- Abstract:

- 1 Introduction▲

- 2 Flame shape▲

- 3 Recognition methods▲

- 4 Flame image recognition...▲

- 5 Conclusions▲

- References

- Figure

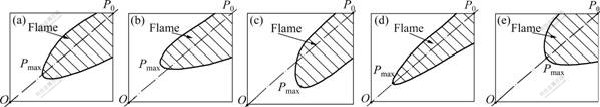

- Fig.1 Sketches of alumina rotary kiln flame shapes: (a) Normal shape; (b) Up deflected shape; (c) Down deflected shape; (d) Thin and long shape; (e) Fat and short shape

- Fig.2 Calculation principle of shape distance function

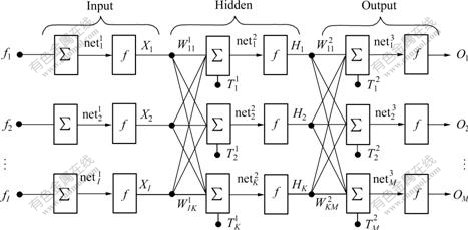

- Fig.3 Detailed structure of ANN-based classifier

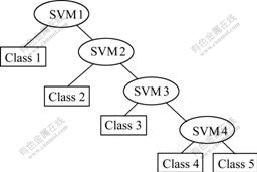

- Fig.4 Structure of SVM-based classifier

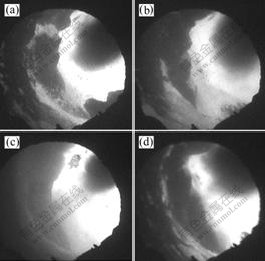

- Fig.5 Training images for alumina rotary kiln flame image recognition: (a) Normal shape; (b) Deflected shape; (c) Thin and long shape; (d) Fat and short shape

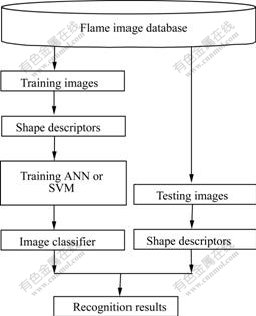

- Fig.6 Experimental procedure of alumina rotary kiln flame image recognition

J. Cent. South Univ. Technol. (2008) 15: 39-43

DOI: 10.1007/s11771-008-0009-8

![]()

Flame image recognition of alumina rotary kiln by artificial neural network and support vector machine methods

ZHANG Hong-liang(张红亮)1, ZOU Zhong(邹 忠)1, LI Jie(李 劼)1, CHEN Xiang-tao(陈湘涛)2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract:

Based on the Fourier transform, a new shape descriptor was proposed to represent the flame image. By employing the shape descriptor as the input, the flame image recognition was studied by the methods of the artificial neural network(ANN) and the support vector machine(SVM) respectively. And the recognition experiments were carried out by using flame image data sampled from an alumina rotary kiln to evaluate their effectiveness. The results show that the two recognition methods can achieve good results, which verify the effectiveness of the shape descriptor. The highest recognition rate is 88.83% for SVM and 87.38% for ANN, which means that the performance of the SVM is better than that of the ANN.

Key words:

1 Introduction

Due to the mechanical particularity, high temperature and corrosive condition of rotary kiln, it is difficult to measure its key parameters. Therefore, the control method of alumina rotary kiln is often based on the “watching flame” operations that are performed by experienced workers. Although it can be effective in most of time, it suffers from serious drawbacks: firstly, it is hard to quantify since it is based on the human experience; secondly, the working environment is very poor.

Recently, along with the development of the digital image processing and the computer hardware technology, more and more researchers have studied the rotary kiln flame image processing in order to realize the intelligent control of the rotary kiln. On the one hand, the flame image is utilized to detect the temperature of flame by radiation, but great deviation is often generated due to the complex working condition[1-2]. On the other hand, the single character is utilized to recognize the flame image, which causes low recognition rate and lost application value[3]. However, as one of the most important objects in rotary kiln flame image, the processing and recognition of the flame shape image is still an open question. While in other image processing fields, shape processing have attracted much attention because of its good performance. Many shape descriptors have been proposed, which can be generally divided into two categories: 1) contour-based methods, such as invariant moments and Zernike moments[4-7]; 2) region-based methods, exemplified by centroid distance, Fourier descriptors (FD) and curvature scale space descriptors (CSSD)[8]. In addition, many recognition methods including artificial neural network(ANN), support vector machine(SVM), evolution algorithm and Bayesian[9-10] have also been successfully applied in the field of image recognition.

Accordingly, in this work, the shape-based rotary kiln flame image recognition was studied by using the ANN and SVM, respectively. The recognition experiments were also carried out to evaluate the validity of them.

2 Flame shape

2.1 Flame shape

In rotary kiln operation, flame is one of the most important features. It not only indicates the combustion status of the pulverized coal, but also reflects the running status of the rotary kiln.

According to the “watching flame” operations, the flame shape can be divided into five categories. The sketch maps for all kinds of the flame shapes are presented in Fig.1, where P0 is the reference starting point, Pmax is the end point, and P0O is the reference central axes. P0 and P0O can be defined according to the human experience because the flame image is captured from the same rotary kiln with the same hardware.

Fig.1 Sketches of alumina rotary kiln flame shapes: (a) Normal shape; (b) Up deflected shape; (c) Down deflected shape; (d) Thin and long shape; (e) Fat and short shape

In addition, Figs.1(b)-(e) are all abnormal flame shapes. When they are formed, some corresponding operations must be performed to correct them, or they would lead to production accident. Therefore, the recognition of the flame shape is very important for rotary kiln intelligent control.

2.2 Flame shape descriptors

In image processing, the shape contour can be assumed as a set of the pixels {(x(i), y(i)), i=0, 1, 2,…, N-1}, where N is the number of the contour pixels. Since different flame shapes have different N and the angle between the line P1P0 and P91P0 equals 90?, the shape contour can be normalized by the angle(shown in Fig.2). The normalized flame contour has 91 pixel points {P1, P2, …,P91}. Consequently, according to Fig.2, the proposed distance function r(t) can be written as

![]()

(t=0, 1, 2, …, 90) (1)

where (![]()

![]() ) is the coordinate of referenced point, which can be defined by the experienced “watching flame” operators,

) is the coordinate of referenced point, which can be defined by the experienced “watching flame” operators, ![]() is the distance of the diagonal P0O,

is the distance of the diagonal P0O, ![]() is the coordinate of point Pt.

is the coordinate of point Pt.

Fig.2 Calculation principle of shape distance function

Then the Fourier transform is carried out for r(t), and the corresponding Fourier coefficient |F(u)| is also calculated as the shape descriptor. It can be written as

![]() (2)

(2)

![]() (3)

(3)

Since |F(0)| is the largest coefficient, it is employed as the normalization factor. Furthermore, in order to reduce the dimensionality of the shape descriptor, the first 40 coefficients are chosen as the final flame shape descriptor![]() . It can be written as

. It can be written as

![]() (u=1, 2, …, 40) (4)

(u=1, 2, …, 40) (4)

3 Recognition methods

3.1 Artificial neural network

ANN is a biologically inspired form of distributed computation. It is composed of simple processing units and connections. The ANN has been successfully applied in various fields, including network reliability, sports winning prediction, medical, marketing, retail, banking and finance[11-13].

Researchers have tried different neural network architectures to build the optimal neural network model for better prediction performance[14]. A classic feed-forward neural network trained with the improved back-propagation (BP) algorithm is employed for rotary kiln flame image recognition. Its detailed structure is shown in Fig.3, where fj is the input feature factor, Xj is the output of the jth input neuron, Hj is the output of the jth hidden neuron, Oj is the output of the jth output neuron, W1ji is the connection weight between the ith input neuron and jth hidden neuron, T1j is the threshold of the jth hidden neuron, W2ji is the connection weight between the ith hidden neuron and the jth output neuron, T2j is the threshold of the jth output neuron, f is the Sigmoid activation function.

Fig.3 Detailed structure of ANN-based classifier

3.2 Support vector machine

The SVM, derived from the Vapnik’s structural risk minimization (SRM) principle[15], can reduce the empirical risk. Its basic idea is to transform the training data into a higher dimensional space and then to find the hyperplane that maximizes the margin between classes.

SVMs are originally designed for binary classifications, but many real-world problems have more than two classes. Until now, the SVM-based multi-class classification is still an open research issue[16]. Generally, there are three kinds of widely applied approaches: one-vs-all method, one-vs-one method and tree-based method. The one-vs-all method separates each class from all others and constructs a combined classifier, while the one-vs-one method separates all classes’ pair wise and constructs a combined classifier using voting schemes. The tree-based method is the modification of the one-vs-one method. It classifies k classes into two big classes, and each class is also divided into two sub-classes. In this way, all k classes are divided into different levels.

As shown in Fig.4, a tree structure, which is similar to binary tree, is applied to build another rotary kiln flame image classifier.

Fig.4 Structure of SVM-based classifier

4 Flame image recognition experiments

According to the rotary kiln flame shape descriptors and the flame image classifiers, the recognition experiments were carried out to evaluate their validity.

4.1 Flame image preparation

The original rotary kiln flame image, which was 768×576 pixels gray scale BMP format image, was captured from an alumina rotary kiln by charge coupled device(CCD) and digital image card. After that, 200 images were randomly selected, preprocessed and manually labeled. Then, their shape descriptors were calculated and stored into the image database. From these images, 50 images were selected as the training samples, and the rest were the testing samples. Some of the training samples are illustrated in Fig.5.

Fig.5 Training images for alumina rotary kiln flame image recognition: (a) Normal shape; (b) Deflected shape; (c) Thin and long shape; (d) Fat and short shape

The procedure of the flame image recognition experiments is shown in Fig.6. It includes training and testing procedures: firstly, the training samples were applied to train the ANN and SVM; secondly, the ANN and SVM were tested with the testing samples.

Fig.6 Experimental procedure of alumina rotary kiln flame image recognition

4.2 Recognition experiments

4.2.1 ANN-based recognition experiments

BP training algorithm has been widely used in ANN because of its good performance, but it still has some weaknesses such as the long training time and the local minimum. The improved BP algorithm, Levenberg- Marquardt (L-M) algorithm, was adopted since it could overcome the above shortcomings.

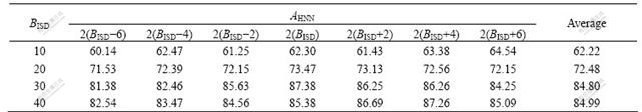

The input and output neurons of ANN can represent the input features and the image classes respectively, thus the number of the input and output neuron can be determined very easily. But for the number of hidden neuron, no theoretical method is now available. Therefore, through the empirical equation several candidate numbers were selected, and then the final hidden neuron number(AHNN) was determined based on the recognition performance. The results of the experiments are shown in Table 1, where the number the output neuron is 5, and the input shape descriptors (BISD) are the first 10, 20, 30 or 40 shape descriptors.

Table 1 lists the results of the ANN recognition experiments. It indicates that the average recognition rates are increased gradually from 62.22% to 84.99% with the increase of the input neuron number from 10 to 40; different hidden neuron numbers yield different recognition rates. For example, when the input neuron number is 10, the optimal hidden neuron number is 2(10+6)=32; the highest recognition rate is 87.38% when the input neuron number is 30 and hidden neuron number is 2×30=60.

4.2.2 SVM-based recognition experiments

The kernel function is one of the most important parts in SVM. The typical kernel functions are the polynomial kernel k(x, x1)=(x, x1+θ)d and Gaussian kernel k(x, x1)=exp[-||x-x1||2/(2σ)], where d is the degree of the polynomial kernel, θ is constant parameter, σ is the bandwidth of the Gaussian kernel, x1, x are the input feature vectors.

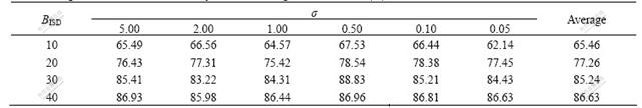

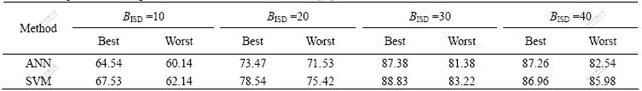

In flame image recognition, Gaussian kernel was adopted due to its better performance. So the parameter that must be determined was the kernel bandwidth (σ). Similarly, the parameter σ was also determined by the recognition performance in experiments. The recognition results of the experiments based on SVM are shown in Table 2. Moreover, the comparison results between ANN and SVM are shown in Table 3.

Table 1 Recognition rates of alumina rotary kiln flame image based on ANN(%)

Table 2 Recognition rates of alumina rotary kiln flame image based on SVM(%)

Table 3 Comparison of recognition rates between ANN and SVM(%)

Table 2 indicates that the recognition rates are also increased with the increase of the input neuron number; the optimal kernel function parameter σ is 0.50 because it yields the highest recognition rates for each input neuron numbers; the highest recognition rate is 88.83% when the input neuron number is 30 and σ is 0.50.

In Table 3, the comparison between the SVM and ANN is shown. It indicates that the performance of the SVM is better than the ANN because not only the highest recognition rate of SVM is higher than that o f the ANN, but also the average recognition rates of SVM are higher than those of ANN. Another conclusion is that the highest recognition rate is not corresponding to the largest input neuron number. One possible reason is that when the dimension of the input shape descriptors is too small, it cannot include all the shape information, and when it is too large, it will include much redundant information, which will disturb the recognition.

Therefore, the conclusion can be drawn that the SVM is the better recognition method as compared with ANN and the optimal input shape descriptor equals 30. It verifies the validity of the shape descriptors and the recognition methods which can provide a base for the intelligent control of alumina rotary kiln.

5 Conclusions

1) A flame shape descriptor is proposed and an alumina rotary kiln flame image recognition procedure is developed based on the SVM and ANN.

2) Recognition experiments with the flame image indicate that the flame image recognition method based on both SVM and ANN can achieve good recognition performance. The recognition rates of SVM and ANN are all larger than 85% when input shape descriptor is larger than 30, which verifies the effectiveness of the shape descriptors. The highest recognition rate is 88.83% and 87.38% for SVM and ANN, respectively, which indicates that SVM is better than ANN in flame image recognition.

References

[1] ZHANG Jing, LIU Xiao-yan. Measuring the temperature of calcining zone in rotary kiln by flame sequence process[J]. Journal of Electronic Measurement and Instrument, 1999, 13(4): 67-71. (in Chinese)

[2] YI Zheng-ming, ZHOU Jie-ming, LIU Zhi-ming, LI Yuan-feng. Study on flame monitoring system of rotary kiln based on image processing[J]. Control and Instruments in Chemical Industry, 2005, 32(5): 54-56. (in Chinese)

[3] WEI Zhao-yi. Optical flow algorithm and research on its application to rotary kiln status recognition[D]. Shenyang: Northeastern University, 2005: 53-55. (in Chinese)

[4] RAJ B Y, NAVEEN K N, ARUN K G, VINOD K R. Retrieval and classification of objects using generic Fourier, Legendre moment, and wavelet Zernike moment descriptors and recognition using joint transform correlator[J]. Optics and Laser Technology, 2008, 40(3): 517-527.

[5] PAPAKOSTAS G A, BOUTALIS Y S, PAPAODYSSEUS C N, FRPGOULIS D K. Numerical stability of fast computation algorithms of Zernike moments[J]. Applied Mathematics and Computation, 2008, 195(1): 326-345.

[6] CHONG Y W, RAVEENDRAN P. On the computational aspects of Zernike moments[J]. Image and Vision Computing, 2007, 25(6): 967-980.

[7] KIM H K, KIM J D. Region-based shape descriptor invariant to rotation, scale and translation[J]. Signal Processing: Image Communication, 2000, 16(1): 87-93.

[8] BOBER M. MPEG-7 visual shape descriptors[J]. IEEE Transactions on Circuits Systems Video Technology, 2001, 11(6): 716-719.

[9] DU Ji-xiang, HUANG De-shuang, WANG Xiao-feng. Shape recognition based on neural networks trained by differential evolution algorithm[J]. Neurocomputing, 2007, 70(4): 896-903.

[10] XUE Z, STAN Z L, EAM K T. Bayesian shape model for facial feature extraction and recognition [J]. Pattern Recognition, 2003, 36(12): 2819-2833.

[11] XIAO Dong-rong, HOU Jian-min. Application research of neural network in fault diagnosis[J]. Journal of Central South University of Technology: Natural Science, 2003, 34(1): 206-208. (in Chinese)

[12] DING De-xin, ZHANG Zhi-jun. Artificial neural network based on inverse design method for circular sliding slopes[J]. Journal of Central South University of Technology, 2004, 11(1): 89-92.

[13] BISHOP C M. Neural networks for pattern recognition[M]. New York: Oxford University Press, 1995: 216-302.

[14] RAQUEL F L. Modelling of insurers’ rating determinants: An application of machine learning techniques and statistical models[J]. European Journal of Operational Research, 2007, 183(3): 1488-1512.

[15] VAPNIK V. Statistical learning theory[M]. New York: John Wiley and Sons, 1998: 98-208.

[16] HSU C W, LIN C J. A comparison of methods for multi-class support vector machines[J]. IEEE Transactions on Neural Networks, 2002, 13(2): 415-425.

Foundation item: Project(60634020) supported by the National Natural Science Foundation of China

Received date: 2007-06-22; Accepted date: 2007-07-30

Corresponding author: ZHANG Hong-liang, Doctoral candidate; Tel: +86-731-2790787; E-mail: net_hotang@163.com

- Flame image recognition of alumina rotary kiln by artificial neural network and support vector machine methods