Trans. Nonferrous Met. Soc. China 29(2019) 296-304

Strain-induced α-to-β phase transformation during hot compression in Ti-5Al-5Mo-5V-1Cr-1Fe alloy

Kai LI, Ping YANG

School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China

Received 21 December 2017; accepted 2 May 2018

Abstract:

The dynamic phase transformation of Ti-5Al-5Mo-5V-1Cr-1Fe alloy during hot compression below the β transus temperature was investigated. Strain-induced α-to-β transformation is observed in the samples compressed at 0-100 K below the β transus temperature. The deformation stored energy by compression provides a significant driving force for the α-to-β phase transformation. The re-distribution of the solute elements induced by defects during deformation promotes the occurrence of dynamic transformation. Orientation dependence for the α-to-β phase transformation promotion is observed between {100}-orientated grains and {111}-orientated grains. Incomplete recovery in {111}-orientated grains would create a large amount of diffusion channels, which is in favor of the α-to-β transformation. The effects of reduction ratio and strain rate on the dynamic phase transformation were also investigated.

Key words:

titanium alloy; hot compression; phase transformation; orientation dependence;

1 Introduction

Titanium and titanium alloys are widely utilized in aviation, aerospace, marine and other special applications for the corresponding low density, high strength, and good fatigue and corrosion resistance. In order to obtain ideal microstructure and good mechanical properties, hot processing is often applied to titanium alloys. The Ti-5Al-5Mo-5V-1Cr-1Fe is a dual-phase alloy containing both α and β phases at room temperature. The Ti-5Al-5Mo-5V-1Cr-1Fe alloy is often deformed in the α+β phase region around the β-to-α+β transformation temperature [1-3]. Moreover, complicated evolutions such as phase transformation, dynamic recrystallization and dynamic recovery would occur along with hot deformation. The phase distribution has large effect on deformation properties of titanium alloys during hot mechanical processing [4]. The microstructure and mechanical properties of titanium alloys are sensitive to processing parameters such as deformation temperature and strain rate [5-9]. HUA et al [7] compressed the Ti-5553 alloy with various parameters. It was discovered that deformation parameters could significantly affect the microstructure evolution, and the dynamic recrystallization was more noticeable at high temperature and low strain rate. WANG et al [8] discovered that the fraction of dynamic globularization increased approximately with increasing strain, temperature and decreasing strain rate. However, the effect of deformation parameters on phase transformation was less described.

Deformation-induced phase transformation is widely reported. Different conclusions or even disagreements in various types of titanium alloys exist. The stress-induced martensite transformation in metastable β titanium alloys was investigated by many researchers [10,11]. The Ti-6Al-2Sn-4Zr-6Mo alloy was researched by DEHGHAN-MANSHADI and DIPPENAAR [12], where the alloy was deformed near the β transfer temperature and an apparent strain-induced β→α transformation was discovered during the thermo-mechanical schedules. KOIKE et al [13] reported that the tensile deformation at temperatures ranging from 1050 to 1200 K could promote the α→β phase transformation. It was explained that the distribution of Fe element between α and β phases in highly deformed areas differed from the less deformed area and the β transus temperature could be lowered by more than 70 K. LIU et al [14] discovered that compressive deformation restrained the α→β phase transformation in the Ti-1.5Fe-2.25Mo alloy. It was demonstrated that the compressive stress might impose a negative effect on the α→β transformation with a volume expansion. This might be one of the reasons for the stabilization of α phase under compressive loading. Therefore, the re-distribution of the solute elements was investigated to explain the driving force for dynamic phase transformation during hot compression. The effects of different hot processing parameters were investigated to establish a relationship between phase fractions and deformation parameters.

2 Experimental

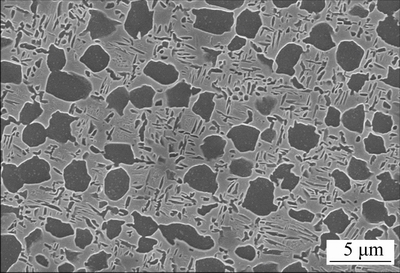

The Ti-5Al-5Mo-5V-1Cr-1Fe alloy in the present work was obtained from a hot forged bar with a diameter of 350 mm. The initial microstructure of the as-forged bar is shown in Fig. 1. The composition of the alloy is presented in Table 1. The β transus temperature of the experimental alloy was approximately 1143 K.

Fig. 1 Microstructure of initial forged bar by SEM

Table 1 Chemical compositions of Ti-5Al-5Mo-5V-1Cr-1Fe alloy (wt.%)

Cylindrical samples of 6 mm in diameter and 12 mm in height were severed from the as-received Ti-5Al-5Mo-5V-1Cr-1Fe alloy bar. Prior to compression, each sample was heated to the corresponding temperature and retained for 15 min on a G1500-Gleeble simulation machine, to acquire microstructure in a thermodynamic equilibrium. The deformation temperatures ranged from 1053 to 1113 K with an interval of 20 K. For the samples compressed at 1073 K, the strain rates were 0.01, 0.1, 1 and 10 s-1 and the height reductions were 20%, 40%, 60% and 80%. All samples were quenched in water to retain the deformed microstructure.

The sections along the axial direction of the compressed samples were prepared for both microstructure and orientation determination. Regarding the electron backscattered diffraction (EBSD) examination, the samples were electropolished with a polishing solution consisting of 5% perchloric acid and 95% ethyl alcohol with a voltage of 30 V for 30 s at room temperature. The EBSD system (Channel 5), mounted on an Ultra55 scanning electron microscope, was applied to presenting the phase distribution and orientation features after compression. The element mappings of both compressed and un-compressed samples at 1073 K were acquired by a JXA-8530F electron probe microanalyzer (EPMA).

3 Results and discussion

3.1 Strain-induced α-to-β transformation

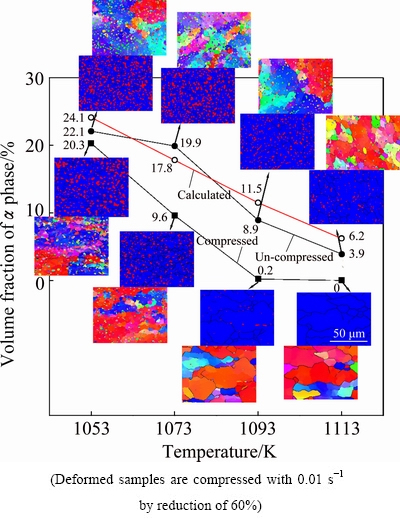

The comparison of α phase volume fractions between the compressed samples and un-compressed samples at corresponding temperatures is presented in Fig. 2. To obtain the thermodynamic equilibrium state of the alloy, α phase volume fractions at different temperatures are calculated by Thermal-Calc. The calculation results demonstrate that the un-compressed samples retain a fine consistency with the true thermodynamic equilibrium state as the samples are retained for several minutes at the relevant temperatures.

Fig. 2 Phase distribution maps and orientation maps of both compressed and un-compressed samples at 1053, 1073, 1093 and 1113 K

The α-to-β transformation promotion is indistinctive at 1053 K or lower temperatures, whereas strain-induced α-to-β phase transformation becomes a major factor on α volume fraction along with the temperature increasing. The α phase has completely transformed into β phase when the compressing temperature reaches up to 1093 K. The β transus temperature has been decreased by an excess of 50 K during hot compression as the equilibrium β transus temperature of the Ti-5Al-5Mo- 5V-1Cr-1Fe is approximately 1143 K.

The α-to-β transformation is determined by the free energy variation of both phases, caused by the temperature increase when the samples are heated without deformation. Whereas, when the samples are under deformed state, the stress concentration increases within the material, especially on the phase boundaries. The stress concentration caused by the boundary compression would change the total free energy of the system [15]. As a result, the phase system equilibrium is broken near the boundary and it prompts α phase transforming into β phase. The solute elements diffusion between the phases has a significant effect on the α-to-β transformation, due to the fact that α-to-β is a diffusion controlled phase transformation process.

Since α phase has a hexagonal structure and β phase has a body-centered cubic structure, a strain during the α-to-β transformation exists, which would cause a volume change. The lattice constants are determined as a=0.3241 nm for β phase and a=0.2951 nm and c= 0.4683 nm for α phase by the X-ray diffraction method.

(1)

(1)

From the view of thermodynamics, the total free energy without deformation can be expressed as [16]

ΔGs=ΔG(α→β)+PΔV (2)

where ΔGs is the change of total free energy, ΔG(α→β) is the energy change associated with the α-to-β transformation and PΔV is the strain energy during the α-to-β transformation. The ΔGs should be zero when the system resides in thermodynamic equilibrium.

Also, the total free energy along with compression can be expressed as

ΔGs=ΔG(α→β)+PΔV+ΔGd (3)

where ΔGd is released deformation-stored energy. Moreover, the value of ΔGd is affected by the ΔV. If ΔV is negative, it can contribute to the deformation energy release caused by compression. As a result, the value of ΔGd is negative and ΔGs is also in a negative value. Consequently, the α-to-β transformation would occur with compression.

3.2 Dynamic mechanism of transformation

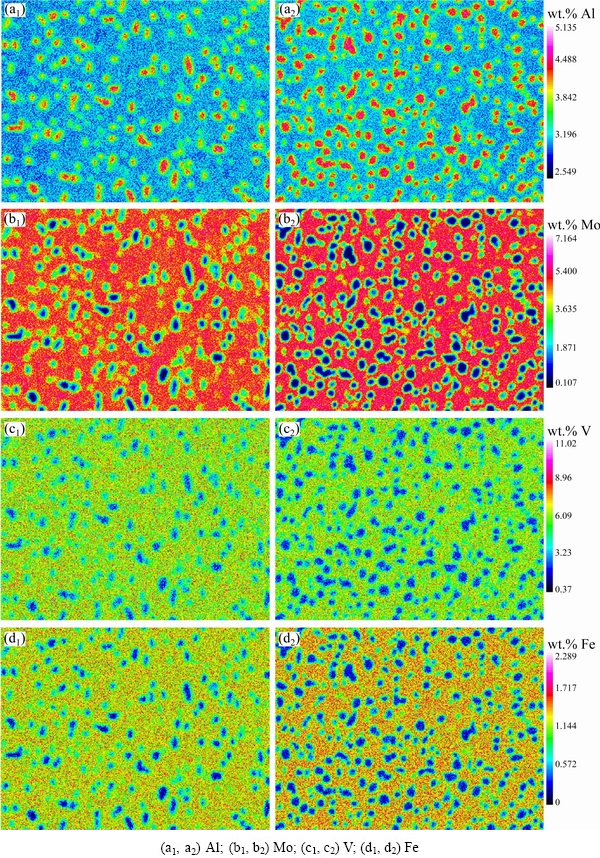

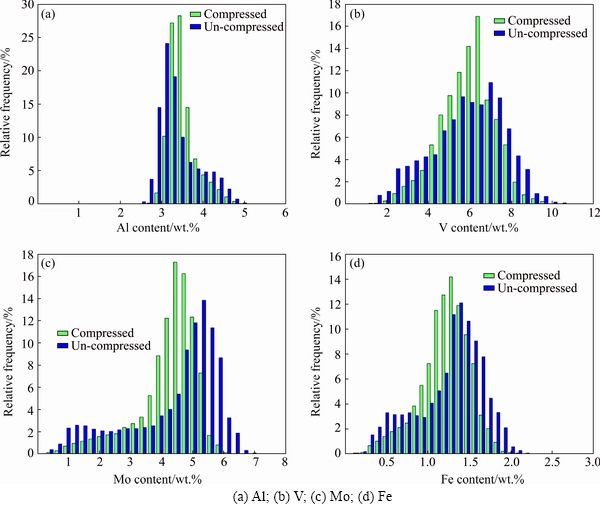

The diffusion of solute elements is promoted during hot compression because of the formation of dislocations and the migration of the sub-grain boundary during dynamic recovery and recrystallization. As α-stabilized element, the decrease of Al element fraction in α phase would cause α phase free energy to increase. On the contrary, other solute elements including Mo, V, Fe and Cr are β-stabilized elements and the corresponding increase of these elements may also lead to the increase of α phase free energy. The Al, Mo, V and Fe element maps in both compressed and un-compressed samples at 1073 K are presented in Fig. 3. It is apparently observed that the distributions of solute elements in the compressed sample are quite homogeneous compared to those in un-compressed sample. The Al element fraction of α phase in the compressed sample is lower than that in the un-compressed sample. On the contrary, Mo, V and Fe element fractions of α phase are higher in the compressed sample. The Mo and Fe elements demonstrate significant differences between the compressed and un-compressed samples. Figure 4 presents the relative frequencies of various elements in different samples. The element distributions are quite dispersive in the compressed sample, which indicates that the diffusion has occurred earlier and faster between α and β phases due to the deformation.

The Fe element diffuses more easily than other elements, due to certain diffusion mechanism [17]. Since Fe enriches almost entirely in the β phase, only a slight contribution to α phase transformation exists. The diffusion of Mo is relatively difficult compared with other solute elements within the Ti matrix under the un-deformed condition. Therefore, under the effect of compression, Mo element displays a significant difference, causing the transfer temperature to decrease in α phase. As the α and β phases have different crystal structures, more deformation defects would concentrate near the phase boundaries during compression. The defects offer a large amount of diffusion channels for the solute elements in both phases. Therefore, the solute elements display a new distribution and they are more continuous near the phase boundaries compared to the un-compressed samples. The Mo element displays an evident distinction compared to the other elements, as presented in Fig. 4. The α-to-β transformation temperature would change due to the elemental reassignment adjacent to the phase boundaries, which provides a possibility for the strain-induced α-to-β phase transformation.

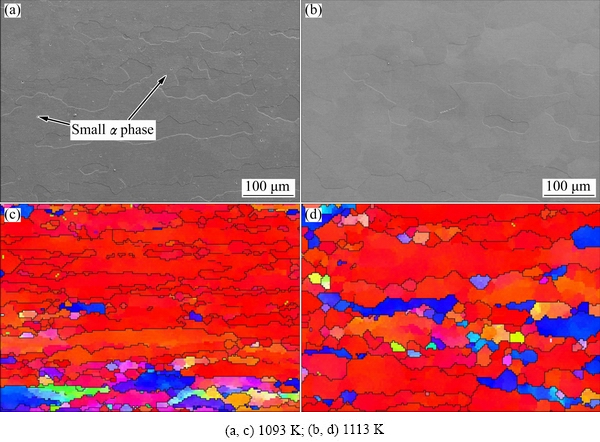

3.3 Strain-restricted β-to-α transformation

For the strain energy effect on phase transformation during compression to be further understood, two samples were heated to 1173 K (30 K beyond transformation temperature) and retained for 15 min to obtain complete β phase. Then, the samples were cooled down to 1093 and 1113 K, respectively, for compression. The microstructures under SEM and EBSD are presented in Fig. 5. The sample compressed at 1113 K retains a complete β phase, which indicates that the β-to-α transformation does not occur during compression. The α phase occurs until 1093 K, with a significantly low fraction and in a small size. The β-to-α transformation would even be restricted by compression as the α phase has a higher free energy during compression. If α phase forms, it would transform back to β phase again during compression. As a result, the β-to-α transformation is restricted during hot compression.

Fig. 3 Distribution maps of solute elements in both compressed (a1-d1) and un-compressed (a2-d2) samples at 1073 K

3.4 Orientation dependence of α-to-β transformation

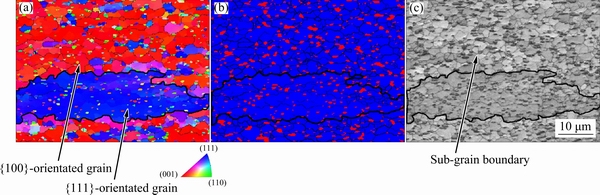

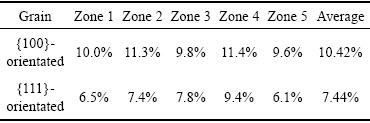

Although compressing strain could generally promote the α-to-β transformation, much difference between {100}- and {111}-orientated grains exists. Figure 6 presents the EBSD maps of various grains. The volume fraction of each grain can be obtained from the phase distribution maps. For statistics purposes, five EBSD maps at various locations of the sample are obtained. The α phase fraction in the {100}-orientated grain is 10.42% and the fraction in the {111}-orientated grain is 7.44%, as listed in Table 2. In addition, it can also be discovered that the α grain size in the {111}- orientated grain is less than that in {100}-orientated grain. It can be concluded that there is more opportunity for the α-to-β transformation in {111}-orientated grains than in {100}-orientated grains.

Fig. 4 Relative frequencies of elements in compressed and un-compressed samples at 1073 K

Fig. 5 Micrographs (a, b) and EBSD maps (c, d) of samples heated to 1173 K and compressed at different temperatures

Fig. 6 Orientation map (a), phase distribution map (b) and band contrast map (c) of {100}-orientated grains and {111}-orientated grains in sample compressed at 1073 K

Table 2 Volume fractions of α phase in both {100}- and {111}- orientated grains within various zones by EBSD

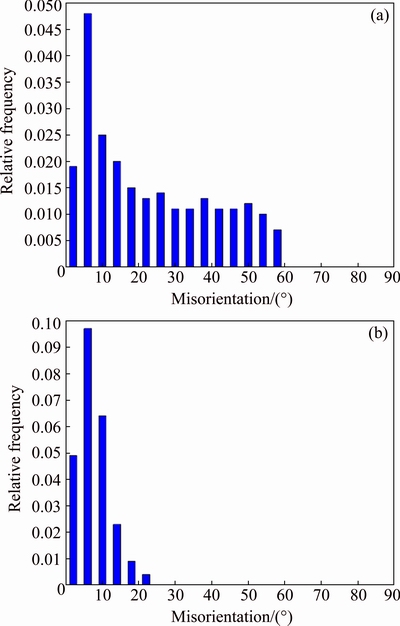

Fig. 7 Misorientations of {100}-orientated (a) and {111}- orientated (b) grains in Fig. 6

Figure 6 presents one of the EBSD maps with IPF colors, phase distribution and band contrast. A large amount of high-angle grain boundaries exist in the {100}-orientated grain, as presented in Fig. 6(c), and the amount of high-angle grain boundaries is less in the {111}-orientated grain. The misorientation distributions of various grains are presented in Fig. 7. A large amount of middle-angle grain boundaries of β phase exist besides low-angle grain boundaries in {100}-orientated grains. On the contrary, the {111}-orientated grains contain the low-angle grain boundaries only. Three microstructural changes in the {100}-orientated grains would occur during compression. Firstly, dynamic recovery is the main mechanism, which is beneficial to strain energy release. Due to the migration and tangling of dislocations, certain sub-grains form during compression. Secondly, partly dynamic recrystallization occurs at the {100}-orientated grain boundaries and the recrystallized grains maintain a medium misorientation with the main {100}- orientated grains. This is the main reason that causes a relatively high misorientation in the {100}-orientated grains than in {111}-orientated grains. Finally, the {100}-orientated grains merge with {111}-orientated grains during compression; therefore, the volume fraction of the {100}-orientated grains increases. As a result, most of the deformation energy in the {100}-orientated grains has been released by these ways. In contrast, the orientation in the {111}-orientated grains varies continuously, inducing more low misorientation in the {111}-orientated grains. It can be concluded that the {111}-orientated grains are in a deformed state. Higher stored deformation energy is retained in the {111}- orientated grains and it is converted to the driving force of α-to-β transformation enhancement. A higher amount of diffusion channels exist near the phase boundary in the {111}-orientated grains, which can promote the phase transformation. Under the effect of the strain-induced α-to-β transformation, the transformed volume fraction in the {111}-orientated grains should exceed that in the {100}-orientated grains. As a result, the orientation dependence occurs during the α-to-β transformation between the {111}-orientated and {100}-orientated grains.

3.5 Effects of deformation parameters on phase transformation

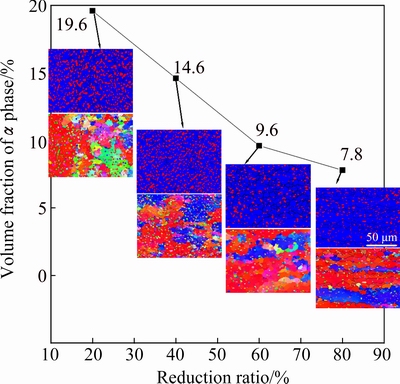

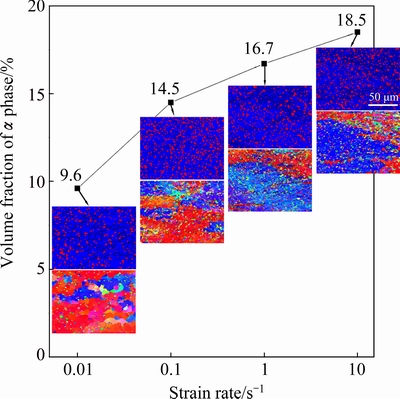

Other deformation parameters also have significant effect on phase transformation kinetics besides deformation temperature during compression. The phase distributions of the samples compressed with various strains are presented in Fig. 8. The α phase gradually transforms to β phase as the strain increases and α phase grain size correspondingly decreases. The α-to-β transformation is a certain diffusion transformation and a large amount of solute atoms are required to diffuse between the two phases. In addition, a large deformation reduction would provide significant energy to promote the α-to-β transformation in non-equilibrium state. Various strain rates can also make a difference in the α-to-β transformation, as presented in Fig. 9. Compressed by the same reduction ratio of 60%, the fractions of α phase increase evidently as the strain rate increases. Time is insufficient for the complete transformation in the sample with the higher-strain rate even higher speed deformation could provide more stored energy in way of more defects. Therefore, the diffusion rate is the main factor that controls the phase transformation under high strain rate.

Fig. 8 Phase and orientation distribution of samples compressed under various reduction ratios at 1073 K with strain rate of 0.01 s-1

Fig. 9 Phase and orientation distribution of samples compressed under various strain rates at 1073 K with reduction ratio of 60%

As a kind of diffusion-controlled phase transformation, the α-to-β transformation is related mainly to two factors of diffusion difficulty and time. The diffusion rate of the solute elements depends on the diffusion coefficient, which is affected by the defect density and deforming temperature. A sufficiently high temperature is necessary because the free energy of both phases increase as the temperature increases, whereas α phase has a relatively faster increasing rate. As a result, transformation would occur beyond a particular temperature. In the present study, the critical temperature by such strain-induced transformation is approximately 50 K under the equilibrium temperature. The defect density depends on the deformation parameters and the orientation characterization of the deformed grains. Dislocation density increases with increasing deformation reduction and strain rate and it can be obviously found that the α-to-β transformation is promoted with increasing deformation. The orientation of deformed grains would also cause defect difference between {111}-orientated and {100}-orientated grains due to their different recovery ability. As a result, the transformation is further promoted in the {111}- orientated grains than in {100}-orientated grains. The sufficient time is another factor that affects diffusion- controlled phase transformation. Although the dislocation density is sufficient for transformation at high strain rate, the sustaining time of deformation is too short to complete the diffusion of solute atoms. Therefore, the higher strain rate restrains the α-to-β transformation compared with the lower strain rate.

4 Conclusions

1) Strain-induced α-to-β transformation is discovered in compressed Ti-5Al-5Mo-5V-1Cr-1Fe alloy at temperatures below the β transus temperature and the β-to-α transformation could not be induced or even be restricted. The free energy increase of α phase and the free energy decrease of β phase induced by compression lead to the enhanced α-to-β transformation. The β-to-α+β transformation temperature can be decreased by as high as 50 K.

2) For the dynamics explanation, the defects induced by compression provide a large amount of diffusion channels for the solute elements. This causes the reassignment of solute elements, which provides an extra driving force for the α-to-β transformation. As diffusion is a time controlled process, the strain rate would have an important effect on strain-induced transformation by the influence on deforming time.

3) Orientation dependence during α-to-β transformation occurs between {100}-orientated grains and {111}-orientated grains. The partly dynamic recrystallization and sufficient dynamic recovery caused by compression in {100}-orientated grains would eliminate the strain energy. Therefore, α-to-β transformation is adequately promoted in {111}- orientated grains than in {100}-orientated grains.

References

[1] CARMAN A, ZHANG L C, IVASISHIN O M, SAVVAKIN D G, MATVIYCHUK M V, PERELOMA E V. Role of alloying elements in microstructure evolution and alloying elements behaviour during sintering of a near-β titanium alloy [J]. Materials Science and Engineering A, 2011, 528: 1686-1693.

[2] ZHEREBTSOV S V, MURZINOVA M A, KLIMOVA M V, SALISHCHEV G A, POPOV A A, SEMIATIN S L. Microstructure evolution during warm working of Ti-5Al-5Mo-5V-1Cr-1Fe at 600 and 800 °C [J]. Materials Science and Engineering A, 2013, 563: 168-176.

[3] FAN Xiao-guang, YANG He, GAO Peng-fei, ZUO Rui, LEI Peng-hui, JI Zhe. Morphology transformation of primary strip α phase in hot working of two-phase titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 1294-1305.

[4] LIANG H Q, GUO H Z. The integrated influence on hot deformation of dual-phase titanium alloys incorporating dynamic recrystallization evolution and α/β phase transformation [J]. Materials Letters, 2015, 151: 57-60.

[5] FAN J K, KOU H C, LAI M J, TANG B, CHANG H, LI J S. Hot deformation mechanism and microstructure evolution of a new near β titanium alloy [J]. Materials Science and Engineering A, 2013, 584: 121-132.

[6] ZENG Zhi-peng, ZHANG Yan-shu, JONSSON S. Deformation behaviour of commercially pure titanium during simple hot compression [J]. Materials & Design, 2009, 30: 3105-3111.

[7] HUA Ke, XUE Xiang-yi, KOU Hong-chao, FAN Jiang-kun, TANG Bin, LI Jin-shan. Characterization of hot deformation microstructure of a near beta titanium alloy Ti-5553 [J]. Journal of Alloys and Compounds, 2014, 615: 531-537.

[8] WANG Kai-xuan, ZENG Wei-dong, ZHAO Yong-qing, LAI Yun-jin, ZHOU Yi-gang. Dynamic globularization kinetics during hot working of Ti-17 alloy with initial lamellar microstructure [J]. Materials Science and Engineering A, 2010, 527: 2559-2566.

[9] QIN Chun, YAO Ze-kun, NING Yong-quan, SHI Zhi-feng, GUO Hong-zhen. Hot deformation behavior of TC11/Ti-22Al-25Nb dual alloy in isothermal compression [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2195-2205.

[10] CAI M, LEE C, LEE Y. Effect of grain size on tensile properties of fine-grained metastable β titanium alloys fabricated by stress-induced martensite and its reverse transformations [J]. Scripta Materialia, 2012, 66: 606-609.

[11] SADEGHPOUR S, ABBASI S M, MORAKABATI M. Deformation-induced martensitic transformation in a new metastable β titanium alloy [J]. Journal of Alloys and Compounds, 2015, 650: 22-29.

[12] DEHGHAN-MANSHADI A, DIPPENAAR R J. Strain-induced phase transformation during thermo-mechanical processing of titanium alloys [J]. Materials Science and Engineering A, 2012, 552: 451-456.

[13] KOIKE J, SHIMOYAMA Y, OHNUMA I, OKAMURA T, KAINUMA R, ISHIDA K, MARUYAMA K. Stress-induced phase transformation during superplastic deformation in two-phase Ti-Al-Fe alloy [J]. Acta Materialia, 2000, 48: 2059-2069.

[14] LIU Bin, LI Yun-ping, MATSUMOTO H, KOIZUMI Y, LIU Yong, CHIBA A. Enhanced grain refinement through deformation induced α precipitation in hot working of α+β titanium alloy [J]. Advanced Engineering Materials, 2012, 14: 785-789.

[15] HAN Y, ZHUANG Y H, LU J. Deformation-induced ambient temperature α-to-β phase transition and nanocrystallization in (α+β) titanium alloy [J]. Journal of Materials Research, 2009, 24: 3439-3445.

[16] LIU Bin, LIU Yong, HUANG Lan, LI Hui-zhong, HE Yue-hui. Characterization of phase transformation during hot compressive deformation in a β-stabilized Ti-45Al-7Nb-0.4W-0.15B alloy [J]. Materials Characterization, 2015, 105: 113-117.

[17] NAKAJIMA H, OHSHIDA S, NONAKA K, YOSHIDA Y, FUJITA F E. Diffusion of iron in β Ti-Fe alloys [J]. Scripta Materialia, 1996, 34: 949-953.

Ti-5Al-5Mo-5V-1Cr-1Fe合金热压缩过程中的形变促进α→β相变

李 凯,杨 平

北京科技大学 材料科学与工程学院,北京 100083

摘 要:研究Ti-5Al-5Mo-5V-1Cr-1Fe合金在β→α+β相变点以下热缩变形时的动态相变过程。发现在相变点以下0~100 K压缩时会促进应变诱导的α→β相变的发生。压缩过程中的形变储存能为相变提供驱动力。变形过程中位错和亚晶等缺陷增加,促进溶质元素的扩散,溶质元素的重新分布引起两相自由能的重新分布,促进α→β的转变。在{100}取向和{111}取向晶粒中还发现存在取向依赖特征,{111}取向晶粒中不充分的回复为相变提供更大的驱动力。另外,还研究了变形量和应变速率对相变的影响。

关键词:钛合金;热压缩;相变;取向依赖性

(Edited by Bing YANG)

Foundation item: Project (51771024) supported by the National Natural Science Foundation of China

Corresponding author: Ping YANG; Tel: +86-10-82376968; E-mail: yangp@mater.ustb.edu.cn

DOI: 10.1016/S1003-6326(19)64939-3

Abstract: The dynamic phase transformation of Ti-5Al-5Mo-5V-1Cr-1Fe alloy during hot compression below the β transus temperature was investigated. Strain-induced α-to-β transformation is observed in the samples compressed at 0-100 K below the β transus temperature. The deformation stored energy by compression provides a significant driving force for the α-to-β phase transformation. The re-distribution of the solute elements induced by defects during deformation promotes the occurrence of dynamic transformation. Orientation dependence for the α-to-β phase transformation promotion is observed between {100}-orientated grains and {111}-orientated grains. Incomplete recovery in {111}-orientated grains would create a large amount of diffusion channels, which is in favor of the α-to-β transformation. The effects of reduction ratio and strain rate on the dynamic phase transformation were also investigated.