稀有金属2020年第3期

铜铟镓硒基薄膜太阳电池的研究进展

曲晶晶 张林睿 宋雪梅 张永哲 汪浩 严辉

北京工业大学材料科学与工程学院教育部先进功能材料重点实验室北京先进材料微观结构与性能重点实验室

摘 要:

铜铟镓硒(CIGS)基太阳电池是一种具有高转换效率的薄膜太阳电池,实验室制备的CIGS电池转换效率已达22.9%,接近于晶硅类电池最高的转换效率。同时CIGS电池还具有吸收系数高,制造成本较低,并且应用非常广泛等优点。然而,在商业化的大规模生产中,CIGS太阳电池不论在效率还是稳定性上仍与晶硅电池存在差距。进一步提升CIGS电池效率,优化电池性能,扩大电池产业化规模是CIGS太阳电池今后发展的必经之路。当前CIGS太阳电池的发展取得的重大成就,主要原因在于人们对CIGS材料与器件原理的进一步认识。本文综合介绍了CIGS太阳电池作为当前热点的潜力和优势,回顾了近期关于CIGS的研究进展,主要包括电池的缓冲层、吸收层和窗口层的改进,及层界面之间的处理手段,这些技术的发展提高了CIGS电池的转换效率,推动了其产业化进程,同时在电池未来发展方面阐述了相关问题,并对解决方案进行了展望。

关键词:

铜铟镓硒 ;太阳电池 ;高效率 ;产业化 ;

中图分类号: TM914.42

作者简介: 曲晶晶(1995-),女,河北石家庄人,硕士研究生,研究方向:薄膜太阳电池、铜铟镓硒电池;E-mail:479640028@qq.com;; *严辉,教授,电话:010-67391876;E-mail:hyan@bjut.edu.cn;

收稿日期: 2018-09-20

基金: 国家自然科学基金项目(61574009,11574014)资助;

Research Progress of Copper Indium Gallium Selenide Thin Film Solar Cells

Qu Jingjing Zhang Linrui Song Xuemei Zhang Yongzhe Wang Hao Yan Hui

Key Laboratory of Advanced Functional Materials of Education Ministry of China,Beijing Key Laboratory of Microstructure and Property of Advanced Materials,College of Materials Science and Engineering,Beijing University of Technology

Abstract:

Copp er indium gallium selenium(CIGS) based solar cells were thin film solar cells with high conversion efficiency.The conversion efficiency of CIGS solar cells prepared in the laboratory reached 22.9%,which was close to the highest conversion efficiency of crystal silicon solar cells.At the same time,CIGS cells also had the advantages of high absorption coefficient,low manufacturing cost,and wide application.However,in large-scale commercial production,CIGS solar cells were still far from silicon-based solar cells in terms of efficiency and stability.Further improving the efficiency of CIGS solar cells,expanding the scale of cells industrialization and optimizing their performance were the only way for the future development of CIGS solar cells.The main achievements of the current development of CIGS solar cells were mainly due to people's understanding of CIGS materials and device principles.In this paper,the potential and advantages of CIGS solar cells as a hot spot and recent research progresses on CIGS solar cells were reviewed,including the improvement of buffer layer,absorption layer and window layer,as well as the treatment methods between the layers.The development of these technologies improved the conversion efficiency of CIGS solar cells and promoted its industrialization.At the same time,the related problems in the future development of cells and the solutions were discussed.

Keyword:

copper indium gallium selenium(CIGS); solar cell; high efficiency; industrialization;

Received: 2018-09-20

日益紧张的世界能源形势,使得新能源技术获得了长足发展。其中,对于太阳能的有效利用一直是目前的研究热点之一。近年来,实验室太阳电池的转换效率不断突破世界纪录,在产业化方面,光伏制造与生产技术也取得了巨大进步。目前商业上最常用的光伏产品是晶体硅和薄膜太阳电池,其中晶体硅是最常见的光伏材料,在整个光伏市场中占有重要地位。而非晶硅,CdTe以及Cu(In,Ga)(S,Se)2 等薄膜材料由于其优异的光电特性也逐渐在光伏领域得到了越来越多的重视。其中,基于Cu(In,Ga)(S,Se)2 (CIGS)的薄膜太阳电池是最有发展前景的光伏(PV)技术代表之一,其实验室规模的电池转换效率已经稳步提高

[1 ]

。

铜铟硒化物(CuInSe2 或CIS)是一种属于Ⅰ-Ⅲ-Ⅵ族的三元化合物,在太阳电池中常用作p型吸收层材料,具有四方黄铜矿晶体结构

[2 ]

。1953年,Hahn等

[3 ]

首先合成了带隙为1.04 eV的CIS材料,之后实验室制备出的单晶CuInSe2 基太阳电池的在1974年认证的转换效率已经达到12%

[4 ]

。1976年,Kazmerski等

[5 ]

通过在过量的Se蒸气条件下共蒸发CuInSe2 粉末,制备出了第一个CuInSe2 /CdS薄膜太阳电池,其转换效率达到了4%~5%。数年后,波音公司报道了其通过使用共蒸发技术制备出了铜铟硫(CuInS2 )薄膜电池,并取得了11.4%的转换效率

[6 ]

。几乎同一时间,Kazmerski和Sanborn

[7 ]

制备出了效率为3%的CuInS2 薄膜同质结太阳电池。CIS的薄膜太阳电池在1981年开始得到了广泛关注,与此同时Mickelsen和Chen

[8 ]

使用元素共蒸发法制备出的电池的转换效率达到了9.4%。1987年,CuInSe2 薄膜电池长期记录的转换效率已经达到了14.1%

[9 ]

。十年后,于1998年,第一个商业化的CIGS太阳电池组件投入生产

[10 ]

。而伴随着各种技术的突破,例如镓(Ga)的不同量掺杂,钠(Na)、钾(K)等碱金属掺杂,硫化镉(CdS)窗口层的减薄,通过添加本征和掺杂氧化锌(ZnO)层等的优化,在短短的十几年间,CuInSe电池的转换效率比过去的几十年提高的还要明显。最近,通过使用无镉缓冲材料(Zn,Mg)O/Zn(O,S,OH)制备的Cu(InGa)Se2 电池,最佳转换效率已经达到了22.8%

[11 ]

,实验室制备的CIGJS电池转换效率已达22.9%,接近于晶硅类电池最高的转换效率

[12 ]

。

CIGS薄膜的带隙可以通过用Ga取代In来调整,这就使其可以更好地匹配太阳光谱。并且CIGS是一种直接带隙材料,具有较高的吸收系数,近1μm厚的薄膜就能吸收大部分太阳光谱,约2.0~2.5μm的薄层就足以满足器件设备的需要。因为较薄的吸收层可以减少原材料的使用,所以可以有效地降低成本。通过应用各种不同的沉积技术,CIGS材料可在刚性以及柔性基底上沉积,所以CIGS太阳电池的应用可以遍及多个方面。并且除了地面应用,CIGS太阳电池由于其高辐射耐受性也可用于空间设备上。此外,由于电池制备的步骤较少,因此CIGS适用于单片集成,这样可以进一步降低生产成本

[13 ,14 ,15 ,16 ,17 ,18 ,19 ,20 ]

。

虽然CIGS薄膜电池优点众多,但是对于其的进一步商业化,目前仍存在不少限制,例如器件制备过程中每次运行的成分均匀性就是其一,所以在运行过程控制中,一个完备的原位诊断工具是至关重要的。同时,用于CIGS太阳电池大规模制造的多源共蒸发和两阶段工艺设备的标准是另一个非常关键的限制。这就导致了目前实验室小面积电池单元(>22.9%)和市售电池模块(16.1%)之间效率差别很大。此外,在批量生产中,还可能会出现铟的供应问题,导致生产成本的急剧上升(生产1 GW光伏组件需要31 t铟)

[21 ]

。

CIGS材料良好的光电特性以及适用于大规模生产的制备方法体现了其作为新型薄膜太阳电池的潜力和优势。当前CIGS太阳电池的发展取得的重大成就,主要原因在于人们对CIGS材料与器件原理的进一步认识,本文就对CIGS太阳电池缓冲层,吸收层的改进,窗口层和界面处理方法等方面进行详细介绍。

1 结构与特点

1.1 材料结构

CIGS的组成材料CuInSe2 和CuGaSe2 属于Ⅰ-Ⅲ-Ⅵ族化合物,呈现四方黄铜矿晶体结构

[22 ]

。这种四方黄铜矿结构是通过I族(Cu)和Ⅲ族(In或Ga)元素对II族元素(Zn)的有序取代,由Ⅱ-Ⅵ族材料(ZnSe)的立方体闪锌矿结构演变而来,每个Ⅰ(Cu)或Ⅳ(In)族原子与Ⅵ族原子(Se或S)形成四个键。在这个四方晶胞中,晶格常数比(c/a)接近于2,由于Cu-Se,In-Se和Ga-Se键的强度不同,同时还会造成晶格偏差(称为四方畸变)。

1.2 CIGS结构

CIGS薄膜太阳电池的基本结构为衬底/Mo/吸收层/缓冲层/高阻层/窗口层/减反层/金属栅线

[23 ,24 ,25 ]

。衬底多用普通的刚性钠钙玻璃(SLG),因为它可以为高效电池提供碱性金属元素,同时还具有较好的热稳定性和化学惰性,与吸收层相似的热膨胀系数,而且其表面光滑。此外,近几年的柔性电池中,也使用不锈钢箔片或聚酰亚胺(PI)作为柔性衬底,获得柔性CIGS多晶薄膜太阳电池

[23 ]

。常采用真空溅射方式在衬底上溅射一层Mo,作为电池的背电极,传导空穴。背电极的厚度一般在0.5~1.0μm,以保证电极层与衬底之间具有良好的附着力,同时可以与吸收层形成良好的欧姆接触。在背电极上可以采用真空或者非真空(化学水浴沉积等)工艺得到一层厚度为1~3μm的p型CIGS吸收层和厚度为0.03~0.05μm的n型CdS缓冲层来构成异质结。在缓冲层表面采用射频和直流磁控溅射制备透明导电氧化物(TCO)来作为窗口层,目前常见的窗口层主要由一层薄的本征氧化锌(i-ZnO,0.05μm)和铝掺杂的氧化锌组成(ZnO:Al,0.1~0.3μm)

[26 ]

。本征层有助于防止薄层局部的不均匀性或缓冲区覆盖不完全导致的范围内的漏电流

[27 ,28 ]

,也可以保护缓冲层在TCO溅射期间免受离子损伤。

1.3 CIGS薄膜电池与c-Si电池的比较

Si元素是一种储量丰富的元素,在地壳中的含量仅次于氧,占地壳总质量的26.4%,是制造硅基太阳电池的重要材料。而相对于硅基太阳电池来说,CIGS的原材料储量较少。但是为了获得高吸收和高机械强度的组件,硅基太阳电池模块生产中经常使用较厚的c-Si晶圆(180 mm)作为吸收层,这就会造成电池生产成本的约50%是为了制备出c-Si晶圆,同时c-Si太阳电池需要生长大尺寸的纯Si单晶,这就导致其生产工艺昂贵。近期SunPower报道了由NREL认证的c-Si电池组件转换效率已经达到了24.1%(面积11310.1 cm2 )。而对于CIGS太阳电池来说,组件效率约为16.1%,远低于c-Si电池的效率。目前市场上大约92%的商业组件为c-Si产品,薄膜组件仅占8%,而其中CIGS组件仅为2%

[29 ]

。Si基太阳电池的可靠性是任何其他太阳电池技术无法比拟的,目前已经建立了成熟的工艺技术。同时,c-Si太阳电池的性能已经被证明可以达到长期稳定(大约20年)。而对于CIGS电池,还没有足够可靠的稳定性报告可以参考。

CIGS太阳电池作为硅太阳电池的新型替代品,与Si基太阳电池相比,依然具有很多优势。如相比于Si基太阳电池,CIGS电池不易受到损坏,同时CIGS电池中使用了多种功能层,有助于减少短路电流(Jsc )损耗。当前CIGS电池的制备技术种类很多,同时涉及的原材料、成本和制备时间都比较少。CIGS薄膜可以直接沉积在各种衬底上,与Si晶体的生长和切割相比,需要消耗的能量很少。在组件生产上,CIGS电池需要的温度(约550℃)比c-Si电池(约1100℃)要低,并且CIGS电池可以在电池处理过程中单片集成,而在Si基太阳电池中,单片集成是不可能实现的。在常规的c-Si太阳电池中,为了获得欧姆接触并降低串联电阻,丝网印刷栅线电极和背面的Al接触分别需要约20和40μm厚,而在CIGS太阳电池中,接触厚度比c-Si太阳电池要小。

由于Si为间接带隙材料,所以它的吸收系数很低(1×104 cm-1 )。而CIGS作为直接带隙材料,其吸收系数较高,因此CIGS吸收层的厚度可以比c-Si晶片的厚度小约100倍,从而降低了制造原料用量。此外,CIGS技术的能源投资回收期(1年)要少于cSi技术(2年)

[30 ]

。由于制造材料用量和能源需求较低,CIGS太阳电池的生产成本低于Si太阳电池。

在c-Si太阳电池中,通过将铝与p型c-Si合金化而在Si晶片的背面产生背面场,所述p型c—Si作为重掺杂区并在重掺杂区和低掺杂区之间的后侧产生势垒(p+ -p结,称为高-低结)。穿过高-低结的电场使电子远离后部接触点/表面,因此减少了背面的复合。类似地,在CIGS的背面(朝向CIGS/Mo界面)的Ga浓度的渐变产生背表面场,并且电子远离到达Mo背触点并且朝向前触点,由此增加收集效率。在实验室规模(2 cm×2 cm),CIGS太阳电池的效率已经非常接近c-Si(CIGS22.9%,c-Si 25.6%)。

2 近期研究方向及进展

2.1 吸收层

2.1.1 碱金属掺杂

吸收层碱金属元素的掺杂一直是CIGS太阳电池研究的热点。碱金属可以通过由玻璃衬底扩散(预沉积)

[31 ]

,或者在CIGS层生长之前、期间或之后以受控的方式(预沉积,共蒸发,后沉积)添加。它们分别对应着碱金属引入的技术是碱金属衬底或衬底表面的扩散,吸收层沉积过程中共蒸发,沉积吸收层制备后碱金属表面引入的退火(也称为PDT方法)处理,这些添加方式都会对电池性质产生有益影响

[32 ]

。

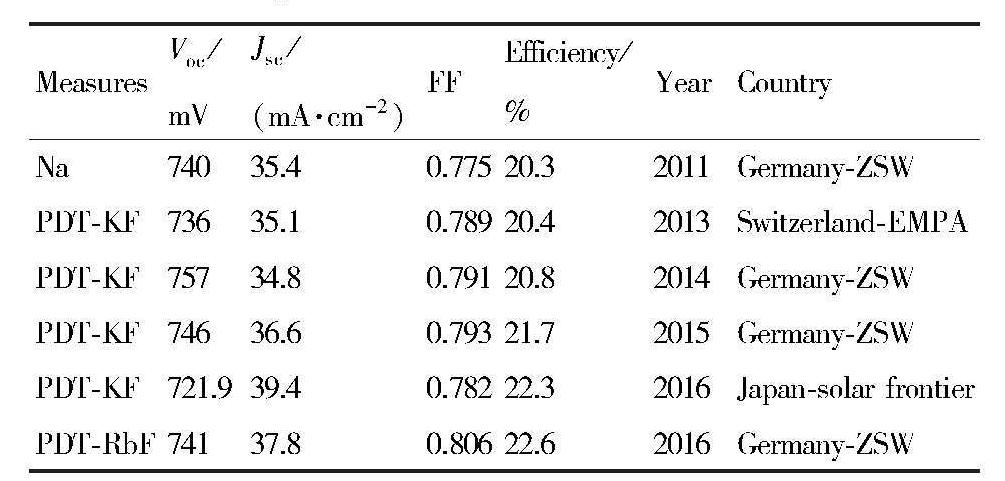

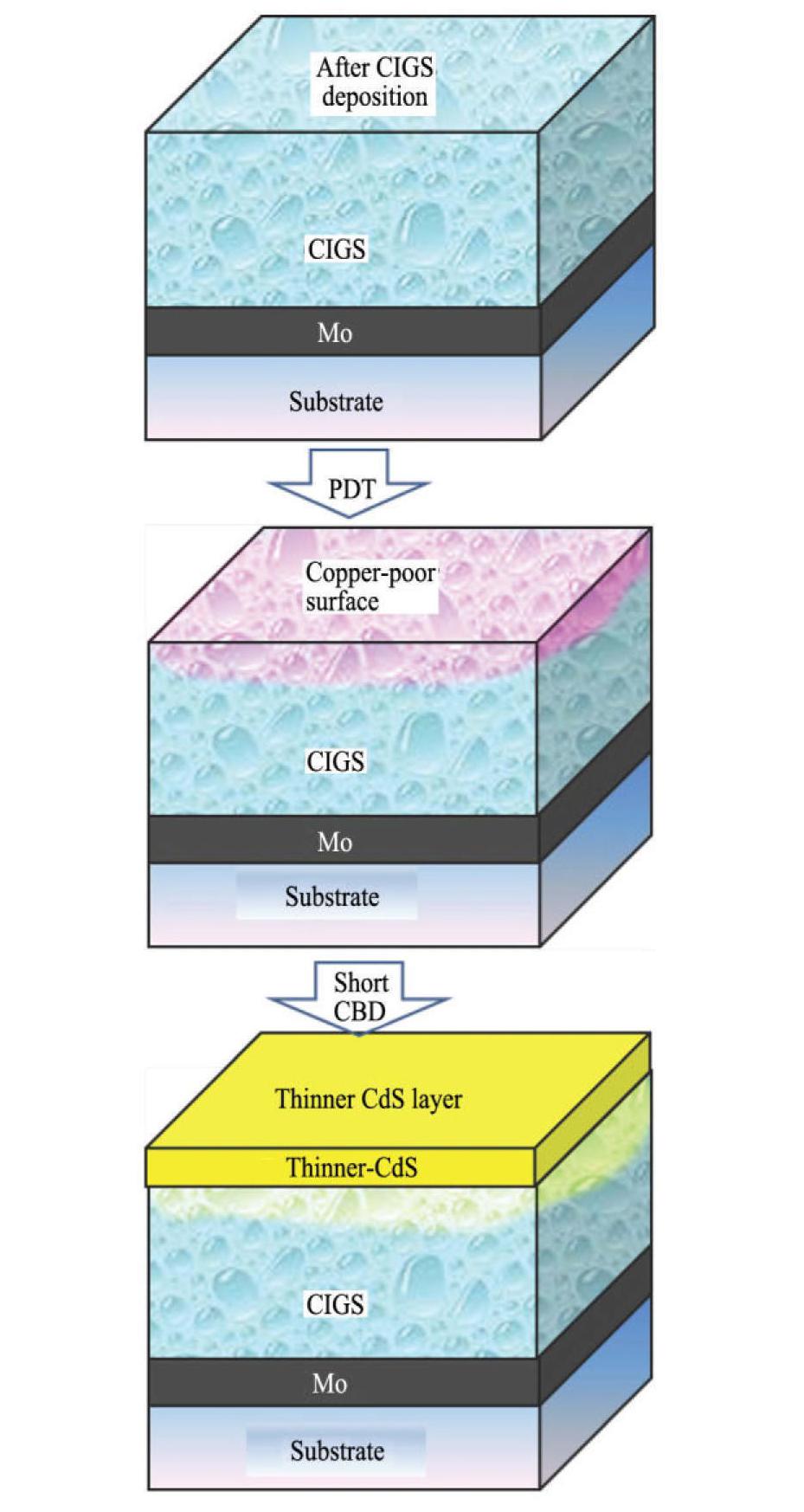

预沉积掺杂一般是在CIGS层制备过程中,Na由钠钙玻璃衬底内部扩散得到,但是对于大规模组件,Na含量和分布的均匀性会对器件产生影响,并降低组件效率。所以通常需要在玻璃衬底上沉积一薄层氧化铝或氮化硅阻挡层,再制备含Na的Mo(MoNa)背接触,实现Na的均匀分布;或在Mo背接触上沉积一层NaF前体层,确保吸收层沉积期间Na的充足供应。Na掺杂量由NaF层的厚度控制,NaF量不足会导致开路电压(Voe )和填充因子(FF)过低,过量则会导致吸收层沉积过程中发生剥离,并且会降低太阳电池的性能。碱金属的共蒸发通常使用在三段共蒸发工艺制备CIGS层的工艺中。研究表明,在第一和第二阶段掺入Na会使CIGS结晶度降低,在第三阶段的掺入仅略微影响膜表面的结晶度,而不含Na的样品显示较大的晶粒尺寸而没有分层。PDT方法对掺杂碱金属的浓度限制不大,由于发生在晶粒生长之后,因而PDT过程可以钝化缺陷而不影响结晶度,并显著改善CIGS太阳电池的性能。近期在世界纪录效率的CIGS太阳电池中,多个记录效率电池使用了KF或RbF后沉积处理的方法。如表1所示,从2011年到2016年,CIGS的转换效率由20.3%达到了22.6%。KF的PDT处理方法在实验室中取得了成功,并且已经开始延展到了商业电池的生产中。碱金属PDT加入到CIGS电池中对电池表面以及性能产生的积极作用如下:

(1)有效减薄CdS层厚度,同时提升Jsc。

Chirilǎ等

[34 ]

用X射线光电子能谱(XPS)分析发现Cu和Ga在CIGS表面上低于30 nm深度就已经耗尽,因此在CIGS表面的原始有序空位化合物(OVC)区域中,受主缺陷Cu 施主。使用碱金属PDT的材料施主密度高于没有使用PDT的材料,这会导致表面反应更强烈,从而增强了埋藏的同质结。因此如图1所示,在较厚的贫铜表面层进行碱金属PDT处理后,理想因子和反向饱和电流降低,少数载流子寿命增加,复合降低,电荷载流子密度增加,Voe 升高,所以只需要使用很薄的的缓冲层就可以形成高质量的CIGS/CdS异质结,同时可以提升Jsc 。此外,如图2所示,对于使用KF-PDT的样品,CdS层在CBD的早期阶段表现出良好的覆盖力和均匀性

[40 ]

,因此CdS膜可以更薄,这有利于对短波长光照的吸收,从而增加Jsc 。

表1 近期不同碱金属掺杂对电池性能的影响 下载原图

Table 1 Effect of recent alkali metal doping on solar cell performance

[33-39]

图1 PDT处理后可使用更薄的缓冲层

Fig.1 A thinner buffer layer being used after PDT treatment

图2 非PDT样品与PDT样品表面CdS的差异

Fig.2 The differences in CdS surface between no-PDT samples(a)and PDT samples (b)

[40]

(2)有效增加CIGS近表面的空穴浓度 [41,42]。

如图3所示

[42 ]

,对于PDT样品,与非PDT样品相比,CIGS近表面处的空穴载流子浓度明显增加。NaF-PDT样品的载流子浓度比(NaF+KF)-PDT样品高约一个数量级,同时也高于KF-PDT样品的载流子浓度。高效电池的CIGS吸收层表面由OVC组成。大量的浅受主缺陷Cu ),从而提高CIGS层中的空穴载流子浓度。Na还可以占据In空位(VIn ),形成比+ 会吸收O2 ,将Se空位(Vsc )转换成Osc (Se被O替代),并会降低补偿电子浓度。综上所述,Na可以使CIGS近表面的空穴浓度增加。

(3)使CIGS表面带隙更宽且价带更低。

Handick

[43 ]

对在PI衬底上沉积的CIGS吸收层的表面进行了能带结构测量,发现NaF-PDT样品的近表面带隙为1.61 eV(+0.14/-0.51 eV),(NaF+KF)-PDT样品的近表面带隙为2.52 eV(+0.14/-0.51 eV),价带最大值(VBM)相对于EF位置有明显的下移。Handick等

[43 ]

提出了表面带隙的扩大是由于材料结构变化引起的电子结构的变化。表征结果表明,表面区主要由K,In和Se组成,且In2 Se3 化合物的带隙具有明显的厚度依赖性,基于当前的带隙数据,不能区分它是哪种化合物,这两种化合物可能共存,但比例尚不明确。由于(NaF+KF)-PDT样品的VBM明显下移,比NaF-PDT样品的VBM偏移明显,并且空穴浓度在很大程度上降低,故界面复合进一步降低,Voe 和转化效率明显提高。

图3 通过C-V测量获得的空穴浓度(N)在材料厚度(W)上的分布

Fig.3 Distribution of hole concentration (N) on material thickness (W) obtained by C-V measurements

[42]

(a) No-PDT samples;(b) PDT samples

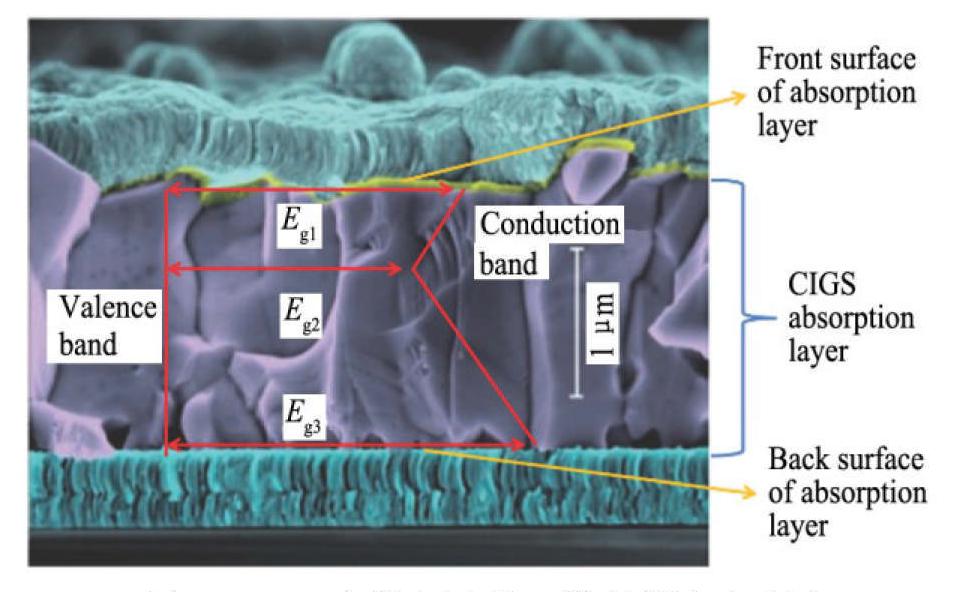

2.1.2 Ga元素的梯度分布

CIGS薄膜的带隙可以通过用镓取代铟来调整,CIGS器件显著的发展潜力在于其带隙的可调节性。Ga引入CIS中主要改变导带的位置从而调整带隙。随着Ga/(Ga+In)的比率改变,CIGS的带隙可以从1.04 eV增加到1.67 eV

[44 ,45 ]

。由于固定带隙半导体材料对太阳光谱的吸收不充分,小于固定带隙的光子能量不能产生电子-空穴对,就会导致一部分太阳光无法被材料吸收,对材料的短路电流提升产生影响;而大于固定带隙的光子能量也只能产生一个电子-空穴对,多余的能量转化为热能损害器件。所以在CIGS电池中采用改变Ga的梯度形成梯度带隙可以更加充分地利用太阳光谱。在梯度带隙中最常见的就是反向梯度带隙(吸收层带隙从前电极向背电极呈线性减小的趋势)和正向梯度带隙(吸收层带隙从前电极向背电极呈线性增大的趋势)。在反向梯度结构中,电子获得能量由价带跃迁到导带,而导带的倾斜,会使电子由高能量处向低能量处运动。这与空间电荷区(SCR)中电子分离后的运动方向相反,产生一个与内建电场方向相反的附加电场,会导致(1) SCR中总场强减弱,不利于载流子分离;(2)在吸收层中性区电子移向SCR的几率降低,背电极处复合几率增强。因此,这种结构将不利于电池中光生载流子的收集,进而影响电池的Jxc 。在正向梯度结构中,由于势能的变化,这种形状的带隙同样会形成一个与内建电场方向相同的附加准静电场,有利于光生载流子的分离,同时还能减小电子被复合的几率。并且随着梯度斜率的增大,背电极处的复合逐渐降低,这可以加强对器件中少数载流子的收集能力,但同时也会导致器件对长波段光吸收的减小。为了兼顾以上两个方面,在CIGS电池中常采用具有高吸收光谱的双梯度带隙,这是目前CIGS太阳电池中最有效的结构

[46 ,47 ,48 ]

。CIGS太阳电池的双梯度带隙示意图如图4所示,其中£g1 ,Eg2 ,Eg3 为材料不同位置的带隙。

通过三段共蒸发技术可以制备出具有双梯度带隙的CIGS薄膜,其导带凹陷处(缺口)靠近吸收层前表面,此处带隙较窄(Ga%较低),而吸收层表面两侧的带隙较宽(Ga%较高),从而使得Eg3 >Eg1 >Eg2 。具有双梯度带隙的CIGS太阳电池,在SCR中的前部梯度可以有效地降低CIGS/CdS界面的复合,后部梯度通过减少背面复合和增加有效载流子扩散长度来诱导反向准电场,从而潜在地增强载流子收集,使得短路电流密度(Jsc )和开路电压(Voc )增加

[49 ,50 ]

。所以在吸收层中通过控制Ga/(Ga+In)的空间分布就可以调整能带来提高CIGS电池的整体性能。因此,优化Ga/(Ga+In)比率在吸收层的分布是非常重要的研究热点。Dullweber等

[51 ]

采用多元共蒸发法制备出正向梯度带隙CIGS电池,研究结果显示正向梯度带隙能明显抑制背电极处的复合,并且SCAPS的模拟结果与实验结果相一致。Amin等

[52 ]

研究了超薄吸收层中带隙梯度对电池性能的影响,实验结果显示如果在相应的电池结构中应用正向带隙结构,其电池性能将分别从10.74%上升到12.38%,14.36%上升到17.26%。理论显示在超薄吸收层中应用双带隙结构是更好的选择,但是目前在制备上依然存在难点。实际上,对不同层进行优化是一种提高电池效率有效的方式

[52 ]

。Jackson等

[37 ]

通过对吸收层陡峭的Ga/(Ga+In)梯度的优化和碱金属PDT处理,同时减薄CdS缓冲层厚度,制备出了转换效率高达21.7%的CIGS电池。

图4 CIGS太阳电池的双梯度带隙示意图

Fig.4 Schematic diagram of double gradient band gap for CIGS solar cells

研究结果表明CIGS器件的带隙工程在提高其性能方面起着重要的作用,但是对于CIGS器件来说,如何实现对Ga元素分布的合理调整是目前研究的难点,这阻碍了其进一步发展和应用。目前的研究主要集中在使用多种手段,如在溅射过程中使用多元多靶材,改变硒化过程中的温度与时间等,来获得梯度CIGS太阳电池,而理论研究较少。因此,为了充分利用太阳光谱,对CIGS吸收层的带隙工程的理论研究是非常必要的。

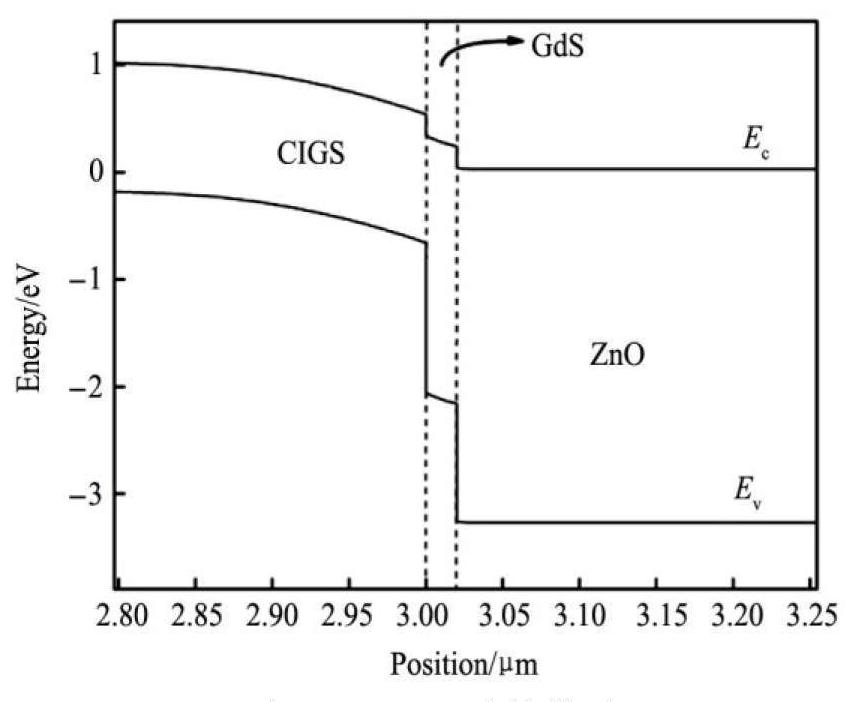

2.2 缓冲层

CIGS太阳电池中通常使用CdS作为缓冲层

[25 ]

。目前,CdS缓冲层已经满足CIGS太阳电池的大部分要求,其与吸收层CIGS和未掺杂的ZnO层具有合适的导带对准,CIGS电池的能带图如图5所示。CdS缓冲层与其他层之间存在有益的界面缺陷化学,据报道,带正电荷的Cd可能在贫铜的黄铜矿表面形成稳定的施主型缺陷,可以产生最佳的电荷密度和明确的费米能级位置

[53 ]

。CdS层通常通过化学水浴沉积(CBD)沉积在CIGS吸收层表面。CBD溶液一般为碱性水溶液(pH>9),主要包含3种成分:镉盐作为镉源(CddSO4 ,CDI2 等),氨水(NH4 OH)作为络合剂,硫脲作为硫源。氨水的作用是为金属离子(Cdd)提供配体,并通过pH变化控制硫脲的水解。同时CBD溶液中的氨可以在一定程度上腐蚀CIGS表面,这样就可以在CdS形成之前去除掉含杂质的CIGS表层(如表层氧化物)

[54 ]

。CdS的主要缺点为其相对较窄的带隙(2.4eV),会导致电池电流的寄生吸收损失,以及Cd的毒性问题。因此,对替代CdS的无镉缓冲层的研究是当前研究热点之一,Zn(S,O,OH),Zn1-x Mgx O,In2 S3 和Zn1-x Snx O等被认为是目前替代CdS的最有前途的缓冲层材料。

图5 CIGS电池能带图

Fig.5 Band diagram of CIGS solar cell

2013年,Solar Frontier在采用CBD法制备Zn(S,O,OH)缓冲层方向已经取得了良好进展,其CIGS电池的转换效率已经达到了19.7%,同时他们已经将这一工艺用于其商业生产

[55 ]

。AGU和ZSW也报道了可以通过使用Zn(O,S)缓冲层实现CIGS电池较高的转换效率(>18%)

[56 ,57 ]

。此外,其他几种材料,如采用物理气相沉积(PVD)、原子层沉积(ALD)、离子层气体反应(ILGAR)等手段制备的Zn1-x Mgx O,InSx Oy 等,作为CIGS太阳电池中的无镉缓冲层材料,近期都取得了进一步的研究进展。经报道,在器件中使用优化的(Zn,Mg)O/Zn(O,S,OH)作为缓冲层时,CIGS电池已经可以实现高达22.8%的转换效率(Voc 为0.711 V,Jsc 为41.4 mA·cm-2 ,填充因子为0.775)

[11 ]

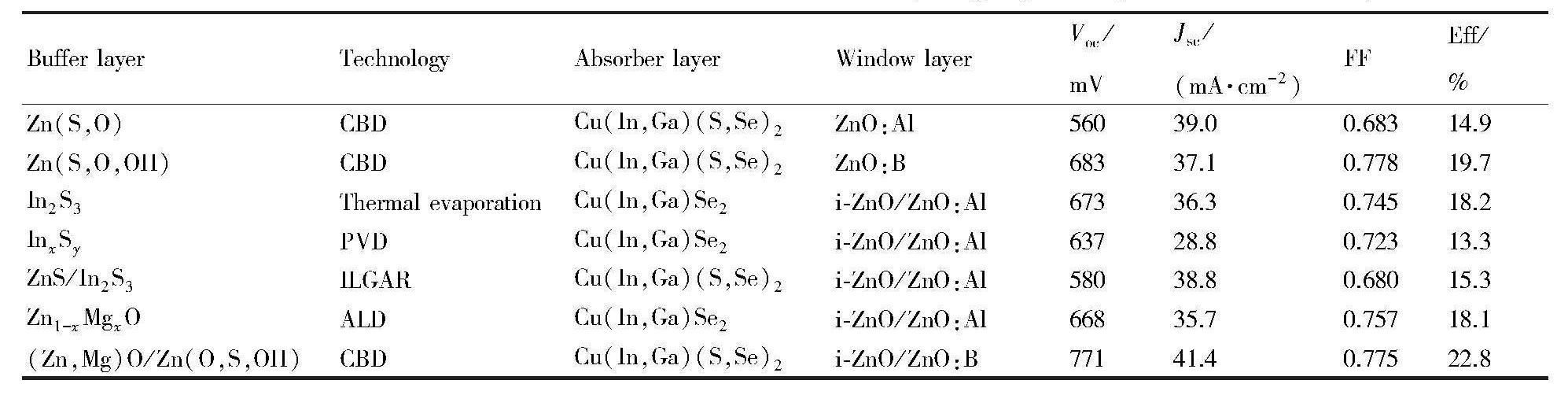

。近期部分具有无镉缓冲层的CIGS电池的性能如表2所示

[58 ]

。

无镉缓冲层的Voc 一般低于CIGS/CdS太阳电池,因为使用CdS层会产生更高的表面光电压

[59 ]

。对于无镉缓冲层,限制其发展的关键问题是缓冲层界面处的带取向和低缺陷密度

[60 ]

。但是,无镉缓冲层材料的带隙比CdS更高,所以可以提高太阳电池的短波段响应,从而提高电池的Jsc 。CdS的带隙是固定值,然而部分材料,例如Zn1-x Mgx O和ZnO1-x Sx ,可以通过改变Mg和S的含量来调节带隙。如ZnO1-x Sx 的带隙可以通过改变S/O比率在3.2 eV(Eg ,ZnO)到3.6 eV(Eg ,ZnS)之间调节,当x=0.45时带隙最小值接近2.6 eV

[61 ,62 ]

。In2 S3 也是CdS当前最有前途的替代品之一,采用热蒸发技术制备的In2 S3 缓冲层电池效率已达到18.2%

[63 ]

。

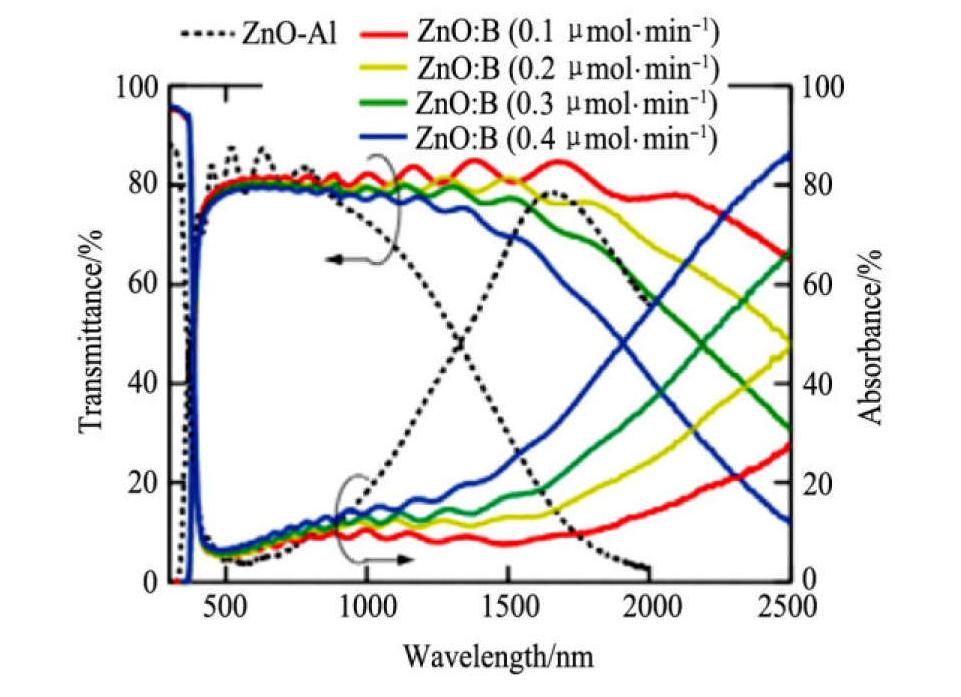

2.3 窗口层

在CdS层的表面上需要添加一层高度透明的、具有合适带隙(>3.3 eV)的n型透明导电氧化物(TCO)层充当前接触,也称为窗口层,它的作用是将光传输到产生电荷载体的吸收层上,同时作为载流子的传输通道。CIGS中最常见的窗口层是双层ZnO层:由薄(100 nm)本征ZnO层和厚(300 nm)n型掺杂ZnO层组成。本征ZnO层可以将CdS层和掺杂ZnO层隔离,以阻止掺杂元素扩散到其他层中。铝掺杂的ZnO(ZnO:Al,AZO)是在CIGS太阳电池中最常用的透明电极材料,一般通过溅射沉积,此外还有ZnO:B,ZnO:Ga层等也常被用作TCO层。在AZO薄膜中,掺杂的Al3+ 替代Zn2+ 并在薄膜中产生额外的自由载流子,因此,AZO薄膜比ZnO薄膜具有更低的电阻率

[64 ]

。此外还可以使用化学气相沉积的硼掺杂氧化锌(ZnO:B,BZO)作为TCO层。采用与CIGS兼容的沉积工艺,可实现高达40cm2 ·V-1 ·s-1 的高迁移率,同时载流子密度保持在1×1020 cm-3 以下,这样可以使TCO的透明度和短路电流输出增加,如图6所示

[65 ]

。近期其他关于CIGS的高迁移率TCO层的研究还包括表面未掺杂ZnO,氢化氧化铟(IOH)和氧化铟锌(IZO)等

[66 ,67 ,68 ,69 ]

。

表2 具有无镉缓冲层(使用不同方法制备)的CIGS电池的性能 下载原图

Table 2 Performance of CIGS solar cell with cadmium free buffer layer (prepared by different methods)

[55-59]

TCO材料的选择是由其导电性、透明度、水分稳定性和进一步加工的相容性的来决定的。AZO膜中Al的存在增强了膜的吸湿性,而水分对AZO薄膜是有害的,在潮湿的环境中,AZO薄膜会出现大约一个数量级的电阻率的退化

[69 ]

。这是因为环境中的氧产生了化学吸附,形成了氢氧化锌和碳酸盐

[70 ]

,导致晶界处形成了势垒,降低了迁移率。因此,当AZO用于CIGS太阳电池时,存在的主要问题是AZO的长期稳定性。目前可以通过增加层密度

[71 ,72 ]

和使用适当的封装(例如具有防潮涂层的透明前板)

[73 ]

来防止TCO在湿度环境中的暴露。除此之外也可以选择其他TCO材料,如氧化铟锡(ITO)或氧化铟锌(IZO)来改善湿热稳定性

[74 ,75 ]

。

图6 SLG上ZnO:Al和ZnO:B薄膜的透射率和吸收光谱

Fig.6 Transmittance and absorption spectra of ZnO:Al and ZnO:Bfilms on SLG

[65]

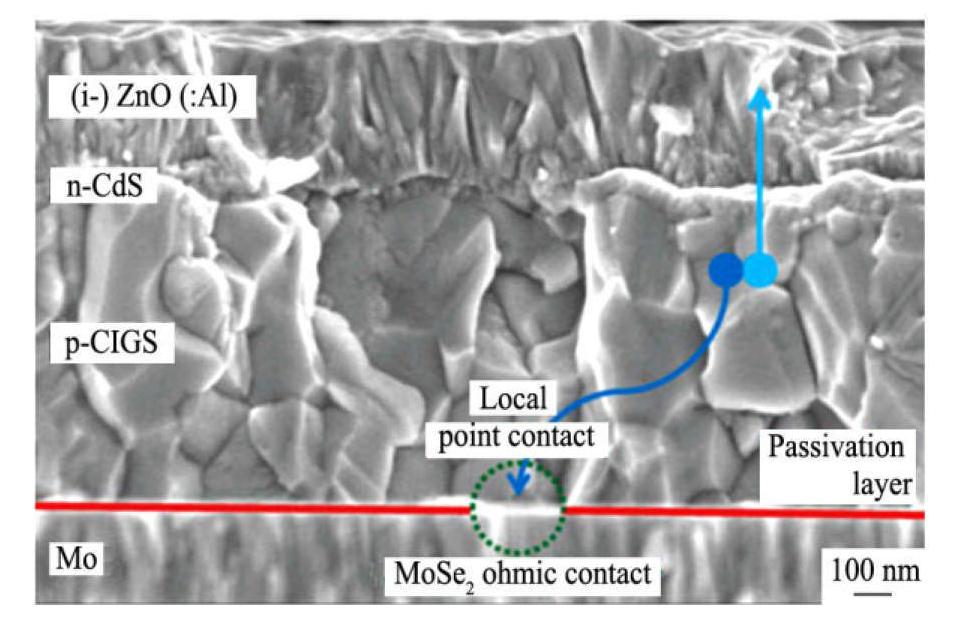

2.4 界面钝化

研究表明,界面处的载流子复合仍然是限制CIGS太阳电池发展的重要原因之一,因而“界面钝化”的观点被提出,以减少吸收层正面和背面界面处的复合。

常用的正面界面处理手段除了前面所说的碱金属PDT处理和CdS缓冲层Cd元素的扩散之外,还包括:(1)通过对吸收层表面进行硫化处理来改变吸收层表面带隙并钝化表面缺陷,从而减少CIGS/CdS界面处的复合;(2)减小CIGS的表面粗

度(<50 nm),使CIGS/CdS界面的表面积减小,以减少界面处的复合及饱和电流,但是这种平滑的表面会使反射增加;(3)吸收层的结构化和添加绝缘钝化层等。在CIGS太阳电池的背接触界面处,通常利用吸收层内Ga的梯度变化产生的背面场(BSF)

[76 ]

,使少数载流子远离Mo/CIGS界面从而减少背面界面处的复合。

除此之外,还可以使用类似于局部点接触的钝化方法

[77 ]

。这种方法是一种接近应用在高效率硅基太阳电池上的钝化方法

[78 ]

。该方法在吸收层正面和背面都可以应用,可以显著改善电池特性,尤其是对于非常薄的或非Ga梯度变化的CIGS吸收层,因为电池中单独的Ga梯度不足以防止背接触处的少数载流子复合。氧化铝(Al2 O3 )是经常用于这种应用的材料之一,它可以减少非辐射复合,用ALD法制备的AI2 O3 是目前CIGS电池中较常用的钝化材料

[79 ,80 ]

。

Vermang等

[81 ]

使用太阳电池模拟软件(SCAPS)进行的模拟表明,如果背接触处的Al2 O3 钝化层与吸收层局部点接触,CIGS器件的背面复合速度可以从1×104 ~1×106 cm-1 降至1×102 ~1×103 cm-1 。通过设计实验,如图7所示,Vermang等

[82 ]

验证了使用5 nm的ALD-Al2 O3 钝化CIGS后表面,并使用CdS离子

[77 ]

或电子束光刻

[73 ]

在CBD-CdS中产生点接触的开口,后表面钝化得到显著改进,Voc 明显增加,特别是对于薄(<1.6μm的无Ga梯度变化吸收层的效率有显著改进,因为这个充分活化的后表面更接近电池的最活跃区域。但是这种背接触钝化方法对Ga梯度变化的器件的效果迄今尚未见报道。钝化背接触的另一个影响是可以进行更好的光管理,近期已经有不同的研究机构表明此方法对薄吸收体的效率有明显改进

[83 ,84 ]

。

图7 使用ALD-Al2O3钝化CIGS后表面示意图

Fig.7 Schematic diagram of passivation ofrear surface of CIGS using ALD-Al2 O3

[82]

正面接触钝化类似于背面的点接触的方式。软件模拟显示,通过选择合适的点开口几何形状

[85 ,86 ,87 ]

和适当的钝化材料,电池性能可以得到改进。基于当前的CIGS层质量,最佳点接触宽度和间距估计在10和100 nm范围内

[86 ]

。Hsu等

[80 ]

首次通过ALD法在CIGS表面制备Al2 O3 用于界面钝化。实验表明即使厚度仅为5 nm,就可以观察到Al2 O3 的钝化效果。ALD-Al2 O3 的钝化效果主要是由于CIGS/Al2 O3 界面的低界面缺陷密度和块状Al2 O3 中的带负电的固定电荷产生的场效应产生。

此外,ZnS层也可以作为一种有效地钝化层

[88 ]

。实验证明In2 S3 缓冲层和CIGS吸收层之间的ZnS薄层改善了太阳电池的性能,提高了Voc

[89 ]

,ZnS钝化层(以喷雾ILGAR方法沉积ZnS纳米颗粒制备)与缓冲层点接触的太阳电池已经被制备出来

[90 ]

,纳米级氟化物晶体在吸收层表面上的自组装,可以用作钝化层沉积的模板

[91 ]

。

3 CIGS电池产业化面临的挑战

(1)组件效率。

理论上CIGS电池的极限效率为33.5%(对应带隙1.14 eV)

[30 ]

,而当前的实验室效率水平最高仅为22.9%左右,大面积制造的电池效率更低,且尚未有完善的技术可以在非破坏条件下评估CIGS薄膜的厚度和成分。实验室效率(22.9%)

[12 ]

和商业模块效率(16.1%)

[92 ]

之间存在较大差距。CIGS商业化的主要挑战是将实验室的制造技术扩展到规模化工业生产上,同时保持高效率。对于高效率CIGS电池,实验室研究采用的是静态沉积工艺(衬底处于固定位置)。但是在生产制造中,生产大面积太阳电池一般采用动态沉积工艺(衬底在运动中),这两种工艺的生长动力学是不同的

[30 ]

。由于设备兼容性问题,在大面积上很难重现小面积电池的高效率。因此我们需要改进关键设备来适应全动态化工艺制备,同时对相关的生长动力学进行进一步研究。

(2)生产工艺。

CIGS是一种四元化合物,大面积衬底上的薄膜均匀性(厚度和成分)对电池的组件生产来说是一个重要问题。薄膜均匀性对高效率太阳电池的电学和光学特性影响很大,同时大面积薄膜的重复性和均匀性直接影响产品的质量和产量。如果CIGS太阳电池的制造涉及非真空和真空两种工艺(例如CBD制备CdS,真空技术制备CIGS),则不同设备之间的基板处理和工艺之间的通量差异都是生产上的关键问题

[93 ]

。这一点目前可以通过使用真空工艺制备所有薄膜来避免,如采用溅射沉积技术,但这会增加生产成本。

(3)组件封装。

在电池稳定性方面,目前大多数研究都是在未封装的CIGS电池上进行的

[87 ]

。Theelen等

[94 ]

的研究表明,背电极处的界面反应对电池来说至关重要,而Mo背电极由于很容易氧化和降解,会导致电池整体的不稳定。为了提高CIGS太阳电池的长期稳定性,需要一种更加稳定的背接触。同时部分TCO薄膜在水分和空气中暴露也会引起性能的退化

[64 ]

,所以基于ZnO和Mo的腐蚀性,使用乙烯-醋酸乙烯共聚物(EVA)/玻璃的CIGS组件还存在很大的问题。为了避免湿气和氧气进入,CIGS电池需要一种具有更好性能(如粘附性,耐久性,低透湿率和热稳定性等)的合适的密封技术。

(4)原材料与生产成本。

由于镉本身具有毒性,会对环境产生不利影响,并对人体产生毒害作用

[88 ]

,所以对无镉的CIGS电池的研究非常必要。此外,In在工业生产上主要是作为Zn的副产品获得的,所以其产量受Zn生产的限制

[95 ]

。可以预见,In的需求可能随着CIGS组件的大量生产而增加,这会导致其价格上升。同时Ga元素在地球上储量并不丰富,其价格较为昂贵。为了解决这个问题,需要提高吸收层的光吸收与光电特性,通过材料的优化与新器件结构的运用,使在器件中CIGS层更薄(≤1μm),同时减少Jsc 的损失。为降低生产成本,应缩短CIGS和TCO层的制备时间,所以也需要使用更薄的CIGS层并且采用TCO的高速生长技术。

4 展望

近几年,CIGS太阳电池的研究取得了重要进展,由不同实验室创造的世界纪录效率飞速提升,但是当前纪录效率与理论效率值还存在较大差距。新技术的出现是提升CIGS电池效率的激发点,对于这些技术的机制认知是提升效率的关键。新技术例如CIGS太阳电池在柔性基底上的生产,CIGS与钙钛矿电池的叠层等策略,已经成为了新的发展方向。目前实验室研究成果应用于批量生产和大型产业化还面临挑战,实验室研究方法转化为工业生产技术也需要一段时间。此外,对CIGS电池的研究也需要进一步深化,从根源上来改善电池性能。

参考文献

[1] Jackson P,Wuerz R,Hariskos D,Lotter E,Witte W,Powalla M.Effects of heavy alkali elements in Cu(In,Ga)Se_2 solar cells with efficiencies up to 22.6%[J].Physica Status Solidi(RRL)-Rapid Research Letters,2016,10(8):583.

[2] Jeyakumar R,Ramamurthy S,Jayachan-dran M,Chockalingam M J.Electrochemical preparation and characterization of copper indium diselenide thin films[J].Materials Research Bulletin,1994,29(2):195.

[3] Hahn H,Frank G,Klingler W,Anne D S,Georg S.Untersuchungenübertem?re Chalkogenide.V.Ubereinigetem?re chalkogenidemit chalkopyritstruktur[J].Zeitschrift für Anorganische und Allgemeine Chemie,1953,271:153.

[4] Wagner S,Shay J L,Migliorato P,Piero M,Kasper H M.CuInSe_2/CdS heterojunction photovoltaic detectors[J].Applied Physics Letters,1974,25(8):434.

[5] Kazmerski L L,White F R,Morgan G K.Thin-film CuInSe_2/CdS heterojunction solar cells[J].Appl.Phys.Lett.,1976,29:268.

[6] Boer K W.Solar Cell Theory[M].Physics and Technology of Solar Energy.Springer Netherlands,1987.9.

[7] Kazmerski L L,Sanborn G A.CuInS_2 thin-film homojunction solar cells[J].Journal of Applied Physics,1977,48(7):3178.

[8] Mickelsen R A,Chen W S.Development of a 9.4%efficient thin-film CuInSe_2/CdS solar cell[A].15th Photovoltaic Specialists Conference[C].1981.800.

[9] Mitchell K,Eberspacher C,Ermer J,Pier D.Single and tandem junction CuInSe_2,cell and module technology[A].Photovoltaic Specialists Conference,1988.Conference Record of the Twentieth IEEE[C].IEEE,1988.1384.

[10] Wieting R D.CIS manufacturing at the megawatt scale[A].Photovoltaic Specialists Conference,2002.Conference Record of the Twenty-Ninth IEEE[C].IEEE,2002.478.

[11] Rui K,Yagioka T,Adachi S,Handa A,Tai K F,Takuya K,Hiroki S.New world record Cu(In,Ga)(Se,S)2 thin film solar cell efficiency beyond 22%[A].Photovoltaic Specialists Conference[C].IEEE,2016.1287.

[12] Green M,Hishikawa Y,Dunlop E,Dean H L,Jochen H E,Anita H B.Solar cell efficiency tables(version51)[J].Progress in Photovoltaics Research&Applications,2018,26(1):51.

[13] Reinhard P,Pianezzi F,Bissig B,Chirila A,Blosch P,Nishiwaki S,Buecheler S,Tiwari A N.Cu(In,Ga)Se_2thin-film solar cells and modules—a boost in efficiency due to potassium[J].IEEE Journal of Photovoltaics,2015,5(2):656.

[14] Rampino S,Annani N,Bissoli F,Rampino S,Annani N,Bissoli F,Bronzoni M,Calestani D,Calicchio M.15%efficient Cu(In,Ga)Se_2 solar cells obtained by lowtemperature pulsed electron deposition[J].Applied Physics Letters,2012,101(13):894.

[15] Fischer J,Larsen J K,Guillot J,Aidac Y,Eisenbartha T,Regescha D,Depreduranda V,Fevrea N,Siebentritta S,Phillip J D.Composition dependent characterization of copper indium diselenide thin film solar cells synthesized from electrodeposited binary selenide precursor stacks[J].Solar Energy Materials&Solar Cells,2014,126(126):88.

[16] Kapur V,Kemmerle R,Bansal A,Haber J,Schmitzberger J,Le P,Guevarra D,Kapur V,StempienT.Manufacturing of ‘ink based’ CIGS solar cells/modules[A].Photovoltaic Specialists Conference,2008.Pvsc'08[C].IEEE,2009.1.

[17] Nakada T.Invited paper:CIGS-based thin film solar cells and modules:unique material properties[J].Electronic Materials Letters,2012,8(2):179.

[18] Romeo A,Terheggen M,Abou-Ras D,B?tzner D L,Haug F J,Kalin M,Rudmann D,Tiwari A N.Development of thin-film Cu(In,Ga)Se_2 and CdTe solar cells[J].Progress in Photovoltaics Research&Applications,2004,12(2-3):93.

[19] Guillemoles J F.The puzzle of Cu(In,Ga)Se_2,(CIGS)solar cells stability[J].Thin Solid Films,2002,s 403-404(-):405.

[20] Kannan R,Miguel A,Contreras,Craig L.Perkins.Properties of 19.2%efficiency ZnO/CdS/CuInGaSe2thin-film solar cells[J].Progress in Photovoltaics Research&Applications,2010,11(4):225.

[21] Katagiri H.Survey of development of CZTS-based thin film solar cells[A].IEEE,International Conference on Photonics[C].IEEE,2012.345.

[22] Ghorbani E,Kiss J,Mirhosseini H,Roma G,Schmidt M,Windeln J,Kühne T D,Felser C.Hybridfunctional calculations on the incorporation of Na and K impurities into the CuInSe_2 and CuIn_5Se_8 solar-cell materials[J].Journal of Physical Chemistiy C,2015,119(7):151014100345001.

[23] Reinhard P,Chirila A,Blosch P,Pianezzi F,Nishiwaki S,Buecheler S,Tiwari A N.Review of progress toward20%efficiency flexible CIGS solar cells and manufacturing issues of solar modules[J].IEEE Journal of Photovoltaics 2013,3(1):572.

[24] Shafarman W N,Stolt L.Cu(InGa)Se_2 Solar Cells[M].Handbook of Photovoltaic Science and Engineering.John Wiley&Sons,Ltd.,2010.546.

[25] Scheer R,Schock H W.Chalcogenide Photovoltaics:Physics,Technologies,and Fhin Film Devices[M].Wiley-VCH,2011.159.

[26] Fortunato E,Ginley D,Hosono H,Paine D C.Transparent conducting oxides for photovoltaics[J].Mrs Bulletin,2007,32(3):242.

[27] Rau U,Grabitz P 0,Werner J J H.Resistive limitations to spatially inhomogeneous electronic losses in solar cells[J].Applied Physics Letters,2004,85(24):6010.

[28] Naghavi N,Abou-Ras D,Allsop N,Barreau N,Bücheler S,Ennaoui A,Fischer C H,Guillen C,Hariskos D,Herrero J,Klenk R,Kushiya K,Lincot D,Menner R,Nakada T,Platzer-Bj?rkman C,Spiering S,Tiwari A N,T?mdahl T.Buffer layers and transparent conducting oxides for chalcopyrite Cu(In,Ga)(S,Se)_2,based thin film photovoltaics:present status and current developments[J].Progress in Photovoltaics Research&Applications,2010,18(6):411.

[29] Ramanujam J,Venna A,Gonzalez-Diaz B,GuerreroLemus R,Cirlin G E.Inorganic photovoltaics-Planar and nanostructured devices[J].Progress in Materials Science,2016,82:294.

[30] Ramanujam J,Singh U P.Copper indium gallium selenide based solar cells-a review[J].Energy&Environmental Science,2017.

[31] Hedstrom J,Ohlsen H,Bodegard M,Kylner A,Stolt L,Hariskos D,Ruckh M,Schock H W.ZnO/CdS/Cu(In,Ga)Se_2 thin film solar cells with improved performance[A].Photovoltaic Specialists Conference,1993.Conference Record of the Twenty Third IEEE[C].IEEE Xplore,1993.364.

[32] Rudmann D,Bremaud D,Cunha A F D,Bilger G,Strohm A,Kaelin M,Zogg H,Tiwari A N.Sodium incorporation strategies for CIGS growth at different temperatures[J].Thin Solid Films,2005,480(11):55.

[33] Jackson P,Hariskos D,Lotter E,Paetel S,Wuerz R,Menner R,Wischmann W,Powalla M.New world record efficiency for Cu(In,Ga)Se_2 thin-film solar cells beyond 20%[J].Progress in Photovoltaics Research&Applications,2011,19(7):894.

[34] Chirila A,Reinhard P,Pianezzi F,Bloesch P,Alexander R Uhl,Fella C,Kranz L,Keller D,Gretener C,Hagendorfer H,Jaeger D,Emi Rolf,Nishiwaki S,Buecheler S,Tiwari A N.Potassium-induced surface modification of Cu(In,Ga)Se_2 thin films for high-efficiency solar cells[J].Nature Materials,2013,12(12):1107.

[35] Green M A,Emery K,Hishikawa Y,Warta W,Dunlop E D.Solar cell efficiency tables(version 41)[J].Progress in Photovoltaics Research&Applications,2013,21(1):49.

[36] Jackson P,Hariskos D,Wuerz R,Wischmann W,Powalla M.Compositional investigation of potassium doped Cu(In,Ga)Se_2,solar cells with efficiencies up to 20.8%[J].Physica Status Solidi(RRL)-Rapid Research Letters,2014,8(3):219.

[37] Jackson P,Hariskos D,Wuerz R,Kiowski O,Bauer A,Friedlmeier T M,Powalla M.Properties of Cu(In,Ga)Se_2 solar cells with new record efficiencies up to 21.7%[J].Physica Status Solidi(RRL)-Rapid Research Letters,2015,9(1):28.

[38] Theresa M F,Philip J,Andreas B,Dimitrios H,Oliver K,Richard M,Roland W,Michael P.High-efficiency Cu(In,Ga)Se_2 solar cells[J].Thin Solid Films,2017,633:13.

[39] Jackson P,Wuerz R,Hariskos D,Lotter E,Witte W,Powalla M.Effects of heavy alkali elements in Cu(In,Ga)Se_2 solar cells with efficiencies up to 22.6%[J].Physica Status Solidi(RRL)-Rapid Research Letters,2016,10(8):583.

[40] Paetel S.Roadmap CIGS towards 25%efficiency[presentation][R].7th International Workshop on CIGS Solar Cell Technology[C].Munich,Gennany,2016.

[41] Yun S,Shuping L,Li Wei,Shiqing C,Yunxiang Z,Yiming L,Wei L.Review on alkali element doping in Cu(In,Ga)Se_2 thin films and solar cells[J].Engineering,2017,3(4):452.

[42] Pianezzi F,Reinhard P,Chirila A,Bissig B,Nishiwaki S,Buecheler S,Tiwari A N.Unveiling the effects of post-deposition treatment with different alkaline elements on the electronic properties of CIGS thin film solar cells[J].Physical Chemistry Chemical Physics Peep,2014,16(19):8843.

[43] Handick E,Reinhard P,Alsmeier J H,Kohler L,Pianezzi F,Krause S,Gorgoi M,Ikenaga E,Koch N,Wilks R G,Buecheler S,Tiwari A N,B?r M.Potassium postdeposition treatment-induced band gap widening at Cu(In,Ga)Se_2 surfaces-reason for performance leap[J].Acs Applied Materials&Interfaces,2015,7(49):27414.

[44] Mahboob S,Malik S N,Haider N,Nguyen C Q,Malik M A,O'Brien P.Deposition of binary,ternary and quaternary metal selenide thin films from diisopropyldiselenophosphinato-metal precursors[J].Journal of Crystal Growth,2014,394(10):39.

[45] Xiao H,Tahirkheli J,Iii W A G.Accurate band gaps for semiconductors from density functional theory[J].2011,2(3):212.

[46] Witte W,Abou-Ras D,Albe K,Bauer G H,Bertram F,Boit C,Brüggemann R,Christen J,Dietrich J,Eicke A,Hariskos D,Maiberg M,Mainz R,Meessen M,Müller M,Neumann O,Orgis T,Paetel S,Pohl J,Rodriguez-Alvarez H,Scheer R,Schock H W,Unold T,Weber A,Powalla M.Gallium gradients in Cu(In,Ga)Se_2 thin-film solar cells:gallium gradients in CIGS thin-film solar cells[J].Progress in Photovoltaics Research&Applications,2015,23:717.

[47] Schleussner S,Zimmennann U,W?tjen T,Leifer K,Edoff M.Effect of gallium grading in Cu(In,Ga)Se_2,solar-cell absorbers produced by multi-stage coevaporation[J].Solar Energy Materials&Solar Cells,2011,95(2):721.

[48] Chirila A,Buecheler S,Pianezzi F,Bloesch P.Gretener C,Uhl A R,Fella C,Kranz L,Perrenoud J,Seyrling S,Venna R,Nishiwaki S,Romanyuk Y E,Bilger G,Tiwari A N.Highly efficient Cu(In,Ga)Se_2solar cells grown on flexible polymer films[J].Nature Materials,2011,10(11):857.

[49] Dullweber T,Hanna G,Shams-Kolahi W,Schwartzlander A,Contreras M A,Noufi R,Schock H W.Study of the effect of gallium grading in Cu(In,Ga)Se_2[J].Thin Solid Films,2000,s361-362(7):478.

[50] Gorji N E,Reggiani U,Sandrolini L.A simple model for the photocurrent density of a graded band gap CIGS thin film solar cell[J].Solar Energy,2012,86(3):920.

[51] Dullweber T,Anna G H,Rau U,Schock H W.A new approach to high-efficiency solar cells by band gap grading in Cu(In,Ga)Se_2 chalcopyrite semiconductors[J].Solar Energy Materials&Solar Cells,2001,67(1):145.

[52] Amin N,Chelvanathan P,Hossain M I,Sopian K.Numerical modelling of ultra thin Cu(In,Ga)Se_2 solar cells[J].Energy Procedia,2012,15(1):291.

[53] Wada T,Hayashi S,Hashimoto Y,Nishiwaki S,Sato T,Negami T,Nishitani M.High efficiency Cu(In,Ga)Se_2(CIGS)solar cells with improved CIGS surface[A].Proceedings of the 2nd World Conference and Exhibition on Photovoltaic Energy Conversion[C].1998.403.

[54] Fjallstrom V,Szaniawski P,Vennang B,Salome P M P,Rostvall F,Zimmennann U,Edoff M.Recovery after potential-induced degradation of Culn_(1-x)Ga_xSe_2 solarcells with CdS and Zn(O,S)buffer layers[J].2015,5(2):664.

[55] Nakamura M,Kouji Y,Chiba Y,Hakuma H,Kobayashi T,Nakada T.Achievement of 19.7%efficiency with a small-sized Cu(InGa)(SeS)_2 solar cells prepared by sulfurization after selenizaion process with Zn-based buffer[A].IEEE Photovoltaic Specialists Conference[C].IEEE,2013.0849.

[56] Kobayashi T,Yamaguchi H,Nakada T.Effects of combined heat and light soaking on device performance of Cu(In,Ga)Se_2,solar cells with ZnS(O,OH)buffer layer[J].Progress in Photovoltaics Research&Applications,2014,22(1):115.

[57] Hariskos D,Menner R,Jackson P,Paetel S,Witte W,Wischmann W,Powalla M,Bürkert L,Kolb T,Oertel M,Dimmler B,Fuchs B.New reaction kinetics for a high-rate chemical bath deposition of the Zn(S,O)buffer layer for Cu(In,Ga)Se_2-based solar cells[J].Progress in Photovoltaics Research&Applications,2012,20(5):534.

[58] Naghavi N,Abou-Ras D,Allsop N,Barreau N,Bücheler S,Ennaoui A,Fischer C H,Guillen C,Hariskos D,Herrero J,Klenk R,Kushiya K,Lincot D,Menner R,Nakada T,Platzer-Bj?rkman C,Spiering S,Tiwari A N,T?rndahl T.Buffer layers and tmnsparent conducting oxides for chalcopyrite Cu(In,Ga)(S,Se)_2based thin film photovoltaics:present status and current developments[J].Progress in Photovoltaics Research&Applications,2010,18(6):411.

[59] Salome P M P,Keller J,Tomdahl T,Teixeira J P,Nicoara N,Andrade R R,Stroppa D G,Gonzalez J C,Edoff M,Leitao J P,Sadewasser S.CdS and Zn_(1-x)Sn_xO_y,buffer layers for CIGS solar cells[J].Solar Energy Materials&Solar Cells,2017,159:272.

[60] Meyer B K,Polity A,Farangis B,He Y,Hasselkamp D,Kr?mer Th,Wang C.Structural properties and bandgap bowing of ZnO_(1-x)S_x thin films deposited by reactive sputtering[J].Applied Physics Letters,2004,85(21):4929.

[61] Persson C,Platzer-Bj?rkman C,Malmstr?m J,Tomdahl T,Edoff M.Strong valence-band offset bowing of ZnO_(1-x)S_x,enhances p-type nitrogen doping of ZnO-like alloys[J].Physical Review Letters,2006,97(14):146403.

[62] Grimm A,Kieven D,Klenk R,Lauennann I,NeisserA,Niesen T,Palm J.Junction formation in chalcopyrite solar cells by sputtered wide gap compound semiconductors[J].Thin Solid Filins,2011,520(4):1330.

[63] Spiering S,Nowitzki A,Kessler F,Igalson M,Maksoud H A.Optimization of buffer-window layer system for CIGS thin film devices with indium sulphide buffer by inline evaporation[J].Solar Energy Materials&Solar Cells,2016,144:544.

[64] Pan J,Kerr L,Li X,Gulley-Stahl H J,Sommer A J.Investigation of aluminum induced degradation in sputtered Al:ZnO for CIGS solar cells applications[A].In:IEEE Photovoltaic Specialists Conference[C].IEEE,2009.000345.

[65] Koida T,Nishinaga J,Higuchi H,Kurokawa A,Iioka M,Kamikawa-Shimizu Y,Yamada A,Shibata H,Niki S.Comparison of ZnO:B and ZnO:Al layers for Cu(In,Ga)Se_2 submodules[J].Thin Solid Filins,2016,4(4):79.

[66] Hala M,Fujii S,Redinger A,Inoue Y,Rey G,Thevenin M,Depredurand V,Weiss T P,Bertram T,Siebentritt S.Highly conductive ZnO films with high near infrared transparency[J].Progress in Photovoltaics Research&Applications,2015,23(11):1630.

[67] Koida T,Fujiwara H,Kondo M.Hydrogen-doped In_2O_3 as high-mobility transparent conductive oxide[J].Japanese Journal of Applied Physics,2007,46(25-28):L685.

[68] Menner R,Cemernjak M,Paetel S,Wischmann W.Application of indium zinc oxide window layers in Cu(In,Ga)Se_2,solar cells[J].Thin Solid Films,2016.

[69] Jager T,Romanyuk Y E,Nishiwaki S,Benjamin B,Fabian P,Peter F,Christina G,Max D,Tiwair A N.Hydrogenated indium oxide window layers for highefficiency Cu(In,Ga)Se_2 solar cells[J].Journal of Applied Physics,2015,117(20):28.

[70] Theelen M,Boumans T,Stegeman F,Colberts F,Illiberi A,Berkum J,Barreau N,Vroon Z,Zeman M.Physical and chemical degradation behavior of sputtered aluminum doped zinc oxide layers for Cu(In,Ga)Se_2,solar cells[J].Thin Solid Films,2014,550(550):530.

[71] Hiipkes J,Owen J I,Wimmer M,Ruske F,Greiner D,Klenk R,Zastrow U,Hotovy J.Damp heat stable doped zinc oxide films[J].Thin Solid Filins,2014,555(555):48.

[72] Greiner D,Gledhill S E,Koble C,Krammer J,Klenk R.Damp heat stability of Al-doped zinc oxide films on smooth and rough substrates[J].Thin Solid Films,2011,520(4):1285.

[73] Carcia P F,Mclean R S,Hegedus S.Encapsulation of Cu(InGa)Se_2 solar cell with Al_2O_3 thin-film moisture barrier grown by atomic layer deposition[J].Solar Energy Materials&Solar Cells,2010,94(12):2375.

[74] Pem F J,Noufi R,Li X,Dehart C,To B.Damp-heat induced degradation of transparent conducting oxides for thin-film solar cells[A].Photovoltaic Specialists Conference,2008.Pvsc'08.IEEE[C].IEEE,2008.1.

[75] Coyle D J,Blaydes H A,Northey R S,Pickett J E,Nagarkar K R,Zhao R A,Gardner J 0.Life prediction for CIGS solar modules part 2:degradation kinetics,accelerated testing,and encapsulant effects[J].Progress in Photovoltaics Research&Applications,2013,21(2):173.

[76] Lundberg O,Edoff M,Stolt L.The effect of Gagrading in CIGS thin film solar cells[J].Thin Solid Films,2005,480(3):520.

[77] Vennang B,Fjallstrom V,Pettersson J,Salome P,Edoff M.Development of rear surface passivated Cu(In,Ga)Se_2,thin film solar cells with nano-sized local rear point contacts[J].Solar Energy Materials&Solar Cells,2013,117(4):505.

[78] Blakers A W,Wang A,Milne A M,Zhao J,Green M A.22.8%efficient silicon solar cell[J].Applied Physics Letters,1989,55(13):1363.

[79] Joel J,Vennang B,Larsen J,Donzel-Gargand O,Edoff M.On the assessment of CIGS surface passivation by photoluminescence[J].Physica Status Solidi(RRL)-Rapid Research Letters,2015,9(5):288.

[80] Hsu W W,Chen J Y,Cheng T H,Lu S C,Ho W S,Chen Y Y,Chien Y J,Liu C W.Surface passivation of Cu(In,Ga)Se_2 using atomic layer deposited Al_2O_3[J].Applied Physics Letters,2012,100(2):235.

[81] Vennang B,W?tjen J T,Frisk C,Fj?llstr?m V,Rostvall F,Edoff M,Salome P,Bonne J,Nicoara N,Sadewasser S.Introduction of Si PERC rear contacting design to boost efficiency of Cu(In,Ga)Se solar cells[J].Photovoltaics IEEE Journal of Photovoltaics,2014,4(6):1644.

[82] Vennang B,Fj?llstr?m V,Gao X,Edoff M.Improvedrear surface passivation of Cu(In,Ga)Se,solar cells:a combination of an Al,O,rear surface passivation layer and banosized local rear point contacts[J].IEEE Journal of Photovoltaics,2014,4(1):486.

[83] Vermang B,W?tjen J T,Fj?llstr?m V,Rostvall F,Edoff M,Gunnarsson R,Pilch I,Helmersson U,Kotipalli R,Henry F,Flandre D.Highly reflective rear surface passivation design for ultra-thin Cu(In,Ga)Se_2solar cells[J].Thin Solid Films,2015,582:300.

[84] Van L C,Yin G,Polman A,Schmid M.Light coupling and trapping in ultrathin Cu(In,Ga)Se_2 solar cells using dielectric scattering patterns[J].Acs Nano,2015,9(10):9603.

[85] Sozzi G,Pignoloni D,Menozzi R,Pianezzi F,Reinhard P,Bissig B,Buecheler S,Tiwari A N.Designing CIGS solar cells with front-side point contacts[A].Photovoltaic Specialist Conference[C].IEEE,2015.1.

[86] Bercegol A,Chacko B,Klenk R,LauennannI,LuxSteiner M C,Liero M.Point contacts at the copper-indium-gallium-selenide interface—a theoretical outlook[J].Journal of Applied Physics,2016,119(15):1107.

[87] Allsop N,Nümberg R,Lux-Steiner M C,SchedelNiedrig T.Three-dimensional simulations of a thin film heterojunction solar cell with a point contact/defect passivation structure at the heterointerface[J].Applied Physics Letters,2009,95(12):235.

[88] Hultqvist A,Li J V,Kuciauskas D,Dippo P,Contreras M A,Levi D H,Bent S F.Reducing interface recombination for Cu(In,Ga)Se_2 by atomic layer deposited buffer layers[J].Applied Physics Letters,2015,107(3):28.

[89] Allsop N A,Camus C,H?nsel A,Gledhilll S E,Lauernann I,Lux-Steiner M C,Fischer C H.Indium sulfide buffer/CIGSSe interface engineering:Improved cell performance by the addition of zinc sulfide[J].Thin Solid Films,2007,515(15):6068.

[90] Fu Y,Saez-Araoz R,Kohler T,Krüger M,Steigert A,Lauennann I,Lux-Steiner M C,Fischer C H.SprayILGAR ZnS nanodots/In_2S_3,as defect passivation/point contact bilayer buffer for Cu(In,Ga)(S,Se)_2,solar cells[J].Solar Energy Materials&Solar Cells,2013,117(10):293.

[91] Reinhard P,Bissig B,Pianezzi F,Hagendorfer H,Sozzi G,Menozzi R,Gretener C,Nishiwaki S,Buecheler S,Tiwari A N.Alkali-templated surface nanopatteming of chalcogenide thin films:a novel approach towards solar cells with enhanced efficiency[J].Nano Letters,2015,15(5):3334.

[92] Green M A.Estimates of Te and In prices from direct mining of known ores[J].Progress in Photovoltaics Research&Applications,2009,17(5):347.

[93] Theelena M,Daume F.Stability of Cu(In,Ga)Se_2solar cells:a literature review[J].Sol.Energy,2016,133:586.

[94] Theelen M,Polman K,Tomassini M,Barreau N,Steijvers H,Berkum J,Vroon Z,Zeman M.Influence of deposition pressure and selenisation on damp heat degra-dation of the Cu(In,Ga)Se_2,back contact molybdenum [J].Surface&Coatings Technology,2014,252(9):157.

[95] Ramanujam J,Venna A,Gonzalez-Diaz B,Guerrero-Le-musd R,Canizo C,Garcia-Tabares E,Rey-Stolle I,Granek F,Korte L,Tucci M,Rath J,Singh U P,Todorov T,Gunawan 0,Rubio S,Plaza J L,Dieguez E,Hoffmann B,Cirlin G E.Inorganic photovoltaics-Planar and nanostructured devices[J].Progress in Ma-terials Science,2016,82:294.