堆浸过程中矿岩散体粒间孔隙尺寸的演化规律

宋 鑫1,杨保华 2, 3,吴爱祥1,王洪江1

(1. 北京科技大学 土木与环境工程学院,北京,100083;

2. 中南大学 资源与安全工程学院,湖南 长沙,410083;

3. 湖南涉外经济学院 电气与通信工程学部,湖南 长沙,410205)

摘 要:

摘 要:根据X射线CT技术无损伤地探测细菌浸出前、后矿岩散体介质孔隙结构特征,利用MATLAB环境编写程序对矿岩散体介质颗粒间横向及纵向孔隙尺寸分布进行统计,研究细菌浸出过程中矿岩散体粒间孔隙尺寸演化规律及其对溶浸液渗流特性的影响。研究结果表明:矿岩散体介质孔隙尺寸分布不均匀,分布范围广,基本呈正态规律分布;浸出后顶部区域中等孔隙和大孔隙数量增加,小孔隙数量减少,底部区域中等孔隙也有所增加,但小孔隙数量减少,横向大孔隙数量减少,纵向大孔隙数量变化不明显;浸出后平均孔隙尺寸比浸出前有所增大,大孔隙含量增加,加强了浸堆的渗流各向异性;微细颗粒的运移和沉积对孔隙尺寸演化影响程度最大。

关键词:

中图分类号:TF18 文献标志码:A 文章编号:1672-7207(2009)06-1712-06

Pore size evolution of granular ore media during heap leaching

SONG Xin1, YANG Bao-hua2, 3, WU Ai-xiang1, WANG Hong-jiang1

(1. School of Civil and Environment Engineering, University of Science and Technology Beijing,Beijing 100083, China;

2. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

3. College of Electrical and Information Engineering, Hunan International Economics University, Changsha 410205, China)

Abstract: The pore structure characteristics of granular ore media before and after bacteria heap leaching were detected by X-ray computed tomography. Based on MATLAB software, the cross sectional and longitudinal pore size distributions of granular ore media were calculated to investigate the evolution of granular ore media’s pore size distribution during heap leaching and its influences on permeability. The results show that intergranular pores are inhomogeneous. The pore size ranges widely and assumes a normal distribution. After leaching, the amounts of middle and large pores at top zone increase, while the amount of small pores decreases. The amount of middle pores at bottom zone increases, small pores decrease, cross sectional large pores decrease, and the longitudinal large pores have no obvious change. Average pore size increases after leaching, so the ratio of large pores increases and the permeability anisotropy is strengthened. The transport and precipitation of fine particles is the most critical factor for the evolution of pore size distribution.

Key words: bacteria heap leaching; granular ore media; pore size; CT technology; image analysis

堆浸系统中的矿岩散体是由不同粒径且形状极不规则的矿石颗粒堆积而成的松散多孔介质,所形成的孔隙结构非常复杂[1]。在浸出过程中,矿岩散体介质受多种因素的影响[2-4],如物理因素、化学因素、微生物因素等,这些因素之间的相互作用直接导致矿岩散体孔隙率、孔隙尺寸及孔隙连通性等孔隙结构参数发生变化,从而进一步影响到溶浸液的渗流效果、浸出速率及最终浸出率。因此,探明孔隙结构在堆浸过程中的演化规律,有助于进一步了解溶浸液在堆中的渗流规律,对于指导筑堆及提高浸出效果具有重要意义。对于堆浸体系孔隙结构演化规律研究,传统的试验方法只能测试其整体孔隙率[5],但无法监测和计算矿岩散体颗粒间孔隙尺寸等结构参数,因此,无法定量描述孔隙结构的演化规律。近年来,计算机断层扫描技术CT(Computed tomography)能无损伤地探测研究对象内部结构特征,已被应用于多孔介质孔隙特征分析,如土壤、岩石及多孔材料等[6-11],但对于堆浸中矿岩散体介质孔隙结构的研究较少,Lin等[12-13]进行了初步研究,对堆浸中矿岩散体介质的孔隙率进行了分析。在此,本文作者基于CT技术及图像处理技术,定量分析了矿岩散体介质细菌浸出前、后横向和纵向粒间孔隙尺寸及其空间分布规律,并对孔隙尺寸变化机理进行分析。

1 实 验

1.1 原 料

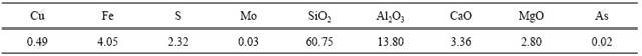

实验所用的矿样来自江西省德兴铜矿的原生矿。经化学元素分析及物相分析,其化学成分及化学物相如表1和表2所示。

表1 矿样的化学成分

Table 1 Chemical composition of ore sample w/%

表2 矿样中铜的化学物相

Table 1 Chemical phases of Cu in ore sample w/%

1.2 实验方法

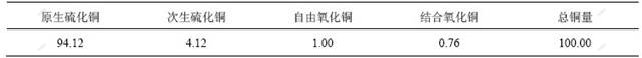

采用以上矿物进行微生物柱浸试验,所用的溶浸柱为有机玻璃柱,柱高为500 mm,内径为60 mm。首先,往溶浸柱内装满不同粒径的矿样,矿样粒径分布见图1。

图1 硫化铜矿颗粒粒径分布

Fig.1 Particle size distribution of sulfide copper ore samples

为了减小边壁效应,最大颗粒粒径控制在10 mm,为浸出圆柱内径的1/6。接着,采用CT机对溶浸柱进行全长扫描,扫描断层厚度为0.75 mm,扫描后产生约700张二维CT图像。对溶浸柱中的矿岩散体进行90 d细菌浸出试验,试验结束后,再以相同参数对溶浸柱进行全长扫描,从而获得浸出后矿岩散体介质孔隙结构图像。

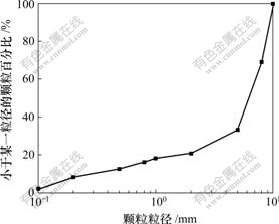

1.3 孔隙尺寸计算方法

对于所获得的二维CT图像,首先进行图像预处理[14],即把CT灰度图像转换成二值化图像,见图2。以不断增大尺寸的圆盘型结构元素对二值化图像进行形态学开运算,便可以统计出孔隙尺寸的分布。开运算是对图像先进行腐蚀,然后进行膨胀。对于每一个开运算,计算所有像素值的和,在此基础上,可以计算某一尺寸的孔隙数量占所有孔隙数量的百分比。由于孔隙的形状不一,尺寸不等,因此,无法准确计算出每一个孔隙的直径,采用此算法计算出的孔隙尺寸实际上是孔隙的圆当量直径。

(a) 原始灰度图像;(b) 二值化图像

图2 图像预处理过程

Fig.2 Preprocessing of CT images

2 结果与讨论

2.1 横向孔隙尺寸分布

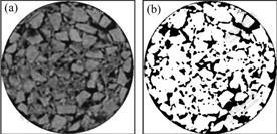

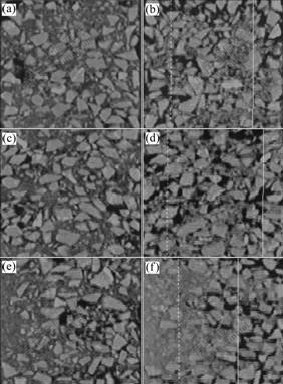

针对浸出前后所获得的CT图像,从溶浸柱标高为475,250及22 mm处的3个位置,分别选择1张图像(见图3)。其中:图3(a)~(c)所示为浸出前矿岩上、中、下横截面图像;图3(d)~(f)所示为浸出后矿岩上、中、下横截面图像。对图像进行预处理后,对孔隙率和孔隙尺寸进行计算,得出图3(a)~(f)所示图像的孔隙率分别为34.03%,25.32%,28.66%,41.03%,27.12%和17.87%。

(a) 浸出前,矿岩上部图像;(b) 浸出后,矿岩上部图像;(c) 浸出前,矿岩中部图像;

(d) 浸出后,矿岩中部图像;(e) 浸出前,矿岩下部图像;(f) 浸出后,矿岩下部图像

图3 浸出前、后矿岩散体典型横截面图像

Fig.3 Typical cross sectional images of granular media before and after leaching

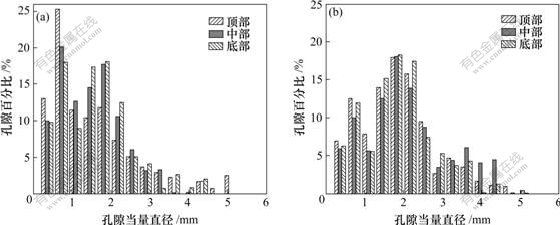

为了对浸出过程中不同时间和不同位置的散体介质横向孔隙尺寸进行比较,分别绘制了横向孔隙尺寸对比图,见图4和图5。由图4可知:在浸出之前,溶浸柱内矿岩散体介质的孔隙尺寸分布不均匀,溶浸柱底部区域存在一些大孔隙(直径>5 mm),而中部区域绝大部分孔隙直径均小于4 mm;浸出结束后,整体孔隙尺寸分布相对浸出前均匀,直径为2 mm左右的中等孔隙分布范围最广,同时,底部区域的大孔隙数量减少,而顶部和中部区域(尤其是顶部区域)的大孔隙数量有所增加。由图5可知:顶部区域在浸出后中等孔隙(直径为1.8~3.0 mm)和大孔隙(直径>5.0 mm)的数量均有所增加,而小孔隙(直径<1 mm)的数量却有所减小。在底部区域大孔隙数量减小和小孔隙数量均有所减小,但是,中等孔隙(尺寸为1.80~3.96 mm)的数量明显增加。对浸出前、后顶部和底部区域的孔隙尺寸分布进行正态分布拟合,发现浸出后孔隙尺寸正态分布曲线的峰值往右偏移,说明浸出后横向平均孔隙尺寸有所增大。

(a) 浸出前;(b) 浸出后

图4 浸出前、后溶浸柱上、中、下3个截面孔隙尺寸比较

Fig.4 Comparisons of cross sectional pore size at top, middle and bottom zone before and after leaching

(a) 溶浸柱顶部;(b) 溶浸柱底部

图5 浸出前、后溶浸柱顶部和底部横向孔隙尺寸比较

Fig.5 Comparisons of cross sectional pore size at top and bottom zone before and after leaching

2.2 纵向孔隙尺寸分布

分别在溶浸柱底部、中部及顶部区域选取100张图像进行三维重构[15],并在同一方位对重构后的三维结构体沿轴线纵向剖开,结果见图6。

(a) 浸出前,浸柱顶部;(b) 浸出后,浸柱顶部;(c) 浸出前,浸柱中部;(d) 浸出后,浸柱中部;(e) 浸出前,浸柱底部;(f) 浸出后,浸柱底部

图6 溶浸柱中矿岩散体浸出前、后纵剖面

Fig.6 Longitudinal profiles of granular ore media before and after leaching

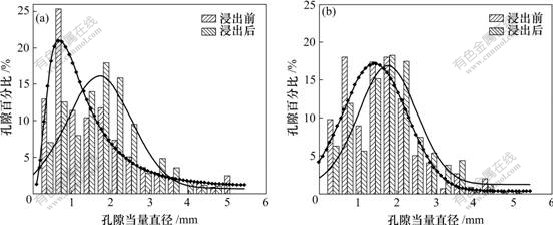

以相同方法对这3个区域的纵剖面图进行孔隙尺寸计算。为了对浸出过程中不同时间和位置的矿岩散体介质纵向孔隙尺寸进行比较,分别绘制纵向孔隙尺寸对比图,见图7和图8。由图7可知:浸出之前,溶浸柱内矿岩散体的孔隙尺寸分布不均匀,尤其是顶部区域,小孔隙(直径<1 mm)分布概率最高,同时也存在着一定数量的大孔隙(直径>5 mm);中部和底部区域孔隙尺寸分布相对均匀,绝大部分孔隙尺寸小于3 mm;浸出结束后,底部、中部及顶部三区域的孔隙尺寸分布相对均匀,直径为2 mm左右的孔隙分布最广。由图8可知:顶部区域在浸出后小孔隙(直径< 1 mm)和大孔隙(直径>5 mm)的数量均有所减少,而直径为2 mm左右的中等孔隙的数量则有所增加;底部区域在浸出后小孔隙(直径<1 mm)的数量同样有所减少,大孔隙数量变化不明显,而直径为2 mm左右的中等孔隙的数量有所增加。通过对浸出前、后顶部和底部区域的纵向孔隙尺寸分布进行正态分布拟合,得知浸出后纵向孔隙尺寸正态分布曲线的峰值往右偏移,说明浸出后纵向平均孔隙尺寸有所增大,这与横向孔隙尺寸分布规律一致。

(a) 浸出前;(b) 浸出后

图7 浸出前、后溶浸柱上、中、下3个区域纵向孔隙尺寸比较

Fig.7 Comparisons of longitudinal pore size at top, middle and bottom zone before and after leaching

(a) 溶浸柱顶部;(b) 溶浸柱底部

图8 浸出前、后溶浸柱顶部和底部纵向孔隙尺寸比较

Fig.8 Comparisons of longitudinal pore size at top and bottom zone before and after leaching

2.3 孔隙尺寸演化对渗流特性的影响

由以上分析得知,矿岩散体介质在细菌浸出前、后的孔隙尺寸分布不均匀,基本呈正态分布。在本实验的级配条件下,孔隙当量直径分布范围为0~6 mm,以中等孔隙尺寸的孔隙数量居多,同时,存在着一定数量的大孔隙;在浸出过程中,孔隙结构不断发生演化,孔隙尺寸也逐渐发生变化。根据图5和图8,浸出后与浸出前最为明显的一个特征是小孔隙数量减小,平均孔隙尺寸增大。细菌堆浸过程孔隙尺寸发生变化主要受以下几个因素的影响:

a. 矿岩散体介质在水力和重力作用下,整体发生变形和沉降。

b. 细菌浸出过程伴随胶状物或沉淀物产生。

c. 细菌在颗粒表面吸附聚集并形成一定厚度的生物膜。

d. 初始及次生微细颗粒随溶浸液发生运移。

颗粒间大孔隙主要受第1个因素的影响,小孔隙则主要受后面3个因素的影响,其中,微细颗粒的运移是对孔隙尺寸影响最大的因素。若细颗粒运移到某一层面并被小孔隙拦截而发生沉积,则小孔隙将被填充,此时,小孔隙数量将减小,同时,中等粒径和大粒径的孔隙比例增加,产生的结果就是孔隙平均直径增大。但平均孔隙尺寸增加,并不说明渗流效果一定就好,因为渗流效果同时还受孔隙率等因素的影 响,如底部区域浸出后孔隙率减小,但同时平均孔隙尺寸很大,说明存在一定数量尺寸较大的孔隙,这会加强浸堆的渗流各向异性,形成优势流,增加浸出盲区,最终降低浸出效果。

3 结 论

a. 在堆浸过程中,矿岩散体介质颗粒间孔隙尺寸不断发生变化,结合CT技术及图像分析可以实现对孔隙尺寸空间分布的定量描述。

b. 浸出前、后矿岩散体介质各区域孔隙尺寸分布不均匀,分布范围广,基本呈正态分布规律。

c. 浸出后,矿岩散体介质平均孔隙尺寸有所增大,大孔隙比例增加,容易形成优势流,增加浸出盲区,降低浸出效果。

d. 矿岩散体介质孔隙尺寸变化受物理、化学及生物等多种因素的影响,其中微细颗粒的运移是影响孔隙尺寸分布最大的因素。

参考文献:

[1] Guyon E. Disorders in granular matter[J]. Physica A, 2005, 357(1): 150-158.

[2] Pradhan N, Nathsarma K C, Rao K S, et al. Heap bioleaching of chalcopyrite: A review[J]. Minerals Engineering, 2008, 21(5): 355-365.

[3] Leahy M J, Davidson M R, Schwarz M P. A model for heap bioleaching of chalcocite with heat balance: Bacterial temperature dependence[J]. Minerals Engineering, 2005, 18(13): 1239-1252.

[4] Mousavi S M, Jafari A, Yaghmaei S, et al. Computer simulation of fluid motion in a porous bed using a volume of fluid method: Application in heap leaching[J]. Minerals Engineering, 2006, 19(10): 1077-1083.

[5] Bartlett R W. Solution mining: Leaching and fluid recovery of materials[M]. New York: Gordon and Breach Science Press, 1998: 33-34.

[6] Al-Raoush R I, Willson C S. Extraction of physically realistic pore network properties from three-dimensional synchrotron X-ray microtomography images of unconsolidated porous media systems[J]. Journal of Hydrology, 2005, 300(1/4): 44-64.

[7] Hirono T, Takahashi M, Nakashima S. In situ visualization of fluid flow image within deformed rock by X-ray CT[J]. Engineering Geology, 2003, 70(1/2): 37-46.

[8] Ketcham R A, Carlson W D. Acquisition, optimization and interpretation of X-ray computed tomographic imagery: Applications to the geosciences[J]. Computers & Geosciences, 2001, 27(4): 381-400.

[9] Monga O, Ngom F N, Delerue J F. Representing geometric structures in 3D tomography soil images: Application to pore-space modeling[J]. Computers & Geosciences, 2007, 33(9): 1140-1161.

[10] Appoloni C R, Fernandes C P, Rodrigues C R O. X-ray microtomography study of a sandstone reservoir rock[J]. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2007, 580(1): 629-632.

[11] Goldstein L, Prasher S O, Ghoshal S. Three-dimensional visualization and quantification of non-aqueous phase liquid volumes in natural porous media using a medical X-ray computed tomography scanner[J]. Journal of Contaminant Hydrology,2007, 93(1/4): 96-110.

[12] Lin C L, Miller J D, Garcia C. Saturated flow characteristics in column leaching as described by LB simulation [J]. Minerals Engineering, 2005, 18(10): 1045-1051.

[13] Miller J D, Lin C L, Garcia C, et al. Ultimate recovery in heap leaching operations as established from mineral exposure analysis by X-ray microtomography[J]. Mineral Processing, 2003, 72(1/4): 331-340.

[14] WU Ai-xiang, YANG Bao-hua, XI Yong. Pore structure of ore granular media by computerized tomography image processing[J]. Journal of Central South University of Technology, 2007, 14(2): 220-224.

[15] 杨保华, 吴爱祥, 王贻明, 等. 堆浸中矿岩散体介质孔隙结构三维可视化[J]. 矿冶工程, 2008, 28(2): 6-9.

YANG Bao-hua, WU Ai-xiang, WANG Yi-ming, et al. Three dimensional visualization of pore structure of ore granular media for heap leaching[J]. Mining and Metallurgical Engineering, 2008, 28(2): 6-9.

收稿日期:2008-11-15;修回日期:2009-02-06

基金项目:国家自然科学基金资助项目(50774011);国家教育部博士点基金资助项目(20070008038)

通信作者:杨保华(1977-),女,湖南永州人,博士研究生,讲师,从事图像处理及可视化技术在溶浸采矿中的应用研究;电话:13975196862;E-mail: yangbaohuar2004@126.com