回收废弃印刷电路板焊锡的新技术

周益辉,丘克强

(中南大学 化学化工学院,湖南 长沙,410083)

摘要:提出一种回收废弃印刷电路板焊锡的有效方法。其步骤为:在整个回收过程中不会对环境造成二次污染:用油加热废弃印刷电路板至焊锡熔化,在离心力的作用下将焊锡分离和回收。实验结果表明:当油温为240 ℃,转鼓转速为1 400 r/min,采用间歇式的方式旋转6 min,废弃印刷电路板焊锡即可回收完全。

关键词:

中图分类号:X705 文献标志码:A 文章编号:1672-7207(2011)07-1883-07

A new technology for recycling solder from

waste printed circuit boards

ZHOU Yi-Hui, QIU Ke-Qiang

(School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: An effective technology without a negative impact on the environment for recycling solder from WPCBs was investigated. The procedures were as follows: WPCBs were heated by immersing in the oil, and the molten solder of WPCBs was separated and recovered by the centrifugal force. The results show that solder is effectively separated from WPCBs when the oil temperature is 240 ℃, and the rotating drum is rotated for 6 min intermittently with a rotational speed of 1 400 r/min.

Key words: waste printed circuit boards; solder; centrifugal separation; recycling

随着经济和电子信息产业的迅速发展,电子电器产品更新换代日益加剧,电子废弃物的回收处理已成为亟需解决的全球性问题[1-3]。废弃电路板是电子废弃物的重要组成部分,而废弃电路板上含有大量的焊锡,因此,分离和回收废弃电路板中的焊锡具有重大的环保意义和经济效益。目前,废弃电路板资源再生技术有火法[4-6]、湿法[7-12]、机械破碎法[13-18]和热解法[19-22]等,但是,至今无论何种技术流程,均未能解决好焊锡的回收问题:有些技术回收焊锡十分困难,回收率甚低;有些技术回收焊锡的成本较高等。因此,如何高效、清洁、低成本回收废弃电路板中的焊锡至今还是废弃电路板资源回收技术中的难题之一。若不解决废弃电路板中焊锡的回收问题,则不仅不能实现资源循环利用,而且不利于其他金属(特别是贵金属)的回收;因此,废弃电路板中的焊锡回收也是一个必须解决的技术问题。基于上述原因,本文作者对废弃电路板中焊锡的高效回收进行研究。

1 实验

1.1 实验原料

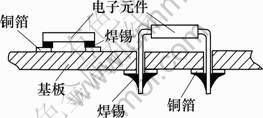

典型的印刷电路板一般由基板、电子元件和焊锡组成,如图1所示。本实验所用废弃印刷电路板有2 种:一种为纸质强化酚醛树脂电路板(商业上称为FR-2),这种电路板是单层结构,其中不含玻璃纤维;另一种为电脑等电子产品的印刷电路板,它通常由玻璃纤维强化环氧树脂制成(FR-4),这种电路板具有多层结构。

图1 典型印刷电路板示意图

Fig.1 Schematic drawing of typical PCB

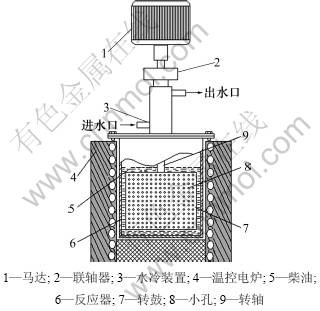

1.2 实验设备

焊锡主要由锡和铅组成。锡的熔点为232 ℃,铅的熔点是327 ℃,合金的熔点一般比组成它的任何一种金属的熔点低,标准焊锡的熔点为183 ℃。若温度控制在焊锡熔点温度,则废弃电路板的其他物质基本不会发生变化,可利用离心的方法,将熔化的焊锡从基板脱除。为此,研制一种专门设备,采用柴油作为加热介质将焊锡熔化,利用固液离心分离的原理将焊锡从废弃电路板中分离,而电路板基板和电子元件则留在转鼓内。这样,既简单又高效地实现了废弃电路板焊锡的清洁分离和回收。该装置由电机、转鼓、电炉等组成,如图2所示。实验所用的电机在工作时能显示转速;转鼓用分离废弃印刷电路板焊锡设计,在其底部和侧面设计有均匀的滤孔;密封套和冷却水套的设置是为了保证体系的正常工作。

图2 废弃电路板焊锡回收装置示意图

Fig.2 Schematic illustration of equipment of recycling solder

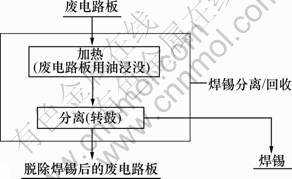

在本实验中,将待处理的带有电子元件的废弃印刷电路板装入焊锡回收装置的转鼓中,然后,使转鼓完全浸没在油中,连接好装置后,打开冷却水。升温至焊锡熔化,控制油温低于电路板的裂解温度,并且待温度恒定后旋转转鼓,使焊锡从转鼓中迅速滤出,沉积在容器底部。待反应器冷却后,取出废弃印刷电路板基板、电子元件及焊锡。整个分离回收过程如图3所示。

图3 焊锡分离回收流程示意图

Fig.3 Solder separation/recovery process

2 实验结果与讨论

2.1 转速对废弃电路板焊锡回收的影响

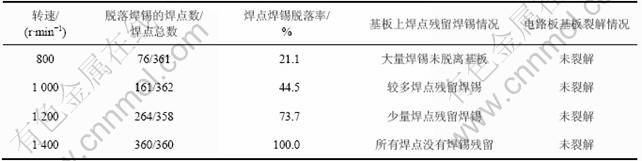

实验温度为240 ℃,旋转时间为6 min,采用间歇式旋转,即在规定的时间内均匀分6次旋转。改变实验转速对废弃电路板进行焊锡回收处理,实验结果见表1。

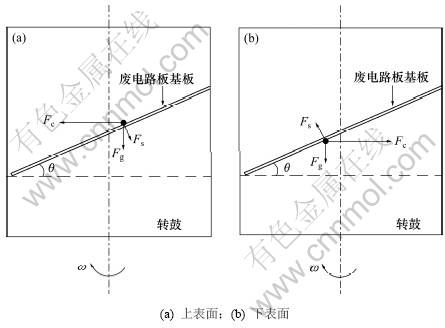

当转鼓旋转时,转鼓内废弃电路板上处于熔融状态的焊锡受到重力Fg、离心力Fc和表面张力Fs的共同作用,如图4所示,其中重力和离心力利于焊锡的分离,表面张力阻碍焊锡脱离。

当转鼓旋转时,熔化的焊锡在离心力的作用下从废弃电路板基板上脱离。设G为转鼓的重力,ω为转鼓的转速,r为旋转半径,g为重力加速度,则所产生的离心力Fc 可由下式确定[23]:

![]()

对于指定的装置,G,g和r均为常数。由上式可见:离心力Fc与转速ω的平方成正比,因此,转速ω越大,离心力Fc就越大;当转速为800 r/min时,焊锡分离差,但是,随着转速加快,焊锡分离效果增大;当转速达到1 400 r/min时,废弃电路板上的焊锡已完全脱除,所有焊点无焊锡残留。

表1 不同转速下废弃电路板焊锡回收实验结果

Table 1 Results of different rotational speeds for recycling solder from WPCBs

图4 熔融焊锡在印刷电路板基板表面的受力示意图

Fig.4 Molten solder on upside (a) and underside (b) of base plates of WPCBs

2.2 温度对废弃电路板焊锡回收的影响

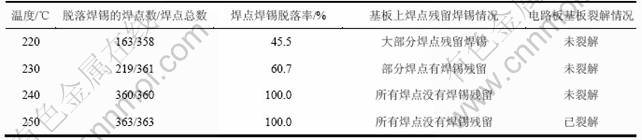

转速恒定为1 400 r/min、旋转时间为6 min,采用间歇式旋转,即在规定的时间内均匀分6次旋转,研究实验温度变化对废弃电路板进行焊锡分离效果的影响,实验结果见表2。

实验温度是焊锡回收的重要影响因素,它决定焊锡熔融的程度。实验温度越高,液态焊锡的黏度越小,从而流动性越好,越易从废弃电路板中分离;因此,在保证废弃电路板不发生裂解的条件下,实验温度应该尽可能高。在220 ℃和230 ℃时,废弃电路板上焊锡分离不彻底,有焊锡残留在基板上的焊点中,但是,230 ℃时比220 ℃时回收的效果好。在240 ℃和250 ℃时,废弃电路板上的焊锡均可分离完全,焊点中无焊锡残留,但是,当温度为250 ℃时,废弃电路板基板上有焦炭产生,表面电路板有机物质已发生裂解。因此,240 ℃应为焊锡分离的理想温度。

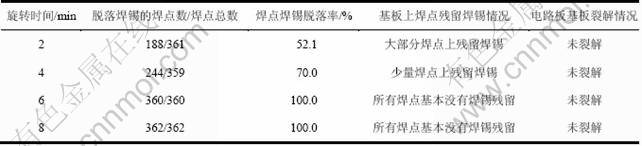

2.3 旋转时间对废弃电路板焊锡回收的影响

在转速恒定为1 400 r/min、实验温度为240 ℃的条件下,采用间歇式旋转(在规定的时间内均匀分6次旋转),考查旋转时间变化对废弃电路板焊锡分离效果的影响,实验结果见表3。

从表3可知:当旋转时间在6 min以下时,废弃电路板上焊锡未能回收完全,有焊锡残留在焊孔中;时间越长,焊点脱落率越高;当旋转时间在6 min以上时,废弃电路板上的焊锡已回收完全,焊点中无焊锡残留。由此说明:旋转时间越长,对焊锡回收更有利。考虑到节能,本实验中旋转时间选择6 min为宜。

表2 不同温度下废弃电路板焊锡回收实验结果

Table 2 Results of different temperatures for recycling solder from WPCBs

表3 旋转时间不同时废弃电路板焊锡回收实验结果

Table 3 Results of rotational time for recycling solder from WPCBs

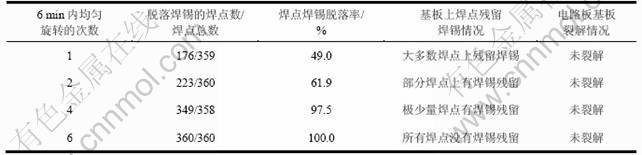

表4 不同旋转次数下废弃电路板焊锡回收实验结果

Table 4 Results of number of rotational times for recycling solder from WPCBs

2.4 旋转次数对废弃电路板焊锡回收的影响

在转速恒定为1 400 r/min、实验温度为240 ℃、旋转时间为6 min的条件下,研究旋转次数对废弃电路板焊锡分离效果的影响,实验结果见表4。在总旋转时间6 min内,分别均匀旋转1次、2次、4次、6次。

从表4可见:随着旋转次数的增加,焊锡的分离效果增强;分6次旋转时焊锡已能完全分离,并且分次旋转的回收效果明显好于一次性旋转的回收效果。

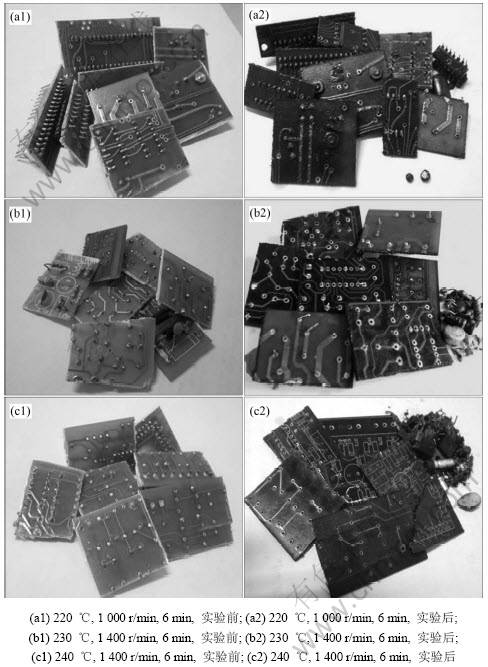

2.5 离心分离焊锡前、后的照片对比

图5所示为FR-4型废弃印刷电路板在不同条件下进行焊锡回收实验前、后的对比照片。从图5可见:在焊锡回收效果较差的实验中,只有极少量的焊锡和电子元件从基板上脱落(如图5(a)所示);焊锡回收效果一般的实验(图5(b))中,仍有少量焊锡残留在基板上,少量电子元件仍连接在废弃电路板上;在焊锡回收效果好的实验中,电路板基板表面非常干净,电子元件全部脱离基板(如图5(c)所示)。部分实验收集的焊锡如图6所示。从图6可见:回收的焊锡性质未发生变化,可直接再次利用或用于精炼锡和铅的原料。

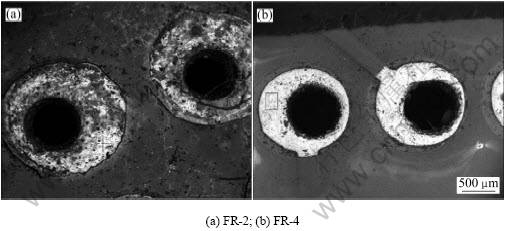

为了确定使用本方法回收焊锡的回收效果,采用扫描电镜对实验后的基板残留焊锡状况进行分析。2种脱焊后的废弃印刷电路板表面SEM照片如图7所示。从图7可以看出:电路板表面非常干净,所有焊锡已脱离基板。这证实在本实验中焊锡已完全分离。

图5 不同条件下FR-4型废弃电路板焊锡回收实验照片

Fig.5 Photographs of examples of separating solder from FR-4 type of WPCBs under different experimental conditions

图6 本实验收集的部分焊锡

Fig.6 Recovered solder obtained from some experiments

图7 2种废弃电路板焊锡分离后表面SEM照片

Fig.7 SEM photographs of two types of WPCBs base plates after solder separation

3 结论

(1) 离心分离废弃电路板焊锡的影响因素有转速、温度、旋转时间、旋转次数。其中,最主要的影响因素为实验温度和转速。

(2) 当油温为240 ℃、转速为1 400 r/min时,在6 min内均匀旋转转鼓6次,废弃印刷电路板焊锡即可实现分离回收。

参考文献:

[1] Lee J C, Song H T, Yoo J M. Present status of the recycling of waste electrical and electronic equipment in Korea: A review[J]. Resources, Conservation and Recycling, 2007, 50(4): 380-397.

[2] HUANG Kui, GUO Jie, XU Zhen-ming. Recycling of waste printed circuit boards: a review of current technologies and treatment status in China[J]. Journal of Hazardous Materials, 2009, 164(2/3): 399-408.

[3] HE Wen-zhi, LI Guang-ming, MA Xing-fa, et al. WEEE recovery strategies and the WEEE treatment status in China[J]. Journal of Hazardous Materials, 2006, 136(3): 502-512.

[4] Veldbuizen H, Sippel B. Mining discarded electronics[J]. Industry and environment, 1994, 17(3): 7-11.

[5] Christian Hagelüken. Recycling of electronic scrap at umicore’s integrated metals smelter and re?nery[J]. World of Metallurgy-Erzmetall, 2006, 59(3): 152-161.

[6] CUI Ji-rang, ZHANG Li-feng. Metallurgical recovery of metals from electronic waste: A review[J]. Journal of Hazardous Materials, 2008, 158(2/3): 228-256.

[7] 巫协森. 由废印刷电路板及含铜废液中回收铜金属的方法: CN 1534111A[P]. 2004-10-06.

WU Xie-sen. Method of recovering copper metal from waste printed circuit board and copper containing waste liquid and its device: CN 1534111A[P]. 2004-10-06.

[8] 李登新, 张武学, 钟非文, 等. 印刷电路板中提取金属的方法: CN 1858277A[P]. 2006-11-08.

LI Deng-xin, ZHANG Wu-xue, ZHONG Fei-wen, et al. Method for extracting metal from printed circuit board: CN 1858277A[P]. 2006-11-08.

[9] Oishi T, Koyama K, Alam S, et al. Recovery of high purity copper cathode from printed circuit boards using ammoniacal sulfate or chloride solutions[J]. Hydrometallurgy, 2007, 89(1/2): 82-88.

[10] Lee M S, Ahn J G, Ahn J W. Recovery of copper, tin and lead from the spent nitric etching solutions of printed circuit board and regeneration of the etching solution[J]. Hydrometallurgy, 2003, 70(1/3): 23-29.

[11] Kinoshita T, Akita S, Kobayashi N, et al. Metal recovery from non-mounted printed wiring boards via hydrometallurgical processing[J]. Hydrometallurgy, 2003, 69(1/3): 73-79.

[12] Young J P, Derek J F. Recovery of high purity precious metals from printed circuit boards[J]. Journal of Hazardous Materials, 2009, 164(2/3): 1152-1158.

[13] 赵跃民, 温雪峰, 何亚群, 等. 废弃电路板中金属富集体的物理回收工艺: CN 1563440A[P]. 2005-01-12.

ZHAO Yue-ming, WEN Xue-feng, HE Ya-qun, et al. Technique for reclaiming metal concentrate in obsolete PCB physically: CN 1563440A[P]. 2005-01-12.

[14] 路迈西, 周翠红, 潘永泰, 等. 一种回收废旧印刷电路板中有价资源的方法: CN 1611309A[P]. 2005-05-04.

LU Mai-xi, ZHOU Cui-hong, PAN Yong-tai, et al. Method for recovering valuable resource from waste printed circuit board: CN 1611309A[P]. 2005-05-04.

[15] 李佳, 许振明. 废旧印刷电路板破碎颗粒的高压静电分离装置及分离方法: CN 1654129A[P]. 2005-08-17.

LI Jia, XU Zhen-ming. High tension electrostatic separating apparatus and method for worn-out broken printed circuit board granules: CN 1654129A[P]. 2005-08-17.

[16] 路迈西, 关杰, 刘文礼, 等. 一种废旧印刷电路板资源回收的方法: CN 1899712A[P]. 2007-01-24.

LU Mai-xi, GUAN Jie, LIU Wen-li, et al. Method for recovering waste printed circuit board resource: CN 1899712A[P]. 2007-01-24.

[17] Eswaraiah C, Kavitha T, Vidyasagar S, et al. Classification of metals and plastics from printed circuit boards (PCB) using air classifier[J]. Chemical Engineering and Processing, 2008, 47(4): 565-576.

[18] Yoo J M, Jeong J, Yoo K, et al. Enrichment of the metallic components from waste printed circuit boards by a mechanical separation process using a stamp mill[J]. Waste Management, 2009, 29(4): 1132-1137.

[19] Vasile C, Brebu M A, Totolin M, et al. Feedstock recycling from the printed circuit boards of used computers[J]. Energy Fuel, 2008, 22(3): 1658-1665.

[20] Hall W J, Williams P T. Separation and recovery of materials from scrap printed circuit boards[J]. Resources, Conservation and Recycling, 2007, 51(3): 691-709.

[21] GUAN Jie, LI Ying-shun, LU Mai-xi. Product characterization of waste printed circuit board by pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2008, 83(2): 185-189.

[22] Benallal B, Roy C, Pakdel H, et al. Characterization of pyrolytic light naphtha from vacuum pyrolysis of used tyres comparison with petroleum naphtha[J]. Fuel, 1995, 74(11): 1589-1594.

[23] 黄位森. 锡[M]. 北京: 冶金工业出版社, 2000: 568-569.

HUANG Wei-sen. Tin[M]. Beijing: Metallurgical Industry Press, 2000: 568-569.

(编辑 陈灿华)

收稿日期:2010-07-12;修回日期:2010-09-28

基金项目:国家高技术研究发展计划(“863”计划)项目(2006AA06Z375)

通信作者:丘克强(1956-),男,广东平远人,博士,教授,博士生导师,从事真空分离理论与工程、高纯材料加工和功能纳米材料制备理论与技术及二次资源绿色循环化学与技术等研究;电话:0731-88877364;E-mail: qiuwhs@sohu.com

[8] 李登新, 张武学, 钟非文, 等. 印刷电路板中提取金属的方法: CN 1858277A[P]. 2006-11-08.

[13] 赵跃民, 温雪峰, 何亚群, 等. 废弃电路板中金属富集体的物理回收工艺: CN 1563440A[P]. 2005-01-12.

[14] 路迈西, 周翠红, 潘永泰, 等. 一种回收废旧印刷电路板中有价资源的方法: CN 1611309A[P]. 2005-05-04.

[15] 李佳, 许振明. 废旧印刷电路板破碎颗粒的高压静电分离装置及分离方法: CN 1654129A[P]. 2005-08-17.

[16] 路迈西, 关杰, 刘文礼, 等. 一种废旧印刷电路板资源回收的方法: CN 1899712A[P]. 2007-01-24.