DOI: 10.11817/j.issn.1672-7207.2019.06.001

锡石多金属硫化矿工艺矿物学及磨矿优化

周文涛1,韩跃新1,李艳军1,孙永升1,杨金林2,马少健2

(1. 东北大学 资源与土木工程学院,辽宁 沈阳,110819;

2. 广西大学 资源环境与材料学院,广西 南宁,530004)

摘 要:

段研究锡石多金属硫化矿化学和矿物组成、矿物产出特征及粒度组成,研究锡石过磨和硫化矿欠磨机理,并基于磨矿特性及优化表征方法开展磨矿试验,在此基础上,提出磨矿优化表征方法和“分步磨矿”的概念。研究结果表明:矿石中有用矿物为磁黄铁矿、闪锌矿、脆硫锑铅矿和锡石,脉石矿物主要为云母和石英;锡石与石英、云母等脉石紧密连生形成集合体,各种硫化矿物关系密切,相互混杂以交生或共生的浸染状细粒产出。以合格粒级金属分布率为目标,磨矿最优条件如下:入磨粒级小于2 mm、矿浆质量分数为65%、磨矿时间为4 min时提Sn,然后,不改变其他磨矿条件,继续磨矿至6 min时入选硫化矿物。

关键词:锡石多金属硫化矿;工艺矿物学;过磨;欠磨;优化表征

中图分类号:TD921 文献标志码:文献标识码:A 文章编号:1672-7207(2019)06-1271-07

Process mineralogy and grinding optimization of cassiterite polymetallic sulphide ore

ZHOU Wentao1, HAN Yuexin1, LI Yanjun1, SUN Yongsheng1, YANG Jinlin2, MA Shaojian2

(1. College of Resources & Civil Engineering, Northeastern University, Shenyang 110819, China;

2. College of Resources, Environment and Materials, Guangxi University, Nanning 530004, China)

Abstract: The chemical composition, mineral composition, mineral dissemination characteristics and particle size composition of cassiterite polymetallic sulfide ore were studied by means of multi-test methods, and the mechanism of cassiterite overgrinding and sulfide ore undergrinding was explored, and grinding experiments were carried out based on grinding characteristics and optimization characterization methods. On this basis, the optimization characterization method and the concept of "step grinding" for cassiterite polymetallic sulphide ore were put forward. The results show that the main components of the cassiterite polymetallic sulfide ore are pyrrhotite, sphalerite, brittle antimony lead ores and cassiterite, and gangue minerals are mainly mica and quartz, and cassiterite is closely linked with quartz, mica and other ganglion, and a variety of sulphide minerals are closely related and intermingled with intergrowth or symbiotic in the form of disseminated fine-grained particles. Taking the qualified particle size metal distribution rate as the target, the optimization conditions can be obtained by controlling the grinding conditions. When the grinding concentration is 65% and the input particle size is less than 2 mm, the grinding time is 4 min, the Sn metal is firstly selected, and no other grinding conditions need to be changed, and then after for 6 min, the sulfide minerals are secondly selected.

Key words: cassiterite polymetallic sulphide ore; process mineralogy; overgrinding; undergrinding; optimization characterization

在锡石多金属硫化矿磨矿实践中,硫化矿物一般采用浮选方法富集和彼此分离,其适宜给料粒度范围为10~150 μm,要求矿石细磨;锡石主要采用重选方法富集回收,其适宜给料粒度范围为74~250 μm,要求矿石粗磨[1-3]。实际中往往难以同时满足锡石重选粗磨要求和硫化矿浮选细磨的要求,大量的锡石被磨成细粒级,为减少细粒锡石生成,磨矿粒度又会偏大,因此,在实际生产中长期存在硫化矿欠磨与锡石过磨的矛盾。近年来,国内外学者对微细锡石开展了大量研究[4-8],浮选在细粒锡石选矿领域得到了主要应用[9-13]。要取得细粒锡石的高效浮选,药剂制度的优化选择是必需条件,众多学者对药剂开发与优化也进行了大量研究工作[14-18]。然而,浮选药剂虽能取得一定的浮选效果,但也存在价格较贵、污染环境的缺点[19-20]。通过建立磨矿过程数学理论关系,模拟磨矿过程和预测磨矿作业指标,已经成为磨矿作业调节和优化的重要途径[21-25]。从经济和环境保护角度考虑,从磨矿优化角度出发,在浮选前采取措施缓解锡石过磨和硫化矿欠磨问题具有一定的经济意义和环保意义,相关工艺矿物学研究对于锡石多金属硫化矿高效利用具有重要的意义。因此,本文作者通过化学分析、MLA、粒度分析仪等分析手段对广西大厂锡石多金属硫化矿的化学组成、矿物组成、矿物产出特征及粒度分布进行分析研究,在此基础上,提出一种优化表征锡石多金属硫化矿磨矿过程的方法,并设计磨矿试验,以求从理论和实践意义上实现磨矿优化。

1 试验原料和方法

1.1 试验原料工艺矿物学研究

1.1.1 矿石化学组成

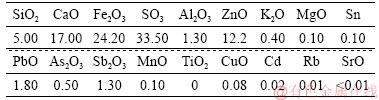

试验所用矿样取自广西大厂某选厂。所取矿石经晒干、破碎、混匀后,缩分装袋备用。试验用锡石多金属硫化矿的化学多元素分析结果如表1所示。

表1 锡石多金属硫化矿的化学多元素分析结果(质量分数)

Table 1 Results of multi-element analysis of cassiterite polymetallic sulphide ore%

由表1可知:锡石多金属硫化矿样中含有铁、锡、铅、锌、铜等大量的金属元素以及硫、砷等非金属元素,其中Fe2O3和SO3的质量分数最高,总质量分数达57.7%,表明硫铁矿物质量分数较高,其重要金属元素锡、铅、锌的质量分数分别为0.1%,1.8%和12.2%。杂质成分为CaO,SiO2与Al2O3,质量分数分别为17.1%,5.0%与1.3%,表明矿石含有一定量的石英和其他硅酸盐矿物。

1.1.2 矿石矿物组成

利用MLA对矿石进行物相分析,如表2所示。

表2 锡石多金属硫化矿物定量检测结果

Table 2 Results of mineral quantitative detection of cassiterite polymetallic sulfide ore

由表2可知:锡石多金属硫化矿中的主要成分是磁黄铁矿和闪锌矿,两者的质量分数合计约90%;铅矿物主要是脆硫锑铅矿;锑矿物为微量硫锑铁矿、自然锑和黄锑矿;银矿物主要是银黝铜矿、自然银、螺状硫银矿和辉锑银矿;锡矿物主要是锡石,少量至微量黝锡矿和硫锡矿;其他金属硫化矿物主要是黄铁矿、毒砂、黄铜矿和辉钼矿;脉石矿物主要是云母、石英等。

1.1.3 矿物粒度组成

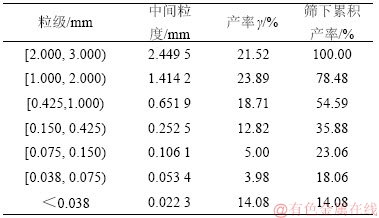

对所取矿样进行粒度测定,结果见表3。

表3 样品的粒度分布

Table 3 Particle size distribution of sample

由表3可知:0.075 mm以上粒级的矿物分布率为81.94%,0.038 mm以下粒级的分布率为14.08%,可见矿物的粒度以中粗粒嵌布为主,颗粒不均匀。

1.1.4 矿石主要矿物产出特征

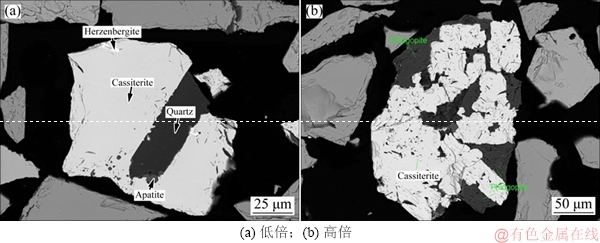

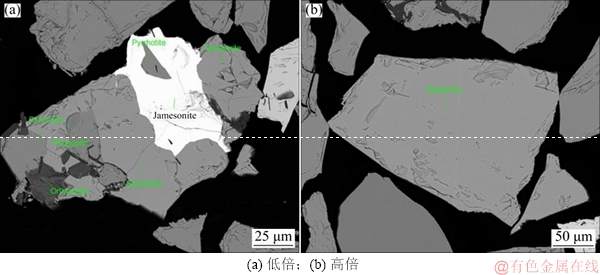

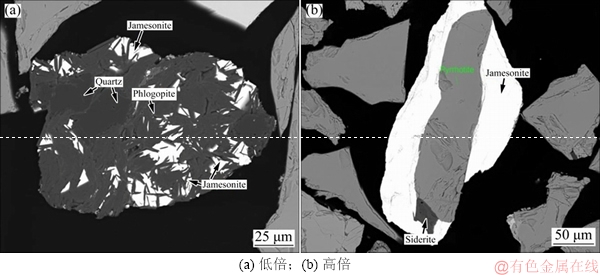

由MLA分析主要矿物的产出特征如图1~3所示。

图1 以粒状或浸染状产出的锡石(Sn)特征

Fig. 1 Characteristics of cassiterite(Sn) produced in granular or disseminated form

图2 胶结于其他硫化矿物中的闪锌矿(Zn)特征

Fig. 2 Characteristics of sphalerite(Zn) cemented in other sulphide minerals

图3 胶结于脆硫锑铅矿(Zn)中的磁黄铁矿特征

Fig. 3 Characteristics of pyrrhotite(Fe) cemented in jamesonite(Pb)

由图1~3可知:矿石中主要含Sn的矿物,能谱分析表明,锡石主要由Sn和O元素组成,含少量Fe,微量Si,其中,Sn的质量分数为77.76%,O的质量分数为21.5%,Fe的质量分数为0.29%;锡石呈自形-半自形粒状,与石英、金云母等脉石紧密连生形成集合体,呈浸染状、团块状分布。硫化矿主要由脆硫锑铅矿、磁黄铁矿和闪锌矿等矿物组成,脆硫锑铅矿主要由Pb,Sb和S组成,含少量Fe,其中,Pb的质量分数为38.98%,Sb的质量分数为35.6%,S的质量分数为21.77%,Fe的质量分数为3.34%。磁黄铁矿主要由Fe和S组成,含少量Si,其中,Fe的质量分数为61.06%,S的质量分数为38.88%,Si的质量分数为0.06%。闪锌矿主要由Zn,Fe和S组成,其中,Zn的质量分数为51.95%,Fe的质量分数为13.57%,S的质量分数为33.35%;各种硫化矿物关系密切,相互混杂以交生或共生的浸染状细粒产出。锡石由于性脆、密度大,在磨矿中容易过磨泥化,导致回收率降低,降低其过磨泥化程度,硫化矿由于嵌布粒度较细而不能得到充分单体解离,最终导致金属互损严重。

1.2 试验方法

基于锡石和硫化矿破碎特性和选别粒度的差别,将锡石多金属硫化矿分为锡石和硫化矿二元结构,其中,锡石以Sn金属元素为代表;由于Sb金属元素与Pb金属元素紧密共生,其物理特性较一致,因此,硫化矿物以Zn,Pb和Fe金属元素为代表。受实验室配套筛子的限制,在尽量满足后续适宜给料粒度范围的前提下,以0.074~0.350 mm为锡石多金属硫化矿中锡石的合格粒级,以0.038~0.150 mm为锡石多金属硫化矿中硫化矿的合格粒级。基于以上分析,提出一种锡石多金属硫化矿磨矿过程优化表征方法,即以合格粒级的金属分布率为目标,通过调控磨矿条件,达到磨矿过程优化的目的。

2 结果与讨论

试验设备选用XMQ-Φ240×90实验室锥形球磨机,磨机转速为96 r/min,磨矿介质充填率为35%。每次试验均对磨矿产物进行湿筛筛分,考察入磨粒度、磨矿时间和矿浆质量分数等因素对磨矿产物中合格粒级金属分布率的影响。

2.1 入磨粒级小于2 mm条件下磨矿时间和矿浆质量分数的影响

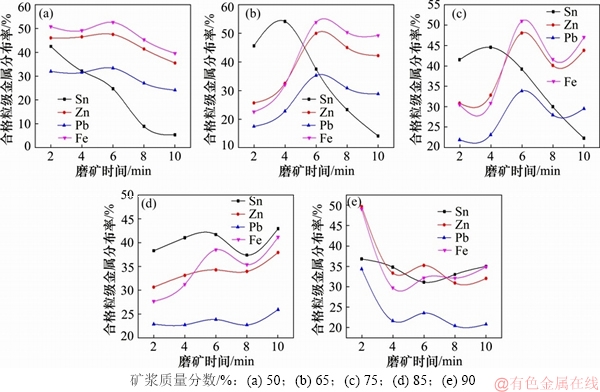

在入磨粒级小于2 mm条件下,矿浆质量分数分别为50%,65%,75%,85%和90%,磨矿时间对锡石和硫化矿物合格粒级金属分布率的影响如图4所示。

图4 入磨粒级小于2 mm且不同矿浆质量分数时磨矿时间对合格粒级金属分布率的影响

Fig. 4 Effect of grinding time on qualified particle size metal distribution rate with different ore pulp mass fractions when particle size is less than 2 mm

由图4可知:不同矿浆质量分数下,Zn,Pb和Fe元素合格粒级金属分布率随着磨矿时间的变化规律基本一致,这也证明了这3种元素代表硫化矿的合理性;当矿浆质量分数为50%时,Sn合格粒级金属分布率在磨矿时间为2 min时最大,而Zn,Pb和Fe合格粒级金属分布率在磨矿时间为6 min时均达到最大,说明锡石和硫化矿二元结构磨矿特性存在差异,且分别在磨矿2 min和6 min时,锡石和硫化矿适宜选别粒度的矿物单体解离最大;当矿浆质量分数为65%和75%时,Sn合格粒级金属分布率磨矿4 min后均达到最大,而Zn,Pb和Fe合格粒级金属分布率在磨矿6 min后均达到最大;当矿浆质量分数为85%和90%时,4种元素合格粒级金属分布率都分别在磨矿时间为10 min和2 min时达到最大,说明矿浆质量分数过大时,罩盖作用严重影响磨矿效果,弱化了锡石和硫化矿磨矿特性差异。

2.2 入磨粒级小于3 mm条件下磨矿时间和矿浆质量分数的影响

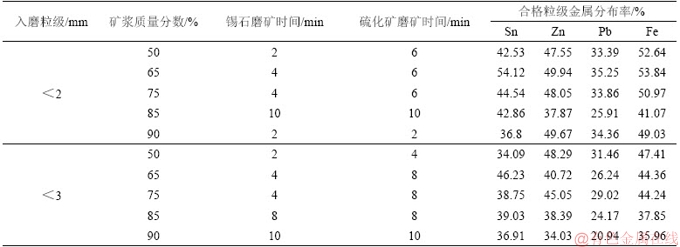

在入磨粒级小于3 mm条件下,矿浆质量分数分别为50%,65%,75%,85%和90%,磨矿时间对锡石和硫化矿物合格粒级金属分布率的影响如图5所示。不同磨矿条件下Sn,Zn,Pb和Fe合格粒级金属分布率的优化调控结果如表4所示。

由图5和表4可知:入磨粒级小于3 mm时的分析结果与入磨粒级小于2 mm时的结果类似;在不同矿浆质量分数下,Zn,Pb和Fe元素合格粒级金属分布率随着磨矿时间的变化规律也基本一致。当矿浆质量分数为50%时,Sn合格粒级金属分布率在磨矿2 min后达到最大,而Zn,Pb和Fe合格粒级金属分布率磨矿4 min后均达到最大;当矿浆质量分数分别为65%和75%时,Sn合格粒级金属分布率在磨矿4 min后均达到最大,而Zn,Pb和Fe合格粒级金属分布率在磨矿8 min后均达到最大;当矿浆质量分数为85%和90%时,这4种元素合格粒级金属分布率都分别在磨矿8 min和10 min时达到最大值,说明矿浆质量分数过大时,罩盖作用严重影响磨矿效果,弱化了锡石和硫化矿磨矿特性差异。

图5 入磨粒级小于3 mm且不同矿浆质量分数时磨矿时间对合格粒级金属分布率的影响

Fig. 5 Effect of grinding time on qualified particle size metal distribution rate with different ore pulp mass fractions when particle size is less than 3 mm

表4 不同磨矿条件优化调控下Sn,Zn,Pb和Fe合格粒级金属分布率

Table 4 Sn, Zn, Pb and Fe of qualified particle size metal distribution rate under different grinding conditions

由表4还可知:不同磨矿条件优化调控下,Sn,Zn,Pb和Fe这4种元素合格粒级金属分布率不同。磨矿优化条件如下:入磨粒级小于2 mm、矿浆质量分数为65%、锡石磨矿4 min、硫化矿物磨矿6 min。此时,Sn,Zn,Pb和Fe这4种元素合格粒级金属分布率分别取得最大值。因此,在入磨粒级小于2 mm、矿浆质量分数为65%时,采用“分步磨矿”方式,即磨矿4 min提Sn后,不改变其他磨矿条件,继续磨矿至6 min时入选硫化矿物。

3 结论

1) 锡石多金属硫化矿中的主要成分是磁黄铁矿和闪锌矿,两者的质量分数合计约90%;铅矿物主要是脆硫锑铅矿;锡矿物主要是锡石;脉石矿物主要是云母、石英等。锡石呈自形-半自形粒状,与石英、云母等脉石紧密连生形成集合体,呈浸染状、团块状分布;硫化矿主要由脆硫锑铅矿、磁黄铁矿和闪锌矿等矿物组成,各种硫化矿物关系密切,相互混杂以交生或共生的浸染状细粒产出。

2) 基于锡石和硫化矿磨矿特性和选别粒度的差别,将锡石多金属硫化矿分为锡石和硫化矿二元结构,提出使用合格粒级金属分布率为锡石多金属硫化矿磨矿过程优化表征方法。通过优化调控磨矿条件,可得出优化条件如下:入磨粒级小于2 mm、矿浆质量分数为65%、锡石磨矿4 min、硫化矿物磨矿6 min。因此,选择入磨粒级小于2 mm、矿浆质量分数为65%时,采用“分步磨矿”方式,即磨矿时间为4 min时提Sn后,不改变其他磨矿条件,继续磨矿至6 min时入选硫化矿物。

参考文献:

[1] 薛天利. 锡石多金属硫化矿选择性磨矿行为研究[D]. 南宁: 广西大学资源与冶金学院, 2014: 1-9.

XUE Tianli. Study on selective grinding behavior of cassiterite polymetallic sulphide ore[D]. Nanning: Guangxi University. College of Resources and Metallurgy, 2014: 1-9.

[2] 刘杰. 双球体新型介质对车河选矿厂磨矿物料试验研究[D]. 南宁: 广西大学资源与冶金学院, 2013: 1-10.

LIU Jie. Experimental study on grinding material of Chehe concentrator with double sphere new medium[D]. Nanning: Guangxi University. College of Resources and Metallurgy, 2013: 1-10.

[3] 邱冠周, 胡岳华, 王淀佐. 颗粒间相互作用与细粒浮选[M]. 长沙: 中南工业大学出版社, 1993: 58-89.

QIU Guanzhou, HU Yuehua, WANG Dianzuo. Interaction between particles and flotation of fine particles[M]. Changsha: Central South University of Technology Press, 1993: 58-89.

[4] 何名飞, 罗朝艳, 陈玉平, 等. 细粒锡石浮选研究[J]. 矿冶工程, 2008, 28(4): 29-31.

HE Mingfei, LUO Chaoyan, CHEN Yuping, et al. Flotation study of fine cassiterite[J]. Mining and Metallurgical Engineering, 2008, 28(4): 29-31.

[5] TAN X, HE F Y, SHANG Y B, et al. Flotation behavior and adsorption mechanism of(1-hydroxy-2-methyl-2-octenyl) phosphonic acid to cassiterite[J]. Transactions of Nonferrous Metals Society of China, 2016, 26 (9): 2469-2478.

[6] 覃文庆, 王佩佩, 任浏祎, 等. 颗粒气泡的匹配关系对细粒锡石浮选的影响[J]. 中国矿业大学学报, 2012, 41(3): 420-424.

QIN Wenqing, WANG Peipei, REN Liuyi, et al. Effect of matching relationship between particles and bubbles on the flotation of fine cassiterite[J]. Journal of China University of Mining and Technology, 2012, 41(3): 420-424.

[7] QIN Wenqing, REN Liuyi, WANG Peipei, et al. Electro-flotation and collision-attachment mechanism of fine cassiterite[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 917-924.

[8] WU X Q, ZHU J G. Selective flotation of cassiterite with benzohydroxamic acid [J]. Minerals Engineering, 2006, 19(14): 1410-1417.

[9] 秦广林. 悬振锥面选矿机处理广西大厂细泥锡尾矿工业试验研究[D]. 昆明: 昆明理工大学国土资源工程学院, 2011: 1-16.

QIN Guanglin. Industrial Test Study on suspension cone concentrator for Guangxi Dachang fine tin tailings[D]. Kunming: Kunming University of Science and Technology. College of Land and Resources Engineering, 2011: 1-16.

[10] QIN Wenqing, REN Liuyi, XU Yangbao, et al. Adsorption mechanism of mixed salicylhydroxamic acid and tributyl phosphate collectors in fine cassiterite electro-flotation system[J]. Journal of Central South University, 2012, 19(6): 1711-1717.

[11] RIVERA Madrid I E, RODRIGUEZ B A, BUSTAMANTE O, et al. Ceramic ball wear prediction in tumbling mills as a grinding media selection tool[J]. Powder Technology, 2014, 26(8): 373-376.

[12] ZHOU Y C, TONG X, SONG S X. Beneficiation of cassiterite fines from a tin tailing slime by froth flotation[J]. Separation Science and Technology, 2014,49(3): 458-463.

[13] 刘琰, 沈战武, 邓军, 等. 锡石振动光谱特征与矿物成因类型[J]. 光谱学与光谱分析, 2008, 28(7): 1506-1509.

LIU Yan, SHEN Zhanwu, DENG Jun,et al. Vibration spectra and genetic type of cassiterites[J]. Spectrosc Spect Anal, 2008, 28(7): 1506-1509.

[14] ALDRICH C, MARAIS C, SHEAN B J, et al. Online monitoring and control of froth flotation systems with machine vision: a review[J]. International Journal of Mineral Processing, 2010, 96(1/2/3/4): 1-13.

[15] QIN Wenqing, XU Yangbao, LIU Hui, et al. Flotation and surface behavior of cassiterite with salicylhydroxamic acid[J]. Industrial and Engineering Chemistry Research, 2011, 50(18): 10778-10783.

[16] 漆燕, 尤翔宇, 向仁军, 等. 尾砂中锡石的综合回收及浮选机理[J]. 湖南科技大学学报(自然科学版), 2015, 30(3): 119-124.

QI Yan, YOU Xiangyu, XIANG Renjun, et al. Comprehensive recovery and flotation mechanism of cassiterite in tailings[J]. Journal of Hunan University of Science and Technology (Natural Science Edition), 2015, 30(3): 119-124.

[17] 农升勤, 邓位鹏, 姚贵明, 等. 低品位细粒锡石浮选试验研究[J]. 有色金属(选矿部分), 2014(3): 37-40.

NONG Shengqin, DENG Weipeng, YAO Guiming, et al. Study on the flotation test of low grade fine cassiterite[J]. Nonferrous Metal (Mineral Processing Section), 2014(3): 37-40.

[18] 刘杰, 宫贵臣, 韩跃新. 有机抑制剂对微细粒锡石可浮性的影响[J]. 中国矿业大学学报, 2016, 45(3): 610-614.

LIU Jie, GONG Guichen, HAN Yuexin. Influence of organic depressants on the floatability of fine cassiterite[J]. Journal of China University of Mining and Technology, 2016, 45(3): 610-614.

[19] AMANKWAH R K, KHAN A U, PICKLES C A, et al. Improved grindability and gold liberation by microwave pretreatment of a free-milling gold ore[J]. Mineral Processing and Extractive Metallurgy, 2005, 114(1): 30-36.

[20] SREENIVAS T, SRINIVAS K, NATARAJAN R, et al. An integrated process for the recovery of tungsten and tin from a combined wolframite scheelite cassiterite concentrate[J]. Mineral Processing and Extractive Metallurgy Review, 2004, 25(3): 193-203.

[21] DUNDAR H, BENZER H, AYDOGAN N. Application of population balance model to HPGR crushing[J]. Minerals Engineering, 2013, 50/51: 114-120.

[22] SAEIDI F, TAVARES L M, YAHYAEI M, et al. A phenomenological model of single particle breakage as a multi-stage process[J]. Minerals Engineering, 2016, 98: 90-100.

[23] GEN

. Optimization of an industrial scale open circuit three-compartment cement grinding ball mill with the aid of simulation[J]. International Journal of Mineral Processing, 2016, 154: 1-9.

. Optimization of an industrial scale open circuit three-compartment cement grinding ball mill with the aid of simulation[J]. International Journal of Mineral Processing, 2016, 154: 1-9.

[24] GHORBANI Y, MAINZA A N, PETERSEN J, et al. Investigation of particles with high crack density produced by HPGR and its effect on the redistribution of the particle size fraction in heaps[J]. Minerals Engineering, 2013, 43: 44-51.

[25] SEGURA-SALAZAR J, BARRIOS G P, RODRIGUEZ V, et al. Mathematical modeling of a vertical shaft impact crusher using the Whiten model[J]. Minerals Engineering, 2017, 111: 222-228.

(编辑 赵俊)

收稿日期: 2018 -06 -04; 修回日期: 2018 -08-09

基金项目(Foundation item):国家自然科学基金资助项目(51741401, 51264001, 51874105);973计划前期研究专项(2014CB460606)(Projects(51741401, 51264001, 51874105) supported by the National Natural Science Foundation of China; Project(2014CB460606) supported by the Preliminary Research Project of 973 Plan)

通信作者:李艳军,博士,教授,从事复杂难选矿石高效开发利用研究;E-mail: liyanjun@mail.neu.edu.cn.

摘要:采用多种检测手段研究锡石多金属硫化矿化学和矿物组成、矿物产出特征及粒度组成,研究锡石过磨和硫化矿欠磨机理,并基于磨矿特性及优化表征方法开展磨矿试验,在此基础上,提出磨矿优化表征方法和“分步磨矿”的概念。研究结果表明:矿石中有用矿物为磁黄铁矿、闪锌矿、脆硫锑铅矿和锡石,脉石矿物主要为云母和石英;锡石与石英、云母等脉石紧密连生形成集合体,各种硫化矿物关系密切,相互混杂以交生或共生的浸染状细粒产出。以合格粒级金属分布率为目标,磨矿最优条件如下:入磨粒级小于2 mm、矿浆质量分数为65%、磨矿时间为4 min时提Sn,然后,不改变其他磨矿条件,继续磨矿至6 min时入选硫化矿物。

[1] 薛天利. 锡石多金属硫化矿选择性磨矿行为研究[D]. 南宁: 广西大学资源与冶金学院, 2014: 1-9.

[2] 刘杰. 双球体新型介质对车河选矿厂磨矿物料试验研究[D]. 南宁: 广西大学资源与冶金学院, 2013: 1-10.

[3] 邱冠周, 胡岳华, 王淀佐. 颗粒间相互作用与细粒浮选[M]. 长沙: 中南工业大学出版社, 1993: 58-89.

[4] 何名飞, 罗朝艳, 陈玉平, 等. 细粒锡石浮选研究[J]. 矿冶工程, 2008, 28(4): 29-31.

[6] 覃文庆, 王佩佩, 任浏祎, 等. 颗粒气泡的匹配关系对细粒锡石浮选的影响[J]. 中国矿业大学学报, 2012, 41(3): 420-424.

[9] 秦广林. 悬振锥面选矿机处理广西大厂细泥锡尾矿工业试验研究[D]. 昆明: 昆明理工大学国土资源工程学院, 2011: 1-16.

[13] 刘琰, 沈战武, 邓军, 等. 锡石振动光谱特征与矿物成因类型[J]. 光谱学与光谱分析, 2008, 28(7): 1506-1509.

[16] 漆燕, 尤翔宇, 向仁军, 等. 尾砂中锡石的综合回收及浮选机理[J]. 湖南科技大学学报(自然科学版), 2015, 30(3): 119-124.

[17] 农升勤, 邓位鹏, 姚贵明, 等. 低品位细粒锡石浮选试验研究[J]. 有色金属(选矿部分), 2014(3): 37-40.

[18] 刘杰, 宫贵臣, 韩跃新. 有机抑制剂对微细粒锡石可浮性的影响[J]. 中国矿业大学学报, 2016, 45(3): 610-614.