DOI: 10.11817/j.issn.1672-7207.2018.09.006

预拉伸对7085铝合金力学及局部腐蚀性能的影响

刘胜胆1, 2, 3,李群1,叶凌英1, 3,汪庆1,邓运来1, 3,张新明1, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 轻质高强结构材料重点实验室,湖南 长沙,410083;

3. 中南大学 有色金属先进结构材料与制造协同创新中心,湖南 长沙,410083)

摘 要:

室温拉伸、极化曲线、晶间腐蚀(IGC)和剥落腐蚀(EXCO)浸泡实验研究预拉伸对7085铝合金力学性能及局部腐蚀性能的影响,结合金相显微镜(OM)、透射电镜(TEM)、扫描透射电镜(STEM)及差示扫描量热法(DSC)等显微组织表征结果探讨和分析其影响机理。研究结果表明:经室温拉伸变形2.5%预拉伸后,合金时效后晶内η′强化相粒径增加,但体积分数增加,硬度和强度变化不大;合金晶界η相粒径、间距及其中Zn和Cu元素摩尔分数增加,晶界无沉淀析出带宽度增加;η相中Zn元素摩尔分数的显著增加和晶界无沉淀析出带宽化增大了腐蚀萌生概率和腐蚀沿晶扩展速率,降低了晶间腐蚀和剥落腐蚀性能。

关键词:

中图分类号:TG146.2+1 文献标志码:A 文章编号:1672-7207(2018)09-2152-08

Effects of pre-stretching on mechanical properties and localized corrosion of 7085 aluminum alloy

LIU Shengdan1, 2, 3, LI Qun1, YE Lingying1, 3 , WANG Qing1, DENG Yunlai1, 3, ZHANG Xinming1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. National Key Laboratory of Light and High Strength Structural Materials, Central South University, Changsha 410083, China;

3. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center, Central South University, Changsha 410083, China)

Abstract: The effects of pre-stretching on mechanical properties and localized corrosion property of 7085 aluminum alloy were investigated by means of hardness test, tensile test, polarization curve test, intergranular corrosion (IGC) immersion and exfoliation corrosion (EXCO) immersion test, and the mechanism was discussed based on microstructural characterization by optical microscopy (OM), transmission electron microscopy (TEM), scanning transmission electron microscopy (STEM) and differential scanning calorimetry (DSC). The results show that 2.5% pre-stretching of tensile deformation in room temperature results in a larger particle diameter but a higher volume fraction of η′ strengthening precipitates in the grains, and therefore almost no change in the hardness and strength of the aged alloy. After pre-stretching, η phase at most grain boundaries becomes larger and more-spaced, and the mole fraction of Zn and Cu in η phase and precipitate free zone (PFZ) adjacent to the grain boundaries increase. The significant increase of Zn mole fraction in η phase and wider PFZ near grain boundaries increases the possibility of corrosion initiation and corrosion propagation rate along grain boundaries, and therefore decreases the properties of IGC and EXCO.

Key words: pre-stretching; 7085 aluminum alloy; mechanical properties; intergranular corrosion; exfoliation corrosion

7×××系铝合金具有强度高、密度低等特点,其厚板广泛用于加工飞机的整体结构[1-2]。固溶和淬火是厚板制备的关键工序。厚板固溶淬火后容易产生较大的残余应力,导致后续加工过程中材料变形甚至开裂。为了消减残余应力,板材淬火后需要进行预拉伸,但这会在板材中引入位错,改变后续时效时沉淀相的析出状态,进而影响材料的性能。李英等[3]研究发现7475铝合金经0~5%预拉伸(室温拉伸变形)后,T6态强度变化不大,但T76态和T73态的强度降低。WATERLOO等[4]研究发现AA7108和AA7030铝合金经10%预拉伸后,晶内η相数量增多,η′相数量减少,T6态的强度降低。AL-RUBAIE等[5]研究发现7475铝合金经3%~5%预拉伸后,T7351态的强度提高。WANG等[6-7]研究发现7050铝合金5%预拉伸后,晶内η′相数量增多,T6态的强度提高;晶界η相粒径增大、间距增加,抗应力腐蚀性能提高。韩念梅等[8-9]研究发现经2.3%预拉伸后,7050合金晶内η′相粒径增大,体积分数减小,HLA态和T74态的强度降低;晶界η相粒径和间距增加,无沉淀析出带(PFZ)宽化,断裂韧性提高。宋丰轩等[10]发现经1.31%~5.46%预拉伸后,7050合金随着预拉伸量增大,晶内η相数量增多、粒径粗化,合金强度降低,晶界η相间距先增大后减小,PFZ先变宽后变窄,抗应力腐蚀性能逐渐下降。由此可知,关于预拉伸对7×××系铝合金强度和腐蚀性能的影响仍有不同的看法,尤其是在对腐蚀性能的影响方面,人们大多关注预拉伸后晶界处η相粒径、间距的变化,对其化学成分变化关注较少,而晶界η相中元素摩尔分数对耐腐蚀性能有很大的影 响[11-12]。7085 铝合金具有高比强度、低淬火敏感性和优异的疲劳性能等特点,已成功应用于波音 787飞机和空客A380飞机的翼梁、起落架等重要承力构件[1-2]。本文作者主要研究预拉伸对7085铝合金板材力学性能和局部腐蚀性能的影响,结合金相和电子显微镜等显微组织表征结果对影响机理进行分析和探讨。

1 实验材料与方法

实验材料7085铝合金厚板,其化学成分为(质量分数,%):Al-7.46Zn-1.58Mg-1.67Cu-0.09Zr。从厚板表层切取厚度为2 mm的试样,在SX-8-10型箱式电阻炉中进行470 ℃/15 min固溶,室温水淬后在0.5 h内进行预拉伸,预拉伸量分别为0和2.5%。试样在室温停放24 h后进行人工时效,制度为121 ℃/900 min+ 155 ℃/780 min。经0和2.5%预拉伸及时效后试样分别标记为P0和P2.5。

采用HV-5B小负载维氏硬度计测试试样的维氏硬度,载荷为3 kg;采用CRIMS-DDL100电子万能试验机测试试样的室温拉伸性能,应变速率为10-4 s-1;采用 IM6ex 电化学工作站进行极化曲线测试,溶液体系为室温3.5%(质量分数)NaCl溶液。

根据国标GB/T 7998—2005进行晶间腐蚀浸泡实验,腐蚀液配比为57 g NaCl+10 mL H2O2+1 L 蒸馏水,面容比为1.8 dm2/L,试样工作面长×宽为40 mm×25 mm,非工作面用松香密封,腐蚀环境温度为(35±2) ℃。浸泡6 h后,将腐蚀样品制样,测量腐蚀深度和等级评定。

根据国标GB/T 22639—2008进行剥落腐蚀浸泡实验,腐蚀液配比为4.0 mol/L NaCl+0.5 mol/L KNO3+ 0.1 mol/L HNO3,溶液容积和试样面积比为30 mL/cm2,试样工作面长×宽为50 mm×30 mm,非工作面用松香密封,腐蚀环境温度(25±2) ℃。浸泡不同时间后取出,记录腐蚀形貌并评定剥蚀等级。浸泡48 h后,将腐蚀样品制样,测量腐蚀深度和等级评定。

采用MX3000型金相显微镜观察金相组织,浸蚀剂配比为1 mL HF+16 mL HNO3+3 g CrO3+83 mL蒸馏水。采用Tecnai G2 F20型透射电镜(TEM)进行析出相分析,加速电压为200 kV,样品先预磨成厚度为80 μm的薄片,冲成直径为 3 mm的圆片后双喷减薄,电解液为20%HNO3+80%CH3OH(体积分数),液氮冷却将温度控制在-20 ℃以下。

差示扫描量热分析(DSC)在NETZSCH STA 449C型热分析仪上进行,试样厚度约为0.2 mm,从室温以15 ℃/min的速率升温至450 ℃,参比样纯度为99.99%高纯铝。

2 实验结果

2.1 显微组织

2.1.1 金相照片

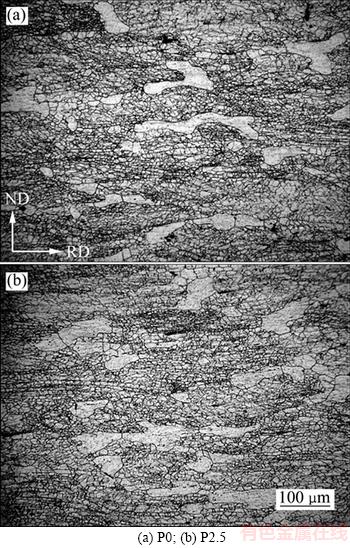

图1所示为试样金相照片。可见P0试样和P2.5试样的晶粒组织无明显差别,都是部分再结晶组织,图1所示大块白色区域为再结晶组织,其他区域为未再结晶组织,包含大量的亚晶粒。这种晶粒组织在含Zr的7×××系铝合金板材非常典型[13-14]。经统计,P0试样再结晶分数(体积分数)为(9.2±1.2)%,P2.5试样再结晶分数为(10.5±2.8)%,预拉伸对试样再结晶分数基本无影响。

2.1.2 TEM和HAADF-STEM结果

图2所示为试样晶内析出相的TEM图及对应的<011>Al选区衍射斑点(SADP)。2个试样中晶内都分布着高密度纳米级的沉淀强化相。据<011>Al SADP可知,除了Al基体的衍射斑点外,还能在1/3和2/3 {220}Al位置看到较强的η′相的衍射斑点,这说明2个试样中的沉淀强化相主要是η′相。η′相通常在{111}Al面上呈片状析出,从<011>Al方向看,呈针状或椭圆状[15]。P0试样晶内η′相粒径较均匀;P2.5试样晶内η′相粒径不均匀,密度似乎有所下降。

图1 试样金相照片

Fig. 1 Optical micrographs of samples

图2 试样晶内沉淀强化相的TEM图及对应<011>Al的选区衍射斑点

Fig. 2 TEM micrographs of strengthening phase and selected area diffraction pattern of corresponding <011>Al

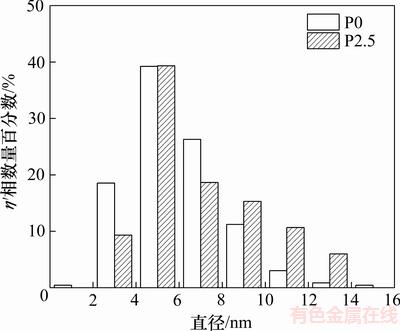

图3所示为P0和P2.5试样中η′相的粒径分布图。由图3可知:2个试样的η′相粒径多为4~6 nm,但P2.5试样大粒径η′相的数量百分数明显增加,这说明预拉伸促使大粒径η′相的形成。此外,从<011>Al SADP还可以在1/2 {220}Al位置看到Al3Zr弥散相衍射斑点;Al3Zr弥散相粒子能有效地钉扎晶界,起到抑制再结晶的作用[16],因而得到图1所示的部分再结晶组织。

图3 晶内η′相粒径分布图

Fig. 3 Size distribution histogram of η′ phase within grains

图4所示为试样典型的晶界HAADF-STEM图,晶界第二相的粒径等特征参数如表1所示。由图4可知:晶界η相衬度明显比基体的高,说明其应富含Zn/Cu元素;P0试样晶界上的η相细小、粒径较均匀,呈链状断续分布状态,晶界无沉淀析出带(PFZ)很窄,宽度约为22 nm;P2.5试样晶界上的η相粗化,呈断续分布,间距增至约23 nm,晶界PFZ宽度增至约27 nm,一些η相粒子在试样双喷时被腐蚀脱落,图片上呈现黑色。由此可知,预拉伸后晶界η相粒径、间距以及PFZ的宽度都增加。

此外,对多个晶界上η相及PFZ的化学成分进行测试,Zn,Mg和Cu元素的摩尔分数如表1所示。由表1可知:预拉伸后晶界η相中的 Zn元素摩尔分数显著增加,Cu元素摩尔分数稍有增加,Mg元素摩尔分数稍有下降;晶界PFZ中的Zn元素和Mg元素摩尔分数稍有降低,Cu元素摩尔分数明显增加。

图4 试样晶界HAADF-STEM图

Fig. 4 HAADF-STEM micrographs at grain boundaries of samples

表1 试样晶界η相和PFZ的粒径和化学成分

Table 1 Particle diameter and chemical compositions of PFZ and η phase at grain boundaries of samples

2.1.3 DSC结果

图5所示为试样的典型DSC曲线。由图5可知:随温度升高,可见A,B和C 3个峰。结合透射电镜分析及以往的研究[17-19],峰A是η′相回溶产生的吸热峰,峰B和峰C分别为η′相转变成η相和η相长大的放热峰。一般而言,峰值温度越高,第二相的粒径越大,峰面积越大,第二相的体积分数越大[20]。P0试样中峰A的峰值温度为209.1 ℃,峰面积为5.9 J/g;P2.5试样中峰A的峰值温度为211.1 ℃,峰面积为6.7 J/g;预拉伸稍提高了η′相的溶解温度,这与TEM分析中η′相粒径增大的结果一致;此外,预拉伸后峰面积增加了0.8 J/g,说明预拉伸后基体内的η′相体积分数增加。

图5 试样的DSC曲线

Fig. 5 DSC curves of samples

2.2 力学性能和局部腐蚀性能

2.2.1 力学性能

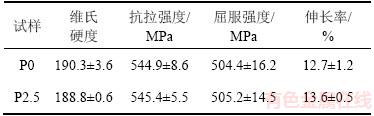

表2所示为试样的硬度和室温拉伸性能。由表2可知:P2.5试样的硬度和强度与P0试样的相差不大,伸长率略增加0.9%。

表2 试样硬度和室温拉伸性能

Table 2 Hardness and room temperature tensile properties of samples

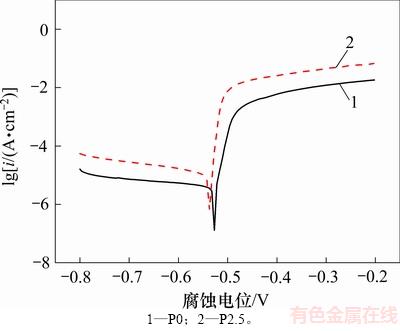

2.2.2 电化学测试结果

图6所示为试样的极化曲线。由图6可知:P2.5试样的极化曲线整体向左上方移动,其自腐蚀电位略低,腐蚀电流密度明显更大,如表3所示。自腐蚀电位和腐蚀电流密度分别反映试样的热力学和动力学倾向,自腐蚀电位更负,腐蚀电流密度越大,试样发生腐蚀的倾向越大[21]。说明预拉伸后试样具有更大的腐蚀倾向,这与后面的浸泡腐蚀结果一致。

图6 试样的极化曲线

Fig. 6 Polarization curves of samples

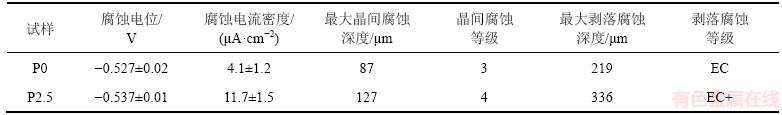

2.2.3 晶间腐蚀和剥落腐蚀

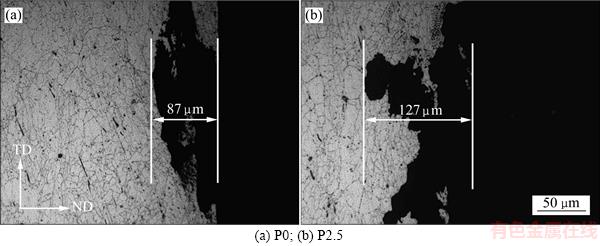

图7所示为试样的晶间腐蚀浸泡后的金相照片。由图7可知:腐蚀沿晶界发生,P0试样的最大腐蚀深度为87 μm,晶间腐蚀等级为3级;P2.5试样的最大腐蚀深度为127 μm,晶间腐蚀等级为4级。预拉伸后试样的晶间腐蚀性能变差。

图8所示为试样浸泡在剥落腐蚀溶液不同时间后的宏观照片。从图8可见:当浸泡12 h时,P0试样表面鼓泡很严重且有轻微的金属掉落,P2.5试样表面有更多的金属脱落,说明P2.5试样的腐蚀性能更差;当浸泡48 h时,预拉伸前、后试样表层金属都大量脱落。P0试样的剥落腐蚀等级为EC级,P2.5试样的腐蚀等级为EC+。为了深入认识剥落腐蚀情况,观察试样截面腐蚀形貌,金相照片如图9所示。P0试样和P2.5试样均有明显剥层现象;P0试样最大腐蚀深度为219 μm,P2.5试样最大腐蚀深度显著增加,约为336 μm。预拉伸后试样的剥落腐蚀性能变差。

3 分析讨论

3.1 预拉伸对力学性能的影响

7×××系铝合金为时效强化合金,合金强化相沉淀顺序为α(过饱和固溶体)→GP区→η′相(MgZn2)→η相(MgZn2)[22-23]。在变形过程中,合金强度取决于强化相的粒径和体积分数;根据不同强化相粒径,位错和其交互作用可分为切割机制和绕过机制,强化相粒径小于临界粒径时为切割机制,大于临界粒径时为绕过机制,一般来说,7×××系铝合金中η′相的临界粒径为3 nm[24],由图3可知,2个试样中大部分η′相粒径大于3 nm,因此,变形时位错绕过机制占主导,此时强化相对强度的贡献如下式所示[25]:

(1)

(1)

式中: 为屈服强度;C为常数;f为沉淀相的体积分数;r为沉淀相直径。材料中位错的存在能加速Zn与Mg溶质原子扩散,促进晶内η′相的析出,提高其长大速率[13, 26]。本研究中2.5%预拉伸在试样中引入位错,η′相粗化,即r增大,在一定程度上减小

为屈服强度;C为常数;f为沉淀相的体积分数;r为沉淀相直径。材料中位错的存在能加速Zn与Mg溶质原子扩散,促进晶内η′相的析出,提高其长大速率[13, 26]。本研究中2.5%预拉伸在试样中引入位错,η′相粗化,即r增大,在一定程度上减小 ;但预拉伸后η′相的峰面积增加了0.8 J/g,说明η′相的体积分数增加,即f增加,

;但预拉伸后η′相的峰面积增加了0.8 J/g,说明η′相的体积分数增加,即f增加, 增加,两者的综合作用导致预拉伸对合金的硬度和强度影响不大(表2),这与以往的一些研究结果不同。例如,WANG等[6]发现5%预拉伸变形提高了7050合金时效后强度,而HAN等[9]研究发现2.3%预拉伸变形降低了7050合金时效后强度。

增加,两者的综合作用导致预拉伸对合金的硬度和强度影响不大(表2),这与以往的一些研究结果不同。例如,WANG等[6]发现5%预拉伸变形提高了7050合金时效后强度,而HAN等[9]研究发现2.3%预拉伸变形降低了7050合金时效后强度。

表3 P0和P2.5试样的腐蚀参数

Table 3 Corrosion parameters of P0 and P2.5 samples

图7 试样晶间腐蚀浸泡后截面的金相照片

Fig. 7 Cross-section optical micrographs of samples after intergranular corrosion immersion

图8 试样浸泡剥落腐蚀溶液12 h和48 h后的宏观照片

Fig.8 Macrographs of samples immersed in EXCO solution for 12 h and 48 h

图9 试样剥落腐蚀溶液浸泡48 h后截面金相照片

Fig. 9 Cross-section optical micrographs of samples after EXCO for 48 h

3.2 预拉伸对合金局部腐蚀性能的影响

晶间腐蚀和剥落腐蚀本质都是沿晶腐蚀[27-28]。剥落腐蚀是晶间腐蚀的一种特殊表现,且拉长的晶粒是发生剥落腐蚀的必要条件[29];在晶间腐蚀过程中,腐蚀产物堆积在晶界,产生楔应力,导致表层金属鼓起至脱落。

7×××系铝合金的局部腐蚀性能主要与晶界析出相粒径、间距及化学成分等有关[12, 30-32]。就腐蚀萌生而言,晶界η相中Cu元素摩尔分数越高越难被腐蚀,而Zn元素摩尔分数增加,η相电化学活性变大,更易被腐蚀[12, 33]。本研究中预拉伸后晶界η相内的Cu元素摩尔分数增加了50%,似乎能改善合金的抗腐蚀性能,但此时Zn元素摩尔分数也增加了130%,这不仅抵消了Cu元素摩尔分数增加的有利影响,还进一步降低了合金的耐腐蚀性能。在STEM试样制备过程中发现P2.5试样中很多晶界上的η相容易被腐蚀(图4(b)),而P0试样中观察到这种现象的概率大大降低,这也说明Zn元素摩尔分数显著增加使η相更易被腐蚀。

腐蚀在晶界η相萌生后沿着晶界扩展。一般而言,7×××系铝合金中晶界η相的粒径和间距增大能延缓沿晶腐蚀的扩展,而PFZ宽度增加能促进晶界溶解的发生,加速腐蚀[32, 34]。本研究中7085铝合金预拉伸后晶界处η相的粒径和间距增加虽然能一定程度地延缓腐蚀的沿晶扩展,但晶界PFZ宽度增加却能提高沿晶腐蚀速率,从而降低了耐腐蚀性能。

4 结论

1) 2.5%预拉伸后,7085铝合金板材中晶内η′相粒径虽然增加,但体积分数增加,因此,时效后的硬度和强度变化不大。

2) 2.5%预拉伸后,7085铝合金板材中晶界η相粒径增大,间距增加,但其Zn元素摩尔分数显著增加,PFZ宽度增加,增加腐蚀萌生概率和腐蚀沿晶扩展速率,晶间腐蚀和剥落腐蚀性能变差。

参考文献:

[1] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials & Design, 2014, 56(4): 862-871.

[2] 张新明, 邓运来, 张勇. 高强铝合金的发展及其材料的制备加工技术[J]. 金属学报, 2015, 51(3): 257-271.

ZHANG Xinming, DENG Yunlai, ZHANG Yong. Development of high strength aluminum alloys and processing techniques for the materials[J]. Acta Metallurgica Sinica, 2015, 51(3): 257-271.

[3] 李英, 魏久祥, 颜鸣皋, 等. 淬火后预拉伸对7475铝合金组织和性能的影响[J]. 航空材料学报, 1990(增刊): 95-101.

YI Ying, WEI Jiuxiang, YAN Minggao, et al. The effect of pre-stretching after quenching on microstructures and properties of 7475 aluminum alloy[J]. Journal of Aeronautical Materials,1990(Suppl): 95-101.

[4] WATERLOO G, HANSEN V, GJ NNES J, et al. Effect of predeformation and preaging at room temperature in Al-Zn-Mg-(Cu, Zr) alloys[J]. Materials Science & Engineering A, 2001, 303(1): 226-233.

NNES J, et al. Effect of predeformation and preaging at room temperature in Al-Zn-Mg-(Cu, Zr) alloys[J]. Materials Science & Engineering A, 2001, 303(1): 226-233.

[5] AL-RUBAIE K S, BARROSO E K L, GODEFROID L B, et al. Fatigue crack growth analysis of pre-strained 7475–T7351 aluminum alloy[J]. International Journal of Fatigue, 2006, 28(8): 934-942.

[6] WANG D, NI D R, MA Z Y, et al. Effect of pre-strain and two-step aging on microstructure and stress corrosion cracking of 7050 alloy[J]. Materials Science and Engineering A, 2008, 494(1): 360-366.

[7] WANG D, MA Z Y. Effect of pre-strain on microstructure and stress corrosion cracking of over-aged 7050 aluminum alloy[J]. Journal of Alloys and Compounds, 2009, 469(1): 445-450.

[8] 韩念梅, 张新明, 刘胜胆, 等. 预拉伸对7050铝合金断裂韧性的影响[J]. 中国有色金属学报, 2010, 20(11): 2088-2093.

HAN Nianmei, ZHANG Xinming, LIU Shengdan, et al. Effect of prestretching on fracture toughness of 7050 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2088-2093.

[9] HAN Nianmei, ZHANG Xinming, LIU Shengdan, et al. Effects of pre-stretching and ageing on the strength and fracture toughness of aluminum alloy 7050[J]. Materials Science and Engineering A, 2011, 528(10): 3714-3721.

[10] 宋丰轩, 张新明, 刘胜胆, 等. 预拉伸对7050铝合金腐蚀性能的影响[J]. 中南大学学报(自然科学版), 2013, 44(5): 1791-1797.

SONG Fengxuan, ZHANG Xinming, LIU Shengdan, et al. Effects of pre-stretching on corrosion resistance of 7050 aluminum alloy[J]. Journal of Central South University(Science and Technology), 2013, 44(5): 1791-1797.

[11] SONG F X, ZHANG X M, LIU S D, et al. The effect of quench transfer time on microstructure and localized corrosion behavior of 7050-T6 Al alloy[J]. Materials & Corrosion, 2014, 65(10): 1007-1016.

[12] LIU S D, CHEN B, LI C B, et al. Mechanism of low exfoliation corrosion resistance due to slow quenching in high strength aluminium alloy[J]. Corrosion Science, 2015, 91(2): 203-212.

[13] LIU Shengdan, WANG Shaoling, YE Lingying, et al. Flow behavior and microstructure evolution of 7055 aluminum alloy impacted at high strain rates[J]. Materials Science and Engineering A, 2016, 677: 203-210.

[14] LI Chengbo, WANG Shaoling, ZHANG Duanzheng, et al. Effect of Zener-Hollomon parameter on quench sensitivity of 7085 aluminum alloy[J]. Journal of Alloys and Compounds, 2016, 688: 456-462.

[15] SAKAKI H, OHNO H, KAWAI S, et al. Superconductors, surfaces and superlattices[C]// Proceedings of the Symposia CC, Superlattice DD, Surfaces and Interfaces HH, Superconducting Materials of the 3rd IUMRS International Conference on Advanced Materials. Tokyo, Japan: Elsevier, 1994: 999-1023.

[16] LI Dongfeng, ZHANG Duanzheng, LIU Shengdan, et al. Dynamic recrystallization behavior of 7085 aluminum alloy during hot deformation[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1491-1497.

[17] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Materials Science and Engineering A, 2008, 492(1/2): 1-10.

[18] KAMP N, SINCLAIR I, STARINK M J. Toughness-strength relations in the overaged 7449 al-based alloy[J]. Metallurgical and Materials Transactions A, 2002, 33(4): 1125-1136.

[19] VIANA F, PINTO A M P, SANTOS H M C, et al. Retrogression and re-ageing of 7075 aluminium alloy: microstructural characterization[J]. Journal of Materials Processing Technology, 1999, 92/93: 54-59.

[20] STARINK M J. Analysis of aluminium based alloys by calorimetry: quantitative analysis of reactions and reaction kinetics[J]. International Materials Reviews, 2004, 36(3): 191-226.

[21] GALVELE J R. Tafel’s law in pitting corrosion and crevice corrosion susceptibility[J]. Corrosion Science, 2005, 47(12): 3053-3067.

[22] HANSEN V, KARLSEN O B, LANGSRUD Y, et al. Precipitates, zones and transitions during aging of Al-Zn-Mg-Zr 7000 series alloy[J]. Materials Science and Technology, 2004, 20(2): 185-193.

[23] SHA G, CEREZO A. Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050)[J]. Acta Materialia, 2004, 52(15): 4503-4516.

[24] GUYOT P, COTTIGNIES L. Precipitation kinetics, mechanical strength and electrical conductivity of AlZnMgCu alloys[J]. Acta Materialia, 1996, 44(10): 4161-4167.

[25] SHERCLIFF H R, ASHBY M F. A process model for age hardening of aluminium alloys:Ⅰ. the model[J]. Acta Metallurgica Et Materialia, 1990, 38(10): 1789-1802.

[26] DESCHAMPS A, LIVET F, BR CHET Y. Influence of predeformation on ageing in an Al-Zn-Mg alloy:Ⅰ. microstructure evolution and mechanical properties[J]. Acta Materialia, 1998, 47(1): 281-292.

CHET Y. Influence of predeformation on ageing in an Al-Zn-Mg alloy:Ⅰ. microstructure evolution and mechanical properties[J]. Acta Materialia, 1998, 47(1): 281-292.

[27] 李获, 左尚志, 郭宝兰. LY12铝合金剥蚀行为的研究[J]. 中国腐蚀与防护学报, 1995, 15(3): 203-209.

LI Di, ZUO Shangzhi, GUO Baolan. Study on exfoliation behavior of LY12 aluminium alloys[J]. Journal of Chinese Society for Corrosion and Protection, 1995, 15(3): 203-209.

[28] 苏景新, 张昭, 曹发和, 等. 铝合金的晶间腐蚀与剥蚀[J]. 中国腐蚀与防护学报, 2005, 25(3): 187-192.

SU Jingxin, ZHANG Zhao, CAO Fahe, et al. Review on the intergranular corrosion and exfoliation corrosion of aluminum alloys[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 25(3): 187-192.

[29] POSADA M, MURR L E, NIOU C S, et al. Exfoliation and related microstructures in 2024 aluminum body skins on aging aircraft[J]. Materials Characterization, 1997, 38(4): 259-272.

[30] 李志辉, 熊柏青, 张永安, 等. 7B04铝合金预拉伸厚板的微观组织与性能[J]. 稀有金属, 2007, 31(4): 440-445.

LI Zhihui, XIONG Baiqing, ZHANG Yongan, et al. Microstructure and properties of 7B04 Al alloy pre-stretched thick plates[J]. Rare Metals, 2007, 31(4): 440-445.

[31] MARLAUD T, MALKI B, HENON C, et al. Relationship between alloy composition, microstructure and exfoliation corrosion in Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2011, 53(10): 3139-3149.

[32] LI Dongfeng, YIN Bangwen, LEI Yue, et al. Critical quenching rate for high hardness and good exfoliation corrosion resistance of Al-Zn-Mg-Cu alloy plate[J]. Metals and Materials International, 2016, 22(2): 222-228.

[33] CHEN Songyi, CHEN Kanghua, PENG Guosheng, et al. Effect of quenching rate on microstructure and stress corrosion cracking of 7085 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 47-52.

[34] 李承波, 张新明, 刘胜胆, 等. 7085铝合金剥落腐蚀的淬火敏感性[J]. 材料研究学报, 2013, 27(5): 454-460.

LI Chengbo, ZHANG Xinming, LIU Shengdan, et al. Quench sensitivity relative to exfoliation corrosion of 7085 aluminum alloy[J]. Chinese Journal of Materials Research, 2013, 27(5): 454-460.

(编辑 刘锦伟)

收稿日期:2017-10-11;修回日期:2017-11-29

基金项目(Foundation item):国家重点研发计划项目(2016YFB0300901);湖南省重大科技专项(2016GK1004);中南大学升华育英计划项目(20130603) (Project(2016YFB0300901) supported by the National Key Research and Development Program of China; Project(2016GK1004) supported by the Key Science and Technology Program of Hunan Province; Project(20130603) supported by the Shenghua Yuying Project of Central South University)

通信作者:叶凌英,博士,副教授,从事高性能铝合金组织与性能调控研究;E-mail: lingyingye@csu.edu.cn

摘要:采用硬度测试、室温拉伸、极化曲线、晶间腐蚀(IGC)和剥落腐蚀(EXCO)浸泡实验研究预拉伸对7085铝合金力学性能及局部腐蚀性能的影响,结合金相显微镜(OM)、透射电镜(TEM)、扫描透射电镜(STEM)及差示扫描量热法(DSC)等显微组织表征结果探讨和分析其影响机理。研究结果表明:经室温拉伸变形2.5%预拉伸后,合金时效后晶内η′强化相粒径增加,但体积分数增加,硬度和强度变化不大;合金晶界η相粒径、间距及其中Zn和Cu元素摩尔分数增加,晶界无沉淀析出带宽度增加;η相中Zn元素摩尔分数的显著增加和晶界无沉淀析出带宽化增大了腐蚀萌生概率和腐蚀沿晶扩展速率,降低了晶间腐蚀和剥落腐蚀性能。

[2] 张新明, 邓运来, 张勇. 高强铝合金的发展及其材料的制备加工技术[J]. 金属学报, 2015, 51(3): 257-271.

[3] 李英, 魏久祥, 颜鸣皋, 等. 淬火后预拉伸对7475铝合金组织和性能的影响[J]. 航空材料学报, 1990(增刊): 95-101.

[8] 韩念梅, 张新明, 刘胜胆, 等. 预拉伸对7050铝合金断裂韧性的影响[J]. 中国有色金属学报, 2010, 20(11): 2088-2093.

[10] 宋丰轩, 张新明, 刘胜胆, 等. 预拉伸对7050铝合金腐蚀性能的影响[J]. 中南大学学报(自然科学版), 2013, 44(5): 1791-1797.

[27] 李获, 左尚志, 郭宝兰. LY12铝合金剥蚀行为的研究[J]. 中国腐蚀与防护学报, 1995, 15(3): 203-209.

[28] 苏景新, 张昭, 曹发和, 等. 铝合金的晶间腐蚀与剥蚀[J]. 中国腐蚀与防护学报, 2005, 25(3): 187-192.

[30] 李志辉, 熊柏青, 张永安, 等. 7B04铝合金预拉伸厚板的微观组织与性能[J]. 稀有金属, 2007, 31(4): 440-445.

[34] 李承波, 张新明, 刘胜胆, 等. 7085铝合金剥落腐蚀的淬火敏感性[J]. 材料研究学报, 2013, 27(5): 454-460.