60%、80%、90%和95%的轧制。

从板材上切取轧面的金相试样,用莱卡金相显微镜LEICA(MEF4A/M)拍摄材料的金相照片。拉伸试样直接从热轧板材上切取,拉伸方向与轧制方向相同,应变速率为10-3 s-1,试样的尺寸为15 mm×4 mm×1.5 mm。断口在JSM-6460扫描电镜上进行观察。

2 结果与讨论

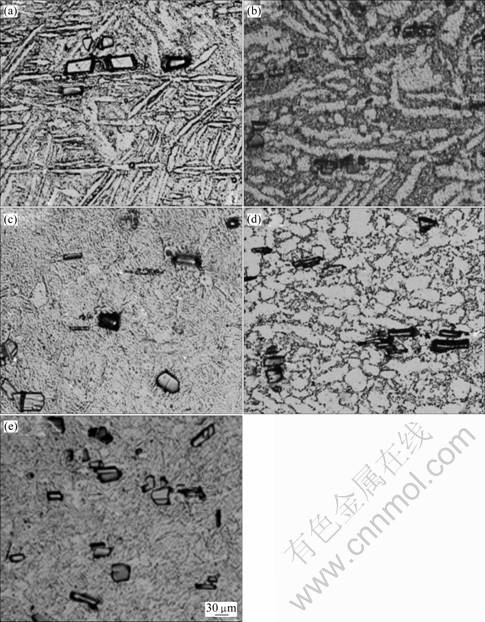

图1所示为在1010℃经不同变形量热轧后钛基复合材料的金相照片。由于随着变形量的增加,α相与β相会出现回复和再结晶,因此,变形量影响α相与β相的大小和形态从而改变复合材料变形后的组织。不同的变形量对材料的组织的影响如图1所示。从图1(a)可知,当变形量为40%的时候,变形后的组织为高温锻造结束后α层片状组织;随着变形量的加大(见图1(b)和(c)),α片的形状改变,α层片在轧制方向上被拉长,形成大小不均匀,形状不统一的α相组合,并且图1(c)中可见一定数量的纤维组织;当变形量达到90%的时候(见图1(d)),变形的α片动态再结晶,形成等轴状的α晶粒;变形继续加大(见图1(e)),材料中出现更加细小的等轴α晶粒和层片状的α组合。金相照片显示,材料中TiB增强体沿热轧的方向分布,与基体的结合良好。

图1 经不同变形量热轧后钛基复合材料的金相照片

Fig.1 Optical micrographs of hot-rolled composite with deformation amounts of 40%(a), 60%(b), 80%(c), 90%(d), 95%(e)

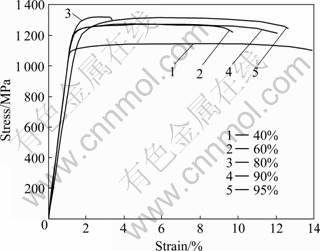

图2所示为不同变形量后材料的室温拉伸应力—应变曲线。不同变形量下材料的各项室温拉伸性能如表1所列。从图2和表1可以看出,随着加工率的提高,材料的断裂伸长率先降低后提高,而材料的室温强度却是先提高后降低。在特定的变形率下,材料的性能实现了强度和断裂韧性的兼顾。材料的热加工过程是一个加工硬化和回复再结晶同时进行的过程,当加工率比较低时,材料中加工硬化起到主要的作用,所以材料的强度上升,伸长率下降,当加工率超过80%的时候,由于变形量增大,回复再结晶过程加剧,缓解了因加工硬化造成的塑性和韧性的下降,所以材料的伸长率增大,强度有所下降。在复合材料中,TiB增强体起到主要的强化作用,根据“剪滞”模型的理论,材料中的长径比较大的增强体可以有效地提高复合材料的强度,这也是复合材料的室温强度比较高的原因。

图2 不同变形量下复合材料的室温应力—应变曲线

Fig.2 Stress—strain curves of titanium matrix composites with different deformation amounts at room temperature

表1 不同变形量下复合材料的室温拉伸性能

Table 1 Mechanical properties of titanium matrix composite with different deformation amounts

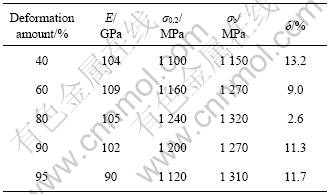

图3所示为复合材料在不同变形量下的室温拉伸断口的SEM像。从图3可以看出,除了变形量为80%的材料外,其他变形量下材料的端口中均有大量的韧窝,这说明材料以韧性断裂为主,对应的复合材料伸长率比较高。在80%变形量下,试样断口中出现的河流状花样,这表明材料的断裂属于脆性的解理断裂,因此在该变形量下,材料的塑性较差,这与室温拉伸应力—应变曲线的结果是一致的。此外,在不同变形量下复合材料的断口中,发现许多TiB纤维被抽离而形成的黑洞,这表明在材料的断裂中,TiB纤维断裂,起到承受载荷的效果。

3 结论

1) 采用原位自生的方法可以获得TiB和La2O3增强的钛基复合材料,经过热加工之后,增强体和基体的结合完好。

2) 在热加工过程中,随着加工变形量的加大,材料的强度先上升后下降,而伸长率先下降后上升,这是由于热加工的初始阶段,材料中加工硬化起到主要的作用,所以材料的强度上升,塑性下降;当热加工率继续上升时,材料中回复和再结晶充分进行,消除了加工硬化的影响,所以材料的塑性提高,强度下降。

3) TiB纤维作为材料中的主要增强体,可以起到承载的作用,使得复合材料的强度比基体的有了很大的提高。

图3 在不同变形量下复合材料室温拉伸断口的SEM像

Fig.3 SEM images of tensile fracture surfaces of samples at different deformation amounts: (a) 40%; (b) 60%; (c) 80%; (d) 90%; (e) 95%

REFERENCES

[1] RANGANATH S. A review on particulate-reinforced titanium matrix composites[J]. J Mater Sci, 1997, 32(1): 1-16.

[2] XIAO Lü, L? Wei-jie, QIN Ji-ning, CHEN Yi-fei, ZHANG Di, WANG Min-min, ZHU Feng, JI Bo. Creep behaviors and stress regions of hybrid reinforced high temperature titanium matrix composite[J]. Composites Science and Technology, 2009, 69: 1925-1931.

[3] XIAO Lü, L? Wei-jie, QIN Ji-ning, CHEN Yi-fei, ZHANG Di, WANG Min-min, ZHU Feng, JI Bo. Steady state creep of in-situ TiB plus La2O3 reinforced high temperature titanium matrix composite[J]. Materials Science and Engineering A, 2009, 499(1/2): 500-506.

[4] RANGANATH S, VIJAYAKUMAR M, SUBRAHMANYAN J. Combustion-assisted synthesis of Ti-TiB-TiC composite via the casting route[J]. Materials Science and Engineering A, 1992, 149(2): 253-357.

[5] BANERJEE R, GENC A, COLLINS P C, FRASER H L. Comparison of microstructural evolution in laser-deposited and arc-melted in situ Ti-TiB composites[J]. Metallurgical and Materials Transactions A, 2004, 35(7): 2143-2152.

[6] SRIVATSAN T S, SOBOYEJO W O, LEDERICH R J. Tensile deformation and fracture behavior of a titanium-alloy metal-matrix composite[J]. Composites A, 1997, 28(4): 365-376.

[7] LI B S, SHANG J L, GUO J J, FU H Z. In situ observation of fracture behavior of in situ TiBw/Ti composites[J]. Materials Science and Engineering A, 2004, 383(2): 316-322.

[8] L? Wei-jie, ZHANG Xiao-nong, ZHANG Di, WU Ren-jie, BIAN Yu-jun, FANG Ping-wei. Microstructure and mechanical properties of in-situ TiC and TiB reinforced TMC[J]. Chinese Journal of Nonferrous Metals, 2000, 10(2): 163-169.

[9] L? Wei-jie, ZHANG Di, ZHANG Xiao-nong, WU Ren-jie, SAKATA T, MORI H. Microstructural characterization of TiB in in situ synthesized titanium matrix composites prepared by common casting technique[J]. Journal of Alloys and Compounds, 2001, 327(1/2): 240-247.

[10] BOYER R, COLLINGS E W, WELSCH G E. Materials properties handbook[M]. Materials Park, OH: ASM International, 1994: 488.

[11] MA Feng-cang, L? Wei-jie, QIN Ji-ning , ZHANG Di , JI Bo. Effect of forging and heat treatment on the microstructure of in situ TiC/Ti-1100 composites[J]. Journal of Alloys and Compounds, 2007, 428: 332-337.

[12] MA Feng-cang, L? Wei-jie, QIN Ji-ning, ZHANG Di. Hot deformation behavior of in situ synthesized Ti-1100 composite reinforced with 5 vol.% TiC particles[J]. Materials Letters, 2006, 60: 400-405.

[13] CROAN L S, RIZZITANA F J. WAL report 401/268[R]. Watertown Arsend Laboratories, Mass, 1958.

[14] RANGANATH S, VIJAYAKUMAR M, SUBRAHMANYAM J. Combustion-assisted synthesis of Ti-TiB-TiC composite via the casting[J]. Materials Science and Engineering A, 1992, A149: 253-257.

[15] SOBOYEJO W O, LEDERICH R J, SASTRY S M L. Mechanical behavior of damage tolerant TiB whisker-reinforced in situ titanium matrix composites[J]. Acta Metallurgica et Materialia, 1994, 42(8): 2579-2591.

基金项目:国家重点基础研究发展计划资助项目(2007CB613806);国家自然科学基金资助项目(50871066);教育部新世纪优秀人才支持计划资助项目(NCET-07-0549);上海市启明星计划资助项目(09QH1401400)

收稿日期:2010-06-20;修订日期:2010-07-30

通信作者:吕维洁,教授,博士;电话:021-34202039;E-mail: luweijie@sjtu.edu.cn