文章编号:1004-0609(2016)-05-0973-07

ZrTiNiCuBe块体非晶合金剪切带内温升与断裂温升

潘念侨1,杜忠华1,朱正旺2,雷晓云1,徐立志1

(1. 南京理工大学 机械工程学院,南京 210094;

2. 中国科学院 金属研究所,沈阳 110016)

摘 要:

在室温环境下(25 ℃)对某ZrTiNiCuBe块体非晶合金材料进行不同应变率条件下的静态与动态压缩实验。并采用扫描电镜技术(SEM)对试样断口、侧面等进行表征,对比静、动态条件下的应力-应变曲线形貌的差异。结果表明:静态压缩时为剪切断裂,微观形貌上出现脉状花样与剪切带;剪切带诱发裂纹的形成,裂纹随着剪切带扩展。动态压缩时为脆性解理断裂,断面粗糙且发现大量熔滴;断口处出现解理台阶,塑性阶段出现明显的锯齿流变现象。从能量守恒定律出发,利用变形过程中弹性应变能的变化规律推测剪切变形区域内温升的变化规律,温升的变化规律揭示锯齿流变与试样的断裂机制。

关键词:

中图分类号:TB33 文献标志码:A

非晶合金的基体中没有晶界、位错等缺陷,与液态金属有近似的结构,因而使非晶合金存在着一些独特的力学性能,如高强度、高硬度、高断裂韧性以及良好的抗剪切等特性,是目前较具优势的新型工程材料与结构材料之一[1-2]。在室温环境下,块状非晶合金在单轴拉伸或者压缩条件下极易形成高度集中局域化的剪切带,这些剪切带迅速扩展,导致材料灾难性宏观脆性断裂,此类行为阻碍块状非晶合金进一步的应用[3]。关于块状非晶合金的温度、应变率效应对其变形机理的影响,国内外相关领域研究人员做过大量的实验分析[4-6]。特别是在高应变率与低温(室温)环境下,非晶合金展现出非均匀变形和锯齿流变现象[7],这些现象主要通过剪切带表现出来的,局域剪切带影响非晶合金的的宏观塑性变形与断裂失效。对比晶体,非晶合金通过剪切软化和剪切带的快速扩展、传播使非晶合金处于预失效状态,局域化剪切带内的结构特征会发生多种变化,如产生纳米晶[8]、纳米孔洞[9]以及自由体积[10]等,WANG等[11-12]认为剪切带造成的这些变化与剪切带内的温升密切相关。同时发现锯齿流变机制也与剪切带内温升紧密相联[13]。在非晶温度效应研究方面,利用扫描电镜(SEM)方法在非晶断口处观测[4, 11, 14],发现脉状花样与大量不同尺寸、形状的熔滴,说明局部发生软化,温度超过了非晶熔点,局部软化发生机理可以用自由体积模型解释,而熔滴的形成必与剪切带内温升有关且不能用自由体积模型解释。上述结果表明,绝热剪切温升在非晶的变形过程中占据着非常重要的因素。在有关剪切带温升的文献中[13, 15-16],所计算的温升均处于静态压缩环境下,且计算的结果仅有几K而已,没有达到非晶的熔点,无法解释SEM像中熔滴形成的原因。

本文作者通过室温环境下的静态与动态压缩实验,从压缩过程中产生的弹性应变能角度出发,建立剪切带形成过程中局域温升模型,模型能够很好地解释块状ZrTiNiCuBe非晶合金塑性变形阶段锯齿形流变现象及块状ZrTiNiCuBe非晶合金扫描电镜(SEM)图中熔滴形成原因以及动态实验过程中观测到“火花”的形成原因。

1 实验

将纯度(质量分数)大于99.5%的Zr、Ti、Ni、Cu、Be 5种高纯度金属按照合金材料比例成分进行配比,采用钨级电弧炉熔炼,为使非晶合金成分均匀,合金反复熔炼3次以上。利用铜模铸造成型,为避免表面杂质干扰,采用超声波在乙醇中清洗。利用铜模铸造法制备锆基非晶合金材料试样,相关详细工艺见文献[17]。为获得准确的静态压缩实验结果,避免实验结果受到惯性、摩擦、二维效应的影响,采用线切割将材料制备成d 4 mm×8 mm的压缩试样,室温下静态压缩采用CSS-44300电子万能材料实验机进行,应变率分别为10-3 s-1和10-2 s-1。室温下动态压缩实验采用14.5 mm分离式Hopkinson压杆(SHPB)加载[18],试样尺寸为d 8 mm×5mm,子弹发射压强为0.3~1 MPa,应变率为400~2000 s-1;试样两端添加两个高强度钢垫片来防止压杆端面屈服,采用不同形状、尺寸的黄铜片作为整形器来消除动态加载过程中的高频分量和获得常应变率加载,压杆端面处采用润滑脂减小摩擦。为减小偶然因素以保证实验数据的准确性,每个应变率的静态或者动态下的压缩实验均进行3次。将回收的压缩试样表面加水细磨、抛光后,加入腐蚀试剂中浸泡,50 ℃恒温静置24 h后,用Hitachi SU9000型扫描电子显微镜(SEM)对试样侧面和断口形貌以及裂纹传播与扩展、断裂特征进行扫描观察与分析。

2 结果与分析

2.1 块状ZrTiNiCuBe非晶合金室温静态压缩力学 性能

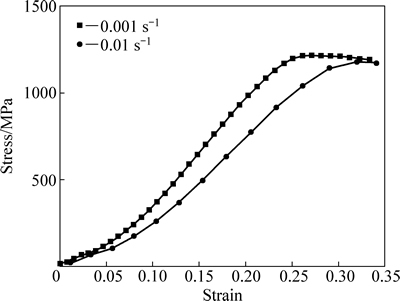

图1所示为ZrTiNiCuBe块体非晶合金室温环境下的静态压缩应力-应变曲线。从图1中可以看出,首先出现近似的线性弹性变形,试样可产生0.25~0.3的弹性应变,随后试样出现明显屈服,塑性应变约为0.05~0.1,最后试样断裂。随着应变率的提高,试样的屈服强度和断裂强度基本保持不变,弹性模量降低,塑性应变下降,且室温静态压缩过程中存在应变软化现象。

图1 ZrTiNiCuBe块体非晶合金室温静态压缩应力-应变曲线

Fig. 1 Quasi-static compression stress-strain curves of ZrTiNiCuBe bulk amorphous alloy at room temperature

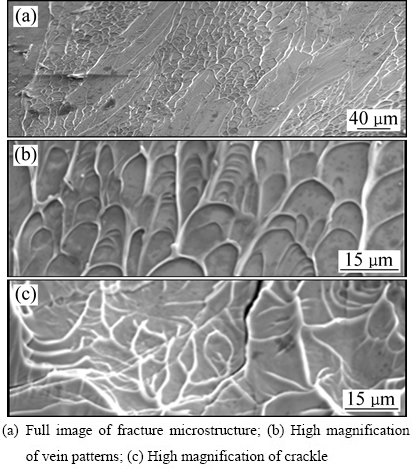

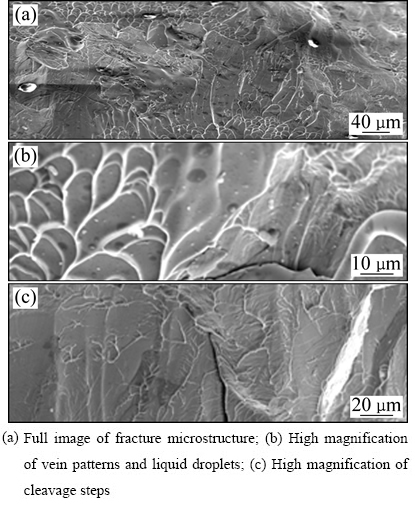

图2所示为ZrTiNiCuBe块体非晶合金室温静态断裂微观形貌图,断裂面沿剪切带传播方向可分为3个区域[19]:Ⅰ) 断裂滑动区;Ⅱ) 断裂传播区域; Ⅲ) 失稳断裂区。图2(b)所示为图2(a)中局部放大图,展现出微米尺度的脉状花样形貌,属于典型剪切破坏模式。一般认为,非晶合金中保存的自由体积作为一种结构缺陷来影响其力学性能,且脉状花样的形成与自由体积数量、浓度等密切相关。图2(c)中可以看到裂纹和剪切带,裂纹扩展的同时伴随着剪切带的扩展,且剪切带末梢有很小的分叉,这些属于二次剪切带,剪切带的滑移分支与相互交叉可以有效防止非晶沿单一剪切带发生快速断裂,从而提高材料塑性。剪切带的诱发形成、传播扩展与变形局部区域自由体积的凝结程度密切相关,变形过程中自由体积的浓度大小是由不断加载的剪切应力造成自由体积的凝聚与原子重排、结构弛豫造成自由体积湮灭竞争结果控制的[14, 20]。剪应力作用下促使局部区域产生应力集中,使该区域的自由体积数量、浓度上升,导致局部黏度下降,进而造成剪切带的形成、扩展,当剪切带传播到一定程度时,诱发裂纹产生,最终造成材料发生软化失效。

图2 ZrTiNiCuBe块体非晶合金室温静态断裂的微观形貌

Fig. 2 Quasi-static compression fracture microstructure of ZrTiNiCuBe bulk amorphous alloy at room temperature

2.2 块状ZrTiNiCuBe非晶合金室温动态压缩力学 性能

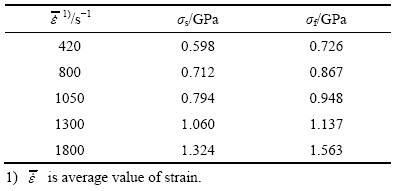

表1所列为ZrTiNiCuBe块体非晶合金室温环境下动态压缩实验应变率数据。图3所示为ZrTiNiCuBe块体非晶合金室温动态压缩应力-应变曲线。通过对比ZrTiNiCuBe块体非晶合金室温静态与动态不同应变率下的压缩应力-应变曲线可知,ZrTiNiCuBe块体非晶合金静态下的塑性和屈服强度明显高于动态下的塑性和屈服强度;且随着应变率的提高,塑性、屈服强度和断裂强度均上升;弹性模量(弹性阶段切线的斜率)基本保持不变,不具有应变率效应。ZrTiNiCuBe块体非晶合金首先发生弹性变形,试样到达屈服点后出现明显屈服,屈服应变约为0.02~0.04;到达断裂强度时产生断裂,试样的整个室温动态压缩过程存在应变硬化和应变率硬化效应。实验过程中发现有明显“火花”出现,同时在SHPB实验结束后,压杆端部发现少量残余熔化的小碎块。

表1 ZrTiNiCuBe块体非晶合金室温动态压缩实验应变率数据

Table 1 Dynamic compression test strain rate date of ZrTiNiCuBe bulk amorphous alloy at room temperature

图3 ZrTiNiCuBe块体非晶合金室温动态压缩应力-应变曲线

Fig. 3 Dynamic compression stress-strain curves of ZrTiNiCuBe bulk amorphous alloy at room temperature

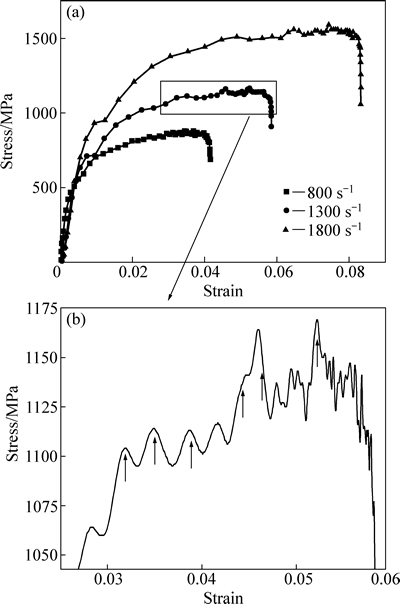

图4所示为ZrTiNiCuBe块体非晶合金室温动态断裂微观形貌图。对比图4(a)与图2(a)可知,断面相对粗糙,脉状花样不如静态压缩断面光滑,说明材料的塑性降低、脆性变大。图4(b)中出现形状不规则的熔滴,熔滴被认为是剪切带内温升急剧上升接近玻璃转变温度Tg造成的结果[6]。图4(c)所示为ZrTiNiCuBe块体非晶合金室温动态断裂微观形貌有十分典型的解理台阶,这是静态环境下没有发现的微观特征;解理台阶旁的河流花样十分明显,河流花样源头与台阶相连,台阶相对粗糙,高度较窄。解理台阶的出现说明断裂模式由静态条件下的纯剪切断裂变为动态条件下的脆性解理断裂。

2.3 块状ZrTiNiCuBe非晶合金剪切带内温升模型

解理台阶的出现说明动态压缩过程中产生的热量被消耗掉,热量的去处是值得考虑的。众所周知,传统典型金属材料的弹性应变很小不超过0.01,而塑性很大,塑性变形是均匀的。然而,非晶合金具有较大的弹性应变与较高的屈服强度,导致材料在断裂失效前存储较高的弹性应变能。材料在断裂瞬间,将积累的弹性应变能释放,会观察到强光[21],断面出现熔滴和脉状花样,可以推测弹性应变能是影响非晶合金材料塑性变形与断裂的一个重要因素[20]。在动态压缩实验过程中,试样加载时间很短, 认为整个过程是绝热的,产生的温升极有可能超过玻璃转变温度甚至熔点;然而剪切带内温升的直接测量很困难,这里从能量守恒定律出发,利用变形过程中弹性应变能的变化规律推测剪切变形区内温升的变化规律。

图4 ZrTiNiCuBe块体非晶合金室温动态断裂微观形貌图

Fig. 4 Dynamic compression fracture microstructures of ZrTiNiCuBe bulk amorphous alloy at room temperature

从图3(b)中可明显发现锯齿形流变现象,且存在锯齿流变幅度随应变的增大而逐渐增大的趋势,最后,曲线经过断裂强度后急剧下降。参考文献[11-12, 22],一般认为高应变率下的锯齿流变现象与剪切带内绝热温升和多重剪切带共同作用有关;锯齿行为反映出材料变形过程中的能量耗散机制,锯齿数量越多、幅度越大表明材料的能量耗散越快,变形过程中形成的热量越不易集中,材料越不易断裂;同时,锯齿流变现象中,应力的上升代表材料弹性再加载过程,而应力的下降则代表剪切变形区内剪切带的迅速扩展、软化过程;锯齿流变现象反映了剪切带的间歇性运动行为,说明块状非晶材料的塑性流变、软化与非均匀性流变密切相关。

试样在应力加载过程中首先发生弹性变形,随后有少许塑性变形,最后发生断裂,如图3所示。试样在弹性加载过程中不断积累弹性应变能,则试样断裂前积累的弹性应变能(Ee)为

(1)

(1)

式中:σ为断裂前强度;ε为断裂前弹性应变;A为试样截面积;L为试样长度。

塑性变形是通过高度集中的局域剪切带作为载体来完成的,绝大大部分弹性应变能以热量形式释放在剪切带区域,由于应力加载时间短,造成该局部区域产生很高的绝热温升。这部分由剪切带内温度急剧上升带来的热量为[21]:

(2)

(2)

式中:cp为材料的等压比热容。

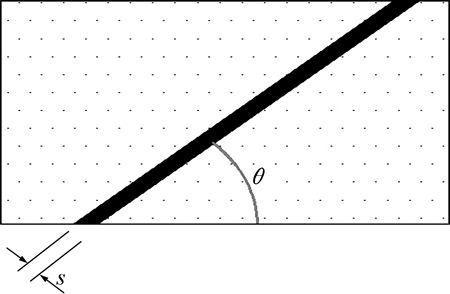

Zr41.25Ti13.75Ni10Cu12.5Be22.5的等压比热容[23-24]为55 J/(K·mol),这里结合材料自身配比近似取为60 J/(K·mol);ΔT为温升;As为剪切带在试样横截面的投影面积;θ断裂角;s为剪切带厚度,其剪切带的示意图如图5所示。

图5 ZrTiNiCuBe块体非晶合金剪切带示意图

Fig. 5 Schematic diagram of observed shear band for ZrTiNiCuBe bulk amorphous alloy specimen

假设α为弹性应变能转化为剪切带内温升带来热量的转化系数[25],有以下关系:

(3)

(3)

式中:α取0.9。

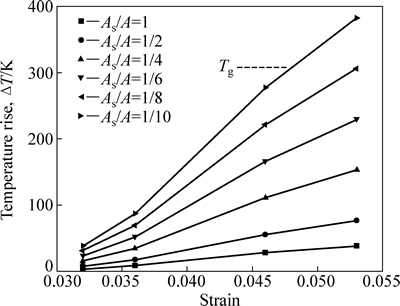

联立(1)~(3)式即可计算出剪切带内的温升ΔT0分析可知剪切带在试样横截面的投影面积As对温升的影响极大,相同的弹性应变能产生同等的热量,热量散布在较小的剪切区域内造成绝热温升很高,使得试样内产生大量熔滴和观察到火花;而热量散布在较大的剪切区域内造成绝热温升很低,不会超过非晶材料的玻璃转变温度,此时温升的影响较小,材料发生结构弛豫现象,也就不能说明熔滴形成原因。结合实验观察到的剪切带在试样横截面的投影面积,以As/A范围在0.1~1为参变量来分析剪切变形过程中的温升。在图5中,选取各应变区间应力下降幅较大的点,计算出相应的压力下降幅值和相应的弹性应变,剪切带厚度s取2 μm,代入相应参数,非晶材料的玻璃转变温度Tg=600 K,熔点Tm=1100 K,理论计算结果如图6所示。

图6剪切带内绝热温升ΔT与As/A、应变ε关系曲线

Fig. 6 Relationship curves of adiabatic temperature in shear band and strain as well as As/A

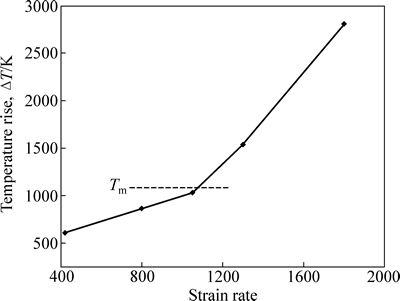

图7 试样断裂绝热温升ΔT与应变率 的关系

的关系

Fig. 7 Relationship between adiabatic temperature in fracture specimen and strain rate

当试样最终断裂失效时,剪切带贯穿整个试样的横截面,这时As=A、σ=σf、ε=σf/E(E为弹性模量),这里考虑应变率效应,代入式中计算,其结果如图7所示。从计算结果可以得到,随着应变的增大,局部温升变化呈非线性增大趋势,说明随着弹性应变能的不断积累,试样内部的温升也不断变大;当剪切带在试样横截面的投影面积越小时,说明弹性应变能聚集在很小的变形区域,造成该局部区域温升的增大,特别是当As/A≤1/8时,接近断裂时试样内最后一个锯齿流动内,其剪切带内的绝热温升超过材料的玻璃转变温度Tg,将使剪切变形区局部黏度急剧下降,随着温升的继续增大,非晶态会逐渐转化为过冷液体,从而使其软化直至失效断裂。从这里可以看出,剪切带内绝热温升是剪切带黏度降低和试样断裂的最直接原因。理论分析得到的结果与实验观察到的结果一致。

同时,试样断裂时的绝热温升与应变率紧密相关,随着应变率的上升,温升呈非线性增大。当应变率超过1050 s-1时,材料的断裂局部温升超过非晶材料的熔点Tm,因此,在试样断裂瞬间会有大量的热通过实验中观察到的“火花”的形式释放出,在断裂面上会观察到液滴的形成,再者,瞬间大量的热量使粘性流层的厚度上升,造成其位置和数量变化,最后造成试样断裂面的粗糙不平,这也解释了图2(a)和图4(a)形貌不同的原因。

3 结论

1) 块体ZrTiNiCuBe非晶合金室温静态压缩时,随着应变率的上升屈服强度、断裂强度无明显变化,压缩过程中存在应变软化效应。然而,在室温动态压缩时,压缩过程中存在应变硬化、应变率硬化效应;屈服强度、塑性均小于静态情形下。

2) 块体ZrTiNiCuBe非晶合金室温静态压缩为剪切断裂,微观形貌上出现脉状花样与剪切带;剪切带诱发裂纹的形成,裂纹的扩展伴随着剪切带的传播。块体ZrTiNiCuBe非晶合金在室温动态压缩条件下,断面相对粗糙,微观形貌上存在熔滴和解理台阶,断裂模式变为脆性解理断裂。

3) 结合锯齿流变对剪切带的形成、扩展、断裂的影响,从弹性应变能的角度出发建立块状ZrTiNiCuBe非晶合金剪切带内温升模型,计算出锯齿流变过程中剪切带形成时局部变形区域的温升。

4) 随着锯齿幅度的增大,弹性应变能的不断存储,温升逐渐升高;特别是当As/A≤1/8时,接近断裂时试样内最后一个锯齿流动内,其剪切带内的绝热温升超过材料的玻璃转变温度 ,将使剪切变形区局部黏度急剧下降,使剪切带扩展到整个试样并最终断裂。

5) 随着应变率的上升,试样断裂时的绝热温升呈非线性上升趋势,应变率超过1050 s-1时,材料的断裂局部温升超过非晶材料的熔点 ,实验中观测到“火花”,从局部温升变化规律阐述块状ZrTiNiCuBe非晶合金锯齿流变和断裂机制。

REFERENCES

[1] 汪卫华. 非晶态物质的本质与特性[J]. 物理学进展, 2013, 33(5): 176-352.

WANG Wei-hua. The nature and properties of amorphous matter[J]. Progress in Physics, 2013, 33(5): 176-352.

[2] 黄劲松, 刘 咏, 陈仕奇, 刘祖铭, 黄伯云. 锆基非晶合金的研究进展与应用[J]. 中国有色金属学报, 2003, 13(6): 1321-1331.

HUANG Jin-song, LIU Yong, CHEN Shi-qi, LIU Zu-ming, HUANG Bai-yun. Progress and application of Zr-based amorphous alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1321-1331.

[3] WU H, LIU Y, LI K Y, ZHANG Z W. Casting effect on compressive brittleness of bulk metallic glass[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 385-392.

[4] 杨元政, 董振江, 仇在宏, 陈小祝, 谢致薇, 白晓军. 块状非晶合金Cu58Zr20Ti20Mo2的形成与力学性能[J]. 中国有色金属学报, 2007, 17(7): 1090-1095.

YANG Yuan-zheng, DONG Zhen-jiang,QIU Zai-hong,CHEN Xiao-zhu, XIE Zhi-wei, BAI Xiao-jun. Formation and mechanical properties of Cu58Zr20Ti20Mo2 bulk metallic glass[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1090-1095.

[5] MA Guang-cai, ZHU Zheng-wang, WANG Zheng, ZHANG Hai-feng. Deformation behavior of the Zr53.5Cu26.5Ni5- Al12Ag3 bulk metallic glass over a wide range of strain rate and temperatures[J]. Journal of Materials Science & Technology, 2015, 31: 941-945.

[6] SUN B A, WANG W H. The fracture of bulk metallic glasses[J]. Progress in Materials Science, 2015, 74: 211-307.

[7] HU J, SUN B A, YANG Y, LIU C T, PAULY S, WENG Y X, ECKERT J. Intrinsic versus extrinsic effects on serrated flow of bulk metallic glasses[J]. Intermetallics, 2015, 66: 31-39.

[8] JIANG W H, PINKERTON F E, ATZMON M. Effect of strain rate on the formation of nanocrystallites in an Al-based amorphous alloy during nanoindentation[J]. Journal of Applied Physics, 2003, 93: 9287-9290.

[9] JIANG W H, ATZMON M. Mechanically-assisted nanocrystallization and defects in amorphous alloys: A high-resolution transmission electron microscopy study[J]. Scripta Materialia, 2006, 54(3): 333-336.

[10] HAJLAOUI K, BENAMEUR T, VAUGHAN G, YAVARI A R. Thermal expansion and indentation-induced free volume in Zr-based metallic glasses measured by real-time diffraction using synchrotron radiation[J]. Scripta Materialia, 2004, 51(9): 843-848.

[11] WANG S, YE Y F, SUN B A, LIU C T, SHI S Q, YANG Y. Softening-induced plastic flow instability and indentation size effect in metallic glass[J]. Journal of the Mechanics and Physics of Solids, 2015, 77: 70-85.

[12] SUN B A, WANG W H. The fracture of bulk metallic glasses[J]. Progress in Materials Science, 2015, 74: 211-307.

[13] 丰 平, 张庆明, 陈 利, 姚 伟. 块体非晶合金剪切带温度的变化分析[J]. 材料科学与工程学报, 2010, 28(1): 36-39.

FENG Ping, ZHANG Qing-ming, CHENG Li, YAO Wei. Temperature change in the shear band of a bulk metallic glass during serrated flow[J]. Journal of Materials Science & Engineering, 2010, 28(1): 36-39.

[14] LIU L F, DAI L H, BAI Y L, WEI B C. Initiation and propagation of shear bands in Zr-based bulk metallic glass under quasi-static and dynamic shear loadings[J]. Journal of Non-Crystalline Solids, 2005, 351: 3259-3270.

[15] JIANG W H, LIAO H H, LIU F X, CHOO H, LIAW P K. Rate-dependent temperature increases in shear bands of a bulk-metallic glass[J]. Metallurgical and Materials Transactions A, 2008, 39: 1822-1830.

[16] LEWANDOWSKI J J, GREER A L. Temperature rise at shear bands in metallic glasses[J]. Nature Materials, 2006, 5: 15-18.

[17] ZHAO S F, CHEN N, GONG P, YAO K F. New centimeter-sized quaternary Ti-Zr-Be-Cu bulk metallic glasses with large glass forming ability[J]. Journal of Alloys and Compounds, 2015, 647: 533-538.

[18] XUE Yun-fei, CAI Hong-nian, WANG Lu, ZHANG Hai-feng, CHENG Huan-wu. Testing of high strength Zr-based bulk metallic glass with the split Hopkinson pressure bar[J]. Journal of Beijing Institute of Technology, 2008,17: 109-114.

[19] MUKAI T, NIEH T G, KAWAMURA Y, INOUE A, HIGASHI K. Effect of strain rate on compressive behavior of a Pd40Ni40P20 bulk metallic glass[J]. Intermetallics, 2002, 10: 1071-1077.

[20] WU F F, ZHENG W, WU S D, ZHANG Z F, SHEN J. Shear stability of metallic glasses[J]. International Journal of Plasticity, 2011, 27(4): 560-575.

[21] LIU C T, HEATHERLY L, EASTON D S. Test environments and mechanical properties of Zr-base bulk amorphous alloys[J]. Metallurgical and Materials Transactions A, 1998, 29(7): 1811-1820.

[22] WANG G, PAULY S, GORANTLA S, MATTERN N, ECKERT J. Plastic flow of a Cu50Zr45Ti5 bulk metallic glass composite[J]. Journal of Materials Science & Technology, 2014, 30(6): 609-615.

[23] BRUCK H A, CHRISTMAN T, ROSAKIS A J, JOHNSON W L. Quasi-static constitutive behavior of Zr41.25Ti13.75Ni10Cu12.5Be22.5 bulk amorphous alloys[J]. Scripta Metallurgica et Materialia, 1994, 30(4): 429-434.

[24] BRUCK H A, ROSAKIS A J, JOHNSON W L. The dynamic compressive behavior of beryllium bearing bulk metallic glasses[J]. Journal of Materials Research, 1996, 11: 503-511.

[25] 陈德民, 孙剑飞, 沈 军. 块体非晶合金绝热升温与锯齿流变机制[J]. 金属学报, 2005, 41(2): 196-198.

CHEN De-min, SUN Jian-fei, SHEN Jun. Localized heating and serrated plastic flow mechanism in bulk amorphous alloys[J]. Acta Metallurgica Sinica, 2005, 41(2): 196-198.

Temperature rise in shear bands and fracture temperature rise of ZrTiNiCuBe bulk amorphous alloy

PAN Nian-qiao1, DU Zhong-hua1, ZHU Zheng-wang2, LEI Xiao-yun1, XU Li-zhi1

(1. College of Mechanical Engineering, Nanjing University of Technology and Engineering, Nanjing 210094, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The quasi-static and dynamic compression mechanical properties of the ZrTiNiCuBe bulk amorphous alloy were investigated under different strain rates at room temperature. The fracture and side face were characterized by the SEM technology. The results show that shear fracture happens when the alloy is quasi-static compressed, the microstructures observed are vein pattern and shear bands. The cracks are generated and propagated along the shear bands. The brittle cleavage fracture happens when the alloy is dynamic compressed, and the rough fracture surfaces containing large amount of liquid droplets are observed. The fracture exhibits the cleavage steps, and the obvious serrated flow phenomenon appears in the plastic deformation stage. In the point of energy conservation law, the temperature rise in shear bands is deduced based on the variation of elastic strain energy. The serrated flow and fracture mechanism of the ZrTiNiCuBe bulk amorphous alloy was revealed.

Key words: bulk amorphous alloy; serrated flow; adiabatic temperature rise; elastic strain energy

Foundation item: Project (11372142) supported by the National Natural Science Foundation of China; Project (KFJJ12-9M) supported by State Key Laboratory of Explosion Science and Technology (Beijing Institute of Technology), China

Received date: 2015-07-09; Accepted date: 2015-11-05

Corresponding author: DU Zhong-hua; Tel: +86-25-84304059; E-mail: duzhonghua@aliyun.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(11372142);北京理工大学爆炸科学与技术国家重点实验室项目(KFJJ12-9M)

收稿日期:2015-07-09;修订日期:2015-11-05

通信作者:杜忠华,教授,博士;电话:025-84304059;E-mail:duzhonghua@aliyun.com

摘 要:在室温环境下(25 ℃)对某ZrTiNiCuBe块体非晶合金材料进行不同应变率条件下的静态与动态压缩实验。并采用扫描电镜技术(SEM)对试样断口、侧面等进行表征,对比静、动态条件下的应力-应变曲线形貌的差异。结果表明:静态压缩时为剪切断裂,微观形貌上出现脉状花样与剪切带;剪切带诱发裂纹的形成,裂纹随着剪切带扩展。动态压缩时为脆性解理断裂,断面粗糙且发现大量熔滴;断口处出现解理台阶,塑性阶段出现明显的锯齿流变现象。从能量守恒定律出发,利用变形过程中弹性应变能的变化规律推测剪切变形区域内温升的变化规律,温升的变化规律揭示锯齿流变与试样的断裂机制。