Structure and property of Cu-based thermosensitive nanocomposite

LOU Bai-yang(楼白杨), XU Bin(徐 斌), MA Xiao-chun(马晓春), LI Le-guo(李乐国)

College of Mechanical and Electronic Engineering, Zhejiang University of Technology,

Hangzhou 310014, China

Received 14 December 2005; accepted 5 July 2006

Abstract:

The Cu-based thermosensitive nanocomposites are made by high energy ball milling. The microstructures and properties of Cu-based thermosensitive nanocomposites are studied by transmission electron microscopy(TEM) and themosensitivity test. The effects of milling time on the microstructures and the thermosensitivity of Cu-based nanocomposite material are researched. The results show that the Cu-based nanocomposite can be made by high energy ball milling. As the milling time increases, the copper particle size decreases in the nanocomposite, then the thermoexpansivity of nanocomposite increases. The nanocomposite is of best thermoexpansivity when the milling time is up to 100 h. At 35-45 ℃, the nanocomposite shows good thermosensitivity.

Key words:

Cu-based nanocomposite; thermosensitivity; microstructure; thermoexpansivity;

I Introduction

Thermosensitive materials are getting more and more attention in recent years. Now major thermo- sensitive materials, such as shape memory alloy, bimetallic strips and shape memory polymer are based on inherent thermal expansivity or phase- transformation mechanism[1-4]. These materials are solid and limited in thermal expansion and shape. Some liquids and gelatins are studied as thermosensitive materials[5-8], but their intensity is weak. Metal-based/polymer functional nanocomposite is a new type of composite materials which arouses people’s interests in resent years. This kind of material has the merits of both metal (thermoconductivity and electroniconductivity) and polymer (thermoexpansivity), furthermore it’s amorphous. It also can be used as thermosensitive and expansive materials for making driver, gearing and controller, which makes them have great advantages in engineering applications[9-12].

The preparation of Cu nanopowder have been reported[13-16], but the research of metal nanopowder is limited. In this paper, we analyze and discuss the preparation, microstructure and thermoexpansivity of Cu-based thermosensitive nanocomposite prepared by high energy ball milling.

2 Experimental

Some Cu powder (about 0.7 mm in diameter) and organic ester were weighed by using JA1003 electronic balance and mixed in mass ratio of 90 to 10 by QM-1SP ball mill machine with Ar propection at 200 r/min. The samples are tested and analyzed after being milled for 50, 80, 100 or 120 h.

Observation of the microstructure, comparison and ascertainment of the particle dimension of the composite were done by using TEM (Type PHILIPS EM430). The ultrasonic vibration was used to distribute the granule before testing.

The expansivity of materials is measured in the small Cu tube by using thermo-controlled optical micro measuring equipment. The small Cu tube is 5 mm in diameter, 20 mm in length and open in one side end, which limits the material expanding in one direction. The material is put into tube at pressure of 10 N, avoiding air in it. The expansivity of materials is represented by the elongation of sample at certain temperature.

3 Results and analysis

3.1 TEM analysis

In order to ascertain the particulates’ dimension, Cu granule in the composite material was analyzed by TEM. And the ultrasonic vibration is used to distribute the granule in pure ethanol before testinig.1 shows TEM images of the particulates separately after milling for 50, 80, 100 and 120 h. It shows that the particulates are of spherical shape after ultrasonic vibration. After milling for 50, 80, 100 or 120 h, sizes of Cu particulates are about 300, 140, 70 or 30 nm respectively. It’s also proved by the test that the Cu particulates are coated by a layer of organism uniformly. During the TEM analysis, the particulates have some movement when electron beam hits the composite particulates, suggesting the existence of organism because organism starts to melt while being heated by electron beam. Organism which coats the Cu particulates can weaken cold-welding effectively during milling process as a lubricant, and it also forms a layer of protective film which increases stability and antioxidant ability of the Cu nanoparticulates.

Fig.1 TEM images of copper particulates after for milling different times: (a) 50 h; (b) 80 h; (c) 100 h; (d) 120 h

Fig.2 shows the relationship between size of Cu particulates and milling time. Because the impacts of the Cu particulates during milling process, plastical deformation appears, dislocation density increases and crystal grains break up. The Cu particulates become smaller along with the increase of milling time. After milling for 80 h, the refining rate of Cu particulates slows down.

Fig.2 Effects of milling time on size of Cu particulates

3.2 Expansivity analysis

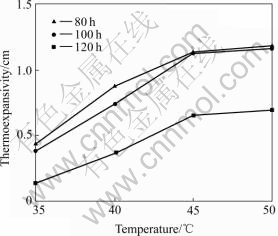

The pipes with the compact materials are heated for 5 min in the open air at 35, 40, 45, 50 and 55 ℃ separately during which the materials are expanded completely and elongated in one side of tube, and then the expansivity of composite materials is measured by using thermo-controlled optical micro measuring equipment. Fig.3 shows the measured results. The composite materials have better expansivity at 35-45 ℃after milling for 80-120 h. The results show that expansivity of materials increases rapidly as the milling time and temperature increase. Above 45 ℃, the expansivity of materials increases slowly when the temperature rises.

Fig.3 Themoexpansivity curve of composite materials milled for different time

The elongated part of materials are repressed into the pipes and heated again several times in constant- temperature water tank at 35, 40, 45, 50 and 55 ℃. The expansitivity is measured 10 times at each temperature. Fig.4 shows the test results for the composites milled for 50 h. As the effect of the heat exchange is better in hot water than in air, the composite materials show better thermosensitivity in hot water. In constant-temperature water tank at 35-45 ℃, expansivity of the composite materials is basically in permissible range of error each time. This shows that the materials can keep almost the same expansivity after heat cycle for some times. Heating the composite materials for long time will make them soft.

Fig.4 Themoexpansivity curve of composite materials at different temperatures

Fig.5 shows the expansivity of the composite particulates after ball milling for 50 h during heating and cooling cycle. The experimental results show that the milling time has great effect on the thermosensitive performance of the composite material and so does the copper particulates. As copper particulates become smaller, the expansivity of composite material increases and reaches the highest value after 100 h ball milling.

Fig.5 Themoexpansivity curve of composite materials at 45 ℃

4 Conclusions

1) Cu-based thermosensitive nanocomposite can be prepared by using high energy ball milling. The sample distributes more uniformly and has nearly spherical shape after using ultrasonic vibration. The organic ester can also cover the Cu nanoparticle completely. After high energy ball milling for 50, 80, 100 or 120 h, the sizes of copper particulates are about 300, 140, 70 or 30 nm, respectively.

2) The composite material has good thermosensitive performance in the temperature range of 35-45 ℃. After heating and cooling circles in constant-temperatured water tank, its expansivity doesn’t change basically.

3) Within 100 h, along with the increase of ball milling time, the thermoexpansivity of the composite material increases. The composite material ball milled for 100 h has better expansivity.

References

[1] ZHU Yu-tian, HAGIWARA I, YASUHIRO M. Research on sensing and control of shape memory alloy embedded in intelligent material [J]. Chinese Journal of Mechanical Engineering. 2005, 41(3): 221-225.

[2] LI Yong-hua, LI Yu-hai, ZHAO Zhong-xing, JIA Wei, DENG Zi-yu. Recent research development of temperature memory effect in TiNi based shape memory alloy [J]. Functional Materials, 2006, 37(4): 650-657.

[3] DONG Jing, CHEN Li, LI Feng-lei. Study on polymerized method of hydrogels with high strength [J]. Functional Materials, 2004, 35(1): 114-116.

[4] JI Shi-dong, WANG Chun-ling. Effect of the form of manganese on the electrical properties of NTC thermister [J]. Electronic Components & Materials, 2005, 24(1): 13-15.

[5] HE Jiang-chuan, LIN Qiang. Synthesis and the properties of micropopous thermo-sensitive hydrogels p(Nipa-co-Sma) [J]. Polymer Materials Science and Engineering, 2005, 21(2): 81-84.

[6] DONG Xiao-chen, HE Ji-dong, WANG Cun-guo, GUO Hong-ge. Newly advances in thermosensitive hydrogel [J]. Plymer Aviso, 2003(4): 53-56.

[7] HAN Zhen-xing, ZHOU Si-jing, LIU Jie, LIU Shi, LIU Jian-jun. Experimental study on color-temperature characteristics of thermochromic liquid crystal [J]. J Engineering Thermophysics, 2005, 26(S6): 203-206.

[8] LI Wei-yong, SONG Bo, CHEN Hua-ting. Study on preparation of thermo-sensitive liposome of ADM [J]. Chin Hosp Pharm J, 2005, 25(5): 439-441.

[9] CHEN Li-hua. Modern Composite Materials [M]. China Materials Publisher, 1998. (in Chinese)

[10] LOU Bai-yan, CHEN Li, LOU Cheng-hua. Discussion about thermosensitive performance of Cu-based composite [J]. Transactions of Yunnan University, 2002, 24(S1): 294-296.

[11] XU Guo-cai, ZHANG Li-de. Nanocomposite Materials [M]. Chemical Industry Publisher, 2002. (in Chinese)

[12] GUO Wei-hong, WANG Li-kui. Modern Functional Materials and Application [M]. Chemical Industry Publisher, 2002. (in Chinese)

[13] XU Li-na, OU Dan-lin, LIU Chun-ping. Preparation and token of Al2O3-centered Cu nanoball [J]. Functional Materials, 2002, 33(3): 278-279.

[14] CHEN Li, LOU Bai-yang, ZHENG Xiao-hua. Study of appearance and dimension of Cu nanopowder [J]. Transactions of Yunnan University, 2002, 24(S1): 187-189.

[15] ZHEN G Jing-wu, JIANG Li-qiang. Study of preparation of Cu powder by using electrolysis [J]. Science and Development of Materials, 2000, 11: 101-103.

[16] ZHAO Bin, LIU Zhi-wu, CAI Meng-jun. Study of stability and preparation of Cu nanopowder using hydrated-hydrazine deoxidization [J]. Transactions of East China University of Science & Technology, 1997, 23(3): 371-376.

Foundation item: Project supported by the Overseas-Returned Researcher Foundation of China

Corresponding author: LOU Bai-yang; Tel: +86-571-88320479; Fax: +86-571-88320130; E-mail: lby00518@163.com

(Edited by YANG Bing)

Abstract: The Cu-based thermosensitive nanocomposites are made by high energy ball milling. The microstructures and properties of Cu-based thermosensitive nanocomposites are studied by transmission electron microscopy(TEM) and themosensitivity test. The effects of milling time on the microstructures and the thermosensitivity of Cu-based nanocomposite material are researched. The results show that the Cu-based nanocomposite can be made by high energy ball milling. As the milling time increases, the copper particle size decreases in the nanocomposite, then the thermoexpansivity of nanocomposite increases. The nanocomposite is of best thermoexpansivity when the milling time is up to 100 h. At 35-45 ℃, the nanocomposite shows good thermosensitivity.