J. Cent. South Univ. (2021) 28: 1679-1691

DOI: https://doi.org/10.1007/s11771-021-4726-6

One-step random-walk process of nanoparticles in cement-based materials

Ali BAHARI1, Aref SADEGHI-NIK2, Elena CERRO-PRADA3,Adel SADEGHI-NIK2, Mandana ROODBARI1, Yan ZHUGE4

1. Department of Physics, University of Mazandaran, Babolsar, Iran;

2. Young Researchers and Elite Club, Sari Branch, Islamic Azad University, Sari, Iran;

3. Department of Civil Engineering, Universidad Politécnica de Madrid, Madrid, Spain;

4. Department of Civil Engineering, University of South Australia, Adelaide, Australia

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract:

Efficient modelling approaches capable of predicting the behavior and effects of nanoparticles in cement-based materials are required for conducting relevant experiments. From the microstructural characterization of a cement-nanoparticle system, this paper investigates the potential of cell-based weighted random-walk method to establish statistically significant relationships between chemical bonding and diffusion processes of nanoparticles within cement matrix. LaSr0.5C0.5O3 (LSCO) nanoparticles were employed to develop a discrete event system that accounts for the behavior of individual cells where nanoparticles and cement components were expected to interact. The stochastic model is based on annihilation (loss) and creation (gain) of a bond in the cell. The model considers both chemical reactions and transport mechanism of nanoparticles from cementitious cells, along with cement hydration process. This approach may be useful for simulating nanoparticle transport in complex 2D cement-based materials systems.

Key words:

Cite this article as:

Ali BAHARI, Aref SADEGHI-NIK, Elena CERRO-PRADA, Adel SADEGHI-NIK, Mandana ROODBARI, Yan ZHUGE. One-step random-walk process of nanoparticles in cement-based materials [J]. Journal of Central South University, 2021, 28(6): 1679-1691.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-021-4726-61 Introduction

Cement-based materials are well-known for their wide variety of uses, from manufacturing conventional concrete to advanced repairing techniques and lightweight construction materials [1-9]. Over the past decades, incorporation of nanoparticles in different materials has enabled a wide set of scientific advances and applications in different industries [10-13], particularly in construction materials [14-19]. Although many investigations have been carried out on construction materials including cement [20-24] and concrete [25-37], more comprehensive research is needed due to the widespread use of cementitious composites. In the past decade, for instance, several novel types of cementitious composites have been developed for special purposes such as self-sensing, crack-closing, and multiple-cracking performance [38-40]. Nowadays, however, a new mode of cementitious composites technology has been shaped in response to a specific technological style based on remarkable nanoscience achievements. This novel paradigm should be understood as a more sustainable organization of cement production, in which nanostructured additives take a key role within and across concrete industry. In this sense, wide efforts have been applied into the preparation of nanoparticles suitable for cement microstructure [41-43]. In the form of nano-additives, well-suited nanostructures have shown a great deal of performance for the improvement of concrete properties [44-49]. Therefore, this new generation of nano-additives opens a wide range of new opportunities for taking advantage of this particular evolution.

For robust nano-additive-cement mix, and to promote relatively quick changes in material design, the characterization analysis is crucial in order to study the behavior and effects of nanostructures within the cement matrix. Hence, a large number of studies have been conducted to report insights into the physical-chemical properties of cementitious materials using various types of cement nano-additives, such as nano-SiO2 [50-52], SiC [53, 54], carbon nanotubes [55-60], nanoclays [61], nano LSCO perovskite [62, 63], montmorillonite [64-66], etc. Besides, nanoparticles that do not directly participate with pozzolanic reactions, like nanotitania, have empirically shown in favor of microstructural mechanisms that improve the mechanical properties in cement-based materials [67-70].

However, in order to make the transition from traditional additives mainly used for stabilization, structural improvement and achievable goals, into novel nanostructured additives catering to specific properties enhancement, innovations research should focus on modelling and simulations techniques based on transport and interaction mechanisms between nanostructures and cement particles. Diffusion processes and chemical reactions of nano-additives in the cement matrix can determine a number of simulation tools for understanding such mechanisms, along with deep knowledge on nanoscale experimental techniques. A theoretical study focused on the simulation of chemical reactions and diffusion processes of LaSr0.5C0.5O3 (LSCO) nanoparticles in cement matrix was reported in Ref. [62], where the non-linear Fokker-Planck equation was used. Despite the satisfactory accuracy of Ref. [62], chemical kinetics and transport of particles through the cement matrix were not specifically considered, and therefore, further research is required in this area.

The nanoparticle behavior in the cement paste, and mortar or concrete is often characterized by stress-strain, crystallite phases, particle size, surface morphology and topography of the sample. Such properties can be obtained from a detailed microstructural characterization, which implies prior to decisions on the material composition. These studies are, without doubt, necessary to establish assumptions in the development of numerical models based on theoretical analysis of the behavior of nanoparticles. In the same way, theoretical models can establish predict specific compositions, thus allowing us to estimate the suitability of certain compositions that can later be tested [71, 72]. Therefore, it is clear that experimental testing and numerical modelling must be both conducted.

To achieve such goals, this work includes two parts. A nano LSCO modified mortar was prepared by adding LSCO nanoparticles into different concentrations. Mechanical testing, scanning electron microscopy (SEM), atomic force microscopy and Fourier transform infrared spectra (FT-IR) were employed to study the structural properties of the samples. The second part was designed to investigate the potential of cell-based weighted random walk method to establish statistically significant relationships between chemical bonding and diffusion processes of LSCO nanoparticles within the cement matrix, by developing a discrete event system that accounts for the behavior of individual cells where nanoparticles and cement components were expected to interact. The theoretical works reported in Refs. [73-76] were considered in this study.

To take into account nanoparticle dispersion in cement microstructure, transport models may be built using the classic random-walk (RW) method. The RW method is based on the stochastic motion of a large number of particles, which obeys a Markovian process. In one dimension, this process can be written as:

(1)

(1)

where  Pn, Pn-1, Pn+1 are the probability function of cell n, and neighborhood cell n-1 and cell n+1), respectively. From this perspective, the discrete cell samples can be considered a set of gain (g) and loss (r) processes, following the one-step Random-Walk stochastic method [77]. Namely, gn and/or rn are the probability, per unit time, for a nanoparticle to diffuse through a cell site n to the nearest neighbor cell n+1 and/or n-1, respectively. Hence, the stochastic process consists of both on the arrival and the discard of LSCO nanoparticle from the cement matrix. This process can be studied by considering the probability of the reaction occurrence, which depends on the number of cells and the reaction rates given by the master equation [78].

Pn, Pn-1, Pn+1 are the probability function of cell n, and neighborhood cell n-1 and cell n+1), respectively. From this perspective, the discrete cell samples can be considered a set of gain (g) and loss (r) processes, following the one-step Random-Walk stochastic method [77]. Namely, gn and/or rn are the probability, per unit time, for a nanoparticle to diffuse through a cell site n to the nearest neighbor cell n+1 and/or n-1, respectively. Hence, the stochastic process consists of both on the arrival and the discard of LSCO nanoparticle from the cement matrix. This process can be studied by considering the probability of the reaction occurrence, which depends on the number of cells and the reaction rates given by the master equation [78].

Now, the large nanoparticle surface to volume relationship, which indeed can give way to large cross section for collisions of LSCO and C, was considered. This fact means that LSCO nanoparticles can walk within a cell until they make a bond as  . This bond is then considered a random walk in each cell with occupation number n through time variation:

. This bond is then considered a random walk in each cell with occupation number n through time variation:

(2)

(2)

(3)

(3)

For the stationary solution, this leads to:

(4)

(4)

where P0 can be available by normalization of LSCO nanoparticle distributions with a certain density ρ:

(5)

(5)

and P0 is the density of an assembled set of LSCO nanoparticles.

The main problem in the above approach is that Eqs. (1) and (3) do not work for a sample with inhomogeneous and unsymmetrical structures. Therefore, a tendency parameter χ for LSCO+C bond formation was defined. Then, the coefficient of γ, as a statistical function, in Eq. (2) can be found from the balance equation:

(6)

(6)

(7)

(7)

where KB is the Boltzmam’s constant; T is the temperature.

In this regard, the fluctuation and movement of a particle for a cell (n) to another cell (n′) can be approximately described in terms of transitions probabilities between the two nearest neighbor cells, under the following conditions:

(8)

(8)

In this paper, an innovative approach that deals with a sample structure consisting of a set of discrete cells was proposed, where introducing a one-step stochastic process is permitted. The representative volume of each cell is required to allow the nanoparticle transitions between one cell and its nearest and next nearest neighbor cells. LSCO nanoparticles that were assumed to interact with the cementitious particles by forming bonds in each cell were proposed. After a while in the cell, due to the stress and chemical reactions, the bonds may be broken, and the particles were then free to move from cell to cell. Diffusion mechanisms are then considered by allowing each particle to execute a random-walk to a neighboring cell, according to Ref. [75]. To control the chemical reactions, a set of stoichiometric coefficients are considered, allowing collisions number and densities (or concentrations) to varied during reactions. van Kampen’s relation [79] is used, which involves the cross-section for a collision of the required particles as well as the probability for the collision to result in a reaction. These assumptions lead to a robust model which may serve to describe chemical and diffusion processes of nanoparticles in cementitious materials.

2 Materials and methods

2.1 Materials and sample preparation

LSCO nanoparticles were sol-gel prepared with n(La):n(Sr):n(Co) of 2:1:1, by reacting 0.5860 g lanthanum chloride (LaCl3·6H2O) and 0.2730 g cetyltrimethylammonium bromide (CTAB) surfactant in 30 mL distilled water to bring about gelation, keeping the mix under magnetic stirring for 24 h at room temperature. The pH value was adjusted from 6.0 to 10.0 by adding 0.1-0.6 mL 25% ammonia. The solution was heat-treated at 50 °C and then powdered at 80 °C for another 24 h.

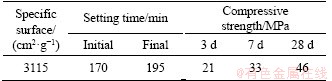

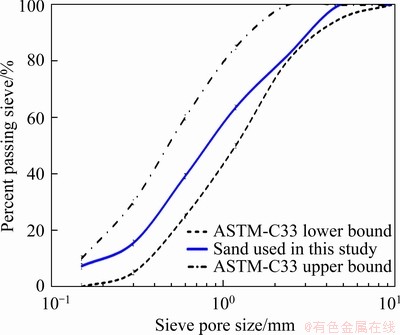

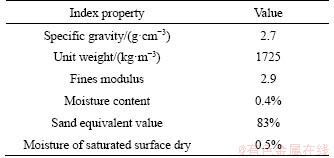

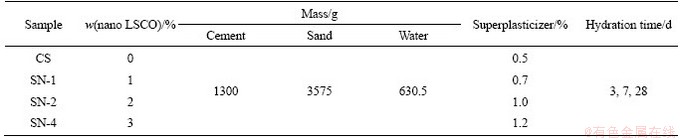

In some previous studies, it was reported that the quality of water could influence the mechanical characteristics of cementitious materials [80-82]. Therefore, in the current research, distilled water was used for the characterization tests and tap (drinking) water for the preparation of mortar specimens [83-85]. Mortar samples of Class A Portland cement were prepared with a water-cement ratio of 0.485 according to European standard EN-UNE 196-1, which states the standard curing conditions as about 100% relative humidity (RH) and 20 °C, with chemical and physical characteristics of the cement as shown in Tables 1 and 2. The sand consumed in this work was natural siliceous sand and the sieve analysis is shown in Figure 1, and its properties are represented in Table 3. A superplasticizer was used in order to keep the flowability constant at about 150 mm. Before mixing and reacting with water, cement clinker was combined with different concentrations of LSCO nanoparticles, without cement replacement, as described in Table 4. Mortar samples were then cast in the form of cube (50 mm×50 mm×50 mm) by pouring the slurry into plastic molds, sealed and afterward submerged into water. Finally, the samples were removed from the molds after 24 h and allowed to cure according to the curing conditions.

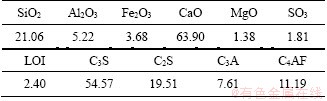

Table 1 Chemical composition of ordinary Portland cement (wt%)

Table 2 Physical properties of cement

2.2 Characterization

The cube specimens of nano LSCO-mortar composites were tested to determine the average compressive strength. To measure the compressive strength of the present samples, ASTM C109 [70] was used.

Morphology and structure characterization of the nano LSCO modified cement mortar were analyzed with SEM Philips XL-30 S-FEG, equipped with W source detectors of secondary and backscattering electrons and a vacuum sample chamber with a vacuum of lower than 4×10-4 Pa. Prior to imaging, the samples were sputtered with a 12 nm thin film of chrome.

Figure 1 Grading curve of natural sand

Table 3 Physical properties of sand

Surface structure was evaluated by using AFM (Daulscope TM DS 95-200/50). Fourier transform infrared spectra (FT-IR) of the samples were obtained by a FT-IR (Bruker-Tensor 27 IR equipment, over the range of 400-4000 cm-1, with 16 scans, at a resolution of 2 cm-1).

3 Results and discussion

3.1 Nano LSCO modified cement mortar characterization

3.1.1 Mechanical properties

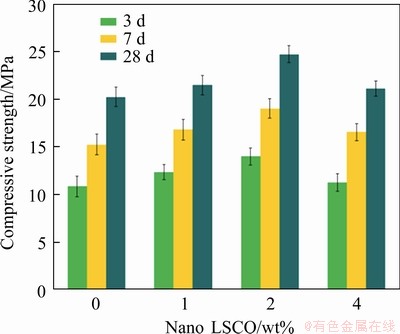

Figure 2 shows the trends of compressive strength for cement mortars with nano LSCO contents (1%, 2% and 4%) without cement replacement, for all test ages (3, 7 and 28 d). As can be observed, no significant improvement is displayed in compressive strength for a content of nano LSCO of 1% and 4%. By adding 2% nano LSCO in mortar, remarkable improvement was obtained up to 20%. Although this research does not attempt to fix the optimal content of LSCO nanoparticles to produce evident improvements in the mechanical behavior of the cement mortar, these results confirmed that the presence of LSCO nanostructures in the cementitious material induced the formation of hydration products, in no case resulting in mechanical detriment [63].

Table 4 Mixing conditions of cement mortars specimens

Figure 2 Compressive strength of cement mortar containing nano LSCO at different mass fraction

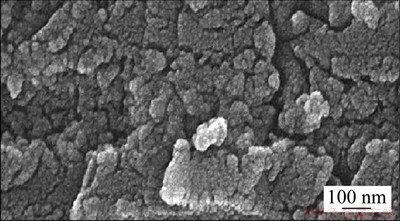

3.1.2 Morphology and surface structure

Figure 3 displays the SEM micrographs of nano LSCO modified cement mortar with 2% nanoparticle addition. As can be observed, the sample consists of particles with quasi spherical morphology and abundant aggregation, attached or inter-grown to the larger cement particle surfaces. Irregular size was found with an average dimension range of 30-50 nm, estimated by image. It can be confirmed by the fact that LSCO nanoparticles improved the particle packing of the blended cement, leading to reduced volume of permeable pores in the cement paste.

Figure 3 SEM micrograph of cement mortar modified with 2% nano LSCO

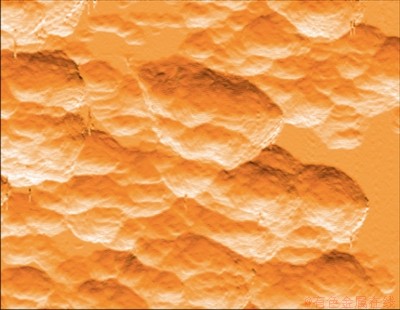

In Figure 4, the AFM image of the same sample confirms that aggregated nanoparticles were gradually set down in the cement porous microstructure, yielding to a quasi-homogenous structure where agglomerated particles with well-defined edges and irregular sizes were dispersed within the cementitious matrix. An average crystallite size ranging from 6 to 70 nm was previously determined for LSCO nanomaterial using Debye-Scherrer equation, as reported in Ref.[62].

Figure 4 AFM micrograph from surface of 28 d cement mortar modified with 2% nano LSCO

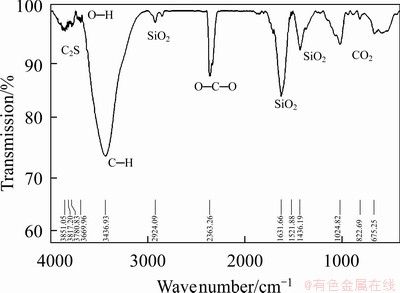

3.1.3 FT-IR spectra

The mortar samples with 2% nano LSCO content were analyzed with FT-IR technique after 28 d curing, as shown in Figure 5. The spectra reveal the presence of two main bands which correspond to the asymmetric stretching vibrations (ν3) of CO32– and Si—O (tetrahedron) stretching vibrations. In addition to these dominating bonds, some other out-of-plane bending vibrations, ν2 of CO32–, and O—H bands were also exhibited. These peaks can be related to high density of crystals, which, due to the Poisson relationship, may produce an electric field and, consequently, band bending in the boundaries and the grain boundary. Such effects are expected to improve the nanostructural, mechanical and chemical properties of the LSCO-cement mortar samples due to large transmittance peak of Si—O.

Figure 5 FT-IR spectrum of cement mortar modified with 2% nano LSCO

Some other vibration peaks at 565 and 799 cm-1 are attributed to O—Si—O bending vibrations and Si—O—Si symmetric stretching vibration, respectively, which represent the major bands of dry cement conducted from C3S and C2S phases.

Another significant peak located at 1429 cm-1 is attributed to the stretching vibration mode of functional group of CO3 leading to the formation of CO+ cement bonds in LSCO. This effect explains the reduced transmittance intensity of ν3 in CO32– peak as shown in Figure 5, from the reaction of LSCO nanoparticles with cement components. This may be due to filling factor of CO—O, CO—La or Sr ions, which can fill octahedral interstitial sites.

A more remarkable feature is revealed when observing the OH bending band of water in the form of gel-like at 1650 cm-1, also OH on the surface at 3050 cm-1. These bands, along with the one at 3449 cm-1, are assigned to the stretching vibration of H2O molecules. In particular, the band detected at 3449 cm-1 reveals typical dry cement frequency which indicates the hardened state of this sample. Si—OH wagging modes at 458 and 954 cm-1 show that stretching vibrations of La—Sr, or Sr—Co and/or La—Co groups are also formed.

Further FT-IR analysis reveals the presence of calcite (CaCO3) due to atmospheric CO2 absorption, larnite (C2S) and calcium silicate (C3S), as stated before, and brownmillerite (Ca2(Al/Fe)2O3) in the samples. Finally, peaks located at 1500, 1860 and 2540 cm-1 are observed and attributed to LSCO crystallite phases, according to Refs. [56, 62, 86].

3.2 Theoretical discussion

As shown in the FT-IR spectra (Figure 5), the species could still create free sites by breaking the LSCO—C bonds. Therefore, Eqs. (1)-(7) are not true for our discrete cell due to the ergodic property [73, 87-89], which demonstrates that, in a block, remaining cell of W is indecomposable and has single stationary solution Pn, which is a statistical function. Therefore, the transition probability should be considered as follows:

(9)

(9)

The evolution of the LSCO—C microstructures in each cycle comprises some diffusion and reaction steps, which need to be taken into account to predict the degree of percolation and, also, to differentiate nanoparticles through the cells [56]. Other model weaknesses that should be solved are the reaction and diffusion phenomena, which need to be explained from analyzing nanoparticles distribution and the thermodynamic of multiphase porous structure. This implies to fully understand the fundamental concept of thermochemical modelling of cement-based materials. In particular, the hydration process and the reaction theory in porous media, include the dominant mechanism of the reaction kinetics and the continuous diffusions of nanoparticles. It is also worth noting that according to Plank relation, entropy is linearly proportional to the logarithm of microstates. Thus, nanoparticle occupation depends strongly on stress-strain and chemical dissipation [75, 87, 90], which can be expressed in the below inequality relation:

(10)

(10)

where σij and εij are the ij component of the stress and strain rate tensor respectively; S, T and A are the entropy, temperature and free energy, respectively; C is the chemical dissipation due to the affinity of the chemical reaction.

Equation (10) is sufficient condition to claim the nanostructural characteristics and thermodynamic process of the interaction between LSCO nanoparticles within the cement system. Therefore, this relation is appropriate to discuss the transition and diffusion of nanoparticles through cells.

On the other hand, researchers normally consider Arrhenius equation where Ea is activation energy; T the absolute temperature; A the pre-exponential factor and KB Boltzmann constant to study and discuss the overcoming of a particle to dielectric barrier. Here, if the total energy of the system had a fixed E, and individual cell energy en, the Arrhenius equation could be converted to the following relation:

where Ea is activation energy; T the absolute temperature; A the pre-exponential factor and KB Boltzmann constant to study and discuss the overcoming of a particle to dielectric barrier. Here, if the total energy of the system had a fixed E, and individual cell energy en, the Arrhenius equation could be converted to the following relation:

(11)

(11)

where a is a constant.

This view can also be expressed by looking at detailed balance for a cell with the nearest-neighbor cells, as shown as follows:

(12)

(12)

which requires no detailed knowledge on the properties of discrete cells. However, a proper study of these processes does need the consideration of nanoparticle behavior within the cement matrix. Accordingly, the master equation will then be:

(13)

(13)

Consequently, for a discrete set of state labelled n, the prior relation can be express as:

(14)

(14)

which describes the gain-loss probability of state n-first (second) term describes the gain (loss) of state n due to the transition from cell n into other nearest neighbor cells.

Now, the parameter  and an arbitrary nonnegative convex function Q(t) could be defined by considering the state function f (n):

and an arbitrary nonnegative convex function Q(t) could be defined by considering the state function f (n):

(15)

(15)

(16)

(16)

(17)

(17)

Thus, for a given number n of  bonds, the probability for producing (gain) and breaking (loss) per unit time, and n′, can be obtained from:

bonds, the probability for producing (gain) and breaking (loss) per unit time, and n′, can be obtained from:

(18)

(18)

(19)

(19)

where α, β are proportional coefficients. It should be noted that Eq. (19) indicates how competition can give rise to an additional death rate γ(n-1), proportional to the number of other cells present. Consequently, the master equation should be rewritten according to the occupation state function, f(n), as below:

(20)

(20)

where

E and E-1 are the creation (gain) and annihilation (loss) energies, respectively.

E and E-1 are the creation (gain) and annihilation (loss) energies, respectively.

It is assumed that the reaction occurred inside a cell, where reaction rate and transition probability in either forward (→) or reverse (←) direction, need to be considered. Therefore, for a typical reaction with a set of stoichiometric coefficients Sj, rj, we have

(21)

(21)

However, the state of {nj} can be changed with reactive collisions and diffusion into {nj+rj-Sj}, in which the cj concentration and/or density defined by rj-Sj and Cj=nj/V, can be completed by adding the cross-section for a collision, which yields to the following expression:

(22)

(22)

where K+ is the reaction rate constant with a constant cross-section. More precisely, the rate equation can be given by:

(23)

(23)

The above discussions, in particular the chemical reaction in Eq. (21), along with the models on which this work is based on, are not universal laws, but can be used when the following requirements are satisfied: 1) the mixture must be homogeneous, and 2) the none-reactive collision must be so fast to ensure that the Boltzmann-Maxwell velocity distribution is satisfied.

The temperature variation in space and time is now considered. The reaction rate and transportation efficiently depend strongly on temperature, which should be reflected in the transition matrix. Hence, in order to describe nanoparticles such as LSCO, or to include the crystalline behavior in the discrete cells, the actual state number fluctuates around nj, which needs the join probability distribution (n, t), P(n, t), not Boltzmann-Maxwell and Poisson distributions. Therefore, the fraction of making-breaking (gain-loss) bonds due to chemical reaction and diffusion of particles, should depend on the details of the distribution over internal states, and not just on the concentration. This leads to the fact that the occupation site number cannot fully be described by the set of numbers. Thus, the occupation site number should be based on the accessible sites Sj as follows:

(24)

(24)

This ensures that the state of the mixture is fully described by the set of numbers nj, therefore,

(25)

(25)

where K- is the reverse reaction rate constant (Eq. (22)) and indicates that both LSCO+C→LSCO and LSCO+C←LSCO should be taken into account. The master equation for reactions p in the LSCOC (and all cementitious structures) can be then described with the above equation. However, as reveled in the previous discussion, given Sjρ, rjρ, K+ρ, and K-ρ coefficients and rate constants for chemical reactions in the cell, Pt(n) is then given by:

(26)

(26)

Here Zj is the partition function for nanoparticles in the cell j:

(27)

(27)

The nj are independent Poisson variables with average  , providing that the below ratio be maintained:

, providing that the below ratio be maintained:

(28)

(28)

This relationship leads to a ratio between the rates of a transition and its reverse. However,Eq. (28) cannot correctly describe the fluctuations of the nj in a cell. The correct distribution should be then given by:

(29)

(29)

where  if n is accessible from n0; and

if n is accessible from n0; and  , if n is inaccessible. Here, for simplicity, it is assumed the stoichiometric coefficients, being s1=1, s2=2, r1=1 and r2=0. Therefore, for an occupation state with

, if n is inaccessible. Here, for simplicity, it is assumed the stoichiometric coefficients, being s1=1, s2=2, r1=1 and r2=0. Therefore, for an occupation state with

the probability is thus found as follows:

the probability is thus found as follows:

(30)

(30)

4 Conclusions

This paper focuses on two issues considered to be key factors in improving nanoparticle modified cement-based materials performance and applications: 1) microstructural characterization of the composite and 2) modelling nanoparticle behavior within the complex cement matrix.

The addition of 2% LSCO nanoparticles produced up to 29% improvement in the compressive strength of cement mortar. Larger addition, as 4%, the compressive strength is reduced mostly due to the formation of secondary bonding-back and dangling bonds, which impeded cement hydration products to fully form, thus diminished the mechanical performance. Nano LSCO-cement mortar system morphology is observed to be formed by quasi-homogeneous structures where agglomerated particles with well-defined edges and irregular sizes were dispersed within the cementitious matrix. As FT-IR analysis indicates, there is a filling effect from the formation of CO-La/Sr chemical bonds.

An efficient one-step random walk method developed in the time domain is proposed for the simulation of nanoparticle transport in a discrete cement matrix. The method handles both chemical reactions and the transport mechanisms of nanoparticles from cementitious cells. The model avoids mass balance problems stemming from dispersion contrast at cell intersections. Thus, it is clear that the hydration problem has been included along with the behavior and amount of nanoparticles in cement materials, which suggests that the one-step random-walk process developed is expected to be very useful for simulating nanoparticle transport in complex 2D cement-based materials systems. This modelling approach should become a convenient tool to fit and interpret real-case experimental studies.

Contributors

Ali BAHARI has played a leading role in this manuscript. Ali BAHARI and Aref SADEGHI-NIK provided the concept and edited the draft of manuscript. Ali BAHARI, Aref SADEGHI-NIK, Elena CERRO-PRADA, Adel SADEGHI-NIK and Mandana ROODBARI conducted the literature review and wrote the first draft of the manuscript. Ali BAHARI, Aref SADEGHI-NIK, Elena CERRO-PRADA, Mandana ROODBARI, and Yan ZHUGE edited the draft of manuscript. Ali BAHARI, Aref SADEGHI-NIK, Elena CERRO-PRADA, Adel SADEGHI-NIK, and Yan ZHUGE analyzed the calculated results. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

Ali BAHARI, Aref SADEGHI-NIK, Elena CERRO-PRADA, Adel SADEGHI-NIK, Mandana ROODBARI and Yan ZHUGE declare that they have no conflict of interest.

References

[1] DEHGHANI A, NATEGHI-ALAHI F, FISCHER G. Engineered cementitious composites for strengthening masonry infilled reinforced concrete frames [J]. Engineering Structures, 2015, 105: 197–208. DOI: 10.1016/j.engstruct. 2015.10.013.

[2] ARIYACHANDRA E, PEETHAMPARAN S, PATEL S, ORLOV A. Effect of NO2 sequestered recycled concrete aggregate (NRCA) on mechanical and durability performance of concrete [J]. Cement and Concrete Research, 2020, 137: 106210. DOI: 10.1016/j.cemconres.2020.106210.

[3] ASLANI F, DEGHANI A, ASIF Z, Development of lightweight rubberized geopolymer concrete by using polystyrene and recycled crumb-rubber aggregates [J]. Journal of Materials in Civil Engineering, 2020, 32: 1-16. DOI: 10.1061/(ASCE)MT.1943-5533.0003008.

[4] VAHABI M Y, TAHMOURESI B, MOSAVI H, FAKHRETAHA AVAL S. Effect of pre-coating lightweight aggregates on the self-compacting concrete [J]. Structural Concrete, 2021. DOI: 10.1002/suco.202000744.

[5] DEHGHANI A, FISCHER G, NATEGHI ALAHI F. Strengthening masonry infill panels using engineered cementitious composites [J]. Materials and Structures, 2015, 48: 185-204. DOI: 10.1617/s11527-013-0176-4.

[6] LI D, MILLS J E, BENN T, MA X, GRAVINA R, ZHUGE Y. Review of the performance of high-strength rubberized concrete and its potential structural applications [J]. Advances in Civil Engineering Materials, 2016, 5(1): 149-166. DOI: 10.1520/ACEM20150026.

[7] ASKARIAN M, FAKHRETAHA AVAL S, JOSHAGHANI A. A comprehensive experimental study on the performance of pumice powder in self-compacting concrete (SCC) [J]. Journal of Sustainable Cement-Based Materials, 2018, 7(6): 340-356. DOI: 10.1080/21650373.2018.1511486.

[8] KARIMIPOUR Arash, EDALATI Mahmoud. Influence of untreated coal and recycled aggregates on the mechanical properties of green concrete [J]. Journal of Cleaner Production, 2020, 276: 124291. DOI: 10.1016/j.jclepro.2020.124291.

[9] ABD-ELAAL E S, ARABY S, MILLS JULIE E, YOUSSF O, ROYCHAND R, MA Xing, ZHUGE Yan, GRAVINA REBECCA J. Novel approach to improve crumb rubber concrete strength using thermal treatment [J]. Construction and Building Materials, 2009, 229: 116901. DOI: 10.1016/j.conbuildmat.2019.116901.

[10] BAHARI A, SADEGHI-NIK A, ROODBARI M, MIRNIA N, Investigation the Al–Fe–Cr–Ti nano composites structures with using XRD and AFM techniques [J]. Sadhana, 2012, 37: 657-664. DOI: 10.1007/s12046-012-0103-3.

[11] HADDAD KOLOUR H, ASHRAF W, LANDIS E N. Hydration and early age properties of cement pastes modified with cellulose nanofibrils [J]. Transportation Research Record, 2020: 0361198120945993. DOI: 10.1177%2F0361198120 945993.

[12] SADEGHI-NIK A, BAHARI A, EBADI A G, SADEGHI-NIK A, GHASEMI-HAMZEKOLAEE A. The role of nano particles (Si) in gate dielectric [J]. Indian Journal of Science and Technology, 2010, 3: 634-636. DOI: 10.17485/ijst/ 2010/v3i6.16.

[13] KIAMAHALLEH M V, GHOLAMPOUR A, TRAN D N H, OZBAKKALOGLU T, LOSIC D. Physiochemical and mechanical properties of reduced graphene oxide–cement mortar composites: Effect of reduced graphene oxide particle size [J]. Construction and Building Materials, 2020, 250: 118832. DOI: 1016/ j.conbuildmat.2020.118832.

[14] SADEGHI-NIK A, BAHARI A, KHORSHIDI Z, GHOLIPUR R. Effect of lanthanum oxide on the bases of cement and concrete [C]// Third International Conference on Construction in Developing Countries (Advancing Civil, Architectural and Construction Engineering & Management). Bangkok, Thailand, 2012: 707-712.

[15] ARCHONTAS N D, PANTAZOPOULOU S J. Microstructural behavior and mechanics of nano-modified cementitious materials [J]. Advances in Concrete Construction, 2015, 3(1): 15-37. DOI: 10.12989/acc.2015.3.1. 015.

[16] ASLANI F, DEHGHANI A, WANG L. The effect of hollow glass microspheres, carbon nanofibers and activated carbon powder on mechanical and dry shrinkage performance of ultra-lightweight engineered cementitious composites [J]. Construction and Building Materials, 2021, 280: 122415. DOI: 10.1016/j.conbuildmat.2021.122415.

[17] WU L P, HUANG G P, LIU W V. Performance evaluation of nano-silica and silica fume on enhancing acid resistance of cement-based composites for underground structures [J]. Journal of Central South University, 2020, 27(1): 3821-3838. DOI: 10.1007/s11771-020-4473-0.

[18] SADEGHI-NIK A, BAHARI A. Nano-particles in concrete and cement mixtures [C]// International Conference on Nano Science and Technology, 2010: 221-223.

[19] SADEGHI-NIK A, BAHARI A, SADEGHI-NIK A, KHALILPASHA M H. Nanotechnology coating of buildings with sol–gel method [J]. American Journal of Scientific Research, 2011, 31: 69-72.

[20] CAO M L, ZHANG H X, ZHANG C. Effect of graphene on mechanical properties of cement mortars [J]. Journal of Central South University, 2016, 23(4): 919-925. DOI: 10.1007/s11771-016-3139-4.

[21] SETAYESH GAR P, LOBANOV S, PERNECHELE M, ZANOTTI C. Lightweight magnesium phosphate cement composites with struvite recovered from wastewater [J]. Canadian Journal of Civil Engineering, 2020, 27(5): 1394-1402. DOI: 10.1139/cjce-2020-0186.

[22] WANG H, ZHANG A L, ZHANG L C, WANG Q, HAN Y, LIU J Z, GAO X J, SHI F T, LIN X Y, FENG L Y. Hydration process of rice husk ash cement paste and its corrosion resistance of embedded steel bar [J]. Journal of Central South University, 2020, 27(11): 3464-3476. DOI: 10.1007/s11771-020-4559-8.

[23] BURRIS L E, JUENGER M C G. Effect of calcination on the reactivity of natural clinoptilolite zeolites used as supplementary cementitious materials [J]. Construction and Building Materials, 2020, 258: 119988. DOI: 10.1016/ j.conbuildmat.2020.119988.

[24] TAN Y N, CHEN W J, LIU Y, LIU Y J. Preparation of tricalcium silicate and investigation of hydrated cement [J]. Journal of Central South University, 2020, 27(11): 3227-3238. DOI: 10.1007/s11771-020-4542-4.

[25] MA Si-wei, HUANG Ci-hang, BAAH P, NANTUNG T, LU Na. The influence of water-to-cement ratio and superabsorbent polymers (SAPs) on solid-like behaviors of fresh cement pastes [J]. Construction and Building Materials, 2021, 275: 122160. DOI: 10.1016/j.conbuildmat.2020. 122160.

[26] KARIMAEI M, DABBAGHI F, SADEGHI-NIK A, DEHESTANI M. Mechanical performance of green concrete produced with untreated coal waste aggregates [J]. Construction and Building Materials, 2020, 233: 117264. DOI: 10.1016/j.conbuildmat.2019.117264.

[27] TOGHROLI A, MEHRABI P, SHARIATI M, TRUNG N T, JAHANDARI S, RASEKH H. Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers [J]. Construction and Building Materials, 2020, 252: 118997. DOI: 10.1016/j.conbuildmat.2020.118997.

[28] ABOLHASANI A, NAZARPOUR H, DEHESTANI M. Effects of silicate impurities on fracture behavior and microstructure of calcium aluminate cement concrete [J]. Engineering Fracture Mechanics, 2021, 242: 107446. DOI: 10.1016/j.engfracmech.2020.107446.

[29] AFROUGHSABET V, TENG S. Experiments on drying shrinkage and creep of high performance hybrid-fiber-reinforced concrete [J]. Cement and Concrete Composites, 2020, 106: 103481. DOI: 10.1016/j.cemconcomp.2019. 103481.

[30] ABOLHASANI A, ASLANI F, SAMALI B, GHAFFAR S H, FALLAHNEJAD H, BANIHASHEMI S. Silicate impurities incorporation in calcium aluminate cement concrete: mechanical and microstructural assessment [J]. Advances in Applied Ceramics, 2021, 120127: 104-116. DOI: 10.1080/ 17436753.2021.1889755.

[31] TAMANNA K, TIZNOBAIK M, BANTHIA N, ALAM M S. Mechanical properties of rubberized concrete containing recycled concrete aggregate [J]. ACI Materials Journal, 2020, 117(3): 169-180.

[32] KAZEMI M, HAJFOROUSH M, KHAKPOUR TALEBI P, DANESHFAR M, SHOKRGOZAR A, JAHANDARI S, SABERIAN M, LI J. In-situ strength estimation of polypropylene fibre reinforced recycled aggregate concrete using Schmidt rebound hammer and point load test [J]. Journal of Sustainable Cement-Based Materials, 2020: 1-18. DOI: 10.1080/21650373.2020.1734983.

[33] KHALILPASHA M H, SADEGHI-NIK A, LOTFI-OMRAN O, KIMIAEIFARD K, AMIRPOUR-MOLLA M. Sustainable development using recyclable rubber in self-compacting concrete [C]// Third International Conference on Construction in Developing Countries (Advancing Civil, Architectural and Construction Engineering & Management). Bangkok, Thailand, 2012: 580-585.

[34] AFSHAR A, JAHANDARI S, RASEKH H, SHARIATI M, AFSHAR A, SHOKRGOZAR A. Corrosion resistance evaluation of rebars with various primers and coatings in concrete modified with different additives [J]. Construction and Building Materials, 2020: 262. DOI: 10.1016/ j.conbuildmat.2020.120034.

[35] HILTON B, BAWDEN K, WINNEBECK K, CHANDRASIRI C, ARIYACHANDRA E, PEETHAMPARAN S. The functional and environmental performance of mixed cathode ray tubes and recycled glass as partial replacement for cement in concrete [J]. Resources, Conservation and Recycling, 2019, 151: 104451. DOI: 10.1016/j.resconrec.2019.104451.

[36] KARIMIPOUR A. Effect of untreated coal waste as fine and coarse aggregates replacement on the properties of steel and polypropylene fibres reinforced concrete [J]. Mechanics of Materials, 2020, 150: 103592. DOI: 10.1016/j.mechmat. 2020.103592.

[37] HAMIDI F, ASLANI F, VALIZADEH A. Compressive and tensile strength fracture models for heavyweight geopolymer concrete [J]. Engineering Fracture Mechanics, 2020, 231: 107023. DOI: 10.1016/ j.engfracmech.2020.107023.

[38] DEHGHANI A, ASLANI F. Piezoresistive sensing of cementitious composites reinforced with shape memory alloy, steel, and carbon fibre [J]. Construction and Building Materials, 2020: 121046. DOI: 10.1016/j.conbuildmat.2020. 121046.

[39] DEHGHANI A, ASLANI F. Piezoelectric behaviour of hybrid engineered cementitious composites containing shape-memory alloy, steel, and carbon fibres under compressive stress cycles [J]. Construction and Building Materials, 2020: 121671. DOI: 10.1016/j.conbuildmat.2020.121671.

[40] DEHGHANI A, ASLANI F. The synergistic effects of shape memory alloy, steel, and carbon fibres with polyvinyl alcohol fibres in hybrid strain-hardening cementitious composites [J]. Construction and Building Materials, 2020, 252: 119061. DOI: 10.1016/j.conbuildmat.2020.119061.

[41] SADEGHI-NIK A, BAHARI A, SADEGHI-NIK A. Investigation of nano structural properties of cement-based materials [J]. American Journal of Scientific Research, 2011, 25: 104-111.

[42] FRANCIOSO V, MORO C, MARTINEZ-LAGE I, VELAY-LIZANCOS M. Curing temperature: A key factor that changes the effect of TiO2 nanoparticles on mechanical properties, calcium hydroxide formation and pore structure of cement mortars [J]. Cement and Concrete Composites, 2019, 104: 103374. DOI: 10.1016/ j.cemconcomp.2019.103374.

[43] SADEGHI-NIK A, BAHARI A, AMIRI B. Nanostructural properties of cement-matrix composite [J]. Journal of Basic and Applied Scientific Research, 2011, 1(11): 2167-2173.

[44] RAMEZANI M. Design and predicting performance of carbon nanotube reinforced cementitious materials: mechanical properties and dipersion characteristics [D]. The University of Luisville’s Institutional Repository, 2019.

[45] ZEYAD A M, JOHARI M A M, TAYEH B A, YUSUF M O. Pozzolanic reactivity of ultrafine palm oil fuel ash waste on strength and durability performances of high strength concrete [J]. Journal of Cleaner Production, 2017, 144: 511-522. DOI: 10.1016/j.jclepro.2016.12.121.

[46] ZEYAD A M, TAYEH B A, SABA A M, JOHARI M A. Workability, setting time and strength of high-strength concrete containing high volume of palm oil fuel ash [J]. The Open Civil Engineering Journal, 2018, 12. DOI: 10.2174/1874149501812010035.

[47] HAMADA H, TAYEH B, YAHAYA F, MUTHUSAMY K, AL-ATTAR A. Effects of nano-palm oil fuel ash and nano-eggshell powder on concrete [J]. Construction and Building Materials, 2020, 261: 119790. DOI: 10.1016/ j.conbuildmat.2020.119790.

[48] HAMADA H M, ALYA’A A, YAHAYA F M, MUTHUSAMY K, TAYEH B A, HUMADA A M. Effect of high-volume ultrafine palm oil fuel ash on the engineering and transport properties of concrete [J]. Case Studies in Construction Materials, 2020, 12: e00318. DOI: 10.1016/j.cscm.2019.e00318.

[49] ZEYAD A M, JOHARI M A, TAYEH B A, SABA A M. Ultrafine palm oil fuel ash: from an agro-industry by-product into a highly efficient mineral admixture for high strength green concrete [J]. Journal of Engineering and Applied Sciences, 2017: 12: 8187-8196.

[50] KULI I, ABU-LEBDEH T M, FINI E H, HAMOUSH S A. The use of nano-silica for improving mechanical properties of hardened cement paste [J]. American Journal of Engineering and Applied Science, 2016, 9: 146-154.

[51] SADEGHI-NIK A, BERENJIAN J, ALIMOHAMMADI S, LOTFI-OMRAN O, SADEGHI-NIK A, KARIMAEI M. The effect of recycled concrete aggregates and metakaolin on the mechanical properties of self-compacting concrete containing nanoparticles [J]. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 2019, 43: 503-515. DOI: 10.1007/s40996-018-0182-4.

[52] JALAL M, MANSOURI E, SHARIFIPOUR M, POULADKHAN A R. Mechanical, rheological, durability and microstructural properties of high performance self-compacting concrete containing SiO2 micro and nanoparticles [J]. Materials & Design, 2012, 34: 389-400. DOI: 10.1016/ j.matdes.2011.08.037.

[53] BAHARI A, BERENJIAN J, SADEGHI-NIK A. Modification of Portland cement with nano SiC [C]// Proceedings of the National Academy of Sciences, India Section A: Physical Sciences. 2016, 86: 323-331. DOI: 10.1007/s40010-015-0244-y.

[54] BAHARI A, SADEGHI-NIK A, ROODBARI M, TAGHAVI K, MIRSHAFIEI S E. Synthesis and strength study of cement mortars containing SiC nano particles [J]. Digest Journal of Nanomaterials and Biostructures, 2012, 7: 1427-1435.

[55] RAMEZANI M, KIM Y H, SUN Z. Modeling the mechanical properties of cementitious materials containing CNTs [J]. Cement and Concrete Composites, 2019, 104: 103347. DOI: 10.1016/j.cemconcomp.2019.103347.

[56] GHAHARPOUR F, BAHARI A, ABBASI M, ASHKARRAN A A. Parametric investigation of CNT deposition on cement by CVD process [J]. Construction and Building Materials, 2016, 113: 523-535. DOI: 10.1016/j.conbuildmat.2016.03.080.

[57] RAMEZANI M, KIM Y H, HASANZADEH B, SUN Z. Influence of carbon nanotubes on SCC flowability [C]// Proceedings of 8th International Rilem Symposium on Self-Compacting Concrete. Washington, DC, USA: 315 Rilem Publications. 2016: 397-406.

[58] CHEN Jia-xin, AKONO A T. Influence of multi-walled carbon nanotubes on the hydration products of ordinary Portland cement paste [J]. Cement and Concrete Research, 2020, 137: 106197. DOI: 10.1016/j.cemconres. 2020.106197.

[59] RAMEZANI M, KIM Y H, SUN Z. Mechanical properties of carbon-nanotube-reinforced cementitious materials: Database and statistical analysis [J]. Magazine of Concrete Research, 2019: 1-25. DOI: 10.1680/jmacr.19.00093.

[60] CERRO-PRADA E, PACHECO-TORRES R, VARELA F. Effect of multi-walled carbon nanotubes on strength and electrical properties of cement mortar [J]. Materials, 2021, 14(1): 79. DOI: 10.3390/ ma14010079.

[61] ISMAIL M, ABDEL-RAHMAN H, YOUNES M, HAMED E, EL-HAMOULY S. Studies on γ-irradiated polymer-nano calcined clay blended cement mortar composites [J]. Journal of Industrial and Engineering Chemistry, 2013, 19: 361-368. DOI: 10.1016/j.jiec.2012.09.003.

[62] BAHARI A, SADEGHI-NIK A, ROODBARI R, SADEGHI-NIK A, MIRSHAFIEI M. Experimental and theoretical studies of ordinary Portland cement composites contains nano LSCO perovskite with Fokker-Planck and chemical reaction equations [J]. Construction and Building Materials, 2018, 163: 247-255. DOI: 10.1016/j.conbuildmat.2017.12.073.

[63] BAHARI A, SADEGHI-NIK A, SHAIKH F Uddin Ahmed, Adel SADEGHI-NIK, CERRO-PRADA E, MIRSHAFIEI Ebrahim, ROODBARI Mandana. Experimental studies on rheological, mechanical, and microstructure properties of self-compacting concrete containing perovskite nanomaterial [J]. Structural Concrete, 2021. DOI: 10.1002/suco.202000548.

[64] KAFI M A, SADEGHI-NIK A, BAHARI A, SADEGHI-NIK A, MIRSHAFIEI E. Microstructural characterization and mechanical properties of cementitious mortar containing montmorillonite nanoparticles [J]. Journal of Materials in Civil Engineering, 2016, 28: 04016155. DOI: 10.1061/ (ASCE)MT.1943-5533.0001671.

[65] OH J A, ZHUGE Y, ARABY S, WANG R, YU H, FAN W, LIU M, LEE S H, ALAM M J, MA J. Cement nanocomposites containing montmorillonite nanosheets modified with surfactants of various chain lengths [J]. Cement and Concrete Composites, 2021, 116: 103894. DOI: 10.1016/ j.cemconcomp.2020.103894.

[66] CHANG T P, SHIH J Y, YANG K M, HSIAO T C. Material properties of Portland cement paste with nano-montmorillonite [J]. Journal of materials science, 2007, 42: 7478-7487. DOI: 10.1007/s10853-006-1462-0.

[67] CERRO-PRADA E, MANSO M, TORRES V, SORIANO J. Microstructural and photocatalytic characterization of cement-paste sol-gel synthesized titanium dioxide [F]. Frontiers of Structural and Civil Engineering, 2016, 10: 189-197. DOI: 10.1007/s11709-015-0326-6.

[68] MORO C, FRANCIOSO V, VELAY-LIZANCOS M. Modification of CO2 capture and pore structure of hardened cement paste made with nano-TiO2 addition: Influence of water-to-cement ratio and CO2 exposure age [J]. Construction and Building Materials, 2021, 275: 122131. DOI: 10.1016/j.conbuildmat.2020.122131.

[69] AKONO A T. Effect of nano-TiO2 on C–S–H phase distribution within Portland cement paste [J]. Journal of Materials Science, 2020, 55: 11106-11119. DOI: 10.1007/s10853-020-04847-5.

[70] CERRO-PRADA E, GARCIA-SALGADO S, QUIJANO M, VARELA F. Controlled synthesis and microstructural properties of sol-gel TiO2 nanoparticles for photocatalytic cement composites [J]. Nanomaterials, 2019, 9: 26. DOI: 10.3390/nano9010026.

[71] RAMEZANI M, KIM Y H, SUN Z. Probabilistic model for flexural strength of carbon nanotube reinforced cement-based materials [J]. Composite Structures, 2020, 253: 112748. DOI: 10.1016/j.compstruct.2020.112748.

[72] RAMEZANI M, KIM Y H, SUN Z. Elastic modulus formulation of cementitious materials incorporating carbon nanotubes: Probabilistic approach [J]. Construction and Building Materials, 2021, 274: 122092. DOI: 10.1016/j.conbuildmat.2020.122092.

[73] WEIBULL W. The phenomenon of rupture in solids [M]. IVA Handlingar, 1939.

[74] BAROGHEL-BOUNY V, MOUNANGA P, LOUKILI A, KHELIDJ A. From chemical and microstructural evolution of cement pastes to the development of autogenous deformations [M]. American Concrete Institute, 2004.

[75] BULLARD J W, ENJOLRAS E, GEORGE W L, SATTERFIELD S G, TERRILL J E. A parallel reaction-transport model applied to cement hydration and microstructure development [J]. Modelling and Simulation in Materials Science and Engineering, 2010, 18: 025007. DOI: 10.1088/0965-0393/18/2/025007.

[76] RISKEN H. Fokker-planck equation [M]. Berlin: Springer, 1996.

[77] COX DR, MILLER H D. The theory of stochastic processes [M]. CRC Press, 1977.

[78] SEKI K, WOJCIK M, TACHIYA M. Fractional reaction-diffusion equation [J]. The Journal of Chemical Physics, 2003, 119: 2165-2170. DOI: 10.1063/1.1587126.

[79] QUACK M N G. Stochastic Processes in Physics and Chemistry [M]. Amsterdam: North Holland Publishing Company, 1981.

[80] RASEKH H, JOSHAGHANI A, JAHANDARI S, ASLANI F, GHODRAT M. Rheology and workability of SCC [M]. Woodhead Publishing Series in Civil and Structural Engineering, 2020: 31-63.

[81] JAHANDARI S, MOJTAHEDI S F, ZIVARI F, JAFARI M, MAHMOUDI M R, SHOKRGOZAR A, KHARAZMI S, VOSOUGH HOSSEINI B, REZVANI S, JALALIFAR H. The impact of long-term curing period on the mechanical features of lime-geogrid treated soils [J]. Geomechanics and Geoengineering, 2020: 1-13. DOI: 10.1080/17486025.2020. 1739753.

[82] JAHANDARI S, SABERIAN M, TAO Z, MOJTAHEDI S F, LI J, GHASEMI M, REZVANI S S, LI W. Effects of saturation degrees, freezing thawing, and curing on geotechnical properties of lime and lime-cement concretes [J]. Cold Regions Science and Technology, 2019, 160: 242-251. DOI: 10.1016/j.coldregions.2019.02.011.

[83] SABERIAN M, JAHANDARI S, LI J, ZIVARI F. Effect of curing, capillary action, and groundwater level increment on geotechnical properties of lime concrete: experimental and prediction studies [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2017, 9(4): 638–647. DOI: 10.1016/j.jrmge.2017.01.004.

[84] JAHANDARI S, TOUFIGH M M, LI J, SABERIAN M. Laboratory study of the effect of degrees of saturation on lime concrete resistance due to the groundwater level increment [J]. Geotechnical and Geological Engineering, 2017, 36(1): 413-424. DOI: 10.1007/s10706-017-0335-4

[85] JAHANDARI S, SABERIAN M, ZIVARI F, LI J, GHASEMI M, VALI R. Experimental study of the effects of curing time on geotechnical properties of stabilized clay with lime and geogrid [J]. International Journal of Geotechnical Engineering, 2017, 13(2): 1-12. DOI: 10.1080/19386362. 2017.1329259.

[86] SADEGHI-NIK A, BERENJIAN J, BAHARI A, SAFAEI A S, DEHESTANI M. Modification of microstructure and mechanical properties of cement by nanoparticles through a sustainable development approach [J]. Construction and Building Materials, 2017, 155: 880-891. DOI: 10.1016/j.conbuildmat.2017.08.107.

[87] HOLTZER A, HOLTZER M F. Use of the van’t Hoff relation in determination of the enthalpy of micelle formation [J]. The Journal of Physical Chemistry, 1974, 78: 1442-1443. DOI: 10.1021/j100607a026.

[88] FOWLES G R, CASSIDAY G L, HELRICR C S. Analytical mechanics [M]. Belmont, CA: Thomson Brooks/Cole, 2005.

[89] REIF F. Fundamentals of statistical and thermal physics [M]. Waveland Press, 2009.

[90] ZHANG M H, LI H. Pore structure and chloride permeability of concrete containing nano-particles for pavement [J]. Construction and Building Materials, 2011, 25: 608-616. DOI: 10.1016/j.conbuildmat.2010.07.032.

(Edited by ZHENG Yu-tong)

中文导读

基于一步随机游走法预测纳米颗粒在水泥基材料中的迁移

摘要:有效的建模方法对于相关实验中预测水泥基材料中纳米颗粒的行为和作用非常重要。根据水泥-纳米颗粒系统的微观结构特征,研究了基于单元格加权随机游走法的化学键与纳米颗粒在水泥基体内扩散过程之间建立统计学关系的可行性。LaSr0.5C0.5O3(LSCO)纳米颗粒被用于开发离散系统,该系统考虑了纳米颗粒和水泥材料可能相互作用的每个单元反应。该随机模型是基于单元键的湮灭(损失)和产生(获得)建立的,并同时考虑了水泥基中纳米颗粒的化学反应和传输机理,以及水泥的水化过程。该方法可用于模拟复杂的基于二维水泥基材料中纳米粒子的迁移。

关键词:马尔可夫链蒙特卡罗算法;随机游走法;Fokker-Planck方程;LaSr0.5C0.5O3(LSCO)水泥;纳米颗粒

Foundation item: Project(93021714) supported by the Iran National Science Foundation

Received date: 2020-12-02; Accepted date: 2021-04-01

Corresponding author: Aref SADEGHI-NIK, Senior Researcher; E-mail: arefsadeghinik@gmail.com; ORCID: https://orcid.org/0000-0003-1440-3575

Abstract: Efficient modelling approaches capable of predicting the behavior and effects of nanoparticles in cement-based materials are required for conducting relevant experiments. From the microstructural characterization of a cement-nanoparticle system, this paper investigates the potential of cell-based weighted random-walk method to establish statistically significant relationships between chemical bonding and diffusion processes of nanoparticles within cement matrix. LaSr0.5C0.5O3 (LSCO) nanoparticles were employed to develop a discrete event system that accounts for the behavior of individual cells where nanoparticles and cement components were expected to interact. The stochastic model is based on annihilation (loss) and creation (gain) of a bond in the cell. The model considers both chemical reactions and transport mechanism of nanoparticles from cementitious cells, along with cement hydration process. This approach may be useful for simulating nanoparticle transport in complex 2D cement-based materials systems.

[73] WEIBULL W. The phenomenon of rupture in solids [M]. IVA Handlingar, 1939.

[76] RISKEN H. Fokker-planck equation [M]. Berlin: Springer, 1996.

[77] COX DR, MILLER H D. The theory of stochastic processes [M]. CRC Press, 1977.

[89] REIF F. Fundamentals of statistical and thermal physics [M]. Waveland Press, 2009.