文章编号:1004-0609(2009)12-2192-06

钎焊立方氮化硼BCu80Ni5SnTi活性钎料的组织与性能

王 毅1, 2,殷世强1,卢广林3,李世权1,邱小明1

(1. 吉林大学 材料科学与工程学院,长春130025;

2. 长春工程学院 机电学院,长春 130012;

3. 吉林大学 地面机械仿生技术教育部重点实验室,长春130025)

摘 要:

研制一种适合钎焊立方氮化硼与45钢异质材料的新型高温BCu80Ni5SnTi活性钎料,采用SEM、EDS及XRD对BCu80Ni5SnTi系活性钎料的微观组织及钎焊接头力学性能进行研究。结果表明:适合钎焊c-BN的活性钎料成分为Cu78~81Ni5~6Sn3~5.5Ti10~12(质量分数,%),固相线温度为858.4 ℃,液相线温度为874.8 ℃;钎料组织由α-Cu固溶体、Ni固溶体、Cu-Sn共晶及少量Cu4Ti3、Cu3Ti2、Cu3Sn、CuSn和Ni17Sn3等化合物组成;该钎料对c-BN的润湿性较好,润湿角为28?~30?,钎焊c-BN与45钢的接头强度为210~230 MPa;新型钎料钎焊冶金特性较好,钎焊接头界面实现冶金结合。

关键词:

中图分类号:TG4; TG454 文献标识码: A

Microstructure and properties of BCu80Ni5SnTi active filler metal for brazing cubic boron nitride

WANG Yi1, 2, YIN Shi-qiang1, LU Guang-lin3, LI Shi-quan1, QIU Xiao-ming1

(1. School of Materials Science and Engineering, Jilin University, Changchun 130025, China;

2. School of Mechatronies Engineering, Changchun Institute of Technology, Changchun 130012, China;

3. The Key Laboratory for Terrain-machine Bionics Engineering, Ministry of Education,

Jilin University, Changchun 130025, China)

Abstract: A new-type BCu80Ni5SnTi filler metal suitable for brazing cubic boron nitride (c-BN) and 45 steel was prepared. The microstructures of BCu80Ni5SnTi active filler metal and mechanical properties of the joints of c-BN and 45 steel brazed with BCu80Ni5SnTi filler metal were analyzed by SEM, EDS and XRD. The results show that the solidus and liquidus temperatures of the novel BCu78-81Ni5-6Sn3-5.5Ti10-12(mass fraction, %) active filler metal are 858.4 and 874.8 ℃, respectively. The microstructure of the filler metal mainly consists of α-Cu solid solution, Ni solid solution, Cu-Sn eutectic phase as well as a little Cu4Ti3,Cu3Ti2,Cu3Sn,CuSn and Ni17Sn3 compounds. The wettability of the filler metal on c-BN is good and the contact angle is about 28?-30?. The shear strength of the brazed joint between c-BN and 45 steel using this active filler metal reaches 210-230 MPa. The new-type BCu78-81Ni5-6Sn3-5.5Ti10-12(mass fraction, %) active filler metal possesses better brazing metallurgy characteristics. Chemical metallurgic joining forms in the interface between c-BN grits and BCu80Ni5SnTi active filler metal.

Key words: CuNiSnTi; cubic boron nitride; active filler metal; vacuum brazing

立方氮化硼(Cubic boron nitride, c-BN)硬度仅次于金刚石,具有优越的物理、化学和力学性能,避免了金刚石制品加工铁基等合金材料发生反应的局限性,其制品非常适合加工铁基合金材料(如淬硬钢、高速工具钢、轴承钢、不锈钢、耐热钢)、高硅铝合金和钛合金等高硬度韧性大的金属材料[1-7]。近年来,随着连接技术的日趋成熟,采用活性钎料钎焊c-BN制造各种制品受到研究人员的关注。有关钎焊c-BN的研究大多采用Ag-Cu-Ti系活性钎料[8-10]。Ag-Cu-Ti系活性钎料钎焊c-BN存在的主要问题如下:1) 成本较高,接头强度仍然较低;2) 银基钎料熔化温度区间为680~820 ℃,制品工作温度低于500 ℃[11-12],与c-BN作为高温耐磨材料不匹配,致使制品在高温磨削过程中性能损失严重。多元铜基活性钎料熔点适中(860~1 000 ℃)、工艺性能较好、强度较高、成本较低。为此,采用兼有上下界约束的极端顶点混料设计试验方法,确定钎料以Cu70~90、Ni4~6(质量分数,%)合金为基础,加入Sn1~10、Ti5~15(质量分数,%)[13-14]。本文作者研究合金元素Sn和Ti对铜基活性钎料的润湿性和力学性能的影响规律,分析铜基活性钎料的微观组织及其钎焊冶金特性,研制适合于钎焊c-BN与钢基体的新型 BCu78~81Ni5~6Sn3~5.5Ti10~12钎料。

1 实验

钎料采用颗粒为180~200 μm、纯度为99.99%的Cu、Ni、Sn、Ti金属按优化试验配比组合,混合均匀装入VQB-10WD型高真空钎焊炉中熔炼而成,熔炼温度为1 000~1 050 ℃,真空度高于2.9×10-3 Pa,保温10 min。试验用c-BN由湖南旭光新材料发展有限公司提供,表面无镀膜,粒度为250~300 μm。将熔炼后钎料制成200 mg润湿试验样品,按国家标准GB/T11364─2008,研究BCu80Ni5SnTi系活性钎料在c-BN聚晶片表面的润湿性,作为评定钎料对c-BN颗粒润湿性的依据。采用BCu80Ni5SnTi系活性钎料真空钎焊连接c-BN聚晶片与45钢,在CSS-44100型电子万能试验机上进行剪切试验,剪切速率1 mm/min。采用DTA-7型差热分析仪测试钎料的固、液相线温度, 加热温度从25~1 150 ℃,加热和冷却速度均为20 ℃/min。采用FeCl3、HCl与H2O体积比为5?10?100的腐蚀液对钎料进行腐蚀,采用OLS3000型激光共聚焦显微镜、JSM-5310型扫描电镜(SEM)及能谱仪(EDS)研究钎料的微观组织及钎焊冶金特性,采用D/MAX-2500型X射线衍射仪分析铜基钎料的组织。

2 结果与分析

2.1 Ti和Sn对铜基钎料润湿性和接头强度的影响

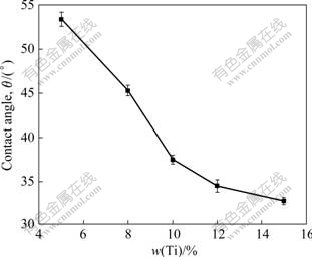

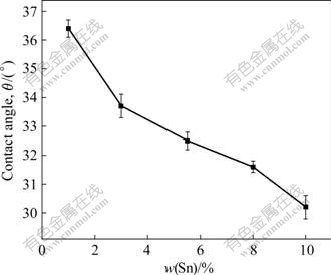

Ti是活性元素,能与c-BN发生反应,在界面处形成与金属结构相同的新相,降低液态活性钎料与c-BN间的固-液界面张力,改善钎料对c-BN的润湿性。试验表明,以CuNi为基的合金系中,未添加活性元素Ti的钎料对c-BN润湿性差,用此钎料钎焊c-BN颗粒,钎料与c-BN分层且颗粒脱落;添加Ti元素后,钎料对c-BN的润湿性显著提高。图1所示为Ti含量对BCuNiSn5.5Ti5~15钎料钎焊c-BN润湿角的影响。由图1可见,Ti含量对润湿角的影响较大。Ti含量为5%(质量分数)时,润湿角为48.4?,随着含Ti量的增加,润湿角下降;当Ti含量为12%时,润湿角降到29.5?;继续增加Ti含量,润湿角下降趋势减缓。图2所示为Sn含量对BCuNi Ti10Sn1~10钎料钎焊c-BN润湿角的影响规律。由图2可见,Sn含量为1%时,润湿角为36.4?;Sn含量10%时,润湿角为30.2?。与Ti相比,Sn对润湿角的影响较小,但对钎焊表面成型的影响显著。图3所示为BCuNiSn5.5Ti10钎料对c-BN的润湿形貌。由图3可看出,钎料在c-BN 聚晶片上熔化完全铺展,润湿角为28?~30?时,润湿前沿形成了一定面积与钎料颜色不一样的润湿环。在钎焊c-BN颗粒时,钎料完全包裹在c-BN颗粒周边,可见,BCuNiSn5.5Ti10活性钎料对c-BN具有良好的润湿性。

图1 铜基钎料中Ti含量对润湿角的影响

Fig.1 Effect of Ti content in Cu-based filler on contact angle

图2 铜基钎料中Sn含量对润湿角的影响

Fig.2 Effect of Sn content in Cu-based filler on contact angle

图3 CuNiSnTi活性钎料对c-BN润湿的形貌

Fig.3 Wetting morphologies of CuNiSnTi active filler metal on c-BN

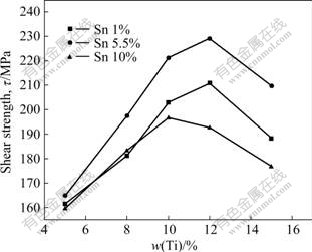

图4所示为Ti和Sn含量对c-BN与45钢钎焊接头抗剪强度的影响规律。由图4可见,Ti和Sn两元素对c-BN与45钢异质钎焊接头抗剪强度均有显著影响。含Sn含量一定时,钎焊接头抗剪强度随含Ti含量增加而变化,当含Ti含量为10%~12%时,钎焊接头抗剪强度达到最大值。Sn含量变化对钎焊接头抗剪强度的影响规律与Ti的相似,Ti含量一定时,当Sn含量为5.5%时,钎焊接头抗剪强度最大。

图4 Ti和Sn含量对钎焊接头抗剪强度的影响

Fig.4 Effect of Ti and Sn contents on shear strength of brazed joint

Ti和Sn对钎料的润湿性、接头抗剪强度和钎焊表面成型都有影响。Ti作为活性元素,在钎料中起决定性作用,增加Ti含量和增大Ti的活性,均可以促进界面反应,有利于钎料润湿新相的形成和提高钎料对c-BN的润湿性,从而提高钎焊接头的抗剪强度。但Ti含量过高钎料容易形成Cu3Ti2和Cu4Ti3等脆性化合物,使接头抗剪强度和塑性急剧下降。Sn在钎料合金中的固溶度较大,可有效改善钎料的流动性,进一步提高钎料的润湿性和强度,使钎焊表面成型更美观。但Sn的熔点较低,与Cu、Ni、Ti的熔化温度相差较大,当含Sn量过高时,钎料中存在着Sn的偏析,使钎料微观力学性能不均匀,在受力时易于出现应力集中产生裂纹,导致接头抗剪强度下降。

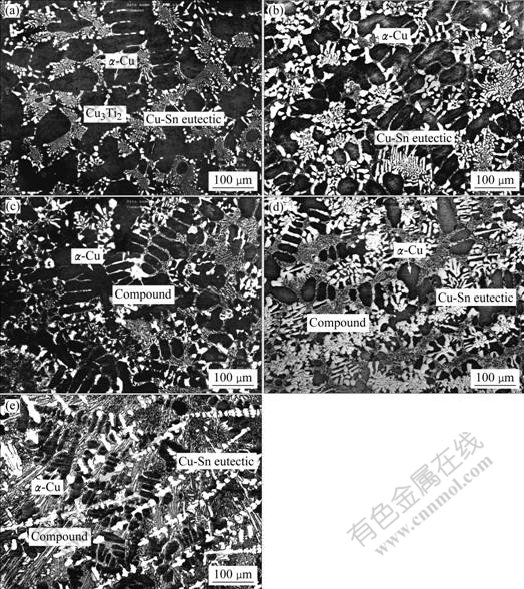

2.2 铜基活性钎料的微观组织

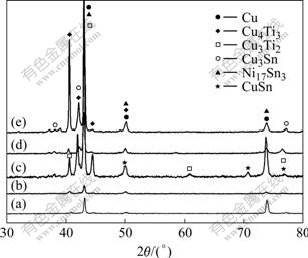

BCu80Ni5SnTi系活性钎料组织由α-Cu固溶体、Ni固溶体、Cu-Sn共晶及其晶界上分布的Cu-Ti,Cu-Sn和Ni-Sn等化合物组成。图5所示为5种不同成分BCu80Ni5SnTi系活性钎料的微观组织。图6所示为钎料的XRD谱。由图5可看出,BCu88Ni5Sn1Ti5钎料由大量黑色初生α-Cu固溶体、Ni固溶体、Cu-Sn共晶及在Cu固溶体晶界上少量白色Cu3Ti2和Ni17Sn3化合物组成;BCu84Ni5Sn3Ti8钎料中α-Cu固溶体晶粒细化,共晶组织减少,化合物增多,并有Cu4Ti3新的化合物生成;BCu79.5Ni5Sn5.5Ti10钎料α-Cu固溶体继续细化,白色化合物增多,有Cu3Sn和CuSn新相生成;BCu75Ni5Sn8Ti12钎料α-Cu固溶体呈弥散分布,共晶组织形态由棒状转变成层片状,金属间化合物明显增多且开始团聚;BCu70Ni5Sn10Ti15钎料中α-Cu固溶体晶粒变得很细小,共晶组织形态逐渐转变为针状,金属间化合物团聚并呈枝状发展。结果表明,Ti、Sn含量对BCu80Ni5SnTi系活性钎料的微观组织影响明显。当含Ti量在5%~10%,含Sn量在1%~5.5%时,钎料主要由α-Cu固溶体、Cu-Sn共晶和化合物相组成,随着Ti、Sn含量的增加,α-Cu固溶体晶粒细化,共晶组织减少,化合物相增加,当含Ti量超过10%,含Sn量超过5.5%时,钎料中α-Cu固溶体晶粒进一步细化,由于Ti、Sn含量的增加,影响晶粒生长速率、结晶 前沿温度梯度,且晶界界面能改变,导致共晶组织形态改变,金属间化合物明显增多并呈枝状发展。由Cu-Sn和Cu-Ti二元相图可知,元素Ti、Sn与Cu都能发生反应,生成金属间化合物,且随Ti和Sn含量的增加,Ti、Sn与Cu反应越激烈,形成的金属间化合物越多,导致钎料脆性增大,钎焊接头强度和塑性降低[15]。

图5 铜基活性钎料微观组织

Fig.5 Microstructures of Cu-based active filler metal: (a) Cu88Ni5Sn1Ti5; (b) Cu84Ni5Sn3Ti8; (c) Cu79.5Ni5Sn5.5Ti10; (d) Cu75Ni5Sn8Ti12; (e) Cu70Ni5Sn10Ti15

图6 CuNiSnTi活性钎料的XRD谱

Fig.6 XRD patterns of CuNiSnTi active filler metal : (a) Cu88Ni5Sn1Ti5; (b) Cu84Ni5Sn3Ti8; (c) Cu79.5Ni5Sn5.5Ti10; (d) Cu75Ni5Sn8Ti12; (e) Cu70Ni5Sn10Ti15

2.3 铜基活性钎料熔化温度和钎焊c-BN冶金特性

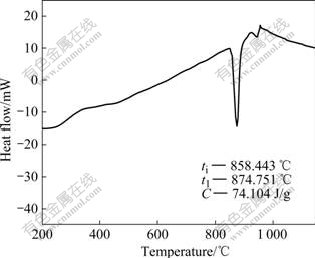

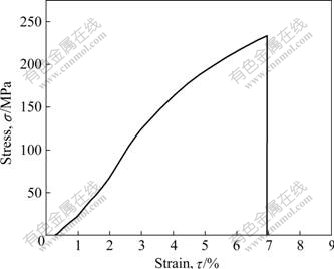

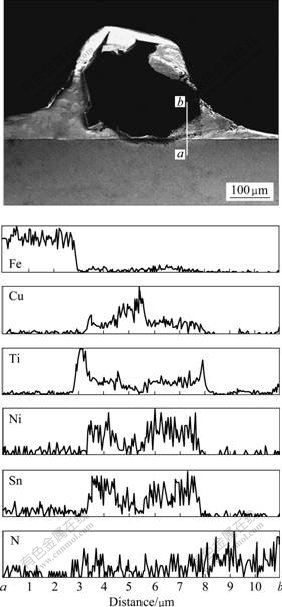

在研究单因素对BCu80Ni5SnTi系活性钎料的润湿性和剪切强度等性能影响因素的基础上,对Cu、Ni、Sn和Ti这4个元素进行混料优化设计试验,确定钎焊c-BN与45钢钎料成分为BCu78~81Ni5~6Sn3~ 5.5Ti10~12。经差热分析试验测得,钎料固相线温度为858.4 ℃,液相线温度为874.8 ℃,如图7所示。Ti和Sn的含量对钎料的熔化温度均有一定影响,随含Ti和Sn量的增加,钎料液相线温度有所降低,固相线温度影响较小。钎料对c-BN的润湿性较好,对c-BN的润湿角约30?,对45钢的润湿角小于20?,采用该钎料钎焊c-BN和45钢接头抗剪强度和塑性伸长率分别为210~230 MPa和6%~7%,如图8所示。图9所示为BCu79.5Ni5Sn5.5Ti10钎料钎焊c-BN颗粒和45钢异质接头的界面微观结构及能谱线扫描分布曲线。由图9可见,钎料与c-BN、钎料与45钢界面结合致密;在表面张力作用下,钎料包裹住c-BN颗粒,钎料中的活性元素与c-BN发生化学反应,使c-BN表面分解,形成新相。能谱分析结果表明,界面处元素成分呈梯度分布,BCu79.5Ni5Sn5.5Ti10钎料中活性元素Ti在界面区c-BN侧发生富集,Ti元素有较高的浓度分布,高于钎料中原始Ti元素的含量。BCu79.5Ni5Sn5.5Ti10活性钎料与c-BN的这种界面冶金结合可提高钎料对c-BN界面的润湿性。

图7 CuNi5Sn5.5Ti10活性钎料的DTA曲线

Fig.7 DTA curve of CuNi5Sn5.5Ti10 active filler metal

图8 异质钎焊接头的应力─应变曲线

Fig.8 Stress─strain curve of inhomogeneous brazing joint

图9 异质钎焊接头界面微观结构和线扫描

Fig.9 Microstructure and EDS line scanning patterns on interface of inhomogeneous brazing joint

3 结 论

1) Ti和Sn可显著提高铜基活性钎料对c-BN的润湿性和钎焊表面的成型质量,且对接头剪切强度有明显影响。二者交互作用结果表明,含Sn量为3%~5.5%,含Ti量为10%~12%时,钎料对c-BN的润湿性较好,接头剪切强度较高;钎焊c-BN与45钢异质接头的CuNiSnTi钎料成分为Cu78~81Ni5~6Sn3~5.5Ti10~12,固相线温度为858.4 ℃,液相线温度为874.8 ℃,接头抗剪强度达210~230 MPa。

2) 该铜基活性钎料由α-Cu固溶体、Ni固溶体、Cu-Sn共晶及少量Cu4Ti3、Cu3Ti2、Cu3Sn、CuSn和Ni17Sn3等化合物组成。采用该钎料钎焊c-BN与45钢,接头界面结合致密,钎料与c-BN发生作用,形成化合物型界面,大大改善采用传统电镀和烧结等方法连接的界面的强度。

REFERENCES

[1] HAIDAR M A, ISHIBASHI A, SONODA K, EZOE S. Minimization of effect of CBN wheel wear on ground gear errors[J]. International Journal of Machine Tools & Manufacture, 1999, 39(4): 607-626.

[2] CHEN X, ROWE W B, CAI R. Precision grinding using CBN wheels[J]. International Journal of Machine Tools & Manufacture, 2002, 42(5): 585-593.

[3] JACKSON M J, DAVIS C J, HITCHINER M P, MILLS B. High-speed grinding with CBN grinding wheels-applications and future technology[J]. Journal of Materials Processing Technology, 2001, 110(1): 78-88.

[4] IGOR L P, SHIPKO A A, NESTERUK I G. Investigation of contact phenomena at cubic boron nitride-filler metal interface during electron beam brazing[J]. Diamond and Related Materials, 1997, 6(8): 1067-1070.

[5] ELSENER H R, KLOTZ U E, KHALID F A, PIAZZA D, KISER M. The role of binder content on microstructure and properties of a Cu-base active brazing filler metal for diamond and cBN[J]. Advanced Engineering Materials, 2005, 7(5): 375-380.

[6] FUJISAKI K, YOKOTA H, FURUSHIRO N, YAMAGATA Y, TANIGUCHI T, HIMENO R, MAKINOUCHI A, HIGUCHI T. Development of ultra-fine-grain binderless c-BN tool for precision cutting of ferrous materials[J]. Journal of Materials Processing Technology, 2009, 209(15/16): 5646-5652.

[7] LIN H M, LIAO Y S, WEI C C. Wear behavior in turning high hardness alloy steel by CBN tool[J]. Wear, 2008, 264(7/8): 679-684.

[8] GHOSH A, CHATTOPADHYAY A K. Experimental investigation on performance of touch-dressed single-layer brazed c-BN wheels[J]. International Journal of Machine Tools & Manufacture, 2007, 47(7/8): 1206-1213.

[9] DING W F, XU J H, SHEN M, SU H H, FU Y C, XIAO B. Joining of CBN abrasive grains to medium carbon steel with Ag-Cu/Ti powder mixture as active brazing alloy[J]. Mater Sci Eng A, 2006, 430(1/2): 301-306.

[10] CHATTOPADHYAY A K, HINTERMANN H E. On brazing of cubic boron nitride abrasive crystals to steel substrate with alloys containing Cr or Ti[J]. Journal of Materials Science, 1993, 28(21): 5887-5893.

[11] LI Jia-ke, LIU Lei, WU Ya-ting, LI Zhi-bin, ZHANG Wen-long, HU Wen-bin. Microstructure of high temperature Ti-based brazing alloys and wettability on SiC ceramic[J]. Materials and Design, 2009, 30(2): 275-279.

[12] ZHANG J, GUO Y L, NAKA M, ZHOU Y. Microstructure and reaction phases in Si3N4/Si3N4 joint brazed with Cu-Pd-Ti filler alloy[J]. Ceramics International, 2008, 34(5): 1159-1164.

[13] 任露泉, 卢广林, 邱小明, 王 毅, 汪春花. 制备立方氮化硼复合材料的方法[P]. 中国专利, 200610016981.4. 2009.

REN Lu-quan, LU Guang-lin, QIU Xiao-ming, WANG Yi, WANG Chun-hua. Method of preparing the cubic boron nitride composites[P]. CN200610016981.4. 2009.

[14] 关颖男. 混料试验设计[M]. 上海: 上海科学技术出版社, 1990.

GUAN Ying-nan. Mixture experimental design[M]. Shanghai: Shanghai Science and Technology Press, 1990.

[15] 虞觉奇, 易文质, 陈邦迪. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1987.

YU Jue-qi, YI Wen-zhi, CHEN Bang-di. Binary alloy state Atlas[M]. Shanghai: Shanghai Science and Technology Press, 1987.

基金项目:国家自然科学基金重点资助项目(50635030);吉林省科技发展计划资助项目(20070309);长春市科技计划资助项目(06GJ22)

收稿日期:2008-11-27;修订日期:2009-03-22

通信作者:邱小明,教授,博士;电话:0431-85094687;E-mail: qiuxm621@yahoo.cn

摘 要:研制一种适合钎焊立方氮化硼与45钢异质材料的新型高温BCu80Ni5SnTi活性钎料,采用SEM、EDS及XRD对BCu80Ni5SnTi系活性钎料的微观组织及钎焊接头力学性能进行研究。结果表明:适合钎焊c-BN的活性钎料成分为Cu78~81Ni5~6Sn3~5.5Ti10~12(质量分数,%),固相线温度为858.4 ℃,液相线温度为874.8 ℃;钎料组织由α-Cu固溶体、Ni固溶体、Cu-Sn共晶及少量Cu4Ti3、Cu3Ti2、Cu3Sn、CuSn和Ni17Sn3等化合物组成;该钎料对c-BN的润湿性较好,润湿角为28?~30?,钎焊c-BN与45钢的接头强度为210~230 MPa;新型钎料钎焊冶金特性较好,钎焊接头界面实现冶金结合。