DOI:10.19476/j.ysxb.1004.0609.2017.04.007

Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区变形行为及工艺参数优化

王克鲁,鲁世强,李 鑫,董显娟

(南昌航空大学 航空制造工程学院,南昌 330063)

摘 要:

在变形温度920~1040 ℃、应变速率0.001~70.0 s-1条件下,采用Thermecmastor-Z热模拟试验机研究Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金在α+β两相区变形时的流动行为和塑性变形机制,得到优化的工艺参数范围。结果表明:该合金在α+β两相区变形时的流动应力对变形温度和应变速率均较敏感,变形温度较低时(920、950和980 ℃),流动应力曲线呈流动软化特征,变形温度较高时(1010和1040 ℃)呈稳态流动特征。失稳变形工艺参数范围为(920~930 ℃、0.2~70 s-1)和(1000~1040 ℃、1~70 s-1)范围,该区域易产生局部流动和机械失稳。综合加工图及微观组织观察结果,优化出的Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区变形时的工艺参数范围为(1000~1030 ℃、0.001~0.1 s-1)及(920~935 ℃、0.001~0.003 s-1),其塑性变形机制为超塑性成形。

关键词:

文章编号:1004-0609(2017)-04-0724-08 中图分类号:TG146.23 文献标志码:A

钛合金是航空发动机中的关键结构材料,进一步提高使用温度是钛合金技术领域的重要研究和发展方向[1]。目前高温钛合金的使用温度已经达到600 ℃,比较典型的高温钛合金主要有IMI834、Ti1100、BT36等[2-3]。Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金为我国自行研制的高温钛合金,具有优良的综合性能,适合在600 ℃条件下长时间工作[4-5]。该钛合金为近α型高温钛合金,成形温度范围较窄,局部容易过热,锻件的组织性能对热加工过程十分敏感,为了获得所需的组织性能,需严格控制其成形过程[6]。

为了满足航空发动机对锻件性能的需要,常要求钛合金具有等轴组织。钛合金在α+β/β转变温度以下30~50 ℃加热、成形,即常规锻造时可得到等轴组织,该组织具有良好的塑性和热稳定性[7-9]。钛合金β锻造一般得到片层状组织,片层状组织较为稳定,难以通过热处理使其球化,主要靠α+β两相区变形得到等轴组织[10-11]。本文作者在热模拟实验的基础上,分析变形工艺参数对Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si- 0.85Nd合金α+β两相区变形时流动应力的影响规律,构建不同应变下的加工图,并进一步分析加工图中不同区域的变形特点及变形机制,得到了优化的变形工艺参数范围,研究结果可以为该合金的实际锻造提供理论依据。

1 实验

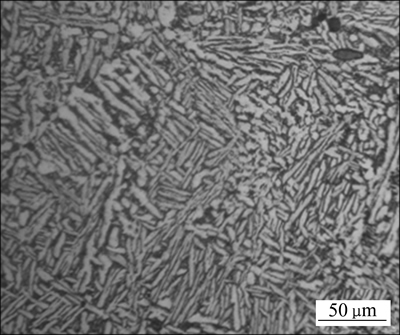

Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金材料取自于轧制环件,其α+β/β转变温度为1040 ℃,原始组织如图1所示。从图1可以看出,热变形前的组织以片层状组织为主。

采用Thermecmastor-Z热模拟试验机进行等温恒应变速率压缩试验,试样尺寸为d 8 mm×12 mm圆柱试样,两端加工有d 7.7 mm、深度0.2 mm的凹槽,用以储存玻璃润滑剂,降低压缩变形时的摩擦因数。以10 ℃/s的加热速率将试样加热到规定温度,保温时间300 s,使温度和组织均匀。变形温度分别取920、950、980、1010及1040 ℃;应变速率分别取1×10-3、1×10-2、1×10-1、1、10及70 s-1;最大高度压下率为50%,对应的真应变约0.7;变形后的试样立即喷氦气冷却。将变形后的试样沿压缩轴纵向切刨,制备金相试样,采用体积比1:3:6的HF+HNO3+H2O的腐蚀剂进行腐蚀,并使用XJP-6P金相显微镜对变形组织进行观察分析。

图1 Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd钛合金的原始组织

Fig. 1 Initial microstructure of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo- 0.35Si-0.85Nd alloy under condition of ring rolling

2 结果与讨论

2.1 流动应力曲线

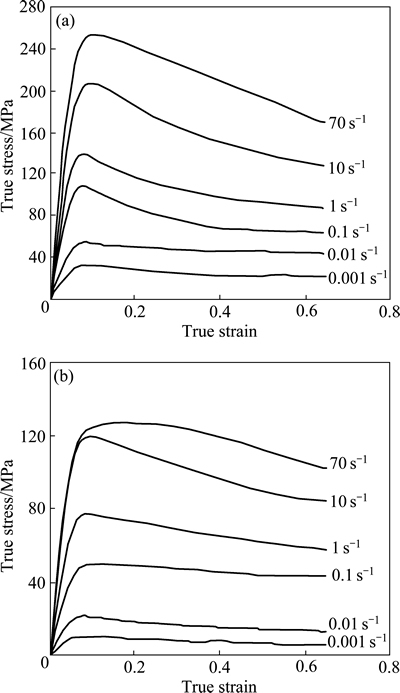

图2所示为不同变形温度下Ti-5.6Al-4.8Sn-2.0Zr- 1.0Mo-0.35Si-0.85Nd合金的流动应力曲线。从图2可以看出,不同变形温度下,在变形的初始阶段(真应变低于0.1时),流动应力均迅速上升,达到峰值。流动应力随应变速率的增大而增加,其增加的程度与变形温度有关,变形温度越低,增加越明显。在变形温度950 ℃条件下(见图2(a)),流动应力达到峰值后,随着真应变的继续增加,流动应力开始下降,呈流动软化特征;应变速率越高,流动软化现象越明显。变形温度920 ℃和980 ℃条件下的流动应力曲线与950 ℃ 时的情况相似,均呈流动软化趋势。在变形温度1010 ℃条件下(见图2(b)),流动应力达到峰值后,随着真应变的继续增加,流动应力变化较小,大致呈稳态流动特征;变形温度1040 ℃时的流动应力曲线变化特征与1010 ℃时的情况相似。

图2 不同变形温度下Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si- 0.85Nd合金的流动应力曲线

Fig. 2 Flow stress curves of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo- 0.35Si-0.85Nd alloy deformed at 950 ℃(a) and 1010 ℃(b)

2.2 热变形行为分析

合金的高温变形是由热力学参数支配的热激活过程,变形温度和应变速率对流动应力的综合影响通常用动力学方程来表示[12-13]:

(

( <0.8) (1)

<0.8) (1)

(

( >1.2) (2)

>1.2) (2)

(for all

(for all  ) (3)

) (3)

式中: 为应变速率,s-1;

为应变速率,s-1; 为流动应力,MPa;Q为变形激活能,kJ/mol;R为气体常数,8.314 J/(mol·K);T为变形温度,K;A1、A2、A 和

为流动应力,MPa;Q为变形激活能,kJ/mol;R为气体常数,8.314 J/(mol·K);T为变形温度,K;A1、A2、A 和 为常数;n、n1和

为常数;n、n1和 为与应变速率敏感性因子有关的参数,

为与应变速率敏感性因子有关的参数, 。

。

由式(1)和(2)取对数可得:

(4)

(4)

(5)

(5)

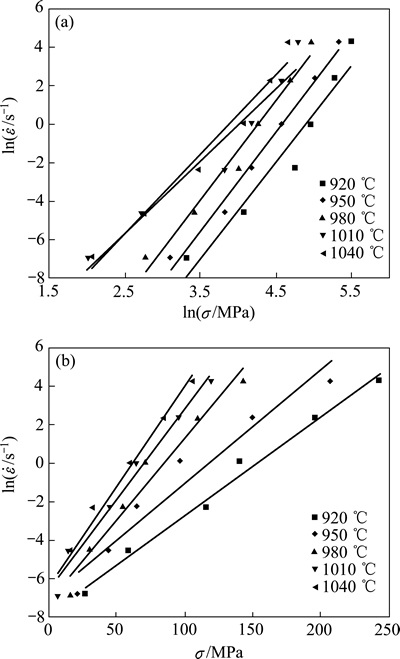

根据Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金的热压缩试验得出的数据,可绘制出 与

与 和

和 与

与 的关系曲线,如图3所示。根据公式(4)和(5)可知,图3中各直线的斜率即为所要求的n1和

的关系曲线,如图3所示。根据公式(4)和(5)可知,图3中各直线的斜率即为所要求的n1和 值,进一步可求出不同温度下的

值,进一步可求出不同温度下的 值。求得的不同温度下的

值。求得的不同温度下的 平均值为0.018。

平均值为0.018。

变形激活能用来衡量材料热变形过程中原子发生重排时的难易程度,其大小受材料的本质、变形温度及应变速率等因素的影响。根据式(3)可推导出激活能Q的表达式[14]如下:

(6)

(6)

式中:令 ;

; 则得到:

则得到:

(7)

(7)

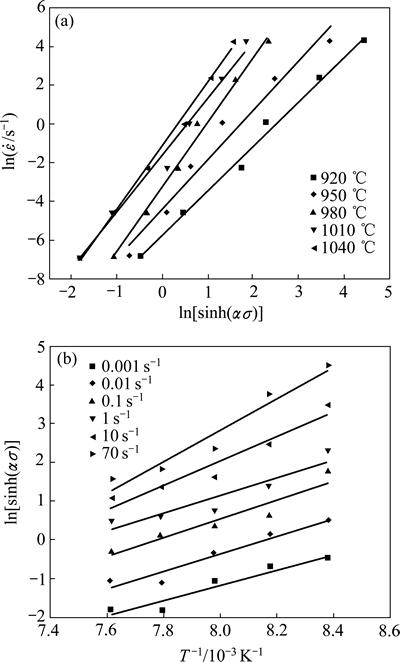

图4所示为Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si- 0.85Nd合金 -

- 和1/T-

和1/T- 关系曲线。通过图4计算得到的n的平均值是2.88,k的平均值是2.69。将n值和k值代入到式(7),可得到该合金在α+β两相区的变形激活能Q值,其值约为644.1 kJ/mol。

关系曲线。通过图4计算得到的n的平均值是2.88,k的平均值是2.69。将n值和k值代入到式(7),可得到该合金在α+β两相区的变形激活能Q值,其值约为644.1 kJ/mol。

图3 Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金的 和

和 的关系曲线

的关系曲线

Fig. 3 Relationship of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si- 0.85Nd alloy during hot compression  (a) and

(a) and  (b)

(b)

图4 Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金的 -

- 和

和 -1/T关系曲线

-1/T关系曲线

Fig. 4 Relationships of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si- 0.85Nd alloy during hot compression  -

- (a) and

(a) and  -1/T(b)

-1/T(b)

应变速率和变形温度对流变应力的影响可用Zener-Hollomom(Z)参数来表示[15]:

(8)

(8)

式中:Z为温度补偿应变速率因子。

将式(8)取自然对数,可得:

(9)

(9)

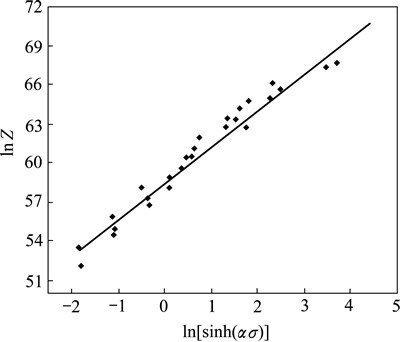

将变形温度、应变速率和激活能带入式(8),可求得Z值;以 和

和 为坐标,进行单因素线性回归,得到

为坐标,进行单因素线性回归,得到 -

- 的关系,如图5所示。由式(9)可知,图5的直线斜率即为n,其值为2.76;截距为

的关系,如图5所示。由式(9)可知,图5的直线斜率即为n,其值为2.76;截距为 ,其值为58.47,则A值为2.47×1025。

,其值为58.47,则A值为2.47×1025。

图5  和

和 的关系曲线

的关系曲线

Fig. 5 Linear relationship between  and

and

因而,Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金的本构方程可表示为

(10)

(10)

2.3 加工图及其分析

根据动态材料模型理论,工件吸收的来自工具的功率P,在塑性变形中通过以下两个方面进行耗 散[16-17]:

(11)

(11)

式中:G为功率耗散量,表示由于塑性变形引起的功率耗散,大部分转化为粘塑性热(见式(12));J为功率耗散协量,表示在变形过程中与组织演变有关的功率耗散[18](见式(13))。

(12)

(12)

(13)

(13)

功率耗散效率η为

(14)

(14)

式中:m为应变速率敏感因子。η为无量纲参数,它随应变速率和温度的变化便形成了功率耗散图,功率耗散图上的η等值线表示与材料的微观结构演变相关的相对熵产率。一般说来,高η值区域对应着较好的加工性能区。

同时,PRASAD等学者[19-20]提出了塑性失稳判据:

(15)

(15)

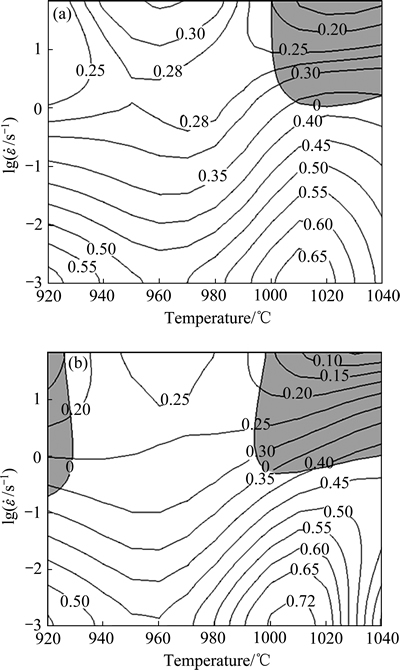

值随应变速率和温度的变化可形成失稳图,功率耗散图与失稳图叠加,可得到加工图。Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区变形时的加工图如图6所示,图6中的阴影部分为失稳区域,等值线上的数字为功率耗散效率值。

值随应变速率和温度的变化可形成失稳图,功率耗散图与失稳图叠加,可得到加工图。Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区变形时的加工图如图6所示,图6中的阴影部分为失稳区域,等值线上的数字为功率耗散效率值。

从图6可以看出,Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo- 0.35Si-0.85Nd合金α+β两相区变形时,在高应变速率区域,存在较大的流变失稳区域,且随着变形程度的增加,合金的流变失稳区域有所扩大。图6(a)所示为真应变0.3时的加工图,从图中可以看出,当变形温度为1000~1040 ℃,应变速率为1~70 s-1时,功率耗散效率均在0.35之下,变形处于流变失稳区。应变速率较低(0.001~0.1 s-1)时,功率耗散效率多在0.4以上,变形处于稳定区域;从图6(a)中还可以看出,加工图中存在两个功率耗散效率峰值区域,分别为:1) 变形温度1000~1030 ℃,应变速率0.001~0.1 s-1区域;2) 变形温度920~940 ℃,应变速率0.001~0.01 s-1区域。这两个区域的功率耗散效率值多在0.50以上,对应的应变速率敏感因子m≥0.33。仅从加工图判断,可认为这两个功率耗散效率峰值区域为该合金真应变为0.3时的较佳变形工艺参数范围。图6(b)所示为真应变0.7时的加工图,同真应变0.3时的加工图相比,在低温高应变速率区域出现了一个流变失稳区域,其范围为变形温度920~930 ℃,应变速率0.2~70 s-1区域。该区域的功率耗散效率多在0.25以下,对应的应变速率敏感因子m≤0.14;变形温度1000~1040 ℃,应变速率1~70 s-1范围,功率耗散效率均在0.35之下,变形同样处于流变失稳区。应变速率较低(0.001~0.1 s-1)时,功率耗散效率多在0.4以上,变形处于稳定区域。从图6(b)还可以看出,加工图中同样存在两个功率耗散效率峰值区域,分别为:1) 变形温度为1000~1030 ℃,应变速率为0.001~0.1 s-1区域;2) 变形温度为920~ 935 ℃,应变速率为0.001~0.003 s-1区域。仅从加工图判断,可认为这两个区域为Ti-5.6Al-4.8Sn- 2.0Zr-1.0Mo-0.35Si-0.85Nd合金真应变为0.7时的适宜的变形工艺参数范围。

图6 Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金不同应变下的加工图

Fig. 6 Processing maps of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo- 0.35Si-0.85Nd alloy as a function of temperature and strain rate at true strains of 0.3(a) and 0.7(b)

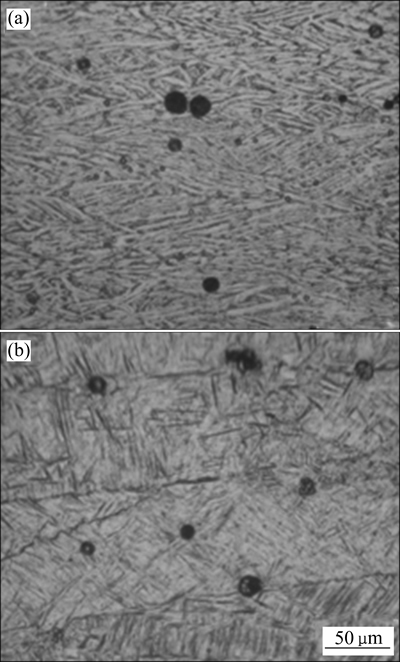

功率耗散效率较高的区域一般对应着较佳的变形工艺参数范围,然而由于楔形裂纹等破坏机制通常也对应于高的功率耗散效率,因此,由加工图优化的变形工艺参数范围还需通过变形显微组织观察和分析来佐证。图7所示为真应变0.7时,加工图中的失稳区域对应的显微组织。图7(a)所示为变形温度920 ℃,应变速率70 s-1时的显微组织,该变形工艺参数条件下,功率耗散效率仅0.11。从图7(a)可以看出,变形试样中可以观察到局部流动现象。图7(b)所示为变形温度1010 ℃,应变速率70 s-1时的显微组织,该变形工艺参数条件下,功率耗散效率为0.20。从图7(b)可以看出,β晶粒沿着压缩方向明显伸长,沿β相界处分布有α相,显微组织明显不均匀,即发生了机械失稳。

图7 α+β两相区变形时Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金的显微组织

Fig. 7 Microstructures of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo- 0.35Si-0.85Nd deformed in α+β phase region at strain rate of 70 s-1 and different temperatures of 920 ℃(a) and 1010 ℃(b)

图8所示为真应变0.7时,加工图中的功率耗散效率峰值区域对应的显微组织。当变形温度为920 ℃,应变速率为0.001 s-1时,功率耗散效率为0.56,该变形条件下的显微组织如图8(a)所示。从图8(a)可以看出,Ti-5.6Al- 4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金中存在较多的α相,组织较为均匀细小。当变形温度为1010 ℃,应变速率为0.001 s-1时,功率耗散效率达0.77,该变形条件下的显微组织照片如图8(b)所示。从图8(b)可以看出,其变形组织更为均匀。应变速率敏感因子m可反映金属产生均匀变形或抵抗局部变形的能力,为超塑性成形的重要指标,由于功率耗散效率峰值区域对应的m值较高,多大于0.35(如(1010 ℃,0.001 s-1)条件下的m值达0.63),可认为该变形工艺参数条件下的塑性变形机制为超塑性成形[21]。超塑性成形过程中,晶界滑移的同时伴随有扩散蠕变,原子的迁移可对晶界滑移起调节作用,因而晶界具有高迁移性,故功率耗散效率较高[22]。组织观察结果说明,由加工图预测的稳定变形区和失稳变形区以及工艺优化结果是可靠的。

图8 α+β两相区变形时Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金的显微组织

Fig. 8 Microstructures of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd deformed in α+β phase region at strain rate of 0.001 s-1 and different temperature of 920 ℃(a) and 1010 ℃(b)

综合加工图和变形显微组织分析结果可知,当真应变为0.7时,变形工艺参数(920~930 ℃、0.2~70 s-1)及(1000~1040 ℃、1~70 s-1)范围为Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区变形时的流变失稳区域,其塑性变形机制为局部流动和机械失稳。变形工艺参数(1000~1030 ℃、0.001~0.1 s-1)及(920~935 ℃、0.001~0.003 s-1)区域为适宜的变形工艺参数范围,其塑性变形机制为超塑性成形。

3 结论

1) Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区热变形时的流动应力对变形温度和应变速率均较敏感,随着变形温度的升高和应变速率的降低,流动应力减小。在变形温度较低时(920、950和980 ℃),流动应力曲线呈流动软化特征。在变形温度较高时(1010和1040 ℃),流动应力曲线呈稳态流动特征。

2) 当变形工艺参数(920~930 ℃、0.2~70 s-1)时,Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金易发生局部流动;在变形工艺参数(1000~1040 ℃、1~70 s-1)范围,易产生机械失稳。

3) 综合加工图以及显微组织观察结果,优化出的Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区变形时的工艺参数范围为(1000~1030 ℃、0.001~ 0.1 s-1)及(920~935 ℃、0.001~0.003 s-1),其塑性变形机制为超塑性成形。

REFERENCES

[1] 蔡建明, 曹春晓. 新一代600℃高温钛合金材料的合金设计及应用展望[J]. 航空材料学报, 2014, 34(4): 27-36.

CAI Jiang-ming, CAO Chun-xiao. Alloy design and application expectation of a new generation 600℃ high temperature titanium alloy[J]. Journal of Aeronautical Materials, 2014, 34(4): 27-36.

[2] GHAVAM M H, MORAKABATI M, ABBASI S M, BADRI H. Flow behavior modeling of IMI834 titanium alloy during hot tensile deformation[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 748-758.

[3] CHANDRAVANSHI V K, SARKAR R, KAMAT S V, NANDY T K. Effect of boron on microstructure and mechanical properties of thermomechanically processed near alpha titanium alloy Ti-1100[J]. Journal of Alloys and Compounds, 2011, 509(18): 5506-5514.

[4] ZHAO Z L, LI H, FU M W, GUO H Z, YAO Z K. Effect of the initial microstructure on the deformation behavior of Ti60 titanium alloy at high temperature processing[J]. Journal of Alloys and Compounds, 2014, 617: 525-533.

[5] PENG Wen-wen, ZENG Wei-dong, WANG Qing-jiang, YU Han-qing. Comparative study on constitutive relationship of as-cast Ti60 titanium alloy during hot deformation based on Arrhenius-type and artificial neural network models[J]. Materials and Design, 2013, 51: 95-104.

[6] LUO J, LI M Q. Strain rate sensitivity and strain hardening exponent during the isothermal compression of Ti60 alloy[J]. Materials Science and Engineering A, 2012, 538: 156-163.

[7] ZHOU Y G, ZENG W D, YU H Q. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components[J]. Materials Science and Engineering A, 2005, 393(1/2): 204-212.

[8] SHI Z F, GUO H Z, LIU R, WANG X C, YAO Z K. Microstructure and mechanical properties of TC21 titanium alloy by near-isothermal forging[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 72-79.

[9] 邵 晖, 赵永庆, 曾卫东, 葛鹏, 杨 义. α+β钛合金微观组织对强韧性的影响概述[J]. 稀有金属材料与工程, 2012, 41(7): 1313-1316.

SHAO Hui, ZHAO Yong-qing, ZENG Wei-dong, GE Ping, YANG Yi. Review on influence of microstructure on strength and fracture toughness in α+β titanium alloy[J]. Rare Metal Materials and Engineering, 2012, 41(7): 1313-1316.

[10] WU Cheng-bao, YANG He, FAN Xiao-guang, SUN Zhi-chao. Dynamic globularization kinetics during hot working of TA15 titanium alloy with colony microstructure[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1963-1969.

[11] SONG Hong-wu, ZHANG Shi-hong, CHENG Ming. Dynamic globularization prediction during cogging process of large size TC11 titanium alloy billet with lamellar structure[J]. Defence Technology, 2014, 10(1): 40-46.

[12] SAREBANZADEH M, MAHMUDI R, ROUMINA R. Constitutive analysis and processing map of an extruded Mg-3Gd-1Zn alloy under hot shear deformation[J]. Materials Science and Engineering A, 2015, 637: 155-161.

[13] 杨胜利, 沈 健, 闫晓东, 李锡武, 孙宝庆, 张 飞. Al-Cu-Li-Mg-Mn-Zn-Ag合金的热变形流变行为与本构方 程[J]. 中国有色金属学报, 2015, 25(8): 2083-2090.

YANG Sheng-li, SHEN Jian, YAN Xiao-dong, LI Xi-wu, SUN Bao-qing, ZHANG Fei. Flow behavior and constitutive equations of Al-Cu-Li-Mg-Mn-Zn-Ag alloy during isothermal compression[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2083-2090.

[14] WU B, LI M Q, MA D W. The flow behavior andconstitutiveequations in isothermal compression of 7050 aluminum alloy[J]. Materials Science and Engineering A, 2012, 542: 79-87.

[15] 李俊儒, 龚 臣, 陈 列, 佐 辉, 刘雅政. 10Cr12Ni3Mo2VN超超临界机组用叶片钢的热变形行为[J]. 金属学报, 2014, 50(9): 1063-1070.

LI Jun-ru, GONG Chen, CHEN Li, ZUO Hui, LIU Yia-zheng. Hot deformation behavior of blades steel 10Cr12Ni3Mo2VN for ultra-supercritical units[J]. Acta Metallurgica Sinica, 2014, 50(9): 1063-1070.

[16] PRASAD Y V R K, GEGEL H L. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metallurgical and Materials TransactionsA, 1984, 15: 1883-1892.

[17] 鲁世强, 李 鑫, 王克鲁, 董显娟, 李臻熙, 曹春晓. 基于DMM的材料热加工工艺优化方法[J]. 中国有色金属学报, 2007, 17(6): 890-896.

LU Shi-qiang, LI Xin, WANG Ke-lu, DONG Xian-juan, LI Zhen-xi, CAO Chun-xiao. Optimizing approach of materials hot working processes based on dynamic material model[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 890-896.

[18] 段永华, 孙 勇, 何建洪, 方东升, 郭中正. Pb-Mg-Al合金的热变形行为与加工图[J]. 中国有色金属学报, 2013, 23(2): 311-319.

DUAN Yong-hua, SUN Yong, HE Jian-hong, FANG Dong-sheng, GUO Zhong-zheng. Hot deformation behavior and processing map of Pb-Mg-Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 311-319.

[19] BHIMAVARAPU S B, MAHESHWARI A K, BHARGAVA D, NARAYAN S P. Compressive deformation behavior of Al 2024 alloy using 2D and 4D processing maps[J]. Journal of Materials Science, 2011, 46: 3191–3199.

[20] 肖宏超, 刘楚明, 徐 璐, 王 霄, 万迎春. Mg-10Gd-4.8Y- 0.6Zr镁合金热变形行为与加工图[J]. 中国有色金属学报, 2013, 23(2): 303-310.

XIAO Hong-chao, LIU Chu-ming, XU Lu, WANG Xiao, WAN Ying-chun. Deformation behavior and processing map of Mg-10Gd-4.8Y-0.6Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 303-310.

[21] 于秋颖, 姚志浩, 董建新, 张盼达, 韩 刚. 难变形高温合金GH4720Li的超塑性变形行为[J]. 材料热处理学报, 2015, 36(7): 30-35.

YU Qiu-ying, YAO Zhi-hao, DONG Jian-xin, ZHANG Pan-da, HAN Gang. Superplastic behavior of hard-to-deformed GH4720Li superalloy[J]. Transactions of Materials and Heat Treatment, 2015, 36(7): 30-35.

[22] 曹富荣, 崔建忠, 丁 桦, 侯红亮, 李志强. 不同初始组织材料超塑性m值模型与验证[J]. 哈尔滨工业大学学报, 2015, 47(10): 50-54.

CAO Fu-rong, CUI Jian-zhong, DING Hua, HOU Hou-liang, LI Zhi-qiang. Modeling the m value and its experimental verification during superplasticity of materials with different initial microstructures[J]. Journal of Harbin Institute of Technology, 2015, 47(10): 50-54.

Deformation behavior and process parameter optimization of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd alloy in α+β forging process

WANG Ke-lu, LU Shi-qing, LI Xin, DONG Xian-juan

(School of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nangchang 330063, China)

Abstract: The flow behavior and plastic deformation mechanism of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd alloy were studied by the hot compression, which was carried out on a Thermecmastor-Z simulator in the temperature range of 920-1040 ℃ and strain rate range of 0.001-70.0 s-1, and the optimization process parameter range was obtained. The results show that the flow stress of this alloy is sensitive to temperature and strain rate in the α+β range. The flow stress curves exhibit a flow softening behavior when the temperature is lower than or equal to 980 ℃; while the flow stress curves exhibit a steady-state characteristic when the temperature is higher than or equal to 1010 ℃. The processing map exhibits two instability fields: 920-930 ℃ at 0.2-70 s-1 and 1000-1040 ℃ at 1-70 s-1. In these instability fields, the flow location or mechanical instability occurs. Combining processing map with microstructure observation, the optimum deformation process parameters in α+β range for Ti-5.6Al-4.8Sn-2.0Zr- 1.0Mo-0.35Si-0.85Nd alloy are (1000-1030 ℃, 0.001-0.1 s-1) and (920-935 ℃, 0.001-0.003 s-1), respectively, and the corresponding plastic deformation mechanism is superplasticity deformation.

Key words: Ti alloy; defomration behavior; process parameter optimization; processing map

Foundation item: Project(51164030) supported by the National Natural Science Foundation of China; Project(GJJ13501) supported by the Education Commission Foundation of Jiangxi Province, China; Project (JW201323004) supported by the Metal Material Microstructure Control in Jiangxi Province Key Laboratory, China

Received date: 2016-01-04; Accepted date: 2016-06-07

Corresponding author: WANG Ke-lu; Tel: +86-13133804266; E-mail: wangkelu@126.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51164030);江西省教育厅科技基金资助项目(GJJ13501);江西省金属材料微结构调控重点实验室开放基金资助项目(JW201323004)

收稿日期:2016-01-04;修订日期:2016-06-07

通信作者:王克鲁,教授,博士;电话:13133804266;E-mail: wangkelu@126.com

摘 要:在变形温度920~1040 ℃、应变速率0.001~70.0 s-1条件下,采用Thermecmastor-Z热模拟试验机研究Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金在α+β两相区变形时的流动行为和塑性变形机制,得到优化的工艺参数范围。结果表明:该合金在α+β两相区变形时的流动应力对变形温度和应变速率均较敏感,变形温度较低时(920、950和980 ℃),流动应力曲线呈流动软化特征,变形温度较高时(1010和1040 ℃)呈稳态流动特征。失稳变形工艺参数范围为(920~930 ℃、0.2~70 s-1)和(1000~1040 ℃、1~70 s-1)范围,该区域易产生局部流动和机械失稳。综合加工图及微观组织观察结果,优化出的Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd合金α+β两相区变形时的工艺参数范围为(1000~1030 ℃、0.001~0.1 s-1)及(920~935 ℃、0.001~0.003 s-1),其塑性变形机制为超塑性成形。

[1] 蔡建明, 曹春晓. 新一代600℃高温钛合金材料的合金设计及应用展望[J]. 航空材料学报, 2014, 34(4): 27-36.

[9] 邵 晖, 赵永庆, 曾卫东, 葛鹏, 杨 义. α+β钛合金微观组织对强韧性的影响概述[J]. 稀有金属材料与工程, 2012, 41(7): 1313-1316.

[15] 李俊儒, 龚 臣, 陈 列, 佐 辉, 刘雅政. 10Cr12Ni3Mo2VN超超临界机组用叶片钢的热变形行为[J]. 金属学报, 2014, 50(9): 1063-1070.

[17] 鲁世强, 李 鑫, 王克鲁, 董显娟, 李臻熙, 曹春晓. 基于DMM的材料热加工工艺优化方法[J]. 中国有色金属学报, 2007, 17(6): 890-896.

[18] 段永华, 孙 勇, 何建洪, 方东升, 郭中正. Pb-Mg-Al合金的热变形行为与加工图[J]. 中国有色金属学报, 2013, 23(2): 311-319.

[20] 肖宏超, 刘楚明, 徐 璐, 王 霄, 万迎春. Mg-10Gd-4.8Y- 0.6Zr镁合金热变形行为与加工图[J]. 中国有色金属学报, 2013, 23(2): 303-310.

[21] 于秋颖, 姚志浩, 董建新, 张盼达, 韩 刚. 难变形高温合金GH4720Li的超塑性变形行为[J]. 材料热处理学报, 2015, 36(7): 30-35.

[22] 曹富荣, 崔建忠, 丁 桦, 侯红亮, 李志强. 不同初始组织材料超塑性m值模型与验证[J]. 哈尔滨工业大学学报, 2015, 47(10): 50-54.