文章编号:1004-0609(2009)11-1908-09

超轻双相镁锂合金的超塑性、显微组织演变与变形机理

曹富荣,丁 桦,李英龙,周 舸

(东北大学 材料与冶金学院 材料成型与控制工程研究所,沈阳 110004)

摘 要:

采用熔铸、大变形轧制(加工率大于92%)和硝酸盐浴退火方法制备Mg-7.83%Li 合金与Mg-8.42%Li合金细晶板材,研究合金的超塑性、显微组织、空洞与断裂形貌和变形机制。计算α相(5.7%Li)和β相(11%Li)的扩散系数和Gibbs自由能,讨论573 K时超塑性晶粒长大的原因。结果表明:Mg-7.83Li和Mg-8.42Li合金分别获得850%和920%的最大超塑性;Mg-7.83Li合金在573 K时发生了显著的超塑性晶粒长大;在573 K和1.67×10-3 s-1条件下制备的Mg-8.42Li合金中的空洞较少,且在变形区中随机而孤立地分布。断裂形貌观察发现Mg-8.42Li合金在573 K和5×10-4 s-1条件下发生穿晶断裂;Mg-7.83Li合金在573 K和1.67×10-3 s-1条件下发生沿晶界韧窝断裂。归一化实验数据与考虑位错数量的变形机制图对比表明合金超塑性变形机制为晶格扩散控制的位错调节的晶界滑移。

关键词:

镁锂合金;超塑性;晶粒长大;原子扩散;热力学;空洞;断裂;变形机制;

中图分类号:TG 146;TG 113 文献标识码:A

Superplasticity, microstructural evolution and deformation

mechanism of super-light two-phase Mg-Li alloys

CAO Fu-rong, DING Hua, LI Ying-long, ZHOU Ge

(Institute of Materials Forming and Control Engineering, School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The fine-grained sheets of Mg-7.83%Li alloy and Mg-8.42%Li alloy were prepared by melting and casting, heavy rolling (reduction more than 92%) and nitrate bath annealing method, and their superplasticity, microstructure, cavitation, fracture morphology and deformation mechanism were investigated. The diffusivities and Gibbs free energy of α phase (5.7%Li) and β phase (11%Li) at 573 K were calculated to discuss the reason of superplastic grain growth. The results show that a few cavitations distribute randomly and isolatedly in the gauge length in Mg-8.42Li alloy at 573 K and 1.67×10-3 s-1. The transgranular fracture appears at 573 K and 5×10-4 s-1 in Mg-8.42Li alloy and dimple fracture along grain boundary appears at 573 K and 1.67×10-3 s-1 in Mg-7.83Li alloy. The maximum superplasticity of 850% and 920% are obtained in Mg-7.83%Li alloy and Mg-8.42%Li alloy. Obvious superplastic grain growth at 573 K appears in Mg-7.83Li alloy. The comparison of normalized experimental data with deformation mechanism map incorporating dislocation quantities inside grains reveals that the dominant deformation mechanisms in two alloys are grain boundary sliding accommodated by slip controlled by lattice diffusion.

Key words: magnesium lithium alloy; superplasticity; grain growth; atomic diffusion; thermodynamics; cavitation; fracture; deformation mechanism

由于镁具有密排六方(HCP)晶体结构和很少的滑移系,所以镁室温下很难变形。因此,大多数镁合金被制成铸件,但是近来变形镁合金,特别是镁锂合金的塑性变形问题引起越来越多的关注[1-3]。根据二元镁锂相图,当锂含量低于5.7%时,仅α相存在;当锂含量大于11%时,仅β相存在;当锂含量介于5.7%和11%之间时,α+β相存在[4]。

超塑性是高温低应变速率下材料表现出大伸长率的能力。超塑性变形是改善成形性的一个良好的途径。FURUI等[5]和LIU等[6]报道了等通道槽挤压(ECAP)的Mg-8Li和Mg-14Li-1Al合金的组织演变和超塑性。SIVAKESAVAM等[7]研究了Mg-Li-Al合金加工图中的超塑性区的特点,还有学者研究了Mg-Li合金与Mg-Li/B/B4C复合材料的高温性能、显微组织和超塑性[8-14]。不同学者[10, 13-14]在Mg-8Li、Mg-8.5Li和Mg-8.3Li-1Zn合金中分别获得580%、630%和840%的超塑性。据报道,在2091铝锂合金中硝酸盐浴退火晶粒细化效果优于空气炉退火效果[15]。而对镁锂合金,以前获得细晶是采用空气炉退火,尚无采用硝酸盐浴退火的报道。

动态晶粒长大或组织不稳定性是超塑性中的一个重要现象。文献[16-17]中报道了超塑性动态晶粒长大的实验工作和模型,其重点是晶界滑动引起的应变诱发晶粒长大,而对超塑性镁锂合金的动态晶粒长大没有引起足够的重视。虽然文献[10, 18-19]中报道了超塑性双相镁锂合金出现的α相长大和β相细化或平均β相含量减少的特殊现象,但是没有工作把它与晶粒长大相联系,也没有阐述其理论原因。空洞和断裂是超塑性中的另一个现象。最近,文献[20-21]中研究了AZ61和Mg-9Li-1Zn合金的空洞特点。

变形机理图为定量描述变形机理指出了一个新方法。文献[22-24]中分别研究了纯铝、奥氏体不锈钢25Cr-20Ni和AZ61和AZ31镁合金超塑性和蠕变过程归一化晶粒尺寸和应力的变形机理图。关于超塑性和蠕变中位错活动的研究已经有大量实验证据和模型报道[25-28],遗憾的是上述机理图[22-24]没有考虑位错变量。因此,有必要把位错引入到机理图的计算和构建中。

在此,本文作者研究了大变形和硝酸盐浴退火的细晶双相Mg-7.83Li 合金和Mg-8.42L合金的超塑性,以期获得更大的伸长率,研究了超塑性晶粒长大并从原子扩散和热力学角度讨论其理论原因,同时研究了双相镁锂合金的空洞和断裂形貌,并在双相镁锂合金中构造晶内位错数量的变形机理图,发现实验数据与理论预测的联系进而揭示变形机理。

1 实验

利用镁和锂熔化和铸造制备Mg-7.83Li 合金和Mg-8.42Li合金铸锭,熔炼在氟化锂和氯化锂熔剂(氟化锂和氯化锂的质量比为1?3)覆盖和氩气保护下在铸铁制坩埚中进行,铸锭在内部水冷的对开式铜模中获得。铸锭在573 K、24 h铣面和均匀化后,进行加工率大于92%的大变形轧制以获得厚1.5 mm的板材,然后经过648 K、30 min硝酸盐浴退火。

拉伸试样从轧制板材上加工获得,试样的拉伸方向平行于轧制方向。在配有加热和保温电炉的日本岛津AG-10电子拉伸机上进行恒夹头速度超塑性拉伸试验,设备温度控制精度在±2 K。试样在573 K保温24 min后以恒定夹头速度变形。

用做光学显微镜(OM)观察的试样被研磨、抛光并在10%盐酸+90%乙醇的溶液中腐蚀,腐蚀后的试样用酒精冲洗,吹干后被放进干燥的容器中,制备的试样在图像分析仪器和光学显微镜上拍照。用做扫描电子显微镜观察的试样按上述方法制备,在SEM505上研究空洞和断裂形貌。用做透射电子显微镜(TEM)观察的试样用金刚砂纸磨到50 μm左右,利用压样机截取直径3 mm的圆盘,采用10%HClO4的乙醇溶液在-15~20 ℃下电解双喷,然后在荷兰产EM400T型透射电子显微镜上观察。晶粒尺寸d = 1.74L,式中L为线截距晶粒尺寸。

2 结果与讨论

2.1 Mg-7.83Li合金和Mg-8.42Li合金变形前的显微组织

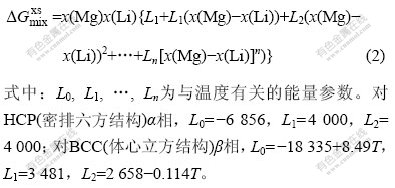

图1所示为Mg-7.83Li合金和Mg-8.42Li合金变形前的显微组织。由图1可知,经648 K、30 min硝酸盐浴退火之后晶粒细小。大变形轧制(加工率大于92%)使双相合金内部储存了大量能量和形核地点。由于硝酸盐浴退火加热速度快,晶粒以高密度进行再结晶形核,从而获得细小的再结晶晶粒。由图1(a)、(b)中可以看到轧制造成的晶粒方向性的“痕迹”,图1(b)中存在一个“虫形”晶粒,而其它晶粒均为细小的等轴晶,这种细小的晶粒组织预示着获得超塑性的可能性。

图1 Mg-7.83Li合金和Mg-8.42Li合金变形前的显微组织

Fig.1 Microstructures of Mg-7.83Li alloy and Mg-8.42Li alloy before superplastic deformation: (a) Mg-7.83Li, 648 K, 30 min nitrate bath annealing, OM; (b) Mg-8.42Li, 648 K, 30 min nitrate bath annealing, OM; (c) Mg-7.83Li, 648 K, 30 min nitrate bath annealing, TEM; (d) Mg-8.42Li, 648 K, 30 min nitrate bath annealing, TEM

2.2 Mg-7.83Li合金和Mg-8.42Li合金的超塑性

图2所示为Mg-7.83Li合金和Mg-8.42Li合金超塑性变形的应力—应变曲线。由图2可见,两种合金在低于峰值应力3.54 MPa和1.9 MPa的应力状态下,获得了较大的应变量,反映了合金在上述细晶组织条件下具有小应力大应变的力学特点。

图2 Mg-7.83Li合金和Mg-8.42Li合金超塑性变形的应 力—应变曲线

Fig.2 Stress versus strain curves of superplastic deformation in Mg-7.83Li alloy and Mg-8.42Li alloy

图3所示为双相合金获得的具最大超塑性的试样照片。从图3可以看出,在573 K和1.67×10-3 s-1初始应变速率下,Mg-7.83Li合金获得了850%的伸长率;在573 K和5×10-4 s-1初始应变速率下,Mg-8.42Li合金获得了920%的伸长率。

图3 双相合金获得的最大超塑性试样的照片

Fig.3 Photos of specimens with maximum superplasticity in two-phase Mg-Li alloys: (a) Original specimen; (b) Mg-7.83Li, 573 K, 1.67×10-3 s-1; (c) Mg-8.42Li, 573 K, 5×10-4 s-1

据m=ε/(2+ε)[29],式中m为应变速率敏感性指数,ε为真应变,ε=ln(1+δ),由δ=850%和920%,分别求得m=0.52和m=0.53,此值接近m=0.5。普遍认为m=0.5是典型超塑性材料的应变速率敏感性指数,预示着晶界滑动是主要的变形机制[12]。另外,δ=850%和920%落在300%~1 000%伸长率之内,300%~1 000%伸长率是经典超塑性变形发生的伸长率[13],表明该实验合金具有经典超塑性变形的特点。

一些研究者在Mg-Li合金中在不同的条件下获得了不同的超塑性。FUJITANI等[10]对Mg-7.81Li合金板在温度573 K和初始应变速率3.3×10-4 s-1条件下获得580%的超塑性。据二元Mg-Li合金相图和金属学杠杆定律,α相体积分数与β相体积分数之比为60?40,超塑性变形前晶粒尺寸为11 μm,由于等轴晶粒尺寸较大,所以微观晶界滑动给出的应变较小,表现为宏观伸长率较低。HIGASHI等[13]对Mg-8.5Li合金板在温度623 K、真应变速率4×10-4 s-1条件下获得610%的超塑性,合金α相体积分数与β相体积分数之比为47?53,超塑性变形前晶粒组织为带状组织,长轴晶粒尺寸为无限长,短轴组织为6.7~17 μm,由于组织由非等轴的晶粒组成,超塑变形时发生动态再结晶,由带状组织变成等轴晶组织,所以宏观伸长率较低。KOJIMA等[14] 对Mg-8.3Li-0.99Zn合金板在温度573 K、初始应变速率4.2×10-4 s-1条件下获得了840%的超塑性,合金α相体积分数与β相体积分数之比为51?49,超塑性变形前晶粒组织为少量的细小晶粒与大量的带状晶粒组成,带状组织长轴晶粒尺寸为有限长为5.8~158 μm,短轴组织为1.9~13 μm。超塑变形时发生动态再结晶—非等轴的晶粒向等轴晶组织的转变,由于短轴晶粒尺寸较小,加上接近50?50的二相比例,所以宏观伸长率较高。

据图1(c)和(d)可得到本实验中两种合金的平均晶粒尺寸为2 μm,主要为等轴晶粒,满足经典超塑性变形晶粒尺寸小于10 μm的组织要求。据二元Mg-Li合金相图和金属学杠杆定律,计算得到Mg-7.83Li合金的α相体积分数与β相体积分数之比为60?40,Mg-8.42Li合金的α相体积分数与β相体积分数之比为49?51。两种合金中α相与β相的相比与50?50比较接近,据等相比例效应(Crane effect),在50?50二相比例时,相界面滑动最活跃,双相合金获得最大超塑伸长率。因此,非常细小的等轴晶尺寸和接近50?50的二相比例是两种合金分别获得850%和920%超塑性的内在原因。结合前述不同作者的数据可以看出,晶粒细小的等轴晶的合金超塑性最大,带状晶粒的合金超塑性次之,晶粒粗大的等轴晶的合金超塑性最小。因此,细小的等轴晶粒是Mg-Li合金获得最大超塑性的关键条件,接近50?50的二相比例是获得较高超塑性的辅助条件。

2.3 Mg-7.83Li合金在不同温度和初始应变速率下超塑性变形后的组织

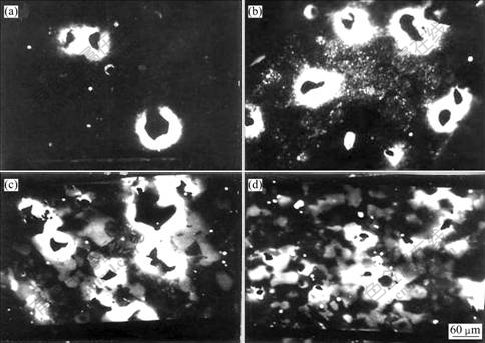

图4所示为Mg-7.83Li合金在不同温度和初始应变速率条件下超塑性变形后的组织。图4中颗粒状相为密排六方晶格的α相,基体相为体心立方晶格的β相。与图1相比,图4中的组织发生晶粒长大。从图4可以看出,当初始应变速率为5×10-4 s-1时,随温度升高,应变诱发的晶粒长大严重。在恒定温度523 K条件下,从图4(c)→(b)→(a),晶粒长大随初始应变速率的降低变化并不明显。在恒定温度573 K条件下,从图4(f)→(e)→(d),晶粒长大随初始应变速率的变化十分明显。这说明573 K温度下合金的晶粒长大比523 K温度下的晶粒长大更加明显。图4(e)所示为与图3(b)中850%超塑性对应的显微照片,可以看出,经过大变形后晶粒组织保持等轴晶的特征,表明合金发生了晶界滑动为主要机制的变形。

图4 Mg-7.83Li 合金在不同温度和初始应变速率条件下超塑性变形后的显微组织

Fig.4 Microstructures of Mg-7.83Li alloy after superplastic deformation at different temperatures and initial strain rates: (a) 523 K, 5×10-4 s-1; (b) 523 K, 1.67×10-3 s-1; (c) 523 K, 1.67×10-2 s-1; (d) 573 K, 5×10-4 s-1; (e) 573 K, 1.67×10-3 s-1; (f) 573 K, 1.67×10-2 s-1

2.4 Mg-7.83Li合金超塑性晶粒长大的原子扩散和热力学分析

由于7.83Li接近8Li(共晶成分),假定Mg-7.83Li合金的显微组织等同于Mg-8Li合金的组织。根据二元Mg-Li合金相图[4],在573 K下Mg-7.83Li合金由平衡的α 相和β相组成,其化学成分分别为5.7Li和11Li。计算确定镁、锂元素和不同相的晶格扩散系数Dl和晶界扩散系数Db,结果如表1所列。

表1 镁、锂元素和不同相的熔点和扩散系数

Table 1 Melting point and diffusivity of Mg, Li elements and different phases

在573 K变形温度下,Li的扩散系数远高于Mg的扩散系数,β相的扩散系数高于α相的扩散系数。如表1所列,在573 K下β相的晶格扩散系数是α相的晶格扩散系数的58倍,β相的晶界扩散系数是α相的晶界扩散系数的1.3倍。据B=D/(kBT),式中B为原子迁移率,D为扩散系数,kB为玻尔兹曼常数,在相同的温度下,原子迁移率之比等于扩散系数之比。因此β相的原子迁移率远高于α相的原子迁移率。由于Li的原子扩散速度较快,β相中出现脱Li现象,根据二元Mg-Li合金相图[4]和金属学杠杆定律,α相分数增加,β相分数减少。由于原子扩散和应变引起的晶界迁移,单个的α晶粒合并,小的α晶粒变成大的α晶粒。SYN等[30]报道了在6090/SiC25p 复合材料的界面上也观察到了脱Li和β相转变成α相的实验现象;双相镁锂合金出现的α长大和β细化或平均β含量减少的特殊现象在文献[10,18-19]中已有实验报道。双相合金中α相的分数增多,α相晶粒长大,β相的分数减少,β相晶粒细化。由于α相分数增多和晶粒长大以及β相分数减少和晶粒细化,α相的晶粒尺寸增加,从而导致显著的晶粒长大。因此,图4中573 K下明显晶粒长大现象是由于α相和β相的原子扩散不同所致。

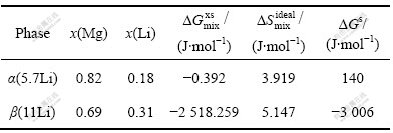

上面分析的573 K时α相体积分数增多和β相体积分数减少情况或文献[19]中报道的高温下平均β相含量减少的实验现象可能与双相合金的热力学稳定性有关。相的稳定性取决于其Gibbs自由能(?G)的变化。?G>0时相稳定,?G<0时相不稳定。根据镁锂相图,假定Mg-7.83Li合金平衡相的化学成分是5.7Li和11Li,即合金由α(5.7Li)和β(11Li)组成,计算两相在573 K的Gibbs自由能。HCP α相和BCC β相的自由能为[31]

![]() 为Gibbs混合过剩自由能:

为Gibbs混合过剩自由能:

α(5.7Li)相和β(11Li)相573 K下自由能计算结果如表2所示。由表2可见,573 K下α(5.7Li)相自由能为140 J/mol(正值),β(11Li)相自由能为-3 006 J/mol(负值)。根据热力学定律,573 K下β相不稳定而α相稳定,这是573 K下α 相分数增多和β相分数减少的热力学原因。因此,不同的扩散系数和热力学特点是Mg-7.83Li合金573 K下明显的晶粒长大的重要原因。

表2 573 K下α(5.7Li)相和β(11Li)相自由能计算结果

Table 2 Free energy calculation for α and β phases at 573 K

2.5 超塑性Mg-8.42Li合金的空洞演变

图5所示为Mg-8.42Li合金在573 K和初始应变速率1.67×10-3 s-1条件下超塑性变形区内空洞演变的SEM像。从图5可见,空洞较少,离散而孤立地分布,呈不规则的形状。CAO等[32]指出,该合金在573 K和初始应变速率1.67×10-3 s-1条件下超塑伸长率为630%, 根据前面m值计算公式,计算出m值为0.498,接近经典超塑性合金典型的m值0.5。由于m值较高,合金变形过程空洞体积分数的增长速率减少,因而空洞数减少,超塑性伸长率较大。高的m值反映了合金抵抗颈缩和空洞发展的能力,既抑制了局部颈缩又抑制了显著的空洞连接。从图3(b)中超塑性试样的照片可以看出颈缩相当小,断裂为完全的扩展性断裂而不是局部颈缩。从图5中几乎看不到明显的空洞连接。上述实验结果与m值的理论预测一致。

图5 Mg-8.42Li合金在573 K和初始应变速率1.67×10-3 s-1时超塑性变形从变形区根部到裂尖的空洞演变SEM像

Fig.5 SEM images of cavitation evolution from deformation root to fracture tip at 573 K and initial strain rate of 1.67×10-3 s-1 in Mg-8.42Li alloy: (a) ε=0, deformation root; (b) ε=1.1, middle section; (c) ε=1.6, middle section; (d) ε=2, near fracture tip

2.6 超塑性Mg-8.42Li合金和Mg-7.83Li合金的断口形貌

图6所示为Mg-8.42Li合金和Mg-7.83Li合金573 K、不同初始应变速率下超塑变形断口的形貌。从图6(a)和(b)可见,Mg-8.42Li合金在573 K、1.67×10-2 s-1和1.67×10-3 s-1条件下发生沿晶界韧窝断裂,而图6(c)表明,在573 K和5×10-4 s-1条件下发生穿晶断裂。与图3(c)中920%超塑性对应的图6(c)在 573 K和5×10-4 s-1条件下发生穿晶断裂的原因分析如下:由于此应变速率下,晶粒长大十分显著(晶粒尺寸达到31.7 μm)[32],晶粒内部位错数量和位错密度增大,造成位错塞积和晶界的应力集中。当应力集中超过断裂应力时,便产生晶界空洞,空洞连接形成裂 纹,裂纹迅速扩展造成穿晶断裂。从图6(d)可见,与图3(b)中850%超塑性对应的Mg-7.83Li合金在573 K、1.67×10-3 s-1条件下发生沿晶界韧窝断裂。

图6 Mg-8.42Li合金和Mg-7.83Li合金在573 K和不同初始应变速率下超塑性变形的断口形貌

Fig.6 Fractographs after superplastic deformation at 573 K and different initial strain rates in Mg-8.42Li alloy and Mg-7.83Li alloy: (a) Mg-8.42Li, 1.67×10-2 s-1; (b) Mg-8.42Li, 1.67×10-3 s-1; (c) Mg-8.42Li, 5×10-4 s-1; (b) Mg-7.83Li, 1.67×10-3 s-1

2.7 Mg-8.42Li合金和Mg-7.83Li合金的超塑性变形机制

通过求解本构方程组,RUANO等[23]提出了超塑性和蠕变的变形机制图。此图缺憾是没有考虑位错变量,因此本文作者将晶粒内部位错数量模型引入参与R-W-S本构方程组计算。

单个晶粒内部位错数量计算公式[33]如下:

本构方程如下[23]:

剪切模量G = 18.4-1.082 4×10-2(T-273),是对文献[9, 11]中的弹性模量数据经处理得到E = 46-2.706×10-2(T-273),并考虑到G = E/2(1+ν)关系可得出,ν = 0.33,b=3×10-10 m。扩散系数模型与处理见附录。

机制图计算按照Mg-8.42Li合金得出。根据Mg-Li合金相图,锂成分变化仅改变相的体积分数,所以对扩散系数影响很小,因此,该计算获得的机制图对Mg-7.83Li合金或其它二元双相Mg-Li合金均适用。

图7所示为573 K下双相Mg-Li合金超塑性和蠕变变形机制图,图中括号里的数据为理论预测的位错数量。图7中显示的变形机制有哈泊-当蠕变、扩散蠕变、晶格扩散控制的晶界滑动、位错管晶界滑动和位错蠕变(应力指数分别为4、5、7)。实验数据落入那个机制区则合金为其变形机制。

图7 双相Mg-Li合金573 K下超塑性和蠕变含位错的变形机制图

Fig.7 Dislocation-incorporation deformation mechanism map of superplasticity and creep at 573 K in two-phase Mg-Li alloys

据图2和图4(e)可知,Mg-7.83Li合金的应力和晶粒尺寸分别为3.54 MPa和19.95 μm,而据图2和文献[32], Mg-8.42Li合金的应力和晶粒尺寸分别为1.9 MPa和31.7 μm,则两个合金归一化应力(σ/G)分别为6.65×104和2.34×10-4,归一化晶粒尺寸(d/b)分别为1.06×105和1.25×10-4。将归一化数据与图7对照,发现数据落入superplastic GBS、DL和σ2区,表明两个合金573 K下超塑性变形的机制为晶格扩散控制的位错调节的晶界滑动。

3 结论

1) 采用大变形轧制和硝酸盐浴退火制备的厚度1.5 mm的Mg-7.83Li 合金与Mg-8.42Li合金板材在573 K及应变速率分别为1.67×10-3 s-1 与 5×10-4 s-1条件下分别获得850%和920%的最大超塑性。

2) 镁、锂元素和α(5.7Li) 相和β(11Li)相不同的原子扩散系数和原子迁移率以及α(5.7Li)相和β(11Li)相Gibbs自由能的差异是出现超塑性晶粒长大现象的理论原因。

3) 在573 K和1.67×10-3 s-1条件下采用扫描电镜观察Mg-8.42Li合金变形区的空洞演变,发现空洞数量较少且孤立而随机地分布。Mg-8.42Li合金在573 K时及1.67×10-2 s-1 和1.67×10-3 s-1条件下发生沿晶界的韧窝断裂,在573 K和5×10-4 s-1条件下发生穿晶断裂。Mg-7.83Li合金在573 K、1.67×10-3 s-1条件下发生沿晶界的韧窝断裂。

4) 573 K下Mg-7.83Li 合金与Mg-8.42Li合金的超塑性变形机制为晶格扩散控制的位错调节的晶界滑动。

附录

晶格扩散系数Dl和晶界扩散系数Db的计算如下。

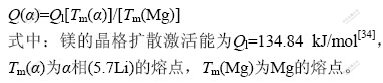

α相(5.7Li)的激活能为

α相晶格扩散系数为

![]()

β相(11Li)的激活能为Ql=14.3RTm,晶格扩散系数为Dl=2.5×10-4exp[-14.3RTm/(RT)][11]。Mg-7.83Li和Mg-8.42Li (α+β)合金的晶格扩散系数为

单相多晶材料的晶界扩散系数为

计算表明文献[26]晶界扩散模型与本文作者处理方法计算的晶界扩散系数差别不大,因此,扩散系数计算可以采用本实验中的处理方法,据文献[4]确定熔点和相体积分数。

REFERENCES

[1] WATANABE H, FUKUSUMI M, ISIKAWA K, SHIMIZU T. Superplasticity in a fullerene-dispersed Mg-Al-Zn alloy composite[J]. Scripta Materialia, 2006, 54: 1575-1580.

[2] DROZD Z, TROJANOVA Z, KUDELA S. Deformation behaviour of Mg-Li-Al alloys[J]. Journal of Alloys and Compounds, 2004, 378: 192-195.

[3] SONG Jenn-ming, WEN Tian-xiang, WANG Jian-yih. Vibration fracture properties of a lightweight Mg-Li-Zn alloy[J]. Scripta Materialia, 2007, 56: 529-532.

[4] NAYEB-HASHEMI A A, CLARK J B, PELTON A D. The Li-Mg (lithium-magnesium) system[J]. Bulletin of Alloy Phase Diagram, 1984, 5: 365-374.

[5] FURUI M, KITAMURA H, ANADA H, LANGDON T G. Influence of preliminary extrusion conditions on the superplastic properties of a magnesium alloy processed by ECAP[J]. Acta Materialia, 2007, 55: 1083-1091.

[6] LIU Teng, WU Shi-ding, LI Sao-xian, LI Pei-jie. Microstructure evolution of Mg-14%Li-1%Al alloy during the process of equal channel angular pressing[J]. Mater Sci Eng A, 2007, 460/461: 499-503.

[7] SIVAKESAVAM O, PRASAD Y V R K. Characteristics of superplasticity domain in the processing map for hot working of as-cast Mg-11.5Li-1.5Al alloy[J]. Mater Sci Eng A, 2002, 323: 270-277.

[8] TROJANOVA Z, DROZD Z, LUKAC P, CHMELIK F. Deformation behaviour of Mg-Li alloys at elevated temperatures[J]. Mater Sci Eng A, 2005, 410/411: 148-151.

[9] TALEFF E M, RUANO O A, WOLFENSTINE J, SHERBY O D. Superplastic behavior of a fine-grained Mg-9Li material at low homologous temperature[J]. Journal of Materials Research, 1992, 7: 2131-2135.

[10] FUJITANI W, FURUSHIRO N, HORI S, KUMEYAMA K. Microstructural change during superplastic deformation of the Mg-8mass%Li alloy[J]. Journal of Japan Institute of Light Metals, 1992, 42: 125-131.

[11] WOLFENSTINE J, GONZALEZ-DOCEL G, SHERBY O D. Elevated temperature properties of Mg-14Li-B particulate composites[J]. Journal of Materials Research, 1990, 5(7): 1359-1362.

[12] GONZALEZ-DOCEL G., WOLFENSTINE J, METENER P, RUANO O A, SHERBY O D. The use of foil metallurgy processing to achieve ultrafine grained Mg-9Li laminates and Mg-9Li-5B4C particulate composites[J]. Journal of Materials Science, 1990, 25: 4535-4540.

[13] HIGASHI K, WOLFENSTINE J. Microstructural evolution during superplastic flow of a binary Mg-8.5wt%Li alloy[J]. Materials Letter, 1991, 10: 329-332.

[14] KOJIMA Y, INOUE M, TANNO O. Superplasticity in Mg-Li alloy[J]. Journal of Japan Institute of Metals, 1990, 54(3): 354-355.

[15] 肖松良. Al-Li合金的发展与历史[D]. 沈阳: 东北大学, 1989: 20-30.

XIAO Song-liang. Development and history of Al-Li alloy[D]. Shenyang: Northeastern University, 1989: 20-30.

[16] 曹富荣, 雷 方, 崔建忠, 温景林. 超塑性晶粒长大模型的修正与实验验正[J]. 金属学报, 1999, 35(7): 770-772.

CAO Fu-rong, LEI Fang, CUI Jian-zhong, WEN Jing-lin. Modification of a deformation induced grain growth model of superplasticity and its experimental verification[J]. Acta Metallurgica Sinica, 1999, 35(7): 770-772.

[17] BATE P. The effect of deformation on grain growth in Zener pined system[J]. Acta Materialia, 2001, 49(8): 1453-1461.

[18] FUJITANI W, HIGASHI K, FURUSHIRO N, UMAKOSHI Y. Effect of Zr addition on superplastic deformation of the Mg-8%Li eutectic alloy[J]. Journal of Japan Institute of Light Metals, 1995, 45(6): 333-338.

[19] MA Ai-bin, NISHIDA Y, SAITO N, SHIGEMATSU I, LIM S W. Movement of alloying elements in Mg-8.5wt%Li and AZ91 alloys during tensile tests for superplasticity[J]. Materials Science and Technology, 2003, 19(12): 1642-1647.

[20] TAKIGAWA Y, AGUIRRE J V, TALEFF E M, HIGASHI K. Cavitation during grain-boundary-sliding deformation in an AZ61 magnesium alloy[J]. Mater Sci Eng A, 2008, 497: 139-146.

[21] KAWASAKI M, KUBOTA K, HIGASHI K, LANGDON T G. Flow and cavitation in a quasi-superplastic two-phase magnesium-lithium alloy[J]. Mater Sci Eng A, 2006, 429: 334-340.

[22] MOHAMED F A, LANGDON T G. Deformation mechanism maps based on grain size[J]. Metal Trans A, 1974, 5: 2339-2345.

[23] RUANO O A, WADSWORTH J, SHERBY O D. Deformation mechanisms in an austenitic stainless steel (25Cr-20Ni) at elevated temperature[J]. Journal of Materials Science, 1985, 20: 3735-3744.

[24] KIM W J, CHUNG S W, CHUNG C S, KUM D. Superplasticity in thin magnesium alloy sheets and deformation mechanism maps for magnesium alloys at elevated temperature[J]. Acta Materialia, 2001, 49: 3337-3345.

[25] ARIELI A, MUKHERJEE A K. A model for the rate-controlling mechanism in superplasticity[J]. Mater Sci Eng, 1980, 45: 61-70.

[26] MUKHERJEE A K. The rate controlling deformation mechanism in superplasticity[J]. Mater Sci Eng, 1971, 8: 83-89.

[27] YAVARI P, LANGDON T G. An examination of the breakdown in creep by viscous glide in solid solution alloys at high stress levels[J]. Acta Metallurgica, 1982, 30: 2181-2196.

[28] SPINGAM J R, NIX W D. A model for creep based on the climb of dislocations at grain boundary[J]. Acta Metallurgica, 1979, 27: 171-177.

[29] SHERBY O D, WADSWORTH J. Development and characterization of fine-grain superplastic materials[C]//. KRAUSS G. Deformation, Processing and Structure. ASM, Metals Park: Ohio, 1982: 355-388.

[30] SYN C K., LESUER D R, SHERBY O D. Enhancing tensile ductility of a particulate-reinforced aluminum metal matrix composite by lamination with Mg-9%Li alloy[J]. Mater Sci Eng A, 1996, 201: 201-206.

[31] SAUNDERS N. Review and thermodynamic assessment of Al-Mg, Mg-Li systems[J]. CALPHAD, 1990, 14(1): 65-70.

[32] CAO Fu-rong, CUI Jian-zhong, WEN Jing-lin, LEI Fang. Mechanical behavior and microstructural evolution of superplastic Mg-8wt pct Li alloy and effect of grain size and phase ratio on its elongation[J]. Journal of Materials Science Technology, 2000, 16(1): 55-58.

[33] ESHELBY J D, FRANK F C, NABARRO F R N A. A dislocation pile-up model[J]. Philosophical Magazine, 1951, 42: 351-355.

[34] BROWN A W, ASHBY M F. Correlations for diffusion constants[J]. Acta Metallurgica, 1980, 28: 1085-1101.

基金项目:国家自然科学基金资助项目(50774023)

收稿日期:2008-12-17;修订日期:2009-08-25

通信作者:曹富荣,副教授,博士;电话:024-83686459;传真:024-83682432;E-mail: cfr-lff@163.com

摘 要:采用熔铸、大变形轧制(加工率大于92%)和硝酸盐浴退火方法制备Mg-7.83%Li 合金与Mg-8.42%Li合金细晶板材,研究合金的超塑性、显微组织、空洞与断裂形貌和变形机制。计算α相(5.7%Li)和β相(11%Li)的扩散系数和Gibbs自由能,讨论573 K时超塑性晶粒长大的原因。结果表明:Mg-7.83Li和Mg-8.42Li合金分别获得850%和920%的最大超塑性;Mg-7.83Li合金在573 K时发生了显著的超塑性晶粒长大;在573 K和1.67×10-3 s-1条件下制备的Mg-8.42Li合金中的空洞较少,且在变形区中随机而孤立地分布。断裂形貌观察发现Mg-8.42Li合金在573 K和5×10-4 s-1条件下发生穿晶断裂;Mg-7.83Li合金在573 K和1.67×10-3 s-1条件下发生沿晶界韧窝断裂。归一化实验数据与考虑位错数量的变形机制图对比表明合金超塑性变形机制为晶格扩散控制的位错调节的晶界滑移。