Annealing behavior of rolled AZ31 alloy sheet

PENG Wei-ping(彭伟平), LI Pei-jie(李培杰), ZENG Pan(曾 攀)

Key Laboratory for Advanced Manufacturing by Materials Processing Technology,

Tsinghua University, Beijing 100084, China

Received 28 July 2006; accepted 15 September 2006

Abstract:

The annealed microstructures of the rolled AZ31 alloy sheets were examined by using light optical microscopy. The mechanical properties were measured by tensile testing, with their crystal orientations analyzed by X-ray diffraction (XRD). After the annealing treatment, the elongated grains were transformed to equiaxed grains with uniform and homogeneous structures. The changes of microstructure decreased the yield strength and enhanced the elongation. The analysis of XRD shows that the AZ31 alloy sheet possesses intense basal-texture, which is weakened during the recrystallization while reinforced during the grain growth. The intense basal-texture induces low ductility, which hence makes the further rolling more difficult. The results indicate that the optimum annealing treatment during AZ31 alloys sheet rolling is at about 300 ℃ for 60-120 min.

Key words:

AZ31 alloys; rolling sheet; annealing treatment; microstructure; mechanical property; crystal orientation;

1 Introduction

Nowadays, the structural applications of magnesium alloys in commercial, aerospace and automobile industries are increasing evidently. The main attractive advantage is their low densities with other excellent properties such as heat dissipating, electro-magnetic shielding, recycling and environment friendly[1-3]. However, due to the hexagonal close packed (HCP) structure, most Mg alloys just have three independent active slip systems under cold deformation conditions, far below the five independent slip systems required for homogeneous deformation. As a result, the low ductility of Mg alloys at room temperature greatly restricts their usage in plastic metal forming. Fortunately, magnesium alloys are readily worked at warm temperatures ranging from 200 to 400 ℃[4-5].

In order to make magnesium alloys become more prevalent in commercial applications, the rolling process is considered to be a potential manufacturing method [6-7]. In addition, proper rolling combined with suitable annealing treatment can produce fine-grained microstructure. Such material’s plastic strain ability is further enhanced to facilitate sheet metal forming. So far, some work on rolling process and annealing treatment of Mg alloys has been carried out[8-10], and the Mg alloy sheets have been proved feasible in industrial applications. However, there are no systematic researches on the annealing treatment during the rolling process of Mg alloy sheets, especially on the relationships among microstructure evolution, mechanical properties, and crystal orientation. For this purpose, the presented study focused on the influence of annealing treatment on the microstructure characters of hot rolled AZ31 alloys. To support these investigations, mechanical testing and crystal orientation characterization were also performed.

2 Experimental

AZ31 alloys were received in as-rolled form, with 1.3 mm in thickness. The main composition is as follows: 2.91% Al, 0.813% Zn, 0.319% Mn and Mg(bal.). Annea- ling treatment was performed in a heating-furnace at 200, 250, 300, 350 and 400 ℃ for 30, 60, 120, 240 and 600 min.

The preparation of samples for optical observations consisted of grinding with fine SiC papers and mechanical polishing with diamond paste. The grain structures were revealed by subsequent etched in a solution of picric acid (5%), acetic acid (10%), and ethanol(85%). Metallurgical structures were observed by Neophot-32 microscope. The average grain size, D, was estimated using the equation, D=1.74L, where L is the linear intercept size.

Uniaxial tensile test was executed at a temperature of 200 ℃ using the tensile mechanical Gleeble-1500D. The gauge length and width of specimens are 20.0 mm×8.0 mm×1.3 mm. The strain rate is kept constant during the test with the rate of 1.6×10-3 s-1 and the tensile direction is parallel to the rolling direction.

X-ray diffraction analysis was carried out in order to investigate the correlation between the tensile mechanical properties and crystal orientation.

3 Results and discussion

3.1 Microstructure and grain size

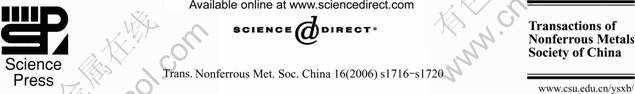

Optical microscopic investigations were carried out on the 1.3 mm-thick AZ31 alloy sheets to characterize the evolution of microstructure and grain size under various annealing treatment conditions. The as-rolled and annealed microstructures are shown in Fig.1. All are in longitudinal section perpendicular to the rolling direction.

Specimens under the as-rolled condition show a fine microstructure with some textures, as shown in Fig.1(a). Many fine recrystallized grains are found to surround the coarse elongated grains, indicating that dynamical recrystallization has taken place during the hot-rolling process and exhibited somewhat inhomogeneity.

It took about 600 min for annealing at 200 ℃ to accomplish the static recrystallization with some extremely fine grains, as shown in Fig.1(b). When annealing at 250, 300, and 350 ℃ for 60-120 min, the grains were transformed to be more equiaxed microstructure, with the texture eliminated. The microstructures of specimens revealed that the grain growth occurred uniformly leading to an improvement of the homogeneity. The grain size of annealed at 300 ℃ exhibited to be somewhat more homogeneous than that of 250 and 350 ℃, as shown in Figs.1(c), (d), and (e).

Fig.1(f) shows the abnormal grain growth at 400 ℃. After annealing treatment at 400 ℃ for 30 min, non-uniform grain growth starts as observed during secondary recrystallization. The abnormally large grains can seriously hurt the mechanical properties, so the higher temperatures were not adopted in the further annealing treatment.

3.2 Tensile mechanical properties

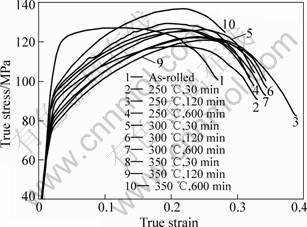

Since the structures of AZ31 alloys annealed at 250, 300, and 350 ℃ seemed to be the best from a microstructure point of view, the mechanical testing has been carried out only for these three temperatures with the annealing time for 30, 120, and 600 min.

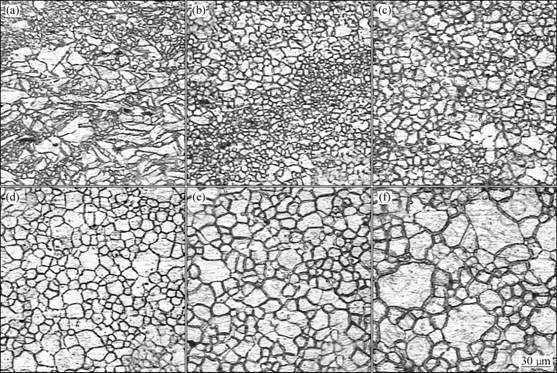

Fig.2 shows the stress—strain curves of the as- rolled and annealed specimens of AZ31 alloys under selected conditions. Fig.3 shows the value of ultimate tensile strength (UTS), yield strength (YS), and elongation (El). Seen from Fig.2, there is no strain hardening observed at as-rolled AZ31 alloys, which could be found in annealed states. The tensile properties of the as-rolled AZ31 alloys are: YS=118 MPa, UTS=129 MPa, and the El=30.1%. Compared with the as-rolled AZ31 alloy sheet, the mechanical properties in the annealed states are restored to a certain extent. The ultimate tensile strength decreased slightly, while the yield strength decreased significantly, with the minimum of 74.7 MPa at 350 ℃ for 120 min, which means the annealing treatment decreasing the yield ratio and improving the ductility of AZ31 alloys sheet. The maximum elongation was 40.2% at 350 ℃ for 30 min.

Fig.1 Evolution of microstructures as-rolled (a), annealed at 200 ℃ for 600 min (b), 250 ℃ for 120 min (c), 300 ℃ for 60 min (d), 350 ℃ for 60 min (e) and 400 ℃ for 30 min (f)

Fig.2 Tensile stress—strain curves of AZ31 under various annealing treatment conditions

Fig.3(a) shows the tensile properties of AZ31 alloy sheet annealed at 250 ℃. It is found that, when the annealing time extended to 120 min, the smallest grain size (GS) was got as 12.1 μm, which means the completion of static recrystallizaiton. The fine grains increased the yield strength, which can be explained qualitatively by Hall-Petch relationship. Figs.3(b) and (c) were the case of 300 and 350 ℃, respectively, with the yield strength being almost the same between 30 min and 120 min, while increasing remarkably after annealed for 600 min. When annealed at 350 ℃ for 30 min, the properties are as follows: YS=79.0 MPa, and GS=18.6 μm, whereas those annealed for 600 min are: YS=91.2 MPa, and GS=22.8 μm, which seems to be contradictory with the Hall-Petch relationship.

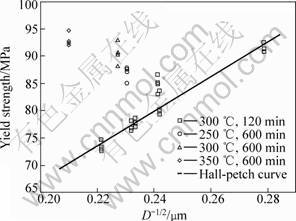

Recrystallized microstructures were observed in the specimens annealed at 250, 300, and 350 ℃. The observation results, combined with the tensile properties, indicate that the tensile yield strength of annealed sheet is largely influenced by the recrystallized grain size. In order to discuss the effect of grain size on the yield strength after annealing, the relationship between the yield strength and the square root of the grain size is shown in Fig.4. The yield strength is proportional to the square root of the grain size, obeying the Hall-Petch relationship, except for the data points of annealed at 250, 300, and 350 ℃ for 600 min. The fitted Hall-Petch equation is

σ=10.3+287D-1/2

where σ is the yield strength(MPa) and D is the grain size(μm). The data points offset to the Hall-Petch curve indicate that the yield strength is affected not only by the grain size but also by the crystal orientation, which was further examined by XRD in the following section.

3.3 Crystal orientation

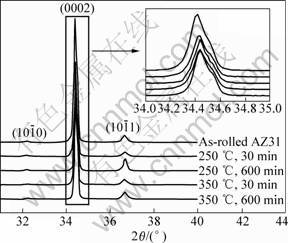

Fig.5 shows X-ray diffraction patterns of the specimens after isothermal annealing under several selected conditions. X-ray diffraction pattern shows a peak confirming that the rolled sheet exhibits preferred orientation in which the (0002) basal plane of AZ31 crystal structure is parallel to the rolling plane. Generally speaking, the intense basal-texture results in low ductility and hence makes the further rolling more difficult[11]. There are slightly differences on the crystal orientation among the selected conditions, which means that the annealing process cannot change the crystal orientation thoroughly.

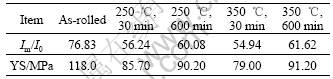

The investigation on crystal orientation was carried out by estimating the magnitude of Im/I0 values, where I0 is a diffraction intensity obtained from standard ASTM value measured using powder sample, and Im is the diffraction intensity obtained from experimental specimens. Consequently, it indicates that the higher the Im/I0 value is, the stronger the crystal orientation is. Table 1 shows the intensity of X-ray diffraction peaks from (0002) planes and the relevant yield strength of specimens annealed at 250 and 350 ℃ for 30 and 600 min. The difference of the crystal orientation influenced the tensile properties largely, especially to the yield strength.

Fig.3 Mechanical properties of rolled AZ31 after annealing at 250 ℃ (a), 300 ℃ (b) and 350 ℃ (c)

Fig.4 Hall-Petch relationship between yield strength and grain size in annealed states

Fig.5 XRD patterns of selected specimens after annealing treatment

Table 1 Basal plane orientation and yield strength of tensile specimens

According to the microstructure evolution, the annealing treatment is divided into two stages. The first stage is the recrystallization process, which is finished within 60 min at 250, 300, and 350 ℃. The following stage is the grain growth. Seen from Table 1, when annealed at 250 and 350 ℃ for 30 min, the Im/I0 values of (0002) basal plane reduced from 76.83 to 56.24 and 54.94, respectively. When annealed for 600 min, the Im/I0 values increased to 60.08 and 61.62, both of these are smaller than 76.83 the as-rolled AZ31 alloys. The results indicated that the basal-texture is weakened during the recrystallization, however, it is reinforced during the grain growth. The similar phenomenon was also observed at hot rolled AZ31[12] and extruded AZ61 alloy sheet[13].

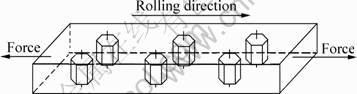

Fig.6 illustrates the orientation of tensile specimens with respect to the deformation and crystallographic reference frames. If the basal plane is parallel to the rolling direction, its Schmid factors will be nearly zero when the tensile direction is paralleled to the rolling direction. When the deformation temperature is blew 225℃, the operating slip system of AZ31 alloys is (0002) basal plane. Thus, it is estimated that the yield strength of AZ31 alloys annealed at 250 and 350℃ for 600 min is higher than that of the corresponding specimens annealed for 30 min, as shown in Table 1, because it is difficult for basal plane slip to operate in the longer annealed alloys. This is why the data points of annealing at 250, 300,350 ℃ for 600 min in Fig.4 are higher than those anticipated from the Hall-Petch curve.

Fig.6 Orientation of tensile specimens with respect to deformation and crystallographic reference frames

4 Conclusions

1) Within the scope of the present study, the microstructure evolution after annealing treatment of as-rolled AZ31 alloys has been carried out. The microstructures of specimens reveal that the grain growth occurs uniformly, leading to an improvement of the homogeneity at about 300 ℃. The change of the microstructure decreases the yield strength and increases the elongation. The mechanical properties are affected not only by the grain size but also by the crystal orientation.

2) Under the annealing treatment, the basal-texture is weakened during the recrystallization, however, it is enhanced during the grain growth. The intense basal-texture results in low ductility and hence makes the further rolling more difficult, so the annealing treatment should hold for a proper time around 60-120 min.

3) Concerning the adopted magnesium alloy sheets, the optimal annealing treatment condition is about 300 ℃ for 60-120 min.

References

[1] AGHION E, BRONFIN B. Magnesium alloys development towards the 21st century[J]. Materials Science Forum, 2000, 350/351: 19-28.

[2] FRIEDRICH H, SCHUMANN S. Current and future use of magnesium in the automobile industry[J]. Materials Science Forum. 2003, 419/422: 51-56.

[3] KOJIMA Y, AIZAWA T, KAMADO S, HIGASHI K. Progressive steps in the platform science and technology for advanced magnesium alloys[J]. Materials Science Forum, 2003, 419/422: 3-20.

[4] KOIKE J, OHYAMA R, KOBAYASHI T, et al. Grain-boundary sliding in AZ31 magnesium alloys at room temperature to 523 K[J]. Materials Transactions, 2003, 44: 445-451.

[5] IWANAGA K, TASHIRO H, OKAMOTO H, SHIMIZU K. Improvement of formability from room temperature to warm temperature in AZ31 magnesium alloy[J]. Journal of Materials Processing Technology, 2004, 155/156: 1313-1316.

[6] YIN D L, ZHANG K F, WANG G F, HAN W B. Warm deformation behavior of hot-rolled AZ31 Mg alloy[J]. Mater Sci Eng A, 2005, A392: 320-325.

[7] HU Xiao-dong, JU Dong-ying. Effect of casting parameters and deformation on microstructure evolution of twin-roll casting magnesium alloy AZ31[J]. Trans Nonferrous Met Soc China, 2006, 16(1): 74-77.

[8] DZWONCZYK J, BOHLEN J, HORT N, KAINER K U. Influence of heat treatment on microstructure of hot extruded AZ31[J]. Materials Science Forum, 2003, 419/422: 297-302.

[9] BARNETTA M R, NAVE M D, BETTLES C J. Deformation microstructures and textures of some cold rolled Mg alloys[J]. Mater Sci Eng A, 2004, A386: 205-211.

[10] YANG X Y, MIURA H, SAKAI T. Isochronal annealing behavior of magnesium alloy AZ31 after hot deformation[J]. Mater Trans, 2005, 46(2): 2981-2987.

[11] HUANG C C, HUANG J C, LIN Y K. Basal-Texture induced low formability during room temperature hydroforming of fine-grained AZ31 Mg tubes[J]. Materials Transaction, 2004, 45(11): 3142-3149.

[12] KIM S H, YOU B S, YIM C D, SEO Y M. Texture and microstructure changes in asymmetrically hot rolled AZ31 magnesium alloy sheets[J]. Materials Letters, 2005, 59: 3876-3880.

[13] PEREZ-PRADO M T, RUANO O A. Texture evolution during grain growth in annealed Mg AZ61 Alloy[J]. Scripta Materialia, 2003, 48: 59-64.

(Edited by YANG Hua)

Foundation item: Project(2002AADF3306) supported by the International Cooperation and Exchanges NSFC of China

Corresponding author: LI Pei-jie; Tel: +86-10-62773639; E-mail: Lipj@mail.tsinghua.edu.cn