Effect of salinity and acidity on bioleaching activity of mesophilic and extremely thermophilic bacteria

H. DEVECI1, M. A. JORDAN2, N. POWELL2, I. ALP1

1. Department of Mining Engineering, Karadeniz Technical University, Trabzon 61080, Turkey;

2. Camborne School of Mines, UEC, Tremough Campus, Penryn, Cornwall, TR10 9EZ, UK

Received 25 July 2007; accepted 29 November 2007

Abstract:

The effects of bacterial strain, salinity and pH on the bioleaching of a complex ore using mesophilic and extremely thermophilic bacteria were investigated and the statistical analysis of the results was performed using ERGUN’s test. The extreme thermophiles were shown to display superior kinetics of dissolution of zinc compared with the mesophiles as confirmed by the statistical analysis. Bioleaching performance of the extreme thermophiles is found to improve in response to the increase in acidity (pH from 2.0 to 1.0) whilst the activity of the mesophiles is adversely affected by decreasing pH. Statistical analysis of the bioleaching data indicates that the effect of pH is insignificant in the range of pH 1.0-1.2 for the extreme thermophiles and pH 1.4-2.0 for the mesophiles. Salinity is shown to have a suppressing effect on the mesophiles. However, the extreme thermophiles appear to be halophilic in character as they could operate efficiently under saline conditions (1%-4%Cl- (w/v)).

Key words:

bacteria; bioleaching; salinity; pH; sulphide;

1 Introduction

In recent years, bioleaching processes have gained importance for the extraction of metals particularly from the difficult-to-treat and low grade ores or concentrates [1]. Bioleaching is essentially a dissolution process based on the exploitation of acidophilic bacteria, which have the ability to derive the energy required for their growth and other metabolic functions from the oxidation of ferrous iron (Eqn.(1)) and/or elemental (Eqn.(2)) or reduced sulphur compounds[2-3]. The reaction products, ferric iron and/or acid attack the sulphide minerals such as sphalerite (Eqns.(3)-(4)) leading to their dissolution [4]. Elemental sulphur that forms/encrusts on the mineral surface mainly by ferric attack (Eqn.(3)) can act as diffusion barrier adversely affecting progress of the dissolution process. Therefore, the main role of bacteria in the oxidation of sulphide minerals is the generation of ferric iron (and the maintenance of a high Fe3+/Fe2+) and the removal of elemental sulphur layer from the unreacted mineral surface[4-5].

2Fe2++1/2O2+2H+![]() 2Fe3++H2O (1)

2Fe3++H2O (1)

S0+3/2O2+H2O![]() H2SO4 (2)

H2SO4 (2)

ZnS+2Fe3+→Zn2++2Fe2++S0 (3)

ZnS+2H+→Zn2++H2S (4)

Mesophilic bacteria such as Acidithiobacillus ferrooxidans, Leptosprillum ferrooxidans and Acidithiobacillus thiooxidans operating at t≤40 ℃ are the most commonly used microorganisms for the bioleaching of sulphide minerals[6]. Thermophilic bacteria with their ability to thrive at high temperatures up to 85 ℃ have great potential for use in bioleaching processes due to the improvement expected in the kinetics of metal dissolution, particularly from the recalcitrant minerals such as chalcopyrite[1,7-8].

In bioleaching processes, the rate and extent of oxidation of sulphide minerals are intimately controlled by the growth (oxidative activity) of bacteria. There are many factors including pH and the toxicity of anions (e.g. Cl-) and cations that may affect the growth and hence the bioleaching activity of a culture[6,9-10]. The quality of process water with regard to salinity may be of great importance for the application of bioleaching processes in the areas where the availability of chloride-free process water may be limited[11-12].

The accurate interpretation of batch leaching data on which the development of a process is based is of vital significance for the determination or optimisation of process conditions. Despite the general availability of a variety of statistical techniques, the time-dependent nature of bioleaching data (i.e. metal extraction varying with time) restricts the use of many conventional statistical methods for the analysis of experimental data [13]. POWELL and JORDAN[14] demonstrated a corrective technique based on ERGUN’s test[15] for the eradication of time-dependency of leaching data.

In this study, the effects of pH and salinity (Cl- ions) on the bioleaching performance of the selected cultures of mesophilic and extremely thermophilic bacteria were investigated. Statistical assessment of the experimental results using ERGUN’s test to eradicate the time- dependency and to examine the differences among the varying experimental conditions (i.e. pH, bacterial strain and chloride concentration) for significance was undertaken.

2 Materials and methods

2.1 Ore sample

A complex zinc/lead/silver sulphide ore sample from the McArthur River deposit, Northern Territory of Australia was used in this study. Mineralogical and chemical analyses have shown that the ore sample contains sphalerite (ZnS), galena (PbS) and pyrite (FeS2) as the major sulphide phases with a chemical composition of 16.2% Zn, 5.6% Pb and 7.95% Fe. The crushed ore sample as received was ground to below 300 ?m (d80= 250 ?m) prior to use in the experiments.

2.2 Bacteria and growth media

The mesophilic cultures, SJ2 (A. ferrooxidans) and the mixed culture designated WJM (which were isolates from the acid mine drainage of Wheal Jane Mine, Cornwall, UK)[16], and the extremely thermophilic cultures, Sulfolobus (S. metallicus) and DSM 1651 (Acidianus brierleyi) were used in the bioleaching experiments. The growth of mesophiles (30 ℃) and extreme thermophiles (70 ℃) on the ore (1%, w/v) were carried out on orbital shakers using an enriched salt solution containing MgSO4.7H2O (0.4 g/L), (NH4)2SO4 (0.2 g/L), K2HPO4.3H2O (0.1 g/L) and KCl (0.1 g/L) as the growth media.

2.3 Bioleaching experiments

Bioleaching experiments were carried out in 250 mL Erlenmeyer flasks with a working volume of 100 mL. A 1% (w/v) ore in enriched salt solution (90 mL) was prepared in flasks, which were then autoclaved prior to the inoculation with a 10 mL (10%, v/v) aliquot of an appropriate culture previously grown under aseptic conditions. In the control experiments in the absence of bacteria, a 10 mL solution of 5% thymol in methanol was transferred into the flasks to prevent any bacterial activity during the experiments. In the chloride experiments, the calculated amounts of chloride (as NaCl) were added to the flasks to produce 1%-4%Cl- (w/v) in the final volume of solution.

The oxidation of the ore was monitored by the daily removal of 1 mL samples. These samples were used to determine the metal concentration (Zn, Fe and Pb) by AAS and pH. If exceeded, pH was adjusted to the predetermined level by the addition of 18 mol/L H2SO4. The mean values of replicate (duplicate or triplicate) experiments were presented in the results.

2.4 Statistical methodology for analysis of data

In bioleaching processes, the oxidation of sphalerite is a heterogeneous reaction controlled by surface chemical reactions by bacterially generated ferric iron and acid and by diffusion of reactants and products through porous layer of elemental sulphur formed on the unreacted mineral surface[5]. In this regard, shrinking core models based on surface reaction (Eqn.(5)) and product layer diffusion (Eqn.(6)) were fitted to describe the bioleaching profiles.

![]() (5)

(5)

![]() (6)

(6)

where R is the fraction reacted; t is the time (h); ks and kp are the rate constant (h-1).

Due to its consistency with the bioleaching data, shrinking core surface reaction control model was adopted in conjunction with ERGUN’s test for the statistical analysis of the bioleaching tests. The model parameter (the rate constant, ks) was initially determined using non-linear regression analysis. The “goodness of fit” of the model for each set of bioleaching data was also evaluated and the rate constants, ks, (i.e. gradients of the plots of 1-(1-R)1/3 vs t) produced with statistically acceptable correlation coefficients (at 5% confidence level) were assigned as an estimate of the rate of metal dissolution characterising the bioleaching data. ERGUN’s test was then applied to eradicate the time-dependent nature of the rates of metal extraction (gradients) and to test for the differences between these for the varying pH, the type/strain of bacteria and the chloride concentrations. The details of statistical analysis procedure used herein and the outlines of the mathematical methodology for ERGUN’s test can be found elsewhere[14].

3. Results and discussion

3.1 Effect of pH and salinity on mesophiles

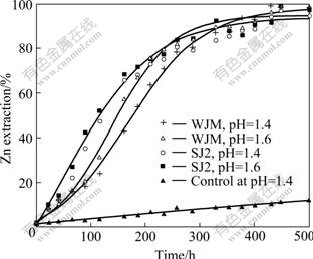

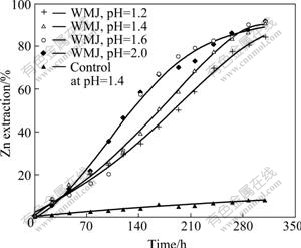

Fig.1 illustrates the bioleaching of the ore using WJM and SJ2 cultures at pH 1.4 and 1.6. Compared with the acid leach as indicated by the control, the contribution of the mesophilic bacteria to the dissolution of zinc was substantial with an enhancement of ≥14-fold in the rate and of ≥8-fold in the recovery. The bioleaching performance of both mesophiles was similar with over 95% of zinc having been dissolved in the presence of both cultures at the both pH levels. An increase in the pH from 1.4 to 1.6 had a positive effect on the bioleaching performance of both cultures with an increase in the dissolution rate of zinc observed for WJM culture, in particular (Fig.1). These findings suggested that the optimum pH for both cultures may well be above pH 1.6 as, in fact, further tests using WJM culture showed that the dissolution of zinc further improved with increasing the pH to 2.0 (Fig.2). This was consistent with the optimum pH range of 2.0-2.5 reported for mesophilic bacteria[6]. However, the potential for the precipitation of iron would increase with decreasing acidity and could become significant at higher pH as the pulp density increases, leading to the increase in the availability of precipitate forming ions such as ferric iron. Considering the extensive dissolution of zinc occurred at pH 1.2 and 1.4 (Figs.1-2), both cultures can be adapted to operate efficiently at lower pH as demonstrated by PORRO et al[17] and DEVECI et al[18].

Fig.1 Extraction of zinc from ore using mesophilic bacteria at 30 ℃ and pH 1.4-1.6

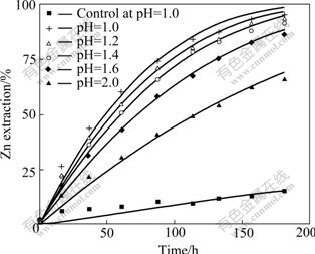

Fig.2 Effect of pH (1.2-2.0) on extraction of zinc from ore (1%, w/v) using WJM culture at 30 ℃

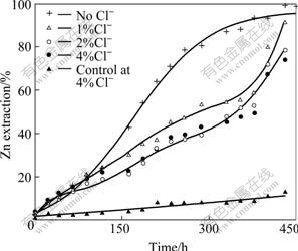

The addition of chloride (1%-4%Cl-, w/v) appeared to severely inhibit the activity of WJM culture (at pH 1.4 and 30 ℃) with a marked decrease in the dissolution rate and extent of zinc, as shown in Fig.3. LEONG et al [19] also noted the detrimental effect of chloride (up to 8 g/L Cl-) on the bioleaching of a copper ore using mixed cultures of Thiobacilli. These investigators also reported that adaptation of bacteria to chloride levels of up to 5 g/L was possibly ameliorating the deleterious effect of chloride on the dissolution process. WESTON et al[12] argued that the deleterious effect of salt was not due to the chloride present, but, rather, due to the coexisting ions such as sodium leading to the formation of jarosite precipitates since they observed no apparent effect of salinity at 1-2 g/L Cl- on the bacterial oxidation rate when operating at lower pH (1.1-1.3). DEW et al[9] suggested that high concentrations of chloride in solution could damage the membrane of the bacteria.

Fig.3 Effect of added chloride (0-4%Cl-, w/v) on extraction of zinc from ore (1%, w/v) using WJM culture at 30 ℃ and pH 1.4

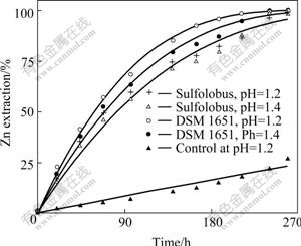

3.2 Effect of pH and salinity on extreme thermophiles

Fig.4 shows the bioleaching of the ore using the extremely thermophilic strains Sulfolobus and DSM 1651 (Acidianus Brierleyi) at pH of 1.2 and 1.4. Compared with the mesophiles (Figs.1-2) the extreme thermophiles were able to dissolve ≥99% of the zinc present in the ore over a relatively short incubation period of 260 h. Although the zinc extraction was practically complete at the end of incubation period, both the extreme thermophiles consistently exhibited a better performance for the dissolution of zinc at a pH of 1.2. This was consistent with the data presented in Fig.5 showing the effect of pH (1.0-2.0) on the bioleaching activity of DSM 1651 culture.

Fig.4 Extraction of zinc from ore using extremely thermophilic bacteria at 70 ℃ with pH (1.2-1.4)

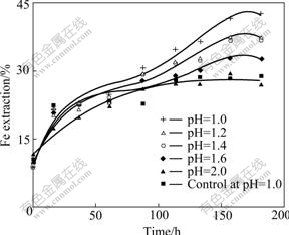

Fig.5 shows that the rate and extent of dissolution of zinc increased with decreasing pH in contrast to the mesophiles, which did not illustrate such a trend in response to the increase in acidity (Fig.2). A limited zinc extraction of only 66% at a dissolution rate of 1.79×10-3 h-1 occurred at pH 2.0 compared with 95% Zn recovery (at 4.21×10-3 h-1) recorded at pH 1.0. JORDAN[16] had showed that the dissolution rate of zinc and copper from a complex concentrate by the extreme thermophile Sulfolobus increased with decreasing the pH in the range of 2.0-1.2 in agreement with the current findings. The enhancement in the bioleaching performance of DSM 1651 culture with increasing acidity was also evident from the bioleaching profiles obtained for iron (Fig.6). The limited extraction of iron (i.e. 43% at pH 1.0) compared with extensive extraction of zinc (i.e. 95%) may be an indication of preferential/selective oxidation of sphalerite over pyrite. This is consistent with the electrochemical properties of both minerals with sphalerite having a lower rest potential and hence being electrochemically more active than pyrite under the oxidising conditions [20].

Fig.5 Effect of pH (1.0-2.0) on extraction of zinc from ore (1%, w/v) using DSM 1651 culture at 70 ℃

Fig.6 Effect of pH (1.0-2.0) on extraction of iron from ore (1%, w/v) using DSM 1651 culture at 70 ℃

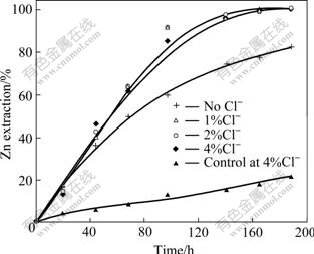

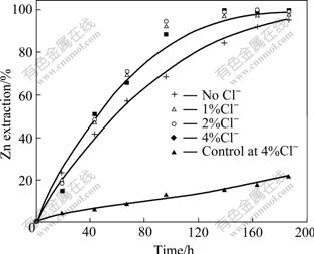

Figs.7-8 show the effect of salinity (0-4%Cl-, w/v) on the extraction of zinc by both the extreme thermophiles at pH 1.2. The response of both cultures to the saline environment was similar in character with an identical pattern for metal extraction under the same experimental conditions. In contrast to the suppressing effect on the mesophiles, the addition of chloride appeared to produce a positive effect on the extraction of zinc by the extreme thermophiles particularly following an initial period of about 50 h. To illustrate, over 98% of zinc was extracted by DSM 1651 culture at 1%-4%Cl- (w/v) compared with 85% Zn recovery in the absence of added chloride. It may be inferred from these findings that the extreme thermophiles are halophilic in nature with their ability to tolerate extremely saline environments.

Fig.7 Effect of added chloride (0-4%Cl-, w/v) on extraction of zinc from ore (1%, w/v) using Sulfolobus culture at 70 ℃ and pH 1.2

Fig.8 Effect of added chloride (0-4%Cl-, w/v) on extraction of zinc from ore (1%, w/v) using DSM 1651 culture at 70 ℃ and pH 1.2

It may be of practical importance to note that the formation of jarosite-type precipitates could present problems in the extremely thermophilic systems operating at high temperatures (70 ℃) presumably due to the availability of counter ions such as Na+ present in saline environments. Such precipitates could adversely affect the metal extraction via the formation of a passivating layer on the unreacted surface of minerals [12, 21]. In this respect, the ability of the extreme thermophiles to operate at lower pH (Fig.5) could become important from the overall process point of view to minimise the formation of potentially deleterious precipitates. It should be noted that the decrease in pH would probably alleviate the formation of jarosite-type precipitates[21-22].

With respect to the behaviour of lead within the experiments where no chloride was added, the solubilisation of lead was minimal with over 98% of lead having reported to the residues most likely in the form of either insoluble lead sulphate or undissolved galena irrespective of the type (and strain) of bacteria and pH. This reflects the selective extraction of zinc from the complex ore within the bioleaching process. However, the dissolution of lead, most likely via lead-chloro complexes was promoted with the addition and/or increasing the concentration of chloride in solution. To illustrate, the extraction of lead increased from 4% to 69% with increasing the level of Cl- from 1% to 4% (w/v) during the bioleaching of the ore using Sulfolobus culture at 70 ℃.

3.3 Bioleaching kinetics and statistical analysis of data

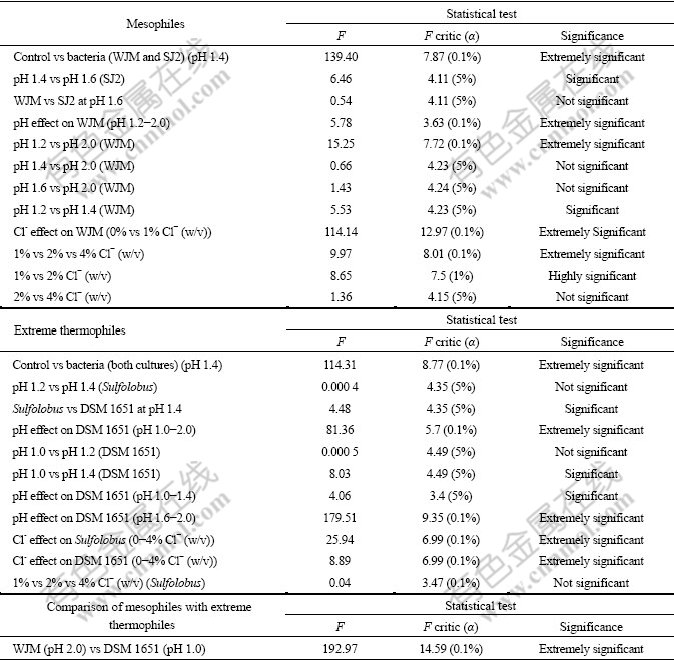

Bioleaching of zinc from the ore under different experimental conditions was described by shrinking core surface reaction model and rate constants (ks) were determined as listed in Table 1. Statistical tests for the significance of the differences in the bioleaching data produced under the experimental conditions were carried out in respect of ERGUN’s test, which is essentially One-way Analysis of Variance (ANOVA) for gradients (i.e. rate constants, ks values). This postulates the equality of the gradients (dissolution rates) as a Null Hypothesis. The outcomes of the statistical analysis of the various tests are summarised in Table 2 where the significance of the differences is indicated either at 5% (“significant”) or 1% (“highly significant”) or 0.1% (“extremely significant”) levels.

Table 1 Kinetics of bioleaching of zinc from ore by mesophilic and extremely thermophilic bacteria under different conditions of pH and salinity using shrinking core surface reaction model

Table 2 Summary of statistical analysis of experimental results using ERGUN’s test (“α” represents level of significance and test results are presented as “significant” at 5%, “highly significant” at 1% and “extremely significant” at 0.1% levels)

Initially the contribution of the mesophilic and extremely thermophilic cultures of bacteria to the dissolution of zinc was tested as indicated by the “control versus bacteria” in Table 2. It was assumed that the dissolution rate of zinc occurred in the control was equal to that in the bioleaching (i.e. Null Hypothesis). This hypothesis was rejected in that the differences in the rates were clearly “extremely significant”. In other words, the dissolution rate of zinc was substantially enhanced in the presence of all the cultures. Since this initial assumption was rejected, subsequent tests were performed for differences between the dissolution rates produced at different conditions in an attempt to compare the performances of strains (and groups) of bacteria, to determine the optimum pH (i.e. the pH effect) for the cultures concerned, and to examine the effect of chloride on the bacterial cultures.

ERGUN’s test did not detect any significant difference between the rates of dissolution of zinc produced by the mesophiles (WJM and SJ2) at pH 1.6. However, the differences in the performance of the extreme thermophiles (Sulfolobus and DSM 1651) at pH 1.4 appeared to be statistically significant probably as an indication of the better performance of DSM 1651 culture.

Statistical analysis of the pH data for WJM and DSM 1651 cultures suggests that the pH in the range of 1.0-2.0 is an important parameter affecting the dissolution process. Notwithstanding this, the differences recorded in the dissolution rates of zinc were found to be statistically insignificant in the pH ranges of 1.4-2.0 and 1.0-1.2 for WJM and DSM 1651 cultures, respectively (Table 2). These may be regarded as the optimum pH range for the process using these cultures.

In a similar manner, ERGUN’s test was applied to evaluate the effect of chloride on the dissolution of zinc by the mesophile WJM and the extreme thermophile Sulfolobus and DSM 1651 cultures. These tests affirmed the inhibitory effect of chloride on the dissolution of zinc by WJM culture and the ability of both the extreme thermophiles to oxidise the ore more efficiently under the saline conditions. Finally, the “best” performed cultures of mesophiles (WJM at pH 2.0) and extreme thermophiles (DSM 1651 at pH 1.0) were compared with the results indicating that the extreme thermophiles have superior capacity for the bioleaching of the ore.

4 Conclusions

1) The bioleaching tests performed within the current study show that the complex sulphide ore is readily amenable to the selective bacterial extraction of zinc with lead present in the ore remaining in the residues during the bioleaching process. pH appears to exert a significant effect on the dissolution process controlling the oxidative activity of the mesophiles and extreme thermophiles. The bioleaching performance of the mesophiles tends to deteriorate with increasing acidity from pH 2.0 to 1.2. The extreme thermophiles, however, have greater tolerance for acidity than the mesophiles as the extraction of zinc was observed to improve with decreasing pH in the range of 1.0-2.0. Statistical analysis of the pH data allowed the determination of the optimum pH range i.e., pH (1.0- 1.2) for the extreme thermophiles and pH (1.4-2.0) for the mesophiles since the differences in the dissolution rates of zinc produced by the respective cultures within these ranges of pH were found to be statistically insignificant.

2) The quality of process water with particular reference to salinity appears to be of practical importance for the mesophiles since the addition of chloride (1%-4%Cl-, w/v) was shown to have a detrimental effect on the bioleaching activity of the mesophilic WJM culture. These findings are consistent with the results of the statistical analysis of the data. However, the extreme thermophiles were found to consistently perform well under the saline conditions tested indicating the halophilic nature of these microorganisms.

3) It is also statistically affirmed that the extreme thermophiles exhibit superior kinetics for the dissolution of zinc from the ore compared with the mesophiles. The statistical methodology adopted herein has proved a useful tool for the accurate interpretation of the batch experimental results and it can be used for the optimisation (or estimation) of process parameters.

Acknowledgements

The author would like to express their appreciation to the Turkish Ministry of Education for financial support to Dr. DEVECI during his studies at Camborne School of Mines, University of Exeter, UK.

References

[1] RAWLINGS D E, DEW D, DU PLESSIS C. Biomineralization of metal containing ores and concentrates [J]. Trends in Biotechnology, 2003, 21: 38-44.

[2] INGLEDEW W J. Thiobacillus ferrooxidans: The bioenergetics of an acidophilic chemolithotroph [J]. Biochimica et Biophysica Acta, 1982, 683: 89-117.

[3] SUZUKI I. Microbial leaching of metals from sulphide minerals [J]. Biotechnology Advances, 2001, 19: 119-132.

[4] SAND W, GEHRKE T, JOZSA P G, SHIPPERS A. (Bio)chemistry of bacterial leaching-direct vs. indirect bioleaching [J]. Hydrometallurgy, 2001, 59: 159-175.

[5] FOWLER T A, CRUNDWELL F K. Leaching of zinc sulphide by Thiobacillus ferrooxidans: Bacterial oxidation of sulphur product layer increases the rate of zinc sulphide dissolution at high concentrations of ferrous iron [J]. Applied and Environmental Microbiology, 1999, 65: 5285-5292.

[6] BOSECKER K. Bioleaching: Metal solubilization by micro- organisms [J]. FEMS Microbiology Reviews, 1997, 20: 591-604.

[7] NORRIS P R, BURTON N P, FOULIS N A M. Acidophiles in bioreactor mineral processing [J]. Extremophiles, 2000, 4: 71-76.

[8] d’HUGUES P, FOUCHER S, GALLE-CAVALLONI P, MORIN D. Continuous bioleaching of chalcopyrite using a novel extremely thermophilic mixed culture [J]. International Journal of Mineral Processing, 2002, 66: 107-119.

[9] DEW D W, LAWSON E N, BROADHURST J L. The BIOX? process for biooxidation of gold bearing ores or concentrates [C]// RAWLINGS D E. Biomining: Theory, Microbes and Industrial Processes. Berlin: Springer-Verlag, 1997: 45-79.

[10] DEVECI H, AKCIL A, ALP I. Parameters for control and optimisation of bioleaching of sulphide minerals [C]// KONGOLI F, THOMAS B, SAWAMIPHAKDI K. Materials Science & Technology 2003 Symposium: Process Control and Optimization in Ferrous and Non Ferrous Industry. Warrendale P.A.: TMS, 2003: 77-90.

[11] BUDDEN J R, SPENCER P A. The effect of temperature and water quality on bacterial oxidation: The advantages of a moderately thermophilic culture over conventional Thiobacillus cultures. Randol Gold Forum. 1991: 271-274.

[12] WESTON T, PERKINS J, RITCHIE I, MARAIS H. Concentrate biooxidation in a hypersaline environment for Knowna Belle [C]// Biomine’94, Int. Conference and Workshop Applications of Biotechnology to the Minerals Industry. Perth W.A.: Australian Mineral Foundation, 1994.

[13] JORDAN M A, POWELL N, PHILLIPS C V, CHIN C K. Experimental data analysis: A guide to the selection of simple statistical tests [J]. Minerals Engineering, 1997, 10: 275-286.

[14] POWELL N, JORDAN M A. Batch leaching data analysis: Eradication of time dependency prior to statistical analysis [J]. Minerals Engineering, 1997, 10: 859-870.

[15] ERGUN S. Application of the principle of least squares to families of straight lines [J]. Industrial and Engineering Chemistry, 1956, 48: 2063-2068.

[16] JORDAN M A. The oxidation of base metal sulphides and mechanisms and preferential release of ferrous iron [D]. Cornwall, UK: University of Exeter, 1993.

[17] PORRO S, BOIARDI J L, TEDESCO P H. Bioleaching improvement at pH 1.4 using selected strains of Thiobacillus ferrooxidans [J]. Biorecovery, 1989, 1: 145-154.

[18] DEVECI H, ALP I, YAZICI E Y. Bench-scale bioleaching of a complex zinc sulphide ore in stirred tank reactors [C]// AKAR A, IPEKOGLU U, COCEN I, POLAT M. Proc of the Xth International Mineral Processing Symposium (IMPS). Izmir: Dokuz Eylul University, 2004: 523-529.

[19] LEONG B J Y., DREISINGER D B, LO M, BRANION R M R. HACKL R P, GORMERLY L S, CROMBIE D R. The microbiological leaching of a sulphidic copper ore in a strongly saline medium (I): Shake flask and column studies [C]// TORMA A E, WEY J E, LAKSHMANAN V I. Biohydrometallurgical Technologies, Vol. 1: Proc. of Int. Biohydrometallurgy Symp. Warrendale, P.A.: TMS, 1993: 117-126.

[20] NATARAJAN K A. Electrochemical aspects of bioleaching of base metal sulphides [C]// EHRLICH H L, BRIERLEY C L. Microbial Mineral Recovery. McGraw-Hill, 1990: 79-106.

[21] DEVECI H, AKCIL A, ALP I. Bioleaching of complex zinc sulphides using mesophilic and thermophilic bacteria: Comparative importance of pH and iron [J]. Hydrometallurgy, 2004, 73: 293-303.

[22] DUTRIZAC J E. Factors affecting alkali jarosite precipitation [J]. Metallurgical Transactions, 1983, 14B: 531-539.

Corresponding author: H. DEVECI; Fax: +90-462-3257405; E-mail: hdeveci@ktu.edu.tr