文章编号:1004-0609(2011)08-1814-06

温热弯曲成形过程中AZ31镁合金型材的微观织构演变

肖 寒1, 2,宋广胜1,严 操1,张士宏1, 2,阮立群3,张兴国2

(1. 中国科学院 金属研究所,沈阳 110016;

2. 大连理工大学 材料科学与工程学院,大连 116085;

3. Department of Mechanical Engineering and Science, Kumamoto University, Kumamoto 8608555, Japan)

摘要:采用光学显微镜、X射线衍射仪和EBSD分析研究AZ31镁合金型材温热弯曲成形前后横截面外侧微观组织和织构的演变规律。结果表明:弯曲成形前,型材为![]() 平行于挤压方向的线织构;弯曲成形后,型材线织构被削弱。弯曲过程中拉伸孪晶数量减少,由弯曲前的5.39%降低至弯曲后的2.22%;压缩孪晶增多,由弯曲前的0.141%增加至弯曲后的0.222%。挤压型材的大量拉伸孪晶使得应力集中,协同温度的影响,非基面滑移开动并协调了晶粒c轴的应变,因而提高型材的塑性变形能力。

平行于挤压方向的线织构;弯曲成形后,型材线织构被削弱。弯曲过程中拉伸孪晶数量减少,由弯曲前的5.39%降低至弯曲后的2.22%;压缩孪晶增多,由弯曲前的0.141%增加至弯曲后的0.222%。挤压型材的大量拉伸孪晶使得应力集中,协同温度的影响,非基面滑移开动并协调了晶粒c轴的应变,因而提高型材的塑性变形能力。

关键词:

中图分类号:TG146.2 文献标志码:A

Microtexture evolution of AZ31 magnesium alloy profile during warm bending process

XIAO Han1, 2, SONG Guang-sheng1, YAN Cao1, ZHANG Shi-hong1, 2, RUAN Li-qun3, ZHANG Xing-guo2

(1. Institute of Metals Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116085, China;

3. Department of Mechanical Engineering and Science, Kumamoto University, Kumamoto 8608555, Japan)

Abstract: The microstructure and microtexture evolution at the outside of the cross-section of AZ31 magnesium alloy profile before and after warm bending were investigated by using optical microscope, X-rays diffractometer and electron back scattering diffraction (EBSD) analysis system. The results indicate that the microtexture of the profile before bending is line texture with ![]() parallel to the extrusion direction. The intensity of line texture of the profile after bending is reduced. During the warm bending process, the amount on the extension twins decrease from 5.39% to 2.22%. Whereas, the amount of the compression twins increases from 0.141% to 0.222%. Under condition of the stress concentration caused by lots of extension twins and the effect of temperature, the non-basal slip systems are activated which coordinate the deformation of the c-axis. As a result, the plastic property of profile is improved.

parallel to the extrusion direction. The intensity of line texture of the profile after bending is reduced. During the warm bending process, the amount on the extension twins decrease from 5.39% to 2.22%. Whereas, the amount of the compression twins increases from 0.141% to 0.222%. Under condition of the stress concentration caused by lots of extension twins and the effect of temperature, the non-basal slip systems are activated which coordinate the deformation of the c-axis. As a result, the plastic property of profile is improved.

Key words: AZ31 magnesium alloy; warm bending; microtexture

型材零部件具有结构轻量化和强度高的特点,广泛应用于航空、航天和轨道交通等行业骨架零件的制造,如飞机框肋缘条、机翼以及进气道的隔框加强缘条、机身前后段和发动机短舱的长桁;高速列车、地铁列车、载重列车和汽车用的大型宽幅薄壁复杂型材;车身结构和保险杠的中空型材等。镁合金具有密度低、比强度和比刚度高、资源丰富等优点,因此,镁合金型材的应用具有更加广阔的前景,开展镁合金型材弯曲成形技术的研究将具有重要的工程意义[1-2]。但是 由于镁为密排六方晶体结构,滑移系比较少,室温下塑性变形能力差。镁合金轧制板材和挤压型材都具有强烈的织构倾向和各向异性,这限制和约束了镁合金的塑性,降低了其冲压成形性能和弯曲成形性能[3-4]。

目前,镁合金织构的研究是一个热点,国内外学者研究了轧制态镁合金在单向拉伸和压缩[5-6]、轧 制[7-9]、ECAP[10-12]、挤压[13-14]等工艺过程中微观织构的演变规律,进而探讨镁合金的塑性变形机理;而关于镁合金型材弯曲成形过程中微观织构的演变还鲜见报道。本文作者在前期开展的AZ31镁合金型材温热弯曲成形工作的基础上[15-16],借助于光学显微镜、X射线衍射仪和EBSD分析系统,分析弯曲成形前后型材横截面外侧的微观组织、衍射峰强度和织构演变,分析AZ31镁合金型材的温热弯曲塑性变形机制。

1 实验

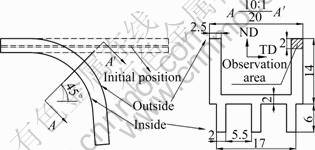

实验材料为挤压态AZ31镁合金,挤压工艺条件如下:坯料温度400 ℃,模具温度360 ℃,挤压速度600 mm/min,型材化学成分如表1所列。温热弯曲过程如下:首先将模具预热60 ℃,型材加热至200 ℃并保温5 min,然后将型材弯曲103°,型材的弯曲半径90 mm,弯曲角速度0.3 rad/s。取弯曲成形前型材横截面外侧和弯曲成形之后变形区45°横截面外侧的试样,分别采用光学显微镜进行金相观察,采用X射线衍射仪进行衍射峰强度分析,采用JSM-7001F型场发射扫描电镜进行EBSD实验。型材的横截面形状与尺寸及取样位置如图1所示,观测区域为型材的法向ND和横向TD组成的平面,挤压方向ED垂直于观测平面。

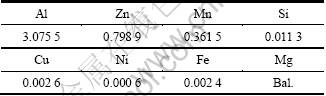

表1 AZ31镁合金型材的化学成分

Table 1 Chemical composition of extruded AZ31 magnesium alloy (mass fraction, %)

图1 型材横截面形状和取样位置

Fig.1 Cross-section of profile(a) and specimen location(b) (mm)

2 结果与分析

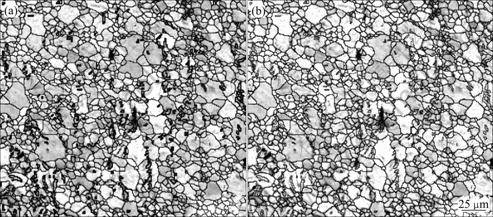

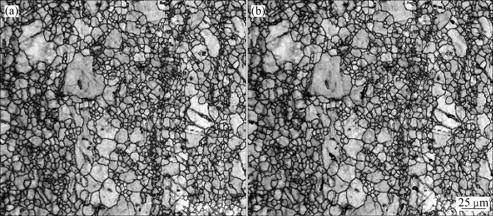

AZ31镁合金型材弯曲成形前后横截面外侧的微观组织如图2所示。图2(a)所示为挤压型材横截面外侧组织,可以看出,晶粒均匀,存在大量孪晶。图2(b)所示为200 ℃弯曲成形之后横截面外侧组织。由图 2(b)可知,200 ℃弯曲成形之后横截面外侧组织中孪晶数量减少,且出现大量细小晶粒。

图2 AZ31镁合金型材横截面外侧后微观组织

Fig.2 Microstructures of zones at outside cross-section of AZ31 magnesium alloy profile: (a) Before bending; (b) After bending

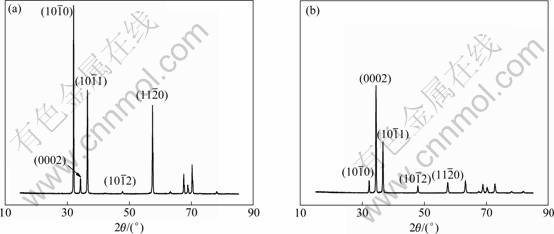

AZ31镁合金型材弯曲成形前后横截面外侧的XRD谱如图3所示。由图3(a)可知,弯曲成形前,型材横截面外侧中![]() 晶面的衍射峰强度最高,其次为

晶面的衍射峰强度最高,其次为![]() 晶面的,(0002)晶面的衍射峰强度最弱。弯曲成形后,型材横截面外侧各晶面衍射峰强度变化很大,

晶面的,(0002)晶面的衍射峰强度最弱。弯曲成形后,型材横截面外侧各晶面衍射峰强度变化很大,![]() 晶面衍射峰强度最弱,变化幅度最大;

晶面衍射峰强度最弱,变化幅度最大;![]() 晶面衍射峰强度降低;(0002)晶面衍射峰强度最高,变化幅度很大,如图3(b)所示。晶面衍射峰强度的变化,主要是由于型材弯曲成形过程中横截面外侧受到挤压方向ED拉应力和横向ND压应力的作用,使晶粒扭转,引起织构发生变化,导致各晶面衍射峰强度的变化。

晶面衍射峰强度降低;(0002)晶面衍射峰强度最高,变化幅度很大,如图3(b)所示。晶面衍射峰强度的变化,主要是由于型材弯曲成形过程中横截面外侧受到挤压方向ED拉应力和横向ND压应力的作用,使晶粒扭转,引起织构发生变化,导致各晶面衍射峰强度的变化。

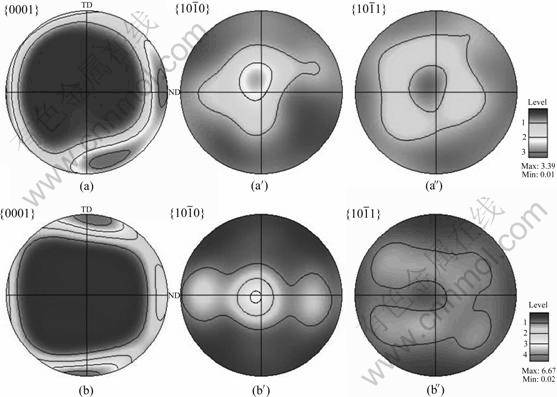

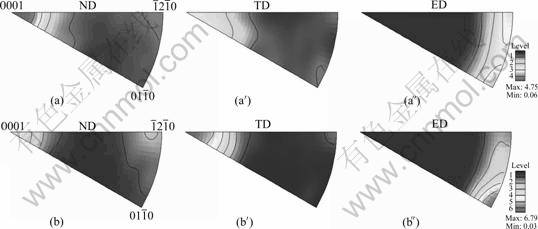

弯曲成形前后AZ31镁合金型材横截面外侧的极图如图4所示。由图4可知,弯曲成形前是典型的![]() 平行于挤压方向的线织构。由{0001}面的极图可知,大部分晶粒的c轴平行于法向ND和横向TD,与挤压方向ED趋近于垂直,如图4(a)所示。弯曲成形之后,大部分晶粒的c轴平行于横向TD,且TD方向织构强度增加,如图4(b)所示。由

平行于挤压方向的线织构。由{0001}面的极图可知,大部分晶粒的c轴平行于法向ND和横向TD,与挤压方向ED趋近于垂直,如图4(a)所示。弯曲成形之后,大部分晶粒的c轴平行于横向TD,且TD方向织构强度增加,如图4(b)所示。由![]() 面的极图可知,弯曲成形之前,大部分晶粒的c轴垂直于挤压方向ED,且强度很高,如图4(a′)所示;弯曲成形之后,向法向ND偏转,如图4(b′)所示。

面的极图可知,弯曲成形之前,大部分晶粒的c轴垂直于挤压方向ED,且强度很高,如图4(a′)所示;弯曲成形之后,向法向ND偏转,如图4(b′)所示。

图3 AZ31型材横截面外侧的XRD谱

Fig.3 XRD patterns of zones at outside of cross-section of AZ31 profile: (a) Before bending; (b) After bending

图4 AZ31型材横截面外侧极图

Fig.4 Pole figures of zone at outside of cross-section of AZ31 profile: (a) {0001} pole figure before bending; (a′) ![]() pole figure before bending; (a″)

pole figure before bending; (a″) ![]() pole figure before bending; (b) {0001} pole figure after bending; (b′)

pole figure before bending; (b) {0001} pole figure after bending; (b′) ![]() pole figure after bending; (b″)

pole figure after bending; (b″) ![]() pole figure after bending

pole figure after bending

图5所示为变形前后型材横截面外侧的反极图。弯曲成形前法向ND平行于c轴,如图5(a)所示;横向TD大部分在![]() 至

至![]() 的连线之间,如图 5(a′)所示;挤压方向ED大部分在

的连线之间,如图 5(a′)所示;挤压方向ED大部分在![]() 至

至![]() 的连线之间,如图5(a″)所示。弯曲成形后法向ND大部分在

的连线之间,如图5(a″)所示。弯曲成形后法向ND大部分在![]() 至

至![]() 的连线之间,如图5(b)所示;横向TD平行于c轴,如图5(b′)所示;挤压方向ED平行于

的连线之间,如图5(b)所示;横向TD平行于c轴,如图5(b′)所示;挤压方向ED平行于![]() ,如图5(b″)所示。

,如图5(b″)所示。

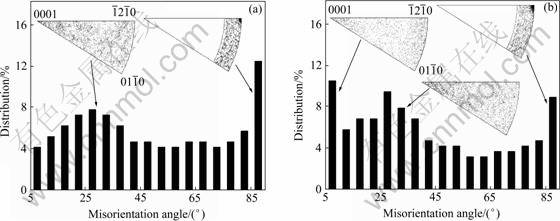

弯曲成形前后型材横截面外侧的取向差角度分布和取向差旋转轴的分布如图6所示。变形前型材为挤压态,其晶界大部分为大角度晶界(取向差角度大于15°),其中取向差角度20°~30°和80°~90°所占比例很高。20°~30°的取向差旋转轴基本呈离散分布;80°~90°的取向差角度分布比例最高,且取向差旋转轴绝大部分集中在![]() 附近,如图6(a)所示。这种取向与拉伸孪晶取向86.3°/

附近,如图6(a)所示。这种取向与拉伸孪晶取向86.3°/![]() (±5°的偏差)相符,说明型材在挤压变形过程中发生明显的拉伸孪生。弯曲成形之后,5°~10°小角度晶界所占比例大幅度提高,由4.2%增加至10.5%,取向差旋转轴呈离散分布,这种取向和拉伸孪生变体间的7.4°/

(±5°的偏差)相符,说明型材在挤压变形过程中发生明显的拉伸孪生。弯曲成形之后,5°~10°小角度晶界所占比例大幅度提高,由4.2%增加至10.5%,取向差旋转轴呈离散分布,这种取向和拉伸孪生变体间的7.4°/![]() (±5°的偏差)取向关系有关。20°~30°取向差角度的比例有一定提高,取向差旋转轴呈离散分布。80°~90°的取向差的分布比例大幅降低,由12.6%降低至8.9%,且取向差旋转轴绝大部分仍然集中在

(±5°的偏差)取向关系有关。20°~30°取向差角度的比例有一定提高,取向差旋转轴呈离散分布。80°~90°的取向差的分布比例大幅降低,由12.6%降低至8.9%,且取向差旋转轴绝大部分仍然集中在![]() 附近,这种取向与拉伸孪晶取向86.3°/

附近,这种取向与拉伸孪晶取向86.3°/![]() (±5°的偏差)相符,说明挤压型材在弯曲变形过程中也发生了明显的拉伸孪晶,但是这种拉伸孪晶是在弯曲卸载时发生的,且孪晶数量逐渐减 少。这是因为型材温热弯曲成形过程中,型材加热到200 ℃后导致非基面滑移系的开动,提高了型材的弯曲成形能力,因此孪晶数量减少。

(±5°的偏差)相符,说明挤压型材在弯曲变形过程中也发生了明显的拉伸孪晶,但是这种拉伸孪晶是在弯曲卸载时发生的,且孪晶数量逐渐减 少。这是因为型材温热弯曲成形过程中,型材加热到200 ℃后导致非基面滑移系的开动,提高了型材的弯曲成形能力,因此孪晶数量减少。

图5 AZ31型材横截面外侧的反极图

Fig.5 Inverse pole figures of zones at outside cross-section of AZ31 profile: (a) Normal direction, before bending; (a′) Transverse direction, before bending; (a″) Extrusion direction, before bending; (b) Normal direction, after bending; (b′) Transverse direction, after bending; (b″) Extrusion direction, after bending

图6 取向差角和旋转轴分布

Fig.6 Distribution of misorientation angle and rotation axis: (a) Before bending; (b) After bending

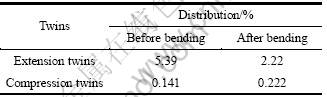

图7和8所示分别为弯曲成形前后AZ31镁合金型材横截面外侧拉伸孪晶和压缩孪晶晶界在菊池带衬度图中的显示。拉伸孪晶和压缩孪晶在晶界的分布比例如表2所列。由图7可知,弯曲成形前,挤压型材横截面外侧区域存在大量拉伸孪晶,几乎没有压缩孪晶,拉伸孪晶比例为5.39%,压缩孪晶比例为0.141%。

由图8可知,弯曲成形后,型材横截面外侧中拉伸孪晶数量减少,由5.39%减少至2.22%;压缩孪晶数量增多,由0.141%增加至0.222%。在弯曲成形过程中,型材横截面外侧所受的最大应力为拉应力且垂直于晶粒c轴,容易产生压缩孪晶,压缩孪晶的含量增多。挤压型材存在大量拉伸孪晶,且拉伸孪晶使得应力集中,达到非基面滑移的临界剪切应力,使非基面滑移启动,协调了晶粒c轴的应变,提高了型材的塑性变形能力。

表2 拉伸孪晶和压缩孪晶在晶界的分布

Table 2 Distribution of extension twins and compression twins at boundary

图7 弯曲成形前型材横截面外侧的孪晶分布

Fig.7 Twins distribution of zones at outside of cross-section of AZ31 profile before bending: (a) Extension twins; (b) Compression twins

图8 弯曲成形后型材横截面外侧的孪晶分布

Fig.8 Twins distribution of zones at outside of cross-section of AZ31 profile after bending: (a) Extension twins; (b) Compression twins

3 结论

1) 弯曲成形前后型材横截面外侧中![]() 晶面和(0002)晶面衍射峰强度的变化是由于横截面外侧切向拉应力和横向压应力的作用,使晶粒扭转,引起织构发生变化,从而导致晶面衍射峰强度的变化。

晶面和(0002)晶面衍射峰强度的变化是由于横截面外侧切向拉应力和横向压应力的作用,使晶粒扭转,引起织构发生变化,从而导致晶面衍射峰强度的变化。

2) 弯曲成形前,型材横截面外侧为![]() 平行于挤压方向的线织构,存在大量拉伸孪晶。

平行于挤压方向的线织构,存在大量拉伸孪晶。

3) 弯曲成形后,型材横截面外侧线织构强度降低,拉伸孪晶数量减少,压缩孪晶数量增加;在弯曲成形过程中,横截面外侧的型材所受的最大应力为拉应力,且垂直晶粒c轴,容易产生压缩孪晶,压缩孪晶含量增多。

REFERENCES

[1] 张士宏, 程 明, 王忠堂, 刘劲松. 有色金属板材若干温热加工成形技术的发展[J]. 锻压技术, 2009, 34(4): 1-9.

ZHANG Shi-hong, CHENG Ming, WANG Zhong-tang, LIU Jin-song. Development of warm forming processes for nonferrous alloy sheets[J]. Forging & Stamping Technology, 2009, 34(4): 1-9.

[2] 张士宏, 许 沂, 王忠堂, 周文龙, 莫立华. 镁合金成形加工技术[J]. 世界科技研究与发展, 2001, 23(6): 18-21.

ZHANG Shi-hong, XU Yi, WANG Zhong-tang, ZHOU Wen-long, MO Li-hua. Processing and forming of magnesium alloys[J]. World Science-Technology Research and Development, 2001, 23(6): 18-21.

[3] CHEN F K, HUANG T B. Formability of stamping magnesium- alloy AZ31 sheets[J]. Journal of Materials Processing Technology, 2003, 142(3): 643-647.

[4] MORDIKE B L, EBERT T. Magnesium: properties applications potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[5] ZHANG S H, LI Z G. Experimental research on grain orientation evolution of extruded Mg alloy AZ31B sheet during uniaxial tensile deformation[J]. Advanced Materials Research, 2008, 32: 87-92.

[6] BARNETT M R, KESHAVARZ Z, BEER A G, ATWELL D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn[J]. Acta Materialia, 2004, 52(17): 5093-5103.

[7] BARNETT M R, NAVE M D, BETTLES C J. Deformation microstructures and textures of some cold rolled Mg alloys[J]. Materials Science and Engineering A, 2004, 386(1/2): 205-211.

[8] SUN Hong-fei, LIANG Shu-jin, WANG Er-de. Mechanical properties and texture evolution during hot rolling of AZ31 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(S2): 349-354.

[9] KIM W J, LEE J B, KIM W Y, JEONG H T, JEONG H G. Microstructure and mechanical properties of Mg-Al-Zn alloy sheets severely deformed by asymmetrical rolling[J]. Scripta Materialia, 2007, 56(4): 309-312.

[10] XIA K, WANG J T, WU X, CHEN G, GURVAN M. Equal channel angular pressing of magnesium alloy AZ31[J]. Materials Science and Engineering A, 2005, 410/411: 324-327.

[11] FENG Xiao-ming, AI Tao-tao. Microstructure evolution and mechanical behavior of AZ31 Mg alloy processed by equal-channel angular pressing[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 293-298.

[12] AGNEW S R, HORTON J A, LILLO T M, BROWN D W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing[J]. Scripta Materialia, 2004, 50(3): 377-381.

[13] WAN G, WU B L, ZHANG Y D, SHA G Y, ESLING C. Anisotropy of dynamic behavior of extruded AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2010, 527(12): 2915-2924.

[14] YU Kun, RUI Shou-tai, WANG Xiao-yan, WANG Ri-chu, LI Wen-xian. Texture evolution of extruded AZ31 magnesium alloy sheets[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 511-516

[15] 王 祺, 刘劲松, 肖 寒, 张士宏. 镁合金型材绕弯成形回弹性能研究[J]. 沈阳理工大学学报, 2009, 28(6): 31-34.

WANG Qi, LIU Jin-song, XIAO Han, ZHANG Shi-hong. Research on springback of magnesium alloy profiles in rotation bending[J]. Transactions of Shenyang Ligong University, 2009, 28(6): 31-34.

[16] 刘劲松, 王 祺, 肖 寒, 张士宏. AZ31镁合金型材温热弯曲实验研究[J]. 材料工程, 2011(3): 20-23.

LIU Jin-song, WANG Qi, XIAO Han, ZHANG Shi-hong. Warm bending experiments of AZ31 magnesium alloy profiles[J]. Journal of Materials Engineering, 2011(3): 20-23.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50775211)

收稿日期:2010-07-16;修订日期:2011-04-29

通信作者:张士宏,研究员,博士;电话:024-83978266;E-mail: shzhang@imr.ac.cn