DOI:10.19476/j.ysxb.1004.0609.2017.12.20

真空烧结泡沫304不锈钢吸声性能

刘培生1, 2,徐新邦1, 2,孙进兴1, 2,崔 光1, 2

(1. 北京师范大学 核科学与技术学院 射线束技术教育部重点实验室,北京 100875;

2. 北京市辐射中心,北京 100875)

摘 要:

利用挂浆工艺,在1050 ℃下真空烧结3 h,成功制备三维网状的泡沫304不锈钢,制品烧结良好。样品平均孔径约1.8 mm,孔隙率约93.7%。测试该泡沫金属在200~6300 Hz及其加入背腔后在2500~4000 Hz时的吸声系数, 探讨背腔对样品吸声性能的影响。结果表明:本制品在测试范围的中高频段表现出较好的吸声效果,其第一共振频率为4000 Hz,此时最大吸声系数约0.7;在1250~3150 Hz之间,增加样品厚度可明显提高吸声效果;加入背腔可大幅度提高样品的整体吸声效果。

关键词:

文章编号:1004-0609(2017)-12-2560-07 中图分类号:TG146 文献标志码:A

噪声不但可以对仪器和设备的正常工作发生影响,还会对人们的身心健康产生危害。利用多孔材料进行吸声处理是解决噪声问题的一项有效措施[1-6]。多孔吸声材料包括聚合物类泡沫材料、玻璃棉等无机多孔材料以及后来的多孔泡沫金属材料,其中前两类吸声材料应用较早,而且更为广泛。泡沫金属具有比聚合物类泡沫材料更高的强度以及更好的耐热性和防火性,同时不会有玻璃棉等无机多孔材料易于破碎扬尘而污染环境的缺点,因此在实际使用过程中可体现自身的独特优势[3-4]。由于受到产品制造难易程度等因素的制约,实际应用的泡沫金属大多是泡沫铝等适于大规模制造的泡沫材料。但是,仍然不乏一些用其他金属成分作为基质的泡沫金属研究,例如,泡沫不锈钢就是其中的一种。这主要是由于不锈钢具有更高的熔点、更好的延展性以及一定的耐腐蚀性能[7]。相对于泡沫铝,泡沫不锈钢具有一些潜在的优势,包括与广泛使用的钢结构的兼容性和更高的工作温度等。业内对常用不锈钢316系列的泡沫材料进行了研究,取得了一些成果:如采用前驱体挂浆高纯氩气保护烧结的方式研制泡沫316L不锈钢[8-9];通过选区激光熔化工艺研制多孔316L不锈钢[10-12];利用松装粉末冶金工艺研制316不锈钢开孔泡沫[13];利用造孔剂的粉末烧结法研制泡沫316不锈钢[14];利用尿素作为造孔剂的烧结水滤工艺制造孔隙率为70%的多孔316L不锈钢[15];运用分形理论研究多孔316L不锈钢材料[16];研究孔隙率为85%且孔径在70~440 μm的316L不锈钢泡沫的生物相容性问题[17];还研究了烧结316不锈钢泡沫的疲劳问题[18]。

对于泡沫金属声学性能的研究,已有工作主要是集中于泡沫铝,并取得了比较丰富的研究成果[3-4, 19-32]:其中由熔体发泡法制备的泡沫铝为胞状闭孔结构,声波难于传入,可通过增加一道打孔处理的工序来获得较好的吸声效果[19, 21];采用渗流法制备的泡沫铝为胞状开孔结构,利于声波传入,但应注意洗脱盐粒易残留而腐蚀制品,此外洗出液还需再处理以免污染环境中的水体[20, 22-24]。相对而言,对非铝质泡沫金属的声学性能研究则很少[33-35]。例如,对于泡沫不锈钢的声学应用及其相关研究就是这样。304不锈钢是除316不锈钢之外的另一种常用牌号,本文作者对该不锈钢成分的泡沫材料开展工作,在研制其网状多孔产品的基础上,初步探讨了该泡沫材料及其复合结构的吸声性能。

1 实验

1.1 泡沫不锈钢的制备

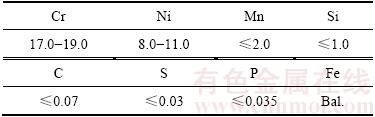

作为原料的304不锈钢是一种通用性的不锈钢材料,具有良好的耐蚀性和耐高温性能(使用温度可达650 ℃),对氧化性酸(如浓度≤65%的硝酸)、碱溶液及大部分有机酸和无机酸都具有很好的耐腐蚀能力。因此,304不锈钢成为应用最广泛的耐热不锈钢,可用于食品生产设备、化工设备、核能设备等。选用北京蒙泰有色金属研究技术开发中心生产的304不锈钢粉末(<48 μm)来制备泡沫不锈钢, 其化学成分见表1。

表1 原材料304不锈钢粉末的化学成分

Table 1 Chemical composition of raw material powder (mass fraction, %)

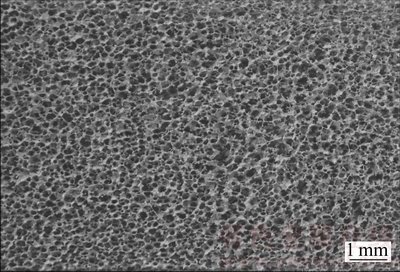

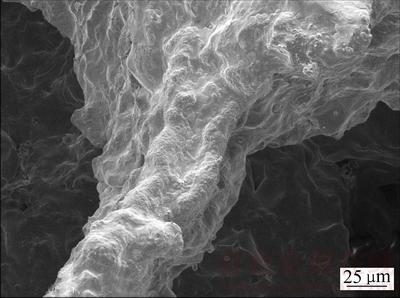

采用浸浆烧结工艺(挂浆法),先将原料粉末和粘结剂按体积比1:2混合、搅拌均匀,配制成浆料;用通孔聚氨酯硬质泡沫(平均孔径约为1.8 mm)进行浸浆处理,制成预制体。然后将处理过的预制体样品放置于干燥箱中,在100 ℃下烘干4 h。最后,将干燥过的预制品在真空环境中于1000~1100℃下烧结2~3 h,制得三维网状的高孔隙率泡沫不锈钢样品。具体的热处理过程如下:先在室温(25 ℃)下抽真空至压力小于5.0×10-3 Pa,再用0.5 h升温至120 ℃,保温2 h并持续抽真空以充分去除水分;然后以10 ℃/min左右的升温速率将温度从120 ℃直接升到1050 ℃,保温3 h以使不锈钢粉末充分烧结。完成后关机炉冷。所得样品宏观形貌见图1,其多孔结构中孔棱的微观形态见图2。从图2可以看出,不锈钢粉末经过本热处理过程的烧结性良好,颗粒间的结合充分。

图1 浸浆烧结法制备的泡沫不锈钢样品宏观形貌

Fig. 1 Macroscopic morphology of 304 stainless steel foam prepared by slurry sintering

图2 本泡沫不锈钢样品的SEM像

Fig. 2 SEM image of stainless steel foam

1.2 泡沫不锈钢样品参数测定

1) 孔径

测定多孔材料孔径的方法很多,主要有压汞法、气泡法、透过法、气体渗透法、气体吸附法和显微分析法等[3-4]。鉴于本泡沫不锈钢样品的孔隙尺寸在毫米量级的水平,采用显微分析法来测量其孔径。首先制备出断面尽量平整的多孔样品,然后用显微镜数出断面在一定长度内的孔隙数目,从而得出样品孔隙的平均弦长L,再通过如下关系计算出样品的平均孔径D:

D ≈ L/0.616 (1)

由此测得本泡沫不锈钢样品的平均孔径约为1.8 mm。

2) 孔隙率

测定多孔材料孔隙率的方法主要有质量/体积直接计算法、浸泡介质称重法、漂浮法和显微分析法等[3-4]。利用质量/体积直接计算法来测量。先后将试样用丙酮超声清洗、清水超声清洗、酒精超声清洗各10 min,烘干后用精度为0.01 g的电子天平称取质量m;将称好的试样进行浸蜡封孔处理,并仔细清理试样表面多余的蜡质,然后利用排液法测出试样体积V。最后通过如下关系计算出样品的孔隙率θ:

θ = 1-(m/V)/ρs (2)

式中:ρs为多孔样品对应致密固体的体密度。由此测得本泡沫不锈钢样品的孔隙率约为93.7%。

1.3 吸声性能测试

采用由北京市世纪建通科技发展有限公司生产的JTZB吸声系数测试系统,对本泡沫不锈钢样品及其复合结构进行系列测试。采用1/3倍频程法[36],选取的中心频率为200、315、400、500、630、800、1000、1250、1600、2000、2500、3150、4000、5000和6300 Hz。根据设备的要求,用于低频段200~2000 Hz测试的圆形样品直径为100 mm,用于中频段2500~4000 Hz的样品直径为50 mm,用于高频段5000~6300 Hz的样品直径为25 mm。

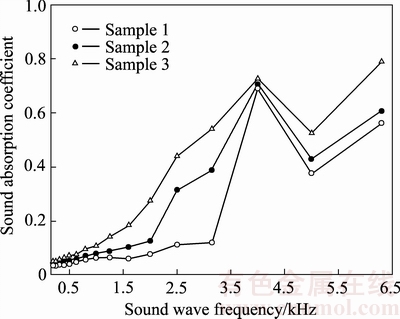

为了研究泡沫不锈钢的厚度变化对样品吸声系数的影响,制备了厚度为9 mm、18 mm和27 mm共3个规格的样品,分别依次称为样品1、2、3。由于受驻波管长度的限制,用于测试中频和高频情况的样品厚度相应减少。

2 结果与讨论

2.1 泡沫不锈钢的吸声性能

不同泡沫不锈钢样品在不同声频下的吸声系数测试结果见图3。从图3可以看出,样品1在低频下的吸声效果不佳,从250 Hz到3150 Hz的吸声系数均低于吸声材料定义的平均吸声系数0.2。中高频下吸声效果良好,从4000 Hz起吸声系数均超过0.2,且当声波频率达到4000 Hz时出现第一共振频率,最大吸声系数为0.69。样品2、3与样品1的吸声曲线相似。在相同声波频率下,随着样品厚度的增加,吸声系数增大,特别是在1250~3150 Hz频段的吸声效果相对增幅十分明显。样品2的吸声系数到2500 Hz时开始高于0.2,样品3则在2000 Hz下即达到0.36,且第一共振频率都为4000 Hz;此时出现最大吸声系数,而且数值都大致相同,在0.7左右。

刚性泡沫金属的吸声机制主要是孔隙内流体与孔壁摩擦的粘滞耗散以及孔隙表面漫反射的干涉消音,而材料本身的阻尼衰减相对较弱。研究表明,对于200~6300 Hz这样一个声频范围,泡沫金属在声频较低时的主要吸声机制是通过孔隙表面反射的干涉消音,而在声频较高时则是粘滞耗散[37]。孔棱/孔壁表面越粗糙,声波在泡沫体内部传播时与孔壁发生作用的面积也就越大,因此孔壁摩擦越大,粘滞损耗越多,能量损耗越大;而且声波在孔壁上发生反射、折射的次数也越多[20]。因此,泡沫体吸声效果越好。图2即显示了本泡沫不锈钢比较粗糙的孔棱表面,这有利于该多孔体的吸声。尽管如此,高孔隙率的网状泡沫金属具有的比表面积终究还是较小的,因此能够提供给空气与孔壁之间发生相互摩擦和粘滞的场所就会较少,吸声性能也就受到限制。所以,要提高该多孔产品的吸声效果,特别是其低频段的吸声效果,就得对其采取加背腔等措施以组成对应的复合结构。

图3 样品1、2、3的吸声系数曲线

Fig. 3 Sound absorption coefficient curves of samples 1, 2 and 3

2.2 加背腔组成复合结构的吸声性能

为了提高整体吸声效果,可以在本泡沫不锈钢板状样品后面设置空腔(背腔)。这是一种常用的方式。在JTZB吸声系数测试系统中,样品加背腔即是在样品与驻波管刚性后壁之间保留一定厚度的空隙。由于测试设备、样品规格以及整体吸声结构的建构等因素的限制,并考虑到人耳对声波的敏感区域,本工作只选择在2500~4000 Hz这一频段做了该实验。为了使样品在驻波管中稳定地安装并造出适当的空腔,首先制备出外径略小于50 mm、内径为40 mm、厚度约3.5 mm的有机玻璃质圆环(圆环宽度5 mm)。在测试过程中,将圆环放在样品与刚性壁之间,即可在样品后面造出空腔。通过多层圆环叠加的方式可以调节空腔的厚度,每层的厚度即为圆环的厚度3.5 mm。

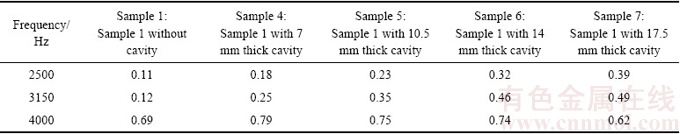

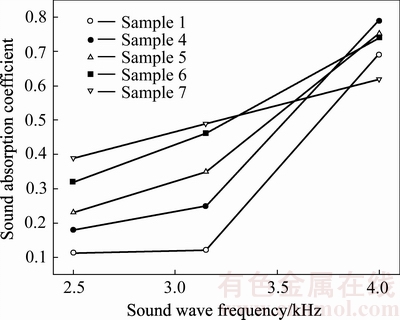

采用厚度最小的样品1为例加背腔的方式,在中频段测得的吸声系数测试结果见表2和图4。结果显示,在2500~3150 Hz的频率范围内,样品的吸声系数随空腔厚度的增加而渐次提高;在3150~4000 Hz之间,吸声系数随频率增大而提高,但空腔厚度的作用呈交错变化。大约3500 Hz后所有吸声系数都超过0.5;到4000 Hz时吸声系数在0.6~0.9之间。这是由于共振频率发生偏移引起的结果:不同的空腔厚度造成的共振频率偏移各不相同,而总体上是显著提高结构的吸声效果。

表2 泡沫不锈钢样品1加空腔的吸声系数测试结果

Table 2 Tested results of sound absorption coefficient of sample 1 with back cavity

图4 样品1加背腔后在中频段的吸声系数曲线

Fig. 4 Sound absorption coefficient curves of sample 1 with back cavity at middle frequencies

在文献[38-40]中,给出了声波正入射时带有空腔的穿孔板吸声体系的吸声系数:

(3)

(3)

式中:r为穿孔板的相对声阻率;ω为入射声波的角频率,rad/s,ω=2πf,其中f是入射声波的频率,Hz;m为穿孔板的相对声质量;ωm为穿孔板的声抗比;D为空腔的厚度,即穿孔板到刚性壁的距离;c0为声波在空气中的传播速度,常温下c0 ≈340 m/s。可见,空腔厚度对吸声系数的影响与声频有关,而且存在周期性的规律。因此,只有对所在频段合适的空腔厚度才能最大限度地提高吸声结构的吸声性能。把泡沫金属板视为一种特殊结构的穿孔板模式,可以得出类似的结果,即某一确定声频下吸声系数也会随空腔厚度呈现周期性的变化。

吸声峰对应穿孔板的共振频率(f0)为[41-42]:

(4)

(4)

式中:P为穿孔率(穿孔面积与总面积之比,%);t为板厚,m;δ为孔口末端修正值,m,可表示为δ=kd,其中,k为穿孔板系统的结构常数(无量纲),d为穿孔孔径,m;c0和D的意义同上式,即分别为声速,m/s和板后空腔厚度,m。

对于本节实验中的样品,用式(4)计算时只有D不同,其他参数均相同。可见,随着空腔厚度的增加,样品的共振频率逐渐减小,即增加空腔厚度使得共振频率向低频移动。这与图4中不同空腔厚度下的吸声系数曲线相对应,即增加空腔厚度使得在较低频率下的吸声系数得到更多的提高。

需要注意的是,加背腔后位于4000 Hz的吸声峰高度出现异常变化,因此将测试频率上限扩大至6300 Hz以找出其原因是一项很有意义的工作。但由于当时实验条件的限制,暂未能开展这一研究,准备留待以后的合适时机去做。

3 结论

1) 浸浆烧结工艺可以成功制备泡沫304不锈钢,所得样品呈三维网状结构,其平均孔径约为1.8 mm,孔隙率约为93.7%。其在中低频段(250~3150 Hz)的吸声效果不佳,而中高频段(4000~6300 Hz)下的吸声效果良好;厚度为9~27 mm的样品均在4000 Hz时出现第一共振频率,最大吸声系数的数值都大致相同,为0.7左右。在1250~3150 Hz这一频段,样品的吸声系数随着厚度增加的相对提高幅度最为明显。

2) 加入背腔可以显著提高本泡沫不锈钢样品的吸声效果,但随声频的不同,其作用程度会发生变化。此外,背腔的增加不但影响样品的吸声系数,还使得样品的共振频率发生偏移,从而出现一定频率下背腔厚度增加,样品吸声系数反而下降的情况。

REFERENCES

[1] Allard J F, Atalla N. Propagation of sound in porous media: Modelling sound absorbing materials[M]. New York: Elsevier Science, 2009.

[2] Sun Peng, Guo Zhan-cheng. Sintering preparation of porous sound-absorbing materials from steel slag[J]. Transaction of Nonferrous Metals Society of China, 2015, 25(7): 2230-2240.

[3] 刘培生, 陈 祥, 李言祥. 泡沫金属[M]. 长沙: 中南大学出版社, 2012.

LIU Pei-sheng, CHEN Xiang, LI Yan-xiang. Metal foams[M]. Changsha: Central South University Press, 2012.

[4] Liu P S, Chen G F. Porous Materials: Processing and applications[M]. Boston: Elsevier Science, 2014.

[5] Oliva D, Hongisto V. Sound absorption of porous materials- Accuracy of prediction methods[J]. Appl Acoust, 2014, 74(12): 1473-1479.

[6] Duan C Y, Cui G, Xu X B, Liu P S. Sound absorption characteristics of a high-temperature sintering porous ceramic material[J]. Appl Acoust, 2012, 73(9): 865-871.

[7] Park C, Nutt S R. PM synthesis and properties of steel foams[J]. Materials Science and Engineering A, 2000, 288(1): 111-118.

[8] 周向阳, 龙 波, 李 劼, 刘宏专. 前驱体制备对三维通孔不锈钢泡沫性能的影响[J]. 中国有色金属学报, 2006, 16(9): 1615-1620.

ZHOU Xiang-yang, LONG Bo, LI Jie, LIU Hong-zhuan. Effects of precursor preparation on performances of stainless steel foam with 3-D open cells network structure[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1615-1620.

[9] 周向阳, 龙 波, 李 劼. 烧结制度对三维通孔不锈钢泡沫性能影响[J]. 粉末冶金技术, 2006, 24(6): 445-452.

ZHOU Xiang-yang, LONG Bo, LI Jie. The effects of sintering schedule on the performance of stainless steel foam with3-D open-celled network structure[J]. Powder Metallurgy Technology, 2006, 24(6): 445-452.

[10] 王志阳, 沈以赴, 顾冬冬, 于秀平. 蜂窝状多孔316L不锈钢的选区激光熔化制备[J]. 稀有金属材料与工程, 2011, 40(1): 161-164.

Wang Zhi-yang, Shen Yi-fu, Gu Dong-dong, YU Xiu-ping. Preparation of honeycomb-like porous 316L stainless steel by selective laser melting[J]. Rare Metal Materials and Engineering, 2011, 40(1): 161-164.

[11] 李 鹏, 刘 斌. 空间网格状多孔316 不锈钢的选区激光熔化制备[J]. 热加工工艺, 2013, 42(8): 50-52.

LI Peng, LIU Bin. Selective laser melting process of space gridded porous 316 stainless steel[J]. Hot Working Technology 2013, 42(8): 50-52.

[12] Xie F X, He X B, Cao S L, Qu X H. Structural and mechanical characteristics of porous 316L stainless steel fabricated by indirect selective laser sintering[J]. Journal of Materials Processing Technology, 2013, 213(6): 838-843.

[13] Kaya A C, Fleck C. Deformation behavior of open-cell stainless steel foams[J]. Materials Science and Engineering A, 2014, 615: 447-456.

[14] Mondal D P, Jain H, Das S, Jha A K. Stainless steel foams made through powder metallurgy route using NH4HCO3 as space holder[J]. Materials & Design, 2015, 88(12): 430-437

[15] Bakan H I. A novel water leaching and sintering process for manufacturing highly porous stainless steel[J]. Scripta Materialia, 2006, 55(2): 203-206.

[16] Tang H P, Wang J Z, Zhu J L, Ao Q B, Wang J Y, Yang B J, Li Y N. Fractal dimension of pore-structure of porous metal materials made by stainless steel powder[J]. POWDER TECHNOLOGY, 2012, 217: 383-387.

[17] Kato K, Yamamoto A, Ochiai S, Wada M, Daigo Y, Kita K, Omori K. Cytocompatibility and mechanical properties of novel porous 316L stainless steel[J]. Materials Science & Engineering C, 2013, 33(5): 2736-2743.

[18] Falkowska A, Seweryn A. Fatigue of sintered porous materials based on 316L stainless steel under uniaxial loading[J]. Materials Science, 2015, 51(2): 200-207.

[19] 梁李斯, 姚广春, 穆永亮, 华中胜. 组合形式对打孔闭孔泡沫铝板吸声效果的影响[J]. 中国有色金属学报, 2011, 21(9): 2132-2137.

LIANG Li-si, YAO Guang-chun, MU Yong-liang, HUA Zhong-sheng. Effect of combining form on sound absorption of closed-cell aluminum foam perforated[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2132-2137.

[20] 胡 松, 左孝青, 谢香云, 陆建生, 周 芸, 刘荣佩. 特殊孔结构 ZA27合金泡沫的吸声性能[J]. 中国有色金属学报, 2014, 24(11): 2798-2804.

HU Song, ZUO Xiao-qing, XIE Xiang-yun, LU Jian-sheng, ZHOU Yun, LIU Rong-pei. Sound absorption properties of ZA27 alloy foams with particular pore structures[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2798-2804.

[21] 袁文文, 李言祥, 陈 祥. 穿孔法改进泡沫铝的吸声性能[J]. 中国有色金属学报, 2010, 21(1): 138-144.

YUAN Wen-wen, LI Yan-xiang, CHEN Xiang. Improving sound absorption of aluminum foams by drilling holes[J]. The Chinese Journal of Nonferrous Metals, 2010, 21(1): 138-144.

[22] 刘伟伟, 何思渊, 黄 可, 何德坪. 孔结构周期调制通孔多孔铝合金及其吸声性能[J]. 材料研究学报, 2009, 23(2): 171-174.

LIU Wei-wei, HE Si-yuan, HUANG Ke, HE De-ping. Sound absorption of periodic porous aluminum with controlled pore structures[J]. Chinese Journal of Materials Research, 2009, 23(2): 171-174.

[23] 王录才, 曾松岩, 王 芳. 复合结构泡沫铝隔声性能的研究[J]. 机械工程材料, 2006, 30(10): 56-58.

WANG Lu-cai, ZENG Song-yan, WANG Fang. Sound insulation property of aluminum foam composite structure[J]. Materials for Mechanical Engineering, 2006, 30(10): 56-58.

[24] 谢香云, 左孝青, 王应武, 钟子龙, 董晓蓉. 特殊孔结构Al-Si12泡沫铝的吸声性能研究[J]. 稀有金属材料与工程, 2013, 42(8): 1649-1653.

XIE Xiang-yun, ZUO Xiao-qing, WANG Ying-wu, ZHONG Zi-long, DONG Xiao-rong. Sound absorption properties of Al-Si12 foams with particular pore structures[J]. Rare Metal Materials and Engineering, 2013, 42(8): 1649-1653.

[25] Yu Hai-jun, Li Bing, Yao Guang-chun, Wang Xiao-lin, Luo Hong-jie, Liu Yi-han. Sound absorption and insulation property of closed-cell aluminum foam[J]. Transaction of Nonferrous Metals Society of China, 2006, 16(S3): s1383-s1387.

[26] Wang Lu-cai, Wang Fang, WU Jian-guo, You Xiao-hong. Sound absorption property of open-pore aluminum foams[J]. Transaction of Nonferrous Metals Society of China, 2006, 16(S3): s1446-s1449.

[27] Wang X F, Wei X, Han F S, Wang X L. Sound absorption of open celled aluminium foam fabricated by investment casting method[J]. Materials science and technology, 2011, 27(4): 800-804.

[28] Srinath G, Vadiraj A, Balachandran G, Sahu S N, Gokhale A A. Characteristics of aluminium metal foam for automotive applications[J]. t indian i metals 2010, 63: 765-772.

[29] Chevillotte F, Perrot C, Panneton R. Microstructure based model for sound absorption predictions of perforated closed-cell metallic foams[J]. Journal of the acoustical society of america, 2010, 128(4): 1766-1776.

[30] Betts C. Benefits of metal foams and developments in modelling techniques to assess their materials behaviour: A review[J]. Mater sci technol, 2012, 28(1): 129-143.

[31] Ko Y H, Son H T, Cho J I, Kang C S, Oh I H, Lee J S, Kim H M, Kim J C. Investigation on the sound absorption and transmission for aluminum foam and its composite[J]. Solid State Phenomena, 2007, 124/126: 1825-1828.

[32] Navacerrada M A, Fernandez P, Diaz C, Pedrero A. Thermal and acoustic properties of aluminium foams manufactured by the infiltration process[J]. Appl Acoust, 2013, 74: 496-501.

[33] 刘培生, 侯红亮, 顷淮斌, 王耀奇, 张艳玲. 网状结构的高孔率泡沫钛特性研究[J]. 中国有色金属学报, 2015, 25(4): 1025-1031.

LIU Pei-sheng, HOU Hong-liang, QING Huai-bin, WANG Yao-qi, ZHANG Yan-lin. Characteristic of highly porous foamed titanium with netlike structure[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 1025-1031.

[34] 汤慧萍, 朱纪磊, 王建永, 葛 渊, 李 程, 邸小波. 不锈钢纤维多孔材料的吸声性能[J]. 中国有色金属学报, 2007, 17(12): 1943-1947.

TANG Hui-ping, ZHU Ji-lei, WANG Jian-yong, GE Yuan, LI Cheng, DI Xiao-bo. Sound absorbing properties of stainless steel fiber porous materials[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1943-1947.

[35] 卢 淼, 姚欣宇, 刘培生, 徐新邦. 电沉积泡沫镍的中频吸声性能[J]. 稀有金属, 2015, 39(1): 49-54.

LU Miao, YAO Xin-yu, LIU Pei-sheng, XU Xin-bang. Sound absorption performance of nickel foam in range of intermediate frequency[J]. Chinese Journal of Rare Metals, 2015, 39(1): 49-54.

[36] 何 琳, 朱海潮, 邱小军, 杜功焕. 声学理论与工程应用[M]. 北京: 科学出版社, 2008: 105-123.

He Lin, Zhu Hai-chao, Qiu Xiao-jun, Du Gong-huan. Acoustical theory and engineering applications[M]. Beijing: Science Press, 2008: 105-123.

[37] 刘培生, 顷淮斌. 一种具有球形孔隙的高孔率泡沫钛合金[J]. 材料研究学报, 2015, 29(5): 246-252.

LIU Pei-sheng, QING Huai-bin. A spherical-pore foamed titanium alloy with high porosity[J]. Chinese Journal of Materials Research, 2015, 29(5): 246-252.

[38] Allard J F. Propagation of sound in porous media: Modeling sound absorbing materials[M]. New York: Elsevier Science, 2009.

[39] 马大猷. 现代声学理论[M]. 北京: 科学出版社, 2004.

MA Da-you. Modern acoustical theory[M]. Beijing: Science Press, 2004.

[40] Chen W S, Qiu X J. Sound insulation character of three-layer panels one with elastic porous material[J]. Applied acoustics, 2008, 27(2): 118-124.

[41] 刘 朴, 王 玮, 鲁 静, 罗洪杰. 泡沫铝材料用于减振、吸声结构的初步设计[J]. 有色矿冶, 2013, 29(4): 32-35.

LIU Pu, WANG Wei, LU Jing, LUO Hong-jie. Primary design for composite structure by using aluminum foam as damping or sound absorption materials[J]. Nonferrous Mining and Metallurgy, 2013, 29(4): 32-35.

[42] 梁李斯, 武姣娜, 刘漫博, 杜金晶, 李奕霏. 孔排列及孔径对闭孔泡沫铝吸声性能的影响[J]. 有色金属,2016(2): 53-57.

Liang Li-si, Wu Jiao-na, Liu Man-bo, DU Jin-jing, Li Yi-fei. Effect of perforation arrangement and size on sound absorption property of closed-cell aluminum foam[J]. Nonferrous Metals, 2016(2): 53-57.

Sound absorption property of vacuum sintered 304 stainless steel foam

LIU Pei-sheng1, 2, XU Xin-bang1, 2, SUN Jin-xing1, 2, CUI Guang1, 2

(1. Key Laboratory of Radiation Beam Technology, Ministry of Education, College of Nuclear Science and Technology, Beijing Normal University, Beijing 100875, China;

2. Beijing Radiation Center, Beijing 100875, China)

abstract: 304 stainless steel foam with the pore size of about 1.8 mm and the porosity of about 93.7% was prepared by the slurry sintering method at 1050 ℃ for 3 h in vacuum. The sound absorption coefficient was tested for the foam at 200-6300 Hz and for the back cavity composite at 2500-4000 Hz. The results show that the foam sample shows a good sound absorption in the middle and high frequency range, exhibiting the first resonance frequency of around 4000 Hz and the maximum absorption coefficient of about 0.7. The absorption performance may be obviously improved by increasing the sample thickness at 1250-3150 Hz and by adding a back cavity at 2500-4000 Hz.

Key words: porous material; metal foam; stainless steel foam; acoustic property

Foundation item: Project(C16) supported by Testing Foundation of BNU, China

Received date: 2016-07-08; Accepted date: 2017-05-16

Corresponding author: LIU Pei-sheng; Tel: +86-10-58807316; E-mail: Liu996@263.net

(编辑 王 超)

基金项目:北师大测试基金C16支持项目

收稿日期:2016-07-08;修订日期:2017-05-16

通信作者:刘培生,教授,博士;电话:010-58807316;E-mail: Liu996@263.net

摘 要:利用挂浆工艺,在1050 ℃下真空烧结3 h,成功制备三维网状的泡沫304不锈钢,制品烧结良好。样品平均孔径约1.8 mm,孔隙率约93.7%。测试该泡沫金属在200~6300 Hz及其加入背腔后在2500~4000 Hz时的吸声系数, 探讨背腔对样品吸声性能的影响。结果表明:本制品在测试范围的中高频段表现出较好的吸声效果,其第一共振频率为4000 Hz,此时最大吸声系数约0.7;在1250~3150 Hz之间,增加样品厚度可明显提高吸声效果;加入背腔可大幅度提高样品的整体吸声效果。

[3] 刘培生, 陈 祥, 李言祥. 泡沫金属[M]. 长沙: 中南大学出版社, 2012.

[8] 周向阳, 龙 波, 李 劼, 刘宏专. 前驱体制备对三维通孔不锈钢泡沫性能的影响[J]. 中国有色金属学报, 2006, 16(9): 1615-1620.

[9] 周向阳, 龙 波, 李 劼. 烧结制度对三维通孔不锈钢泡沫性能影响[J]. 粉末冶金技术, 2006, 24(6): 445-452.

[10] 王志阳, 沈以赴, 顾冬冬, 于秀平. 蜂窝状多孔316L不锈钢的选区激光熔化制备[J]. 稀有金属材料与工程, 2011, 40(1): 161-164.

[11] 李 鹏, 刘 斌. 空间网格状多孔316 不锈钢的选区激光熔化制备[J]. 热加工工艺, 2013, 42(8): 50-52.

[19] 梁李斯, 姚广春, 穆永亮, 华中胜. 组合形式对打孔闭孔泡沫铝板吸声效果的影响[J]. 中国有色金属学报, 2011, 21(9): 2132-2137.

[20] 胡 松, 左孝青, 谢香云, 陆建生, 周 芸, 刘荣佩. 特殊孔结构 ZA27合金泡沫的吸声性能[J]. 中国有色金属学报, 2014, 24(11): 2798-2804.

[21] 袁文文, 李言祥, 陈 祥. 穿孔法改进泡沫铝的吸声性能[J]. 中国有色金属学报, 2010, 21(1): 138-144.

[22] 刘伟伟, 何思渊, 黄 可, 何德坪. 孔结构周期调制通孔多孔铝合金及其吸声性能[J]. 材料研究学报, 2009, 23(2): 171-174.

[23] 王录才, 曾松岩, 王 芳. 复合结构泡沫铝隔声性能的研究[J]. 机械工程材料, 2006, 30(10): 56-58.

[24] 谢香云, 左孝青, 王应武, 钟子龙, 董晓蓉. 特殊孔结构Al-Si12泡沫铝的吸声性能研究[J]. 稀有金属材料与工程, 2013, 42(8): 1649-1653.

[33] 刘培生, 侯红亮, 顷淮斌, 王耀奇, 张艳玲. 网状结构的高孔率泡沫钛特性研究[J]. 中国有色金属学报, 2015, 25(4): 1025-1031.

[34] 汤慧萍, 朱纪磊, 王建永, 葛 渊, 李 程, 邸小波. 不锈钢纤维多孔材料的吸声性能[J]. 中国有色金属学报, 2007, 17(12): 1943-1947.

[35] 卢 淼, 姚欣宇, 刘培生, 徐新邦. 电沉积泡沫镍的中频吸声性能[J]. 稀有金属, 2015, 39(1): 49-54.

[36] 何 琳, 朱海潮, 邱小军, 杜功焕. 声学理论与工程应用[M]. 北京: 科学出版社, 2008: 105-123.

[37] 刘培生, 顷淮斌. 一种具有球形孔隙的高孔率泡沫钛合金[J]. 材料研究学报, 2015, 29(5): 246-252.

[39] 马大猷. 现代声学理论[M]. 北京: 科学出版社, 2004.

MA Da-you. Modern acoustical theory[M]. Beijing: Science Press, 2004.

[41] 刘 朴, 王 玮, 鲁 静, 罗洪杰. 泡沫铝材料用于减振、吸声结构的初步设计[J]. 有色矿冶, 2013, 29(4): 32-35.

[42] 梁李斯, 武姣娜, 刘漫博, 杜金晶, 李奕霏. 孔排列及孔径对闭孔泡沫铝吸声性能的影响[J]. 有色金属,2016(2): 53-57.